lcd module design manufacturer

In addition to custom LCD displays, we provide custom PCB assemblies and turnkey solutions for products that feature a Displaytech LCD. As a display manufacturer, our engineering and production staff are experienced in handling the design and manufacturing of printed circuit board assemblies for front panels, rack mount equipment, handheld devices and many other products.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

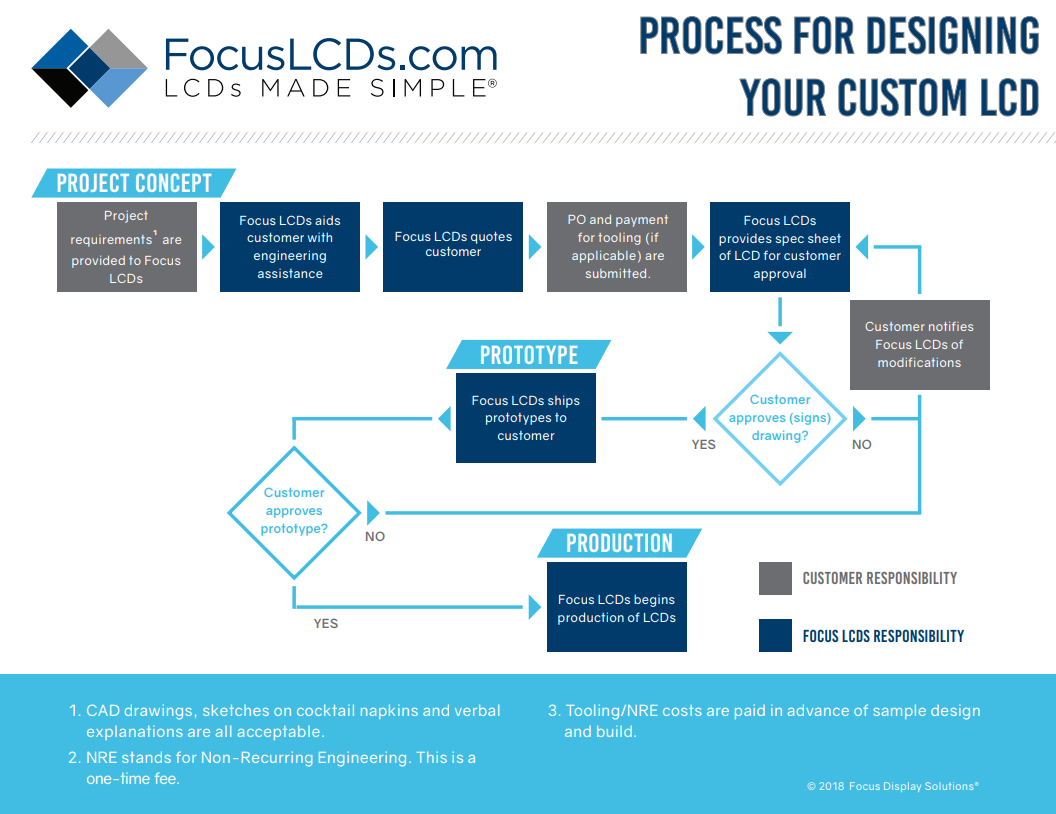

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

As a full service provider of LCD modules, PDI specializes in small format (typically 15” and less) character display, graphic display, color display, and custom display formats. Our Customers leverage PDI’s decades of LCD display experience, technical expertise, and manufacturing capabilities to obtain the most competitively priced, highest quality LCD module solution. These solutions span the spectrum from off the shelf standard products to completely custom display based solutions. PDI’s mission is to actively engage our customers early in the design phase. We will utilize our years of LCD experience and our understanding of the compete LCD module system to provide a smooth transition from design concept to prototypes, through pilot run and into high volume production.

Alternatively, if a 100% identical cross match design of an existing display is needed, our team will evaluate your current solution, offer any recommendations for design improvement and then quote accordingly, typically saving up to 20%. Once PDI develops a 100% compatible drop-in replacement display, this LCD module is then fully tested and qualified in the product application prior to shipping. This process insures a plug and play solution.

PDI produces its LCD displays utilizing the latest or most practical technology trends including Chip on Glass (COG), Chip on Board (COB), Tape Automated Bonding (TAB) and Chip on Flex (COF). PDI can integrate touch panels into any of our display systems. In addition to a full portfolio of standard and custom LCD modules, PDI offers manufacturing services to build your display into the next higher sub-assembly or final assembly to give customers the competitive cost advantages afforded to those utilizing off-shore based manufacturing. Often this practice includes integrating the display design and existing peripheral components such as PCB’s, switches, overlays and custom cables which eliminates interconnects, improves the overall system reliability and most importantly, reduces cost.

Customers that need a new supplier for an existing production display. This occurs for a variety of reasons including cost pressures, lead time concerns, quality issues, stocking needs, or lack of responsiveness from current LCD supplier.

To insure production quality, PDI factories are equipped with state-of-the-art machinery and are ISO9001:2008 Quality Certified. In addition, having factories with front and back end glass processing, as well as module assembly, helps reduce lead-times, while providing lower cost solutions. With vertically integrated organizations, factory personnel have a better “system” understanding and can quickly respond to our customers needs.

Microtips Technology is a leading custom lcd module manufacturer and we offer a full array of products and services. We have the most advances display technologies available to use in your design and if there is anything you want to change about one of our displays, we can make it happen. All of our displays are fully customizable to your specification and can include extra features like a capacitive touchscreen, an anti-reflective or anti-glare coating, or custom cover glass. Our sales and engineering staff will be with you through the entire process and will ensure our custom lcd display and your end product look their very best.

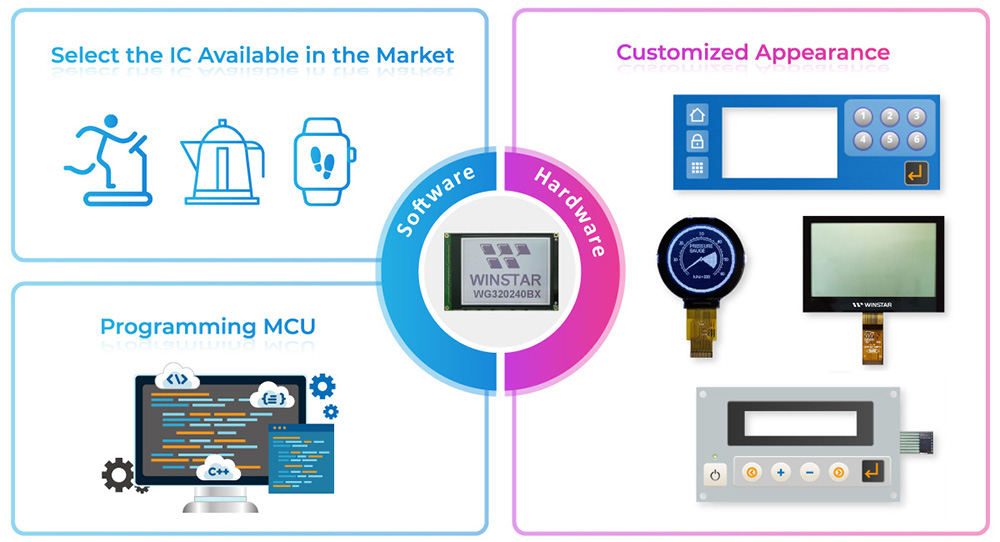

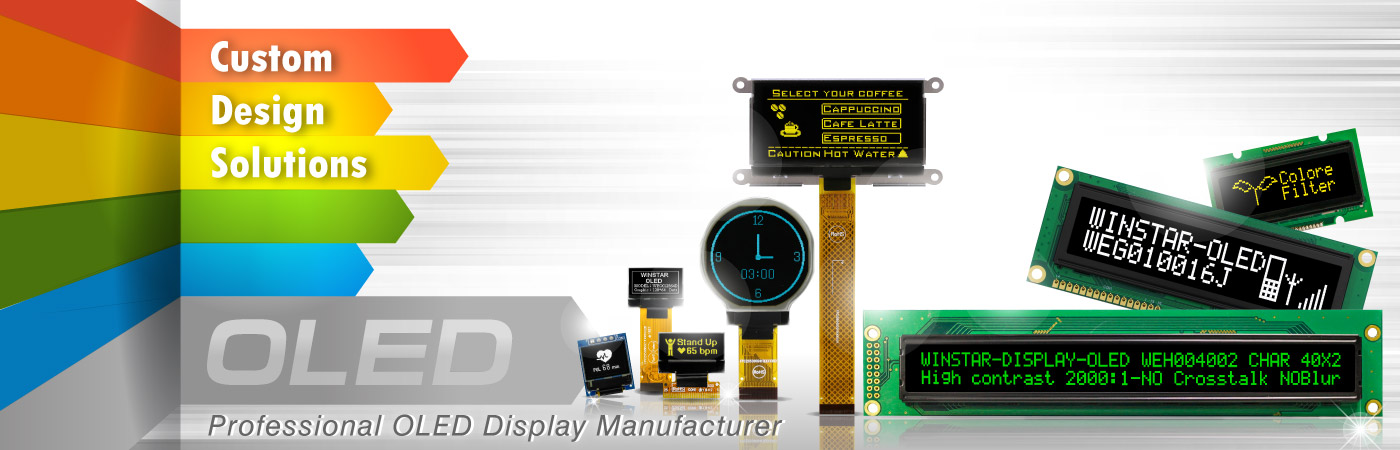

Except the available standard LCD/TFT/OLED display products, Winstar provides tailor made displays. The extensive portfolio makes it possible to create tailor-made solutions for customers to fit their application. We have the advanced display technologies available to use in your design and if there is anything you want to change about one of our existing LCD/TFT/OLED displays, we can make it happen. With more than 23 years experience, our sales and engineering team will be with you through the entire development process and will ensure the semi or fully customization a successful display tailored made to the individual application.

Our LCD/TFT/OLED custom design solutions are available in different options according to customer requirements. Winstar can offer various options on backlight type, pin and connector, cable, resistive touch screen (RTP) and projected capacitive (PCAP) touch screen or anti-reflective or anti-glare coating, or custom cover lens, ZIF PPC or customized PCB board or a fully custom solution for your product application, as well as System Integrated Solution.

LCD Module supplier-Taimates Electronic is a professional solution provider and supplier for small to medium size of LCD modules. Our team members have more than 15 years of LCD/LCM/Embedded boards experience in international sales, manufacturing and engineering development.

Our LCD/LCM product line includes the TFT color display, monochrome display, touch panel, and embedded solution in standard specifications with the options of customization flexibility and value-added functionality. With our abundant experience and know-how in the LCD/LCM industry, we would like to build a long-term partnership by providing the project development from scratch, the complete test program, into the mass production phase and aftersales service.

TFT LCD Module, Monochrome LCD Module, Touch Screen, LCD Module, TFT LCM, Custom LCD Display, Graphic LCD Display, haracter LCD Display, COG LCD Display, IPS TFT LCD

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

In Topway, we work side by side to help you overcome any technical and none technical challenges that may arise during product design, manufacture or installation. We can even take care of component sourcing and manufacturing for you.

Looking to take your project to the next level in terms of functionality and appearance? A custom LCD display might be the thing that gets you there, at least compared to the dot-matrix or seven-segment displays that anyone and their uncle can buy from the usual sources for pennies. But how does one create such a thing, and what are the costs involved? As is so often the case these days, it’s simpler and cheaper than you think, and [Dave Jones] has a great primer on designing and specifying custom LCDs.

The video below is part of an ongoing series; a previous video covered the design process, turning the design into a spec, and choosing a manufacturer; another discussed the manufacturer’s design document approval and developing a test plan for the module. This one shows the testing plan in action on the insanely cheap modules – [Dave] was able to have a small run of five modules made up for only $138, which included $33 shipping. The display is for a custom power supply and has over 200 segments, including four numeric sections, a clock display, a bar graph, and custom icons for volts, amps, millijoules, and watt-hours. It’s a big piece of glass and the quality is remarkable for the price. It’s not perfect – [Dave] noted a group of segments on the same common lines that were a bit dimmer than the rest, but was able to work around it by tweaking the supply voltage a bit.

We’re amazed at how low the barrier to entry into custom electronics has become, and even if you don’t need a custom LCD, at these prices it’s tempting to order one just because you can. Of course, you can also build your own LCD display completely from scratch too.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey