lcd screen freeze quotation

Read this, it may be useful, especially the bit about how the crystals react to temperature changes.

Various operating environments

Size and efficient use of power aren"t the only factors the designer of portable-device displays must face. Wireless and portable devices are subjected to a wide range of operating temperatures and varying operating environment conditions. Even if it"s small and power smart, an LCD won"t meet performance standards without considering its operating environment.

For example, temperatures affect the viscosity of the liquid-crystal (LC) fluid suspension. At lower temperatures, the LC thickens and requires more voltage to activate the crystals. Conversely, at higher temperatures, less voltage is needed to create the display.

On-board temperature control circuitry has been one solution offered by LCD manufacturers. A driver IC with integrated temperature compensation circuitry reduces the total number of components in the device.

LCDs with operating temperatures of -30° to +80°C (or greater) accommodate designers in automotive, aerospace, avionics, and other industries where LCDs must perform in demanding environments. Some manufacturers supply LCDs with an integrated heater to control the LC temperature, ensuring optimum display performance.

Until a few years ago, many cell phones made in the United States used light-emitting diodes (LEDs), which typically washed out under intense ambient light and bright sunlight. The answer has been the development of LCDs with properties that optimize readability under varying ambient light conditions.

Such transflective LCDs exhibit both transmissive and reflective properties, combining backlighting and highly efficient inner-mirror technology. The resultis an LCD that uses both illumination methods (backlighting and reflectivity) to match the display to ambient light.

In reflective mode, transflective LCDs achieve 40% reflectivity in monochrome. Reflection and brightness can also be controlled through the use of special films.

Transflective (and reflective) STN-LCDs with inner-mirror technology exhibit a natural change of image against ambient light conditions, resulting in excellent interior matching between the electronic display and mechanical (or printed) displays.

Display contrast, particularly at high temperatures, is enhanced through multiline addressing (MLA), which simultaneously applies activation pulses to several rows in a display frame to ensure fast, flicker-free response across the LCD"s operating temperature range.

-- View image here: https://cdn.arstechnica.net/forum/smilies/biggrin.gif -- I did a google search for LCD operating temperatures

I"m tearing my hair out trying to get my project to work. I have an Arduino Uno R3 clone (Freetronics 100% compatible) with a 20x4 I2C LCD from DX (part number GY-LCD-V1). I also have four pushbuttons connected via the analog pins (in digital mode.) Other than that I have nothing connected to the arduino other than power via USB to my Mac.

My problem is that the screen freezes or starts showing garbage after a couple of minutes of the sketch running. Sometimes it seems that the screen gets half way through redrawing then just stops (in which case nothing updates the screen until I disconnect/reconnect the power) or starts drawing garbage to the screen, which also takes a cold boot to fix. Either way, the sketch continues running, i.e. the buttons produce output via the serial monitor and the heartbeat LED on pin 13 continues flashing (the main loop flashes it every second). Occasionally the sketch crashes, i.e. no response to button pushes and the LED stops flashing. If I reset the unit (either via the reset button or by closing/reopening the serial monitor) the screen sometimes won"t re-initialise, i.e. the last drawn screen remains and won"t redraw until the power is cycled.

Initially I thought this might be a memory problem. The sketch is big (about 28KB compiled without debug/info defines) and very nearly 32Kb with them compiled in. Free RAM is about 800bytes according to the debug statements. I"ve been mounting the hardware (LCD + buttons so far) in an enclosure, and I had a few days of the sketch running flawlessly, but now it"s back to the normal problems.

The use of liquid crystal displays (LCDs) in user interface assemblies is widespread across nearly all industries, locations, and operating environments. Over the last 20 years, the cost of LCD displays has significantly dropped, allowing for this technology to be incorporated into many of the everyday devices we rely on.

The odds are high you are reading this blog post on a laptop or tablet, and it’s likely the actual screen uses LCD technology to render the image onto a low-profile pane of glass. Reach into your pocket. Yes, that smartphone likely uses LCD technology for the screen. As you enter your car, does your dashboard come alive with a complex user interface? What about the menu at your favorite local drive-thru restaurant? These are some everyday examples of the widespread use of LCD technology.

But did you know that the U.S. military is using LCD displays to improve the ability of our warfighters to interact with their equipment? In hospitals around the world, lifesaving medical devices are monitored and controlled by an LCD touchscreen interface. Maritime GPS and navigation systems provide real-time location, heading, and speed information to captains while on the high seas. It’s clear that people’s lives depend on these devices operating in a range of environments.

As the use of LCDs continues to expand, and larger screen sizes become even less expensive, one inherent flaw of LCDs remains: LCD pixels behave poorly at low temperatures. For some applications, LCD displays will not operate whatsoever at low temperatures. This is important because for mil-aero applications, outdoor consumer products, automobiles, or anywhere the temperature is below freezing, the LCD crystal’s performance will begin to deteriorate. If the LCD display exhibits poor color viewing, sluggish resolution, or even worse, permanently damaged pixels, this will limit the ability to use LCD technologies in frigid environments. To address this, there are several design measures that can be explored to minimize the impact of low temperatures on LCDs.

Most LCD displays utilize pixels known as TFT (Thin-Film-Transistor) Color Liquid Crystals, which are the backbone to the billions of LCD screens in use today. Since the individual pixels utilize a fluid-like crystal material as the ambient temperature is reduced, this fluid will become more viscous compromising performance. For many LCD displays, temperatures below 0°C represent the point where performance degrades.

Have you tried to use your smartphone while skiing or ice fishing? What about those of you living in the northern latitudes - have you accidently left your phone in your car overnight where the temperatures drop well below freezing? You may have noticed a sluggish screen response, poor contrast with certain colors, or even worse permanent damage to your screen. While this is normal, it’s certainly a nuisance. As a design engineer, the goal is to select an LCD technology that offers the best performance at the desired temperature range. If your LCD display is required to operate at temperatures below freezing, review the manufacturer’s data sheets for both the operating and storage temperature ranges. Listed below are two different off-the-shelf LCD displays, each with different temperature ratings. It should be noted that there are limited options for off-the-shelf displays with resilience to extreme low temperatures.

For many military applications, in order to comply with the various mil standards a product must be rated for -30°C operational temperature and -51°C storage temperature. The question remains: how can you operate an LCD display at -30°C if the product is only rated for -20°C operating temperature? The answer is to use a heat source to raise the display temperature to an acceptable range. If there is an adjacent motor or another device that generates heat, this alone may be enough to warm the display. If not, a dedicated low-profile heater is an excellent option to consider.

Made of an etched layer of steel and enveloped in an electrically insulating material, a flat flexible polyimide heater is an excellent option where space and power are limited. These devices behave as resistive heaters and can operate off a wide range of voltages all the way up to 120V. These heaters can also function with both AC and DC power sources. Their heat output is typically characterized by watts per unit area and must be sized to the product specifications. These heaters can also be affixed with a pressure sensitive adhesive on the rear, allowing them to be “glued” to any surface. The flying leads off the heater can be further customized to support any type of custom interconnect. A full-service manufacturing partner like Epec can help develop a custom solution for any LCD application that requires a custom low-profile heater.

With no thermal mass to dissipate the heat, polyimide heaters can reach temperatures in excess of 100°C in less than a few minutes of operation. Incorporating a heater by itself is not enough to manage the low temperature effects on an LCD display. What if the heater is improperly sized and damages the LCD display? What happens if the heater remains on too long and damages other components in your system? Just like the thermostat in your home, it’s important to incorporate a real-temp temperature sensing feedback loop to control the on/off function of the heater.

Another important consideration when selecting a temperature sensor is how to mount the individual sensors onto the display. Most LCD displays are designed with a sheet metal backer that serves as an ideal surface to mount the temperature sensors. There are several types of thermally conductive epoxies that provide a robust and cost-effective way to affix the delicate items onto the display. Since there are several types of epoxies to choose from, it’s important to use a compound with the appropriate working life and cure time.

For example, if you are kitting 20 LCD displays and the working life of the thermal epoxy is 8 minutes, you may find yourself struggling to complete the project before the epoxy begins to harden.

Before building any type of prototype LCD heater assembly, it’s important to carefully study the heat transfer of the system. Heat will be generated by the flexible polyimide heater and then will transfer to the LCD display and other parts of the system. Although heat will radiate, convect, and be conducted away from the heater, the primary type of heat transfer will be through conduction. This is important because if your heater is touching a large heat sink (ex. aluminum chassis), this will impact the ability of the heater to warm your LCD display as heat will be drawn toward the heat sink.

Before freezing the design (no pun intended) on any project that requires an LCD display to operate at low temperatures, it’s critical to perform low temperature first. This type of testing usually involves a thermal chamber, a way to operate the system, and a means to measure the temperature vs time. Most thermal chambers provide an access port or other means to snake wires into the chamber without compromising performance. This way, power can be supplied to the heater and display, while data can be captured from the temperature sensors.

The first objective of the low-temperature testing is to determine the actual effects of cold exposure on the LCD display itself. Does the LCD display function at cold? Are certain colors more impacted by the cold than others? How sluggish is the screen? Does the LCD display performance improve once the system is returned to ambient conditions? These are all significant and appropriate questions and nearly impossible to answer without actual testing.

As LCD displays continue to be a critical part of our society, their use will become even more widespread. Costs will continue to decrease with larger and larger screens being launched into production every year. This means there will be more applications that require their operation in extreme environments, including the low-temperature regions of the world. By incorporating design measures to mitigate the effects of cold on LCD displays, they can be used virtually anywhere. But this doesn’t come easy. Engineers must understand the design limitations and ways to address the overarching design challenges.

A full-service manufacturing partner like Epec offers a high-value solution to be able to design, develop, and manufacture systems that push the limits of off-the-shelf hardware like LCD displays. This fact helps lower the effective program cost and decreases the time to market for any high-risk development project.

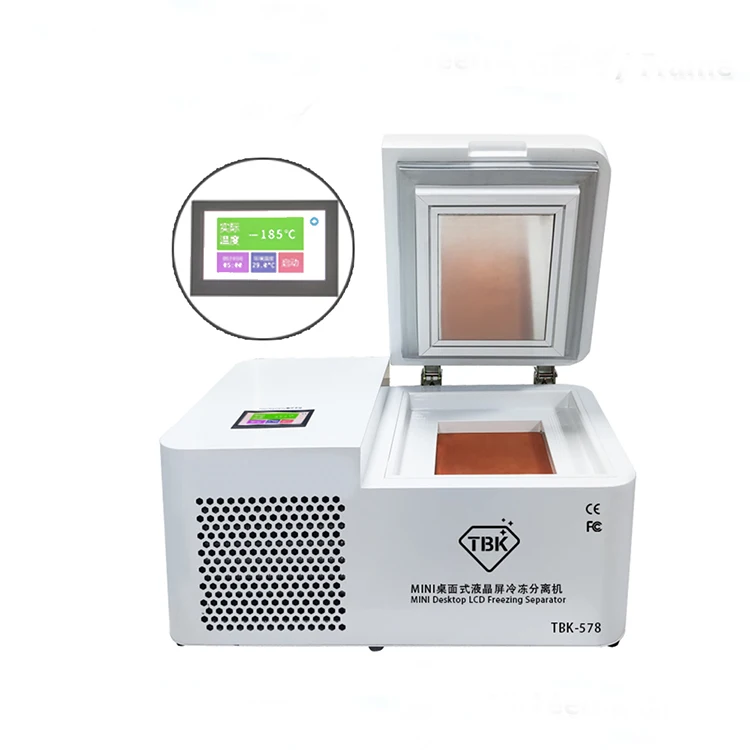

Try using lcd glass screen freeze machine found on Alibaba.com to make many types of production jobs faster and easier. Each model can be filled with different types of liquid and quickly dispensed into containers. Use lcd glass screen freeze machine to fill paint cans with speed and precision. Other compatible fluids include resin or glue, making such devices suitable for manufacturing all kinds of helpful products.

All lcd glass screen freeze machine are built to be easy to operate, reducing labor and training times needed. Some versions can pour food-grade liquids such as beer or milk into bottles for future sealing. Most units work automatically so workers can program them and stay back as they work on their own. When installed on a factory floor, they offer greater efficiency to help save time and costs.

Shop for lcd glass screen freeze machine at Alibaba.com to find many helpful suppliers with a wide range of options that can be ordered. Choose just the right size to fit the intended workspace. Pick a wattage level that promises good speed and power without using too much electricity and driving up costs. Certain designs can dispense products in the form of powder or granules into nearby containers. Use these to package particular powdered food and pharmaceutical ingredients.

Search for lcd glass screen freeze machine on Alibaba.com and enjoy lower costs when working with various liquids or powders. Whether for use in food manufacturing or building materials, there are plenty of options to browse. Find a satisfactory brand that will improve efficiency for better overall quality in each final product.

Alibaba.com is the go-to choice for any buyer seeking new and used equipment at affordable prices. Within the product catalog, you can find descriptions of the machinery, its parts, and possible accessories you should get. From the multiple brands and manufacturers, you will get all sorts of lcd freezing machine for your project. From construction to farming, manufacturing to packaging, every piece of the heavy equipment you might want, you have find it at affordableib...ourour listings for lcd Freezing machine are starting to search as a aso as possible.

Alibaba.com remains home to one of the largest inventories of both used and new lcd freezing machine. If you run a rental equipment shop, then the supply at Alibaba.com will be a great place to browse. From tractors and excavators, skid steers and forklifts to dozers and backhoes for your construction, everything you need, Alibaba.com has it. The product variety goes beyond loaders and utility trailers, cranes, and dump trucks to small ones used to compress and package materials. The dairy and food processing equipment will be a good category to look through if you operate a farm.

LCD screens use liquid crystal molecules for display and these molecules align to give the desired display pattern. However, exposure to lower temperatures can create bubbles or aggregate liquid molecules (meaning disturbed molecule order), hence leading to permanent damage to the display. It is quite common to observe dimming and screen blackouts at lower temperatures. So, the next time your display turns sluggish, try keeping it in your pockets!

Answer: Absolutely! As the name "liquid crystal display" (LCD) implies, the display technology uses a substance that shares the same properties as liquids. It therefore can freeze if left in cold enough temperatures. In most cases however, it will also defrost without damage once returned to room temperature. Check the specifications for your LCD device and you"ll find two temperature ranges given, one for storage and one for use. LCDs will only work properly in a certain temperature range, and can usually be stored in a larger range with colder and warmer temperatures. Most LCDs can be stored down to -40F or up to 115F before damage occurs, but will only operate properly in a more comfortable 50F to 90F range, but this varies by screen so you"ll want to check the specifications in your TV"s manual. If your LCD is left out in the cold, make sure to allow it to rise to room temperature before attempting to power it on, and it should be just fine.

I just had an "interesting" K-3 lockup today. Camera was on a tripod set for 2-second timer. It had been powered up for about a minute. I used live view to manually focus. Hit the red button to turn off LV, then pressed the shutter button to start the 2-second timer. After 4 beeps (less than one second) the camera froze. No more beeps, shutter did not fire. After 5 or 10 seconds the camera powered itself down (top LCD went off). My first thought was that the battery died. I powered it back on and successfully made the shot. Battery is a Pentax Ricoh D-LI90 recently charged (LCD shows 3 bars - full). Firmware 1.03. No grip.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey