tft display layers supplier

Color TFT LCDs (Thin Film Transistor LCDs) give your product a beautiful appearance with high-resolution, full-color graphics. Our modern, automated LCD factories can create custom TFT displays for extreme temperature functionality, sunlight readability, shock and vibration durability, and more. Whether you need a stand-alone TFT LCD display or fully integrated assembly with touch and cover lens, custom FPC, or custom backlight, our experienced team can develop the right solution for your project.

A TFT LCD, or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, compactness, and cost of the product. In conjunction with its semiconductor properties, the TFT LCD is an active matrix display, controlling pixels individually and actively rather than passively, furthering the benefits of this semiconductor device.

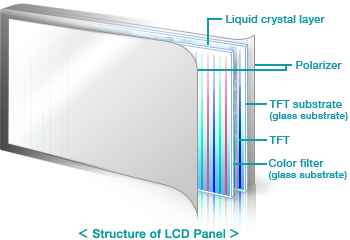

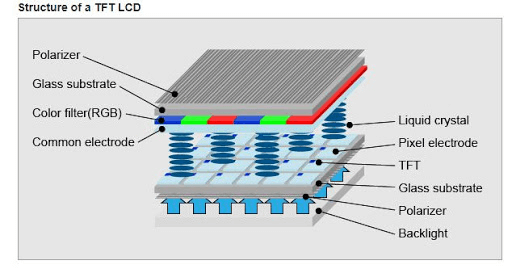

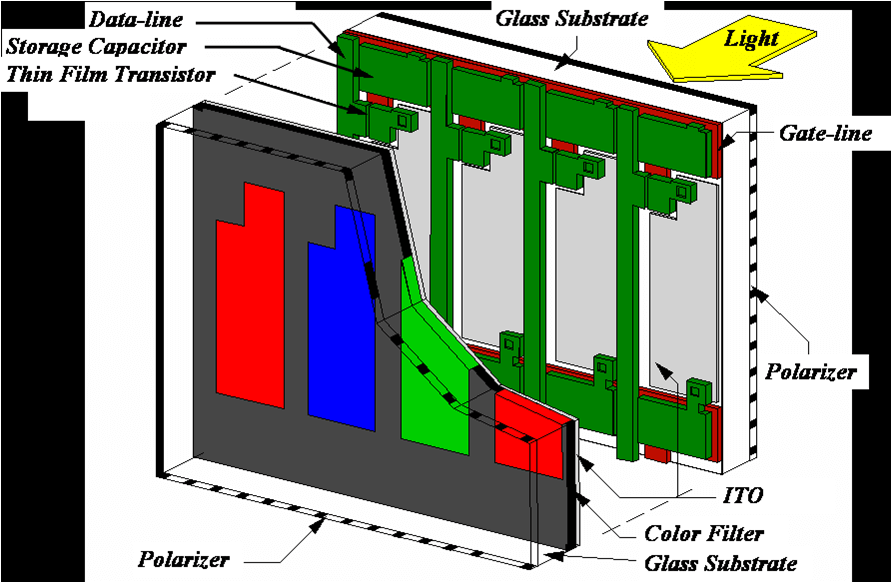

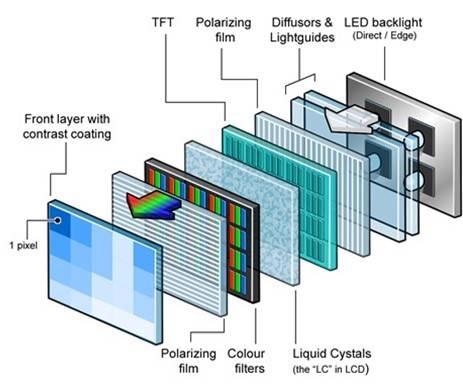

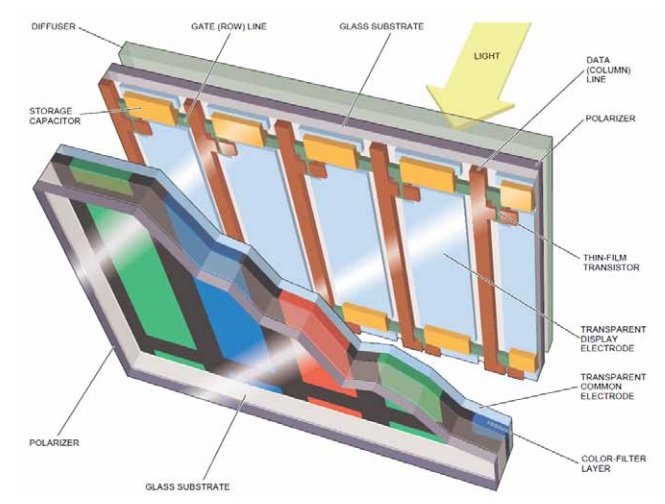

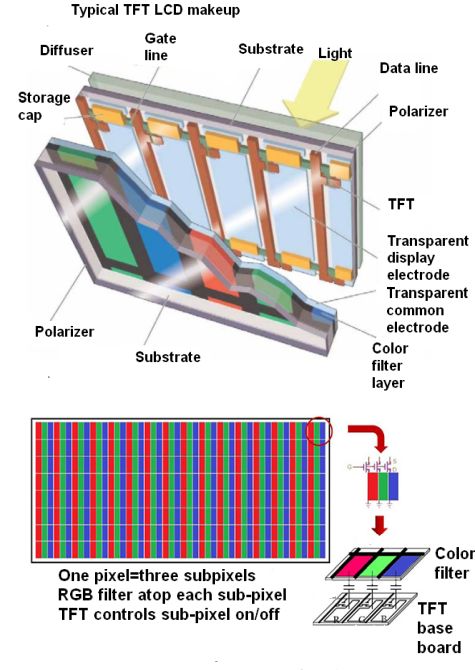

The TFT LCD is built with three key layers. Two sandwiching layers consist of glass substrates, though one includes TFTs while the other has an RGB, or red green blue, color filter. The layer between the glass layers is a liquid crystal layer.

The Architecture of a TFT Pixelbelow) from the other substrate layer of the device and control the amount of voltage applied to their respective sub-pixels. This layer also has pixel electrodes between the substrate and the liquid crystal layer. Electrodes are conductors that channel electricity into or out of something, in this case, pixels.

On the surface level is the other glass substrate. Just beneath this glass substrate is where the actual pixels and sub-pixels reside, forming the RGB color filter. In order to counteract the electrodes of the previously mentioned layer, this surface layer has counter (or common) electrodes on the side closer to the liquid crystals that close off the circuit that travels between the two layers. In both these substrate layers, the electrodes are most frequently made of indium tin oxide (ITO) because they allow for transparency and have good conductive properties.

The outer sides of the glass substrates (closest to the surface or closest to the back) have filter layers called polarizers. These filters allow only certain beams of light to pass through if they are polarized in a specific manner, meaning that the geometric waves of the light are appropriate for the filter. If not polarized correctly, the light does not pass through the polarizer which creates an opaque LCD screen.

Between the two substrate layers lie liquid crystals. Together, the liquid crystal molecules may behave as a liquid in terms of movement, but it holds its structure as a crystal. There are a variety of chemical formulas available for use in this layer. Typically, liquid crystals are aligned to position the molecules in a certain way to induce specific behaviors of passing light through the polarization of the light waves. To do this, either a magnetic or electric field must be used; however, with displays, for a magnetic field to be usable, it will be too strong for the display itself, and thus electric fields, using very low power and requiring no current, are used.

Before applying an electric field to the crystals between the electrodes, the alignment of the crystals is in a 90 degree twisted pattern, allowing a properly crystal-polarized light to pass through the surface polarizer in a display’s “normal white” mode. This state is caused by electrodes that are purposely coated in a material that orients the structure with this specific twist.

However, when the electric field is applied, the twist is broken as the crystals straighten out, otherwise known as re-aligning. The passing light can still pass through the back polarizer, but because the crystal layer does not polarize the lights to pass through the surface polarizer, light is not transmitted to the surface, thus an opaque display. If the voltage is lessened, only some crystals re-align, allowing for a partial amount of light to pass and creating different shades of grey (levels of light). This effect is called the twisted nematic effect.

Fig. 3:The top row characterizes the nature of alignment in using IPS as well as the quality of viewing angles. The bottom row displays how the twisted nematic is used to align the crystals and how viewing angles are affected by it.

The light that passes through the device is sourced from the backlight which can shine light from the back or the side of the display. Because the LCD does not produce its own light, it needs to use the backlight in the OLED) have come into use as well. Typically white, this light, if polarized correctly, will pass through the RGB color filter of the surface substrate layer, displaying the color signaled for by the TFT device.

Within an LCD, each pixel can be characterized by its three sub-pixels. These three sub-pixels create the RGB colorization of that overall pixel. These sub-pixels act as capacitors, or electrical storage units within a device, each with their own independent structural and functional layers as described earlier. With the three sub-pixels per pixel, colors of almost any kind can be mixed from the light passing through the filters and polarizer at different brightness based on the liquid crystal alignment.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Without a shadow of a doubt, Orient Display stands out from other custom display manufacturers. Why? Because we employ 3600 specialists, includingmore than 720 engineers that constantly research available solutions in order to refine strategies that allow us to keep up with the latest technologiesand manufacture the finest displays showing our innovative and creative approach. We continuously strive to improve our skills and stay up to date with the changing world of displays so that we can provide our customers with supreme, cutting-edge solutions that make their lives easier and more enjoyable.

Customer service is another element we are particularly proud of. To facilitate the pre-production and product development process, thousands of standard solutions are stored in our warehouses. This ensures efficient order realization which is a recipe to win the hearts of customers who chose Orient Display. We always go to great lengths to respond to any inquiries and questions in less than 24 hours which proves that we treat buyers with due respect.

Choosing services offered by Orient Display equals a fair, side-by-side cooperation between the customer and our specialists. In each and every project, we strive to develop the most appropriate concepts and prototypes that allow us to seamlessly deliver satisfactory end-products. Forget about irritating employee turnover - with us, you will always work with a prepared expert informed about your needs.

In a nutshell, Orient Display means 18% of global market share for automotive touch screen displays, emphasis on innovation, flexibility and customer satisfaction.Don"t wait and see for yourself that the game is worth the candle!

TFT is an LCD Technology which adds a thin-film transistor at each pixel to supply common voltages to all elements. This voltage improves video content frame rates. Displays are predominantly utilizing color filter layers and white LED backlighting.

IPS TFT is a deviation of a traditional TN TFT Display. The most fundamental difference is that light is not rotated in plane and passing through polarizer films, but instead perpendicular to shutter the light. This approach to the technology improves contrast and enables symmetrical viewing angles from all directions.

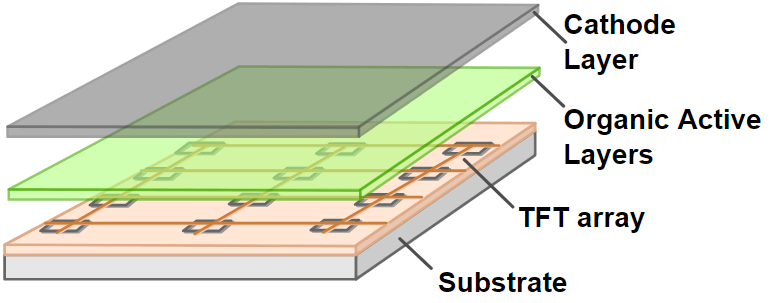

OLED Displays are emissive displays and do not utilize liquid crystal. Each pixel is emissive with light. Passive OLED displays multiplex power and logic through the IC. Active OLED displays add a transistor at each pixel to supply power directly to the pixels and the IC only performs logical functions.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

In the era of touchscreen smartphones, TFT LCD display technology has become one of the unique features and primary selling points. Consumers’ device needs and requirements have evolved along with the continuous innovations in technology. Aside from unique features (i.e., touchscreens, crisp text, blur-free video, vibrant images), more and more people now demand mobile devices at low cost. Now, how is this possible?

There are several options available in the market. Here, we’ve rounded up all the things you need to know about TFT LCD module so you’ll know what to look out for on your mobile hunt.

TFT module is suitable for a variety of applications, such as smartphones, game consoles, and navigation systems, among others. It has a low power draw when showing colors, making it easier to see displayed images outdoors.

TFT Display is the most common display technology for mobile phones. TFT LCD enhances image quality, offering better image quality and higher image resolutions compared to earlier LCD display generation.

TFT module is offered in a standard display, resistive touch, and capacitive touch versions. It also comes in a variety of sizes. Mobile devices with TFT LCD display have a full-color RGB mode that showcases rich colors, detailed images, and bright graphics.

This type of touchscreen LCD display module contains two layers of conductive material with a small gap that acts as resistance. Here’s what happens when an object touches the resistive touch screen:

It is undeniable that LCD display technology has significantly made its way in our daily lives. Aside from mobile devices, TFT LCD screens are now also being used with computer monitors, television screens, game devices, and more.

Consumers hold Light Crystal Display (LCD) in high regard for the crisp, image quality that it projects. But now experts in the field are adopting new technologies into LCD screen production. Emerging innovations, such as the TFT LCD Monitor, recently took the tech world by storm, replacing obsolete LCD models. And advanced TFT technology is what we offer here at Microtips Technology.

Now the distinction between LCD and TFT (Thin-Film Transistor) has become increasingly difficult to determine. There are also distinct versions of TFT technology that you may have a hard time following. Here’s a quick look at the technology.

A common misconception about TFT and LCD displays is that they are the same thing. The belief is not completely misguided, but it’s still wrong to claim that the two are the same.

Both terms refer to flat-panel displays that TVs and phones of today possess, yet there is a difference between TFT and LCD: TFT is a clearer version of LCD.

An LCD screen is composed of liquid crystals embedded between two layers of polarizing material. A backlight, which is responsible for producing the light lies behind these layers since liquid crystals can’t emit light on their own. By regulating voltage between glass plates, the crystals rotate, and the backlight transmits light, displaying the content that you see on your phone, TV, or monitor.

TFT displays are LCD screens that use thin film transistor technology. Adding a TFT layer to an LCD display provides a sharper image. TFT displays consist of the same parts as an LCD, but with an added TFT layer. Simply put, TFT equipment provide better quality than standard LCDs.

One variation of TFT display is the Twisted Nematic (TN) TFT display. TN technology is the oldest method for crystals to transmit light. TN technology usually has fast response times and is affordable, making it a popular choice for gamers.

Another version is the Multiple-domain Vertical Alignment model. MVA TFT displays possess high contrast and beautiful colors displays that make it a great option for moving images. It also provides better viewing angles than TN technology.

The third variation of TFT technology is In-Plane Switching (IPS) that manufacturers typically use for phones, laptops, or computer displays. Its base is similar to TN and MVA, but with IPS, each pixel has a transistor. This gives IPS wide viewing angles and consistent colors.

A thin-film transistor liquid crystal display, TFT LCD display for short, is a type of LCD display that uses thin-film transistor technology to improve image quality.

TFT LCD displays have many advantages over traditional LCD displays. While traditional LCDs use a single layer of transistors, TFT LCDs use a thin film of transistors. This allows for better image quality, as well as improved response time and lower power consumption. TFT LCDs are also thinner and lighter than traditional LCDs, making them ideal for use in portable devices.

When choosing a TFT LCD, it is important to consider the viewing angle and colour reproduction. While TFT IPS displays offer better image quality, they are also more expensive.

TFT LCDs are used in a wide variety of industries, including consumer electronics, computing, telecommunications, automotive, and medical to name a few. Specifically, they are used in:Computers and laptop computers

TFT LCDs use two types of cover glass. Rigid cover glass is made of either soda-lime glass or Gorilla Glass. Flexible cover glass is used in some TFT LCDs, such as those used in mobile phones. The flexible cover glass is more resistant to breakage than rigid cover glass, making it ideal for use in portable devices.

The touchscreen is an optional part of the display module that allows the user to interact with the display. A touchscreen is a layer of glass that is coated with a material that is sensitive to pressure. When the user presses on the touchscreen, the pressure is registered and converted into an electrical signal.

Nauticomp Inc. is a leading provider of industrial LCD displays. Our products are designed for use in a variety of industries, including maritime, aerospace, and military. We offer a wide range of LCDs, including TFT LCDs, OLEDs, and LEDs. Contact us today to learn more about our products and services.

For its transparency, flat and smooth surface, and excellent heat resistance, this product is used as a substrate for various types of displays such as televisions, personal computers, smart phones, tablet devices, and in-vehicle infotainment. It is an alkali-free aluminosilicate glass that was developed by using the float process.

It is necessary for TFT-LCD glass to meet many strict quality requirements. Unlike window pane glass, glass for TFT-LCDs is not allowed to contain alkalis. This is because alkali-ions contaminate liquid crystal materials and even adversely affect the characteristics of the TFT. Additionally, the glass should not exhibit large sagging even though its thickness is just 0.3 to 0.7 mm and should have excellent heat resistance while assuring dimensional stability even after being heated at high temperature. The glass also should have properties that its composition does not dissolve during the fabrication process using chemicals. "AN100", non-alkali glass developed by us, is the one that has fulfilled those various requirements. Furthermore, since "AN100" does not contain hazardous materials such as arsenic or antimony, it has high reputation for being an environment-friendly glass. Our technologies are supporting the design of thin, large, and environmentally friendly LCD TVs.

Majority of LCDs in wide use now are TFT-LCDs. In a TFT-LCD, a layer of thin film that forms transistors is used as a device that applies voltage to the liquid crystal layer, and those transistors control the voltage supplied to each pixel. The advantages of a TFT-LCD are high resolution and quick response time that enables motion image to be fine and clear.

Recently, displays with higher resolution such as 4K and 8K are being developed one after another and have made it possible for viewers to enjoy vivid and fine picture even in very large screen sizes.

It is AGC’s display glass substrates, developed using its distinctive precision glass processing technologies, that support these higher resolution TVs.

Smartphones and tablets can now be considered life necessities, and the LCD screen is the most frequently used interface whenever such devices are used. Without the LCD display, it is not possible to send email or view pictures taken by the camera function.

Furthermore, LCDs play an important role in a variety of applications such as in-vehicle displays, e.g. navigation systems and center information displays, and digital signage.

Since 1993 we offer LCDs and LCD system solutions. We are always up to date with the latest technology and are looking for the best products for our customers. Our TFT display range includes high-quality displays:

“LCD glass substrate” is a generic term for the special glass used for thin-film transistor (TFT) LCDs which form the display area of products including LCD televisions, personal computers and mobile phones. An LCD panel consists of various components stacked in a number of layers. These components include a polarizer, a color filter and a liquid crystal layer, with the glass substrate being the most important. Glass substrates are extremely thin – typically about 0.3-0.7 mm – and 8th-generation glass substrates (2,200 x 2,500 mm) are as large as three tatami mats in size.

In order to accurately display beautiful, high-definition images, LCD glass substrates must have super-smooth surfaces with irregularities reduced to the nano-level. It is also necessary to avoid the formation of internal bubbles and the intrusion of foreign matter (dust) too minute for the naked eye. Smooth and scratch-free glass substrates with the ultimate precision represent the maximum quality AvanStrate aims for.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

Remember when your LCD or OLED display had that brand-new, fresh-out-of-the-box shine, feel and look? You are in the right place if your display is now due for deep cleaning.

Things to consider before cleaning or handling an electronic displayAvoid static by grounding your body and following proper ESD-safe handling techniques.

A microfiber cloth and distilled water is recommended for cleaning the display glass. Use Qtips and Isopropyl alcohol for cleaning the printed circuit board.

Although distilled water is recommended for wiping the display glass, you can use a cleanser developed explicitly for cleaning displays. However, do not spray it directly onto the display. Spray a tiny amount of the cleaner onto a microfiber cloth first to avoid getting any cleaning solution inside the display.Never spray any liquids directly onto the display.A spray is too hard to control and confine. The fluids can seep into the other display layers or surrounding components and cause irreversible liquid damage.

Only use a microfiber cloth and don"t use chemicals to clean a resistive touchscreen.Disconnect the display from the power supply and remove any screen protectors or liners.

Cleaning soldering residue on LCD with Isopropyl alcohol and a Q-Tip.Cleaning residue around soldering elements is not necessary if Newhaven Display performed the soldering.

Cleaning your electronic display is a simple task. However, it is essential to consider these steps to handle and clean it properly. You should now have a better understanding of what cleaning products are safe to use, how to clean the display screen glass, how to clean touchscreens and how to clean soldering residue.

The LCD TFT screens are built of thin-film transistors. The transistor is produced by chemical vapor deposition (CVD), based on the use of liquid hydrogen mixture and silicon mixture in an organic solvent, and using the rotation application method of the thin semiconductor.

In the TFT matrix, each pixel is controlled by four transistors, whereone of them is responsible for brightness, and three remain for basic color (red, blue, green). As a result, this solution allows the high resolution, better color and generally higher parameters of displayed images – comparing to common LCD matrix.

Because of the material the TFT is built from, which isglass, TFT displays havelow mechanical toughness,so can be easily damaged. The most popular damage of TFT is:violation of liquid crystal structure – „spilling liquid crystal”,

The majority of damage occurs during the assembly process in the end user devices. Too much pressure on the fragile TFT construction can damage the structure of the liquid crystal or electric lines.

We recommend that you are always careful during the process of assembling the module. This special treatment is necessary to protect the matrix of the display against being hit or put under too much pressure.

The module can be held strictly by the housing, and the unnecessary thrust on display should be avoided. The disassembling of the display housing is not recommended, because this process is very destructive and in most cases, it will leave you with a damaged TFT .

All CategoriesAmplifiersAttenuatorsAudio ComponentsBatteriesCapacitorsCircuit ProtectionClock and TimingCommunicationComputer ProductsConnectorsControllersData AcquisitionDevelopment SystemsDiodes, Transistors and ThyristorsDisplaysDrivers and InterfacesElectromechanical SwitchesElectronic SwitchesEmbedded Controllers and SystemsEMI/RFI SuppressionElectromechanicalFasteners and HardwareFiltersKits and ToolsLEDs and LED LightingLighting SolutionsMagneticsMaterial Handling, Storage and PackagingMaterials, Chemicals and AdhesivesMechanical Power TransmissionMemoryMicrocontrollers and ProcessorsFluid Power Actuators & ValvesMotorsMultimediaOptoelectronicsCrystals and OscillatorsOtherPipe, Tubing, Hose and AccessoriesPower ManagementPower SuppliesProcess ControlProgrammable DevicesRelaysResistorsRF and MicrowaveSensorsSolarStandard and Specialty LogicTest and MeasurementThermal ManagementToolsTransceiversWire and Cable

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey