how to get cured resin off lcd screen in stock

An animated explanation to “Why did this happen?” When you move up to larger resin 3d prints, you also start seeing failures. There’s no blanket answer for all print failures. But in this video, he explores a few reasons why resin 3d prints sometimes fail. And hopefully, show you how you can get better results.

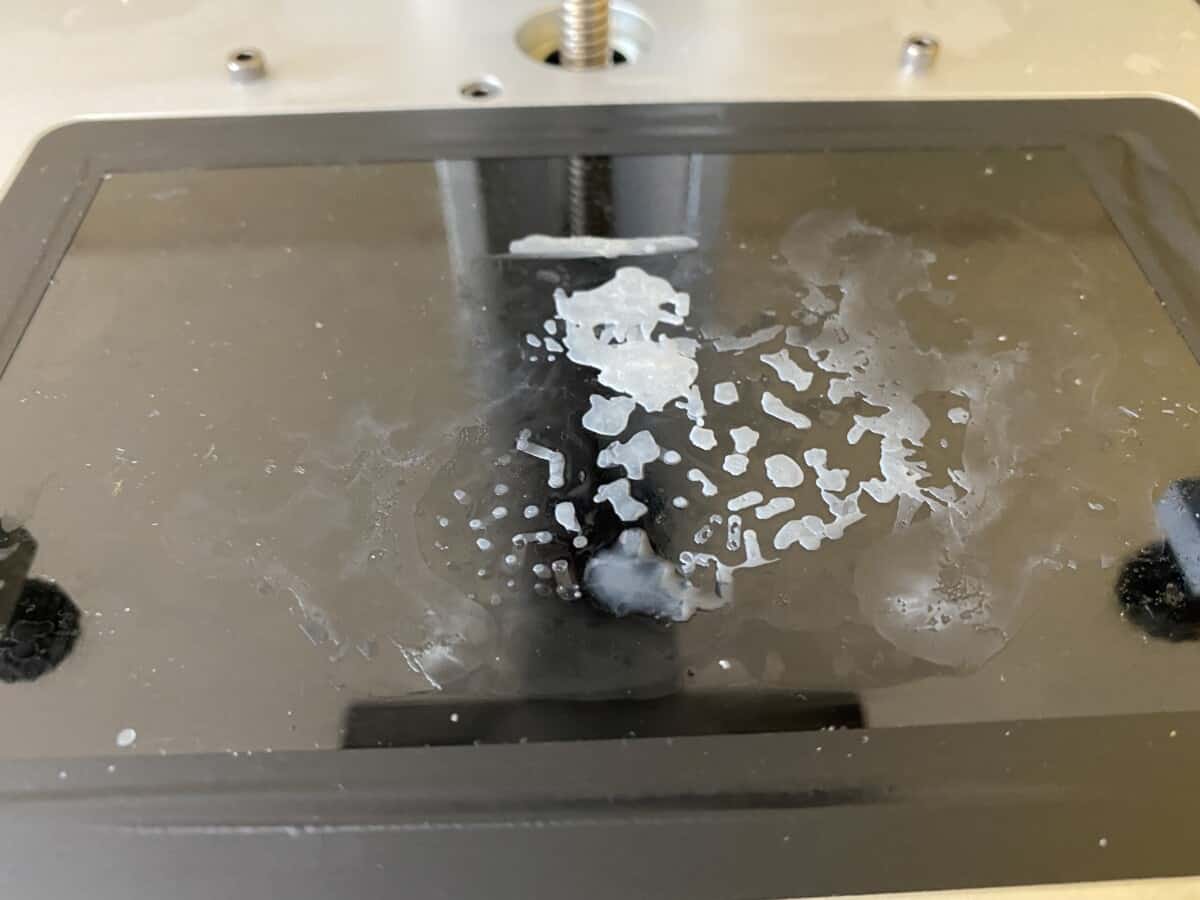

In that case, the Pendrive failed and the top pressed the failed print into the FEP perforating it. At the beginning, I wanted to cry, but I got my spatula and scrapped the shit out of the screen. I was able to remove most of it.

But I couldn’t scrap all. Do you see the top corner? I was not able to remove that little bastard. I poured alcohol and rubbed and rubbed and i was only removing the glue from the sealant. So I checked internet.

I promise that I will make a video with how I scrapped everything because I recorded it. But I wanted to let you know the solution right now before I forget to post.

The solution is a 10 dollar plastic shitty tool from Amazon. It is used for vinyl in cars and it is plainly a godsend tool. It does not damage the screen but it is enough sharp that it gets under the resin. It is plainly amazing. Best 10$ invested of my life.

Resin 3D printers are awesome, however, the whole process is extremely messy. Especially when an accident happens and the resin leaks from the vat all over the printer.

When this happens mid-print, it usually means one thing – the resin will leak onto the precious LCD of the printer and cure. This means one thing – the UV light will be blocked by the cured parts and you will probably experience holes in your printed parts.

Usually, the people on Facebook advise you to scrape the resin away with a plastic razor. This usually works for small leaks, but it doesn’t work well on large leaks.

I experienced a resin leak recently on my Elegoo Saturn. Scraping the resin was not leading anywhere and I managed to scratch the polarizer film on top of the LCD. Therefore I stopped and I decided to make a (successful experiment): use acetone to dissolve the cured resin. It worked flawlessly!

Let me start with a warning – if you decide to follow this guide, you will do it at your own risk. I tested the procedure on the pre-order batch of Elegoo Saturn with the TM089CFSP01 LCD. It is possible that later batches or different LCDs use a polarizer that is not acetone resistant. In that case, the procedure will damage your LCD! If you want to try it, try rubbing a corner of the LCD with acetone first to see if it is acetone resistant or not. On the other hand – if your LCD is ruined with resin, there is nothing you can lose.

The procedure is simple – soak the cured resin with acetone to soften it and scrape it away. However, the acetone evaporates quickly, so simply pouring it on the screen does not work (as it evaporates), nor rubbing an acetone-wet cloth over it. The solution is to soak a paper towel with acetone, put it on the LCD and cover it with plastic foil to prevent evaporation. After 10-15 minutes the resin softens and is easy to scrape off. You can also apply the same feature with IPA – it will just not make the resin as soft as acetone.

We’ll admit it. We like the results of resin 3D printing, but we don’t always care for the mess. We aren’t alone, and a common issue is to have drips of resin on your LCD screen — a potential disaster. You ought to have a screen protector, but yeah… you should back up hard drives, too. [Jessy] has the same problem and he has heard that you can easily clean cured resin from the screen using wood glue. Does it work? Check out the results of three glues in the video below.

We winced to see glue going on the screens. [Jessy] cured some resin on the screens deliberately for a test. He used Elmer’s wood glue, Gorilla wood glue, and Titebond II wood glue. While there is a bit of a price difference between the options, they are all fairly inexpensive.

After letting the glue cure for 24 hours, it should peel up and take the resin up with it. Getting under the corner to start peeling was challenging and the whole thing left a huge mess. In retrospect, [Jessy] mentioned it might be a good idea to put a tab under the glue while wet to provide a handle.

It probably doesn’t matter, though. Only the Gorilla glue grabbed any resin at all and even that wasn’t very effective. [Jessy] suggests using alcohol and a plastic scraper if you have this problem. We suggest a screen protector.

There are two upsides, though. First, the casting of some brands of wood glue made some interesting pieces that might have use in some other context. Second, the video comments have other ideas that might be worth trying including hot sponges and cheap material for screen protection.

Usually, we are more worried about getting resin to stick not unstick. If you are still on the fence about the mess versus rewards of resin printing, check out our overview.

There are many ways you might get resin on the LCD screen of your resin 3D printer. You might have a print failure that causes a tear in your FEP and resin can leak through. You might get some on the bottom of your vat while changing resin types. If it gets exposed to UV light it will cure on and get stuck to your screen. Cured resin can be extremely difficult to remove from solid surfaces.

There are a few ways to get resin off of your screen. But it can be really easy to scratch your screen if you aren’t careful so here is how I have used to get it off of my screen.

The first thing that you need to do is clean the screen to remove any loose particles. I use a little bit of IPA and a clean microfiber cloth to get mine clean. This will not remove any of the cured resin but can help to get rid of any other particles that might cause scratches.

Plastic scrapers use “blades” that are plastic. They have the same form factor as double-sided razor blades but are much safer. They won’t scratch your screen nearly as easily as a traditional metal scraper. I still have some IPA on the screen that helps it to glide above the surface a little bit more and further reduce the possibility of scratches.

There is a reason that they give you a lot of different blades with these scrapers. The blades get nicked up and dull very quickly. Remember to change the blades often. To get the screen clean with the resin that is in the picture at the top of this article, It went through three different blades.

After much persistence, the screen is clean and functional again. Now is the time to add a screen protector to make this process much easier. because it isn’t if you will get more resin on your screen, but rather when will you get more resin on your screen.

Dust, smudges, and/or lint present on the resin 3D printer"s LCD surface may affect printing. In order to increase your success rate in resin 3D printing, we recommend you keep your LCD clean at all times.

Apply a small amount of 95% sanitizing alcohol on the printer’s LCD to remove any cured resin, smudges, and/or fingerprints present on the LCD. Use a soft kitchen paper towel or a fiber cloth and wipe in one direction to thoroughly clean the LCD surface.

Compatible for ELEGOO Mars / ELEGOO Mars Pro / ANYCUBIC Photon / Creality LD002R / ANYCUBIC Photon S / PHROZEN Sonic Mini / LONGER Orange 10 / LONGER Orange 30 / EPAX X1-N

The light source design, exposure time and other printing parameters of different brands of LCD 3D printers are different.The resin composition ratio of SUNLU designed for the photon is special , it is the most consistent with resin photon print parameter.

1. Environmental requirements: 20-30°C ambient temperature, do not print near windows or in other environments exposed to UV light, and try to isolate children and pregnant women.

4. The residue on the surface of the printed resin parts can be washed with alcohol at a concentration of 95% or more, and it is recommended that the cleaning process does not take more than 1 minute.

5. pores and other details of the alcohol is not easy to clean to the place can be used ultrasonic or filled with alcohol syringes and other auxiliary tools to clean, and alcohol should not be cleaned too many times to ensure the purity of alcohol, the concentration of impure alcohol cleaning model will lead to whitening and wash the phenomenon of unclean. Specific cleaning time, until the surface of the resin parts no sticky feeling, no residual resin in the pores of the effect shall prevail.

6. Drain or blow dry the residual alcohol after cleaning and place under UV light or sunlight, and irradiate all parts of the model evenly until the surface of the resin parts feels dry and hard enough.

7. Use hand sanitizer or dishwashing liquid to wash away any resin residue on the skin, but try not to touch the alcohol-washed resin residue with your hands.

Thickened aluminum bottle completely protected from light. Leak-proof bottle fully wrapped with a plastic bubble bag to make sure the resin stays in place where they belong.

This screen protector should be installed on top of your LCD screen to help protect your printer from resin spills. It will prevent any leaked resin from curing to your screen and potentially damaging your printer.

You can use soft tissues and a lil spray of IPA to remove dust. If there is dried resin on the screen, you can carefully scrape it off with a razor, but be careful with that.

With resin 3D printing, it’s common to get resin prints and even cured resin stuck to the build plate. It can be pretty difficult to remove these if you don’t use the right technique, so I decided to look into some of the easiest ways to remove resin prints and cured resin.

To remove resin stuck to your build plate, you should be able to scrape it off using your metal scraper tool, but if that doesn’t work, you can also try using flush cutters or a razor blade scraper. Some people have had success using a heat gun or air dryer to soften the resin. Over curing the resin can make it warp.

The easiest way to get resin prints off the build plate is by using a good metal scraper, gently wiggling and pushing it at the edge of your 3D print so it can get underneath. As you push further through the print, it should gradually weaken the adhesion and come off the build plate.

I like to leave either leave the resin print for some time, so most of the uncured resin drips back into the resin vat, then when I loosen the build plate, I’d angle it down to let more resin drip off.

After that, I change the angle of the build plate so that resin that was dripping down is now at the top of the build plate, kind of vertical and on the side. This means you won’t have resin dripping off the edge.

This gets resin prints off the build plate very easily every time for me. The metal scraper you use does make a difference in how easy models are to remove.

If you find that it’s hard to remove the model, it most likely means your bottom layer settings are too strong. Reduce your bottom layer exposure to 50-70% of what you are currently using and try another print. It should be a lot easier to remove after doing this.

I have put together the different ways by which you can remove cured resin or similarly, a resin print from the build plate and they are as follows:Scrape off the resin with a scraping tool, flush cutters or a razor blade scraper.

If the metal scraper that comes with your 3D printer isn’t good enough to get underneath the cured resin, you may want to get a higher quality version.

The Warner 4″ ProGrip Stiff Broad Knife is a great tool that you can use to remove cured resin from the build plate. It has a strong chiseled edge that makes it ideal for scraping, as well as a tapered rubber handle design that makes it comfortable to hold.

Some people have also had luck with the REPTOR Premium 3D Print Removal Tool Kit from Amazon which has a knife and spatula. Many reviews mention that it made their job a lot easier to remove prints, so it would do well to remove cured resin too.

One thing to keep in mind though is that they aren’t designed for resin printers though because the resin may eat away at the handle if you don’t clean it properly.

Another tool you might have luck with is with using flush cutters. What you do here is place the blade of the flush cutters on any side or corner of the cured resin then press the handle and gently push under the cured resin.

It can help with lifting and separating the cured resin from the build plate. Many users have used this technique successfully to remove cured resin from the build plate.

The last object I’d recommend for getting underneath cured resin on your build plate is a razor blade scraper. These can be very useful for removing cured resin, and can either be plastic or metal razor blades.

The Titan 2-Piece Multipurpose & Mini Razor Scraper Set from Amazon is a good choice here. It has a tough polypropylene handle with a nice ergonomic design to make it easier to operate. It comes with 5 extra heavy-duty replacement razor blades as well.

When cured resin sticks to your build plate, especially after a failed print, you can remove it by heating up the stuck resin on the build plate to weaken the adhesion.

After doing this, you can then use your preferred scraping tool to gradually remove the cured resin. The cured resin may come off now since the resin is now soft and can be easily scraped off.

You want to keep safety in mind here because a heat gun on metal will make it very hot since metal is a good conductor of heat. You can get yourself a decent quality heat gun like the Asnish 1800W Heavy Duty Hot Air Gun from Amazon.

You won’t have to use such high heat but it also has other uses outside of resin 3D printing like for removal labels, residue, removing old paint, melting ice, or even removing white oxidation from vinyl railings like one user mentioned.

If you have tried the methods above and you still can’t get the cured resin off your build plate, you can try to cure the resin with a UV light, UV station or even the sun so it can over-cure and warp.

The reason this can work is because resin reacts to UV light, even past the normal curing stage. If you cure it for several minutes, it should start to react and warp/curl so you can better get underneath the resin.

One person who does this recommended to cover part of the cured resin with something non-transparent, then put the build plate outside to cure in the sun. The exposed area of resin should begin to warp so you can use a scraping tool to get underneath and remove the stuck resin.

One of the most popular UV curing lights for resin printing is the Comgrow 3D Printer UV Resin Curing Light with Turntable from Amazon. It turns on from a simple switch, producing plenty of strong UV light from 6 high-power 405nm UV LEDs.

Another useful but less common way to remove cured resin from your build plate is to actually soak the build plate in isopropyl alcohol (IPA) for a couple of hours.

Usually we use IPA to clean uncured resin from our cured resin 3D prints, but it has a great ability to be absorbed by the cured resin then start swelling up as a result.

One user suggested putting your build plate in a freezer since the resin will react to the rapid change in temperature and hopefully make it easier to remove. You do have to make sure your stored food doesn’t get contaminated though.

They recommend using a freezer that is non-food, but most people won’t have access to that. It may be possible to put the build plate in a Ziploc bag then in another airtight container of some sort so it is safe from contamination.

Another way you can introduce a rapid temperature cooling is actually by using a can of air, namely compressed air. How this one works is by turning the can of compressed air upside down, then spraying the nozzle.

For some reason, this produces a cold liquid that can be aimed and sprayed at your cured to make it very cold, hopefully making it react and warp so it can be removed easier.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey