how to get cured resin off lcd screen brands

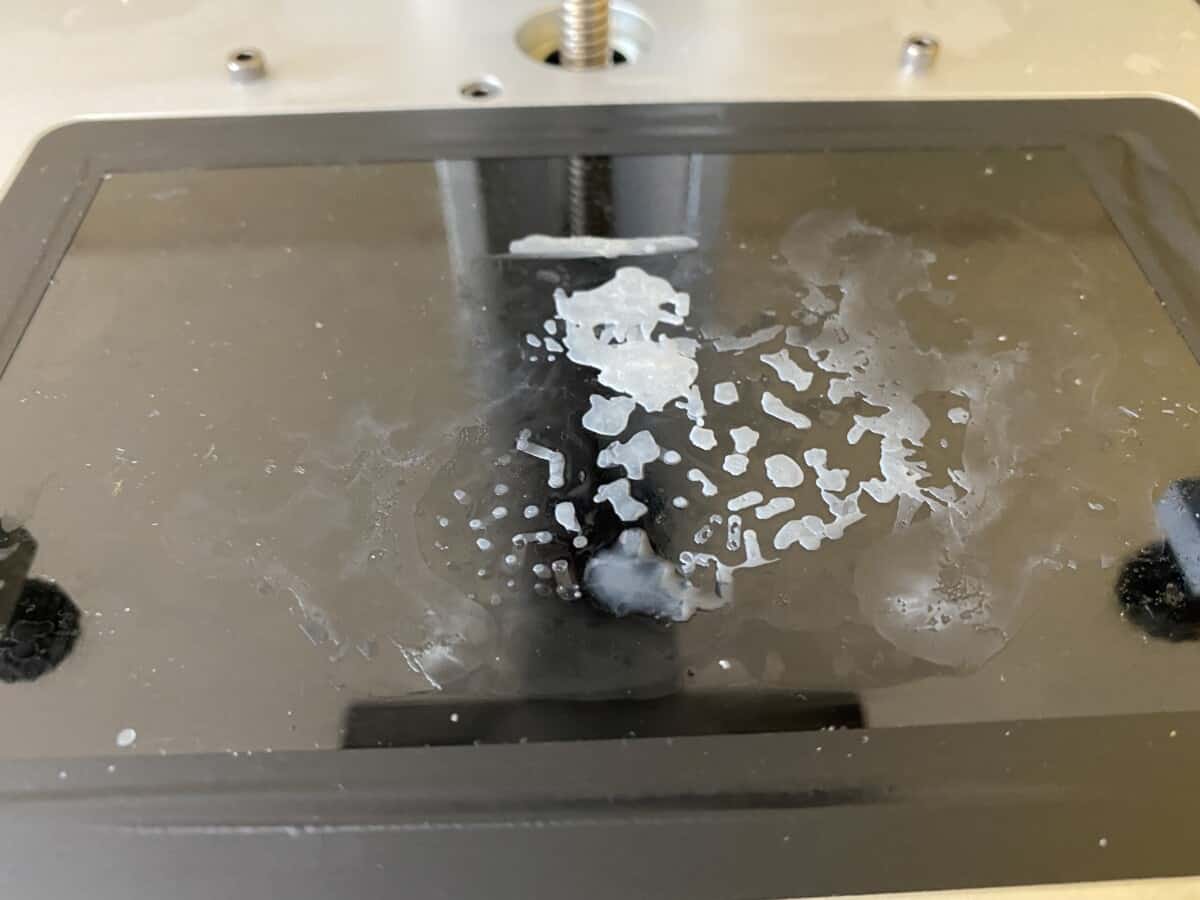

There are many ways you might get resin on the LCD screen of your resin 3D printer. You might have a print failure that causes a tear in your FEP and resin can leak through. You might get some on the bottom of your vat while changing resin types. If it gets exposed to UV light it will cure on and get stuck to your screen. Cured resin can be extremely difficult to remove from solid surfaces.

There are a few ways to get resin off of your screen. But it can be really easy to scratch your screen if you aren’t careful so here is how I have used to get it off of my screen.

The first thing that you need to do is clean the screen to remove any loose particles. I use a little bit of IPA and a clean microfiber cloth to get mine clean. This will not remove any of the cured resin but can help to get rid of any other particles that might cause scratches.

Plastic scrapers use “blades” that are plastic. They have the same form factor as double-sided razor blades but are much safer. They won’t scratch your screen nearly as easily as a traditional metal scraper. I still have some IPA on the screen that helps it to glide above the surface a little bit more and further reduce the possibility of scratches.

There is a reason that they give you a lot of different blades with these scrapers. The blades get nicked up and dull very quickly. Remember to change the blades often. To get the screen clean with the resin that is in the picture at the top of this article, It went through three different blades.

After much persistence, the screen is clean and functional again. Now is the time to add a screen protector to make this process much easier. because it isn’t if you will get more resin on your screen, but rather when will you get more resin on your screen.

We’ll admit it. We like the results of resin 3D printing, but we don’t always care for the mess. We aren’t alone, and a common issue is to have drips of resin on your LCD screen — a potential disaster. You ought to have a screen protector, but yeah… you should back up hard drives, too. [Jessy] has the same problem and he has heard that you can easily clean cured resin from the screen using wood glue. Does it work? Check out the results of three glues in the video below.

We winced to see glue going on the screens. [Jessy] cured some resin on the screens deliberately for a test. He used Elmer’s wood glue, Gorilla wood glue, and Titebond II wood glue. While there is a bit of a price difference between the options, they are all fairly inexpensive.

After letting the glue cure for 24 hours, it should peel up and take the resin up with it. Getting under the corner to start peeling was challenging and the whole thing left a huge mess. In retrospect, [Jessy] mentioned it might be a good idea to put a tab under the glue while wet to provide a handle.

It probably doesn’t matter, though. Only the Gorilla glue grabbed any resin at all and even that wasn’t very effective. [Jessy] suggests using alcohol and a plastic scraper if you have this problem. We suggest a screen protector.

There are two upsides, though. First, the casting of some brands of wood glue made some interesting pieces that might have use in some other context. Second, the video comments have other ideas that might be worth trying including hot sponges and cheap material for screen protection.

Usually, we are more worried about getting resin to stick not unstick. If you are still on the fence about the mess versus rewards of resin printing, check out our overview.

Dust, smudges, and/or lint present on the resin 3D printer"s LCD surface may affect printing. In order to increase your success rate in resin 3D printing, we recommend you keep your LCD clean at all times.

Apply a small amount of 95% sanitizing alcohol on the printer’s LCD to remove any cured resin, smudges, and/or fingerprints present on the LCD. Use a soft kitchen paper towel or a fiber cloth and wipe in one direction to thoroughly clean the LCD surface.

Resin 3D printing produces amazing quality prints, but what about the cleaning aspect of it? Some people don’t use the best methods of cleaning the resin vat on their 3D printer, so this article will help you in that regard.

Ensure you are wearing gloves, disconnect your resin tank from the 3D printer and pour left over resin back into the bottle with a filter on top, scrape any hardened resin too. Gently dab some paper towels to clean any leftover resin. Use isopropyl alcohol to clean the resin vat and FEP film.

People consider it a messy method because it requires a lot of effort but if you know the right way to utilize the resin and its printing properties you will get to know that it is as easy as printing with filaments.

It is clear that you have to take care of some aspects while printing with resin and cleaning the resin vat because the uncured resin can cause irritations to sensitive skin.

Usually, there are two thumb screws on the left and right sides of the vat that can be unscrewed easily. Make sure that you take out the vat smoothly protecting the bottom plate from scratching or hitting with the 3D printer.

Since the filter by itself can be quite flimsy, it’s a good idea to get a silicone filter to go into the bottle and act as a foundation for the thin paper filter to sit inside, so it doesn’t spill or tip over.

Using a funnel is highly recommended because it will help you to filter the impurities or residual crystals so that it can be used for other prints without getting in the way of future prints.

Take a paper towel or any absorbent paper to absorb the liquid resin out of the vat thoroughly. Make sure that you don’t rub the paper too hard on the FEP film as it can damage the material and affect the quality of your future prints.

Rather than rub, you can use a gentle dabbing motion or slightly press the absorbent paper towel and let it absorb the resin. Repeat this until all the resin is cleaned out of the vat.

Most solid deposits of resin should have been filtered out, but if you have hardened resin stuck to the FEP, use your finger (in gloves) on the underside of the FEP to dislodge the resin.

I try to avoid using a scraper on the FEP film as much as I can to make it last longer. I’d use the scraper just to get the residual hardened resin into the filter, but would use my finger (in gloves) to dislodge hardened resin.

I take all the resin deposits and paper towels soaked in resin, and make sure to cure it all under a UV light for around 5 minutes. Resin can be covered and in crevices, so make sure to adjust the uncured resin deposits occasionally.

You should filter out the resin from the resin tank and clear out the rest of the resin with paper towels first, ensuring you have nitrile gloves. Lift the resin tank and gently push the underside of the stuck resin print all around until it loosens from the FEP film.

I had a test print from the Anycubic Photon Mono X which had 8 squares printed, stuck to the FEP sheet. There was no way it was coming off even with the plastic spatula and a decent amount of pressure.

Instead, I learned the technique of using your fingers to remove those failed prints, keeping my FEP in good order and not damaging it. I managed to get all 8 squares that were stuck down off in no time.

Having to clean out the resin and soak the remnants up does become tedious, but it’s part of the experience with resin 3D printing. Although FDM printing requires a lot less clean-up and post-processing, the quality of resin is so much better.

To get resin off your LCD screen, you should wipe up any uncured resin with paper towels. For any resin that’s cured to the actual LCD screen, you can spray some 90%+ isopropyl alcohol on the areas, leave it to sit and soften the resin, then scrape it off with a plastic scraper.

Some people have even recommended further curing the resin so it can warp/expand and be easier to get underneath to remove. If you don’t have a UV light, you can also use the sunlight to cure the resin.

Another user mentioned that the LCD glass is resistant to acetone but resin isn’t so you can use an acetone soaked paper towel to help remove the cured resin.

When using a plastic scraper or razor, make sure you are scraping slowly in one direction, as well as making sure it’s lubricated with something like rubbing alcohol or acetone. Ensure the blade is staying more parallel to the surface rather than at angles.

An animated explanation to “Why did this happen?” When you move up to larger resin 3d prints, you also start seeing failures. There’s no blanket answer for all print failures. But in this video, he explores a few reasons why resin 3d prints sometimes fail. And hopefully, show you how you can get better results.

In that case, the Pendrive failed and the top pressed the failed print into the FEP perforating it. At the beginning, I wanted to cry, but I got my spatula and scrapped the shit out of the screen. I was able to remove most of it.

But I couldn’t scrap all. Do you see the top corner? I was not able to remove that little bastard. I poured alcohol and rubbed and rubbed and i was only removing the glue from the sealant. So I checked internet.

I promise that I will make a video with how I scrapped everything because I recorded it. But I wanted to let you know the solution right now before I forget to post.

The solution is a 10 dollar plastic shitty tool from Amazon. It is used for vinyl in cars and it is plainly a godsend tool. It does not damage the screen but it is enough sharp that it gets under the resin. It is plainly amazing. Best 10$ invested of my life.

Compatible for ELEGOO Mars / ELEGOO Mars Pro / ANYCUBIC Photon / Creality LD002R / ANYCUBIC Photon S / PHROZEN Sonic Mini / LONGER Orange 10 / LONGER Orange 30 / EPAX X1-N

The light source design, exposure time and other printing parameters of different brands of LCD 3D printers are different.The resin composition ratio of SUNLU designed for the photon is special , it is the most consistent with resin photon print parameter.

1. Environmental requirements: 20-30°C ambient temperature, do not print near windows or in other environments exposed to UV light, and try to isolate children and pregnant women.

4. The residue on the surface of the printed resin parts can be washed with alcohol at a concentration of 95% or more, and it is recommended that the cleaning process does not take more than 1 minute.

5. pores and other details of the alcohol is not easy to clean to the place can be used ultrasonic or filled with alcohol syringes and other auxiliary tools to clean, and alcohol should not be cleaned too many times to ensure the purity of alcohol, the concentration of impure alcohol cleaning model will lead to whitening and wash the phenomenon of unclean. Specific cleaning time, until the surface of the resin parts no sticky feeling, no residual resin in the pores of the effect shall prevail.

6. Drain or blow dry the residual alcohol after cleaning and place under UV light or sunlight, and irradiate all parts of the model evenly until the surface of the resin parts feels dry and hard enough.

7. Use hand sanitizer or dishwashing liquid to wash away any resin residue on the skin, but try not to touch the alcohol-washed resin residue with your hands.

Thickened aluminum bottle completely protected from light. Leak-proof bottle fully wrapped with a plastic bubble bag to make sure the resin stays in place where they belong.

The basics of resin 3D-printing are based upon the exact curing of resin at a specific location in the XYZ space. Within regular 3D-printers, the Z resolution is better defined as its layer thickness. while the XY resolution is defined by the imaging technology that makes the resin cure. From the earlier days, these were always laser based printers. Where the laser ‘writes’ in the resin and everywhere it touches the resin the material will cure into a solid plastic. Since then there have been plenty of developments in new imaging techniques. After lasers, Envisiontec (now ETEC) developed a projector based imaging technique in the early 2000’s, still known as DLP 3D-printing. This technology has some benefits over laser based systems and made it possible to develop the first desktop sized resin 3D-printers. Although the DLP technology still has some disadvantages (like limited build size / pixel size ratio and its price at the time). In around 2017 Wanhao brought the first affordable LCD based printer. Although companies like Structo and Photocentric released the technology a few years earlier. This new imaging technology based on LCD screens rapidly took over the entry-level and now even the professional resin 3D-printing space. From here the history in imaging technologies for resin 3D-printing is well-known. From 2K RGB LCD / MSLA resin 3D-printers in the beginning, it evolved to 2K monochrome screens, 4K and even 8K mono LCD screens. In this article you will learn more about the technology differences behind monochrome LCD screens vs RGB LCD imaging technology.

We couldn’t write it better as Ackuretta:“LCD stands for Liquid Crystal Display – you will be familiar with this technology, as you are reading this article either through a mobile device or a computer screen. That bright thing in front of you is the LCD screen.”

Next to the Z-axis, which provides the Z resolution, the most important component of a resin 3D-printer is its imaging system. For LCD printers it is obviously the LCD screen combined with its LED array. The technology of the LCD screens in a resin 3D-printer is quite similar as for instance a laptop LCD (except for the backlight, which we come to later). During the last decades there has been an incredible amount of work by imaging companies to create better, larger and sharper LCD screens.

An LCD screen is build-up with a lot of different layers and each layer has its own function for the LCD to work. As the name LCD tells us, it display is based on liquid crystals. These crystals are randomly present and behave like a liquid in normal state. In this state they are quite transparent to light. When locally (per pixel) a current is applied on these liquid crystals, they will change orientation and block light. By doing this for every pixel and placing a background LED behind it, a 2D image is created.

In other words, if there is an electric charge applied to these liquid crystal molecules, they untwist. When they straighten out, they change the angle of the light passing through them so that it no longer matches the angle of the top polarizing filter. Consequently, no light can pass through that area of the LCD, which makes that area darker than the surrounding areas.

LCD based resin 3D-printers started with RGB LCD type of display, which works perfect for most display work. But for resin 3D-printing it is only important that you have one wavelength (one color) of light to print. This is often 405nm light, which is purple/blue-ish. On this wavelength your standard resins will work fine. The funny thing here is that the “old-fashioned” monochrome (means one color) LCD screens work much better for this. Of course these screens are not really old-fashioned and there has been a lot of development in one-color LCD screens as well in the past decades.

The picture below shows a RGB and a monochrome LCD screen. The RGB screens contain color filters. As RGB is an abbreviation for Red, Green and Blue. The color filters are necessary for color TV, phone and computer screens, but in 3D printing you don’t need color. These color filters from the first generation LCD printers lead to a reduced transmittance rate. Meaning that there is less light output and thus slower curing of the resin.

If we dive deeper into the imaging technology of LCD’s, one important value is the aperture ratio. The Aperture ratio is the ratio of the area of the light transmission part of the pixel to the total area of the pixel. They made a comparison image below with an LCD with aperture ratio of 50 ∼ 80%.

According to Chitusystems: “The increase in aperture ratio is mainly determined by the design scheme and process capability. In the manufacturing process, the alignment accuracy of the array substrate and the color filter substrate will also have a decisive influence on the aperture ratio”.

Going back to the difference with monochrome screens, these do not have a Red, Green or Blue color filters and operate in just one color. Think it as a black and white image (with grey-tones possible). In the pixels that are displayed as white, a lot of the 405nm light from the LED’s below can pass on the complete pixel.

Monochrome LCD’s are better for resin 3D-printing as they will increase printing speed and increase the life-time of the screen. To start with the last one, LCD screens in resin 3D-printing are considered as consumables. These screens need to be replaced when the performance drops. In contrast to DLP systems, which can be re-calibrated and should work for many years. With RGB type LCD screens the lifetime of a screen is approximately 500 hours with normal usage. You will notice dead pixels, flickering LCD screen or parts not working anymore when the life-time of the LCD is over. In our experience this lifetime of an RGB LCD can vary from 200 hours to 700 hours randomly over many different printers. If you replace it yourself it costs around $30-150 on spare parts and it is a fairly easy job, manuals can be found for most printer models online. For monochrome screens the lifetime is advertised at 2000 hours, which is a major improvement over the 500 hours of the RGB LCD screens. We have been working on monochrome printers since their launch (around end of 2020). Although we do not print full-time and only for R&D and quality purpose, we have not replaced any monochrome screen at the time of writing (January 2023). The print hours were not counted but we are sure this is much more compared to the RGB screens LCD’s which we have replaced many times in the past, before de-commissioning these printers.

The brightness and contrast ration of the screens are more dialed in for 405nm light and there are no color filters present, which increases the brightness of the LED’s. These improvements all help in getting a faster print speed. The following printers are both 2K LCD printers, the photon is an RGB type and the Mono is the monochrome version. You can see the difference in print speed there:

Especially for rigid resins the print speed is very much faster on monochrome LCD screens. For instance Liqcreate Premium Model would need 16,0 seconds exposure time for 0,1mm layer thickness on an RGB screen and only 2,0 seconds on the Monochrome LCD screen from the Anycubic Photon Mono. For some specialty resins like Tough-X the print speed will only double from 30 seconds to 14 seconds, as these specialty resins need more time and UV power to cure.

With printing on >20+ LCD type printers for many years we would advise to everyone that is looking for a new resin 3D-printing to choose a monochrome LCD printer. With every new model released we see some new benefits and better LCD screens. The benefits of Monochrome LCD screens are evident and we have not found any negative side of this yet.

As 3D printing continues to become cheaper and more accessible, resin 3D printers have become a popular choice for anyone interested in making highly-detailed models that wouldn’t be feasible using a filament-fed, FDM 3D printer. These MSLA (Masked Stereolithography) resin 3D printers typically have a single axis of motion, and this simple mechanical system means these machines can regularly be found for less than $300. With so many models on the market, we’ve made this list to help you find the best resin 3D printer for you.

The best resin 3D printers are capable of making high-resolution models by curing a liquid resin using a UV light source. This MSLA process uses a masking LCD to selectively block the UV light on a pixel-by-pixel basis, allowing these printers to create models that have a resolution of down to .035mm on the XY axes.

This high resolution comes at a price, as parts made on a resin 3D printer require post-processing after printing, and UV resin requires caution when handling. Because resin requires gloves and a mask to handle, we recommend beginners or anyone with young kids consider one of the FDM (fusion deposit modeling) printers on our overall best 3D printers page.

Why you can trust Tom"s HardwareOur expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.Mono or RGB LCD? The type of masking LCD on your resin 3D printer can have the single largest impact on your overall print speed. Because they are commonly used in other electronics, RGB masking LCDs are cheaper, but slower because they don’t allow UV light to pass through efficiently and need more exposure time per layer. For example, the RGB LCD on the Creality LD-002R requires 9 seconds per layer, while the Mono LCD on the Elegoo Mars 2 Pro requires only 2.2 seconds per layer.

How much build volume do you need?Most resin 3D printers have smaller build volumes than FDM 3D printers, so you may find yourself limited by this relatively small build volume. If you are interested in printing large parts, you’ll want to look at a large format resin 3D printer such as the Elegoo Saturn or theAnycubic Photon Mono X.

2K, 4K, or Beyond?A resin 3D printer that uses a 6.08-inch 2K screen like the Elegoo Mars 2 Pro is capable of an XY resolution of .05mm as well as a layer height of .05mm. For context, this means even a relatively low-resolution resin 3D printer is still capable of making extremely fine details that simply wouldn’t be possible on an FDM printer. If you need even more resolution, a 4K screen is capable of making finer features, but is typically more expensive.

Post Processing Equipment? Resin 3D printers create parts that require post-processing before they are completely finished. Typically, this workflow involves rinsing the parts in a solvent to dissolve any excess resin on the surface of the part, followed by a cure cycle that uses UV light to fully polymerize the part. This process can be done manually by submerging the part in a solvent and using an inexpensive UV light for curing, but some manufacturers have created post-processing equipment like the Elegoo Mercury X that automate the process and reduce the mess.

The Anycubic Photon M3 is the best all around resin 3D printer we’ve reviewed. It produces crisp details with 4K+ quality that rivals more expensive machines and has a wide build plate allowing it to make larger models than competitors in its class.

The etched build plate works really well at holding models tight during printing, but also allows for easy removal when they’re done. The metal vat has a convenient pour spout, and Anycubic includes a screen protector for the LED light source to prevent accidental drips from ruining your printer.

If you’re ready to throw some serious cash down for a decent-sized resin 3D printer with quality that will knock your socks off, the Phrozen Sonic Mighty 8K is here for you. Its roomy 218 x 123 mm build plate can accommodate an army of gaming miniatures or a gift-worthy superhero statue. Priced at around $600 at press time, this printer isn"t cheap. But in return for the premium, you get crispy details, prints that practically slide off the build plate, a built-in webcam and a machine that’s WiFi ready.

We enjoyed navigating through the Mighty 8K’s menus, thanks to its large and easy-to-use touch screen display. There’s little need to consult the manual – the printer walks you through an onboard tutorial to handle leveling and your first test print. Want to rerun a test file at a different exposure? No problem – the Sonic Mighty 8k will let you change exposure settings and more right inside the printer. I found this extremely helpful while dialing in a new resin.

The Phrozen Sonic Mighty 8K size is closer to what we see in FDM printers, without being so large that it dominates your workshop. The quality and extra wiggle room would be a worthwhile investment for someone running an Esty shop or an artist wanting to showcase their work. We were able to print 12 very-detailed gaming figures at once and the process only took 4 hours and 2 minutes.

The Creality Halot-One Plus is the flagship of the Halot line of MSLA resin 3D printers, offering an impressive set of features while still coming in at a prosumer-friendly price of $399. Unlike other printers in this price range, the Halot-One Plus includes Wi-Fi connectivity and a slicer app which allows users to quickly process models and prepare them for printing almost effortlessly.

The large 7.9-inch Mono LCD provides 4K resolution (4320 x 2560), fast per-layer cure times (3 seconds per layer), and a solid dual linear rail Z axis to allow for fast and accurate printing. The Halot-One Plus also includes an integrated air filtration system which reduces the amount of odor when printing, a surprising addition not typically seen at this price point. Finally, the 5-inch LCD interface allows users to adjust settings mid-print (including exposure time), and also provides an accurate estimate of remaining time during a print.

It’s only available for pre-order right now, but when it’s available, Elegoo’s Jupiter printer will offer a combination of great quality and a huge build volume. And, despite its $1,300 price, the Jupiter is actually a great deal for its size, given that competitors cost closer to $1,000.

Where the $499 Saturn provides a 192mm x 120mm x 200mm volume, the Jupiter provides a ton more, going all the way to 277.8mm x 156.3mm x 300mm. And the print quality is pretty good as we found when outputting a detailed model of the Notre Dame Cathedral.

The Anycubic Photon M3 Premium set an impressive standard. Offering both high resolution and large build volume in a single machine, it effectively does the work of two separate printers and still comes in cheaper than buying them individually.

The 10-inch 8K masking LCD provides an ultra-high 0.0285mm XY resolution which allows even the finest details to resolve on printed models. We were particularly impressed when we printed a model that had a tiny, open book on a pedestal; the words on the pages were sharp and legible (though one might need a magnifying glass to see them).

The 219mm x 123mm x 250mm build volume allows users to print large models with high resolution, or simply pack the oversized build platform with multiple small parts to produce many in parallel. Featuring integrated dual air filters, a laser-etched build platform, and a razor-thin NFEP vat film, the Photon M3 Premium is easily capable of handling anything you can throw at it.

If you’re looking for a reliable 3D printer to start your journey with resin printing, the Elegoo Mars 3 is a great place to start. The printer has outstanding 4K resolution for beautifully detailed models and a simple leveling system to get that first layer to stick perfectly.

Beginners should factor the high price of resin when considering their first printer, and the Elegoo Mars 3 only needs 350ml to fill its vat. The build volume is average for its class, with plenty of room for gaming miniatures and models.

If you’re looking to create small models for table-top gaming, or just display, the Elegoo Mars 3 Pro is a great choice, thanks to its great build quality and high resolution. The Mars 3 Pro has an XY resolution of 35 microns (0.035mm) which allows you to show intricate details in even small objects.

When we printed mz4250"s Red Dragon model, fine ridges on the tail and bones in the wing were sharp, without any visible splotching or errors. Even the spines and beard on the head were crystal clear. Its LCD screen provides a 4098 x 2560 resolution for prints, which is higher than the 4K resolutions of competitors like the Phrozen Sonic Mini 4K and AnyCubic Photon Mono 4K.

Unlike the Phrozen Sonic Mini 4K, which is very competitive in this area, the Mars 3 Pro doesn’t suffer from any build quality issues.It’s easy to level and even has a built-in air purifier that, in our tests, mitigated but did not completely remove the resin odor that all MSLA printers emit. With a price in the $300 - $350 range, this isn’t the cheapest resin printer on the market, but it offers great quality output and strong usability for the money.Round up of today"s best deals

Make sure you are using the correct preset with the recommended exposure times for your resin, in PrusaSlicer. If your resin does not have a dedicated preset, use the Resin Calibration (SL1/SL1S) to determine the correct values.

If the resin is not stored correctly, or you use the same batch, again and again, it can lose its original properties and won’t solidify anymore. Try a new batch of resin if you kept re-using one batch several times.

If the resin remains in the vat for too long it can start separating its reactive components and its oil solution (notice the lines of color difference in the picture below). Even though the printer will stir the resin using its tilt platform it may not be sufficient. With a gloved finger or a spatula, carefully stir the resin until its color is uniform.

If the platform is still wet of IPA after cleaning when the print begins, the IPA will repel the resin and the print will not stick to the platform upon exposure. Make sure you wipe the platform dry before starting your print.

If a lot of IPA has dripped into the resin tank it can dilute the resin to the point where it will lose some of its properties. Empty the tank and try a new batch of resin.

Check whether the UV panel and LCD screen work as intended – Run the Display test, found at Settings -> Calibration-> Display test. Follow the onscreen instructions.

If the logo does not appear on the display, but it is lit from the back, check the display’s wiring. To do so, remove the black cover secured by eight screws, then inspect the cable leading from the exposition (print) display. You can carefully disconnect and reconnect the cable header from the mainboard to ensure that it is seated correctly.

If it remains completely dark may be due to a faulty UV LED panel. Check its wiring by unplugging it and plugging it back in, making sure the connector is seated properly. Test the display again and if it still does not work it will have to be replaced.

If you need to change your print display, you need to calibrate the display to your machine. Both are available in the e-shop as a bundle, if you do not have a calibrator already.

Yeah, we felt the same way when we were trying to print miniatures and other thin featured objects that would break with any rough handling or even when we were trying to remove it from the build plate.

After countless iterations and extensive testing across 10+ popular resin printers we created a resin that prints high detailed models well on both classic RGB LCD SLA printers like the Mars or Photon but also prints fast with the new cutting edge mono lcd screen printers.

Water Washable:we wanted a resin that would be easy to clean with a variety of different options including water, various degreasers, and even diluted concentrations of alcohol such as 50% rubbing alcohol will easily clean any uncured resin off the print.

Additionally, our water washable durable resin can be cleaned by hand with soft brush, or with ultrasonic cleaners or wash and cure stations. Our resin can easily fit into your cleaning and post cure workflow.

Flexible and non-brittle:Brittle resins is always a sore spot for us because nothing is worse than spending all that time and money printing a highly detailed miniature model, cleaning it, painting it only for it to break the first time it gets handled roughly or accidentally knocked off the table. Which is why we made sure our resins had a bit of flex to them so that they could take some impacts and bending before breaking.

Low Odor:We hate smelly resin that can be smelled as soon as you enter the room, and often the problem is that a lot of resin ingredients can be very smelly. So we took our time to find a blend that would fill all our other requirements as well as have a very low odor profile.

Optimized for MONO LCD Printers:We were really excited to get our first mono printers in late 2020, but imagine our disappointment when we realized that mono screens overexpose many of the "fast" and "ABS like" resins that were made with RGB printers in mind. So we adjusted the photoinitiator composition that controls how fast resins change from a liquid to a solid.

In short, your experience with Ministry of Resin Durable Resins will be that you can get those ultra sharp details you see in fancy renders while still being forgiving enough to print on Mono LCD printers as well as RGB printers.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey