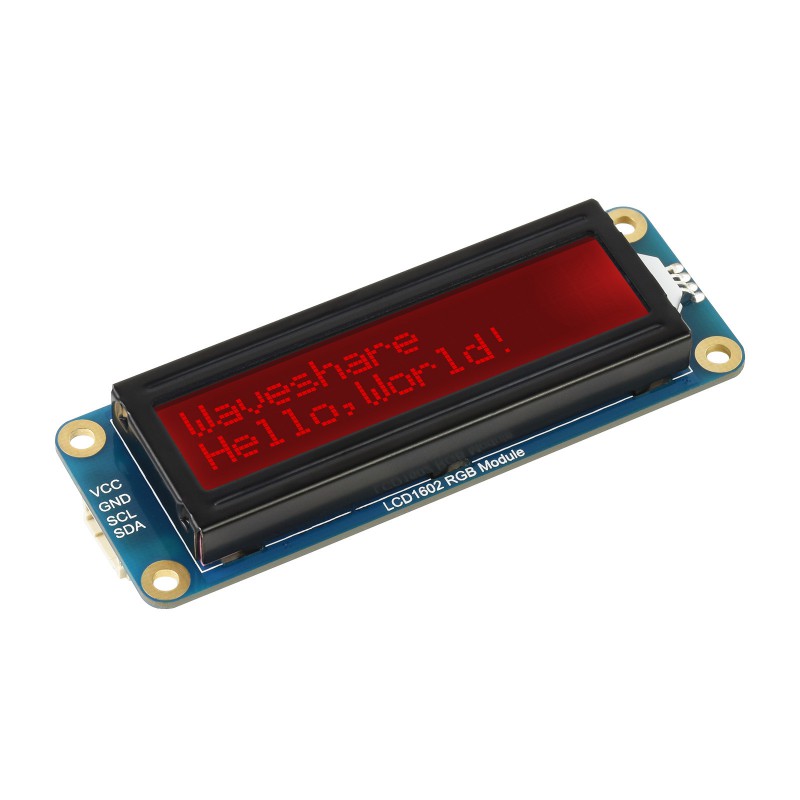

raspberry pi rgb 1602 lcd module quotation

You can directly attach it to the 40PIN GPIO of Raspberry Pi. Or you can wire it to Raspberry Pi with PH2.0 4PIN interface of the Module, please refer to the Pin definition below:

Take the LCD1602 RGB Module as an example, just connect it to the Raspberry Pi. The color of actual cable may be different with the figure here, please connect them according to the pins instead of color.

Find the LCD1602-RGB-Module-demo.uf2 file under the build file under the demo directory, press and hold the BOOTSEL button of Pico, connect the USB of Pico to the PC with a MicroUSB cable, and drag the uf2 file into Pico, and then the Pico will run the demo directly.

1. Copy LCD1602-RGB-Module-demo folder to your pico-examples file directory, and then modify the CMakelists.txt configuration file in the pico-example directory as shown in the figure below.

2. Open Visual Studio Code, open your pico-examples folder, select LCD1602_RGB_Module_demo, click Generate, you can find the LCD1602_RGB_Module_demo.uf2 file in the build folder.

Looking for a simple way to add a text display to your Raspberry Pi or BeagleBone Black project? Consider using a character LCD with the Python character LCD library! These classic displays can show a few lines of text, are inexpensive, and easily readable during the day or night with a bright backlight. You can follow this guide to learn how to connect a character LCD to a Raspberry Pi or BeagleBone Black and control the display from your own Python code!

Before you get started it will help to familiarize yourself with the character LCD guide. You will also want to make sure your Raspberry Pi is running the latest Raspbian operating system, and your BeagleBone Black is running the latest Debian or Debian-based distribution like Ubuntu.

If you haven"t used a Raspberry Pi or BeagleBone Black, be sure to follow the Learn Raspberry Pi series or BeagleBone Black SSH guide to understand the basic usage of each board and how to connect to a command terminal.

When you"re ready to get started, grab a character LCD, contrast adjustment potentiometer (included with Adafruit character LCDs), and a Raspberry Pi or BeagleBone Black. Continue to the next page to learn how to wire the display to your board.

Follow the steps below to wire a character LCD to your development board. Be careful to connect each wire to the correct pins as there are quite a few wires necessary to use the character LCD.

Note: The wiring below is for an RGB backlight display. If you"re using a monochrome backlight display you can use the wiring as-is and ignore the green and blue backlight wires. The red backlight wire will be used to control the monochrome display"s backlight.

If you would like to permanently turn on the LCD backlight, connect the red, green, blue backlight wires to ground instead of to your development board.

Connect Pi 5V power to the power rail of the breadboard. From the power rail connect one outer lead of the potentiometer,LCD pin 2 (VDD), and LCD pin 15 (LED ).

Connect Pi ground to the ground rail of the breadboard. From the ground rail connect the other outer lead of the potentiometer, LCD pin 1 (VSS), and LCD pin 5 (R/W).

Wire your BeagleBone Black to the LCD as follows. If you aren"t familiar with how to identify pins on the board, be sure to read the BeagleBone Black GPIO guide.

Connect BeagleBone Black 5V power pin P9_7 to the power rail of the breadboard. From the power rail connect one outer lead of the potentiometer, LCD pin 2 (VDD), and LCD pin 15 (LED ).

Connect BeagleBone Black ground pin P8_2 to the ground rail of the breadboard. From the ground rail connect the other outer lead of the potentiometer, LCD pin 1 (VSS), and LCD pin 5 (R/W).

The above wiring will use digital IO to control the colors of the backlight display. This means the backlight can only show 7 different colors (all the combinations of the 3 backlight LEDs). However because the BeagleBone Black supports PWM (pulse-width modulation) control of some hardware pins, it"s possible to use PWM pins to control the backlight LEDs and display a range of almost all colors.

To use PWM control of the backlight LEDs, wire your BeagleBone Black to the LCD as follows. Note that this wiring is exactly the same as the non-PWM wiring, except the 3 backlight LED pins (red, green, blue) are moved to different pins.

Connect BeagleBone Black 5V power pin P9_7 to the power rail of the breadboard. From the power rail connect one outer lead of the potentiometer, LCD pin 2 (VDD), and LCD pin 15 (LED ).

Connect BeagleBone Black ground pin P8_2 to the ground rail of the breadboard. From the ground rail connect the other outer lead of the potentiometer, LCD pin 1 (VSS), and LCD pin 5 (R/W).

Before installing the character LCD library you"ll need to make sure a few dependencies are installed by following the steps below. Make sure your development board has access to the internet so the software can be downloaded.

Once the library is installed you can find a few examples of its usage in the examples subdirectory. If you"re using a monochrome backlight LCD (i.e. single color, like a white on blue LCD) the char_lcd.py script will demonstrate the basic usage.

If you"re using a Raspberry Pi and have wired it according to this guide, you can immediately run the example. However if you"re using a BeagleBone Black or changed the wiring, first open char_lcd.py in a text editor (like nano) and uncomment/comment the lines towards the top that set the LCD pins.

The first part of the script are commands to import modules that will be used. In particular the Adafruit_CharLCD module is imported under the name LCD. Later in the script you can see how classes from the char LCD module are used to interact with the LCD.

The next part of the script configures which pins are connected to the LCD. You can see the Raspberry Pi configuration is uncommented by default, and below it the BeagleBone Black configuration is commented. You can use any digital GPIO pins in the configuration.

This section of the script configures the size of the LCD. By default the code assumes a 16 column, 2 row LCD however you can adjust the configuration to a 20x4 or other size display supported by the HD44780.

The next lines demonstrate basic usage of the LCD display class. The message function can be used to write a string of text to the display (including support for line breaks). The clear function clears the display, and the show_cursor and blink functions specify if the cursor is shown and should blink.

Although not shown above, there are other functions you might find useful on the LCD class. To see details on all functions you can have Python print help text for the class by executing (ignore the >>> prompt, it"s only shown for reference as the Python interpreter):

If you"re using a Raspberry Pi and have wired it according to this guide, you can immediately run the script. However if you"re using a BeagleBone Black or have changed the wiring, edit the script with a text editor and uncomment/change the lines at the top that define the LCD pins.

If you open the file char_lcd_rgb.py in a text editor (such as nano) I"ll describe the important differences between it and the previous char_lcd.py example below.

The first important difference is the configuration of LCD pins. Notice there are now explicit pins defined for the red, green, and blue backlight LEDs.

The Adafruit_RGBCharLCD class inherits from the Adafruit_CharLCD class so it has all the same functionality as demonstrated in the char_lcd.py example. In addition to the basic character LCD functionality the RGB character LCD class adds some functions to set the RGB color of the backlight.

If you"re using a RGB character LCD you can use PWM (pulse-width modulation) for fine control of the backlight color. By turning the different backlight red, green, and blue LEDs on and off very quickly with PWM, it"s possible to precisely control the color of the backlight.

Note that PWM control works best when there"s hardware support for PWM on your development board. The BeagleBone Black has support for up to 8 hardware controlled PWM pins and works great with the RGB character LCDs. However, the Raspberry Pi only has one hardware PWM pin and can be a little more troublesome to use PWM.

The RPi.GPIO library which is used by the character LCD library supports a software implementation of PWM on the Raspberry Pi. This lets you PWM control the RGB backlight even though the Pi doesn"t have 3 hardware PWM pins. In my testing software PWM worked reasonably well with the RGB character LCD backlight. You might notice slightly incorrect colors, but otherwise software PWM is worth a shot to finely adjust the backlight color on the Raspberry Pi.

The char_lcd_rgb_pwm.py file demonstrates usage of PWM backlight control. If you"re using a Raspberry Pi and have it wired to the LCD as described in this guide, you can immediately run the script. However if you have a BeagleBone Black or have changed the wiring, edit the file char_lcd_rgb_pwm.py in a text editor and comment/uncomment the lines at the top which define the LCD pins.

If you"re using the BeagleBone Black make sure you"ve followed the wiring for hardware PWM. Specifically, the red, green, and blue backlight pins need to be connected to the P9_16, P9_14, and P8_13 pins respectively.

You should see the backlight turned on to different colors for a short period of time, and then a continuous gradient of colors displayed with a message showing the red, green, and blue color displayed on the LCD. For example:

The code for PWM control is very similar to non-PWM control from char_lcd_rgb.py, however there are a few important differences. The first difference is how the Adafruit_RGBCharLCD class is intialized. Notice the enable_pwm=True flag is passed to the constructor/init function:

One problem with using a character LCD is that you give up a lot of GPIO pins to talk to the LCD. Four pins are used to send data, two pins are used for write and clock signals, and another pin or three are used for the backlight for a total of ~6-9 total pins! On a platform like the Raspberry Pi model A/B with only a dozen or so GPIO pins you can quickly run out of pins for other parts of your project. However with chips like the MCP23008 or MCP23017 you can easily add extra GPIO pins to your development board through an I2C interface!

If you aren"t familiar with the MCP230xx series of chips, there"s a great guide that describes their usage with a Raspberry Pi. Note that you don"t need to install the library or code from the guide, it"s only provided for reference.

To use an MCP230xx chip with a character LCD you will need to wire the MCP chip to your board"s I2C pins, and then wire the LCD to the MCP chip. Below are examples of wiring an MCP23017 to the Raspberry Pi or BeagleBone Black.

If you"d like to use an MCP23008 instead of the MCP23017 the wiring is similar, however consult the MCP23008 datasheet to see which pins are for power, ground, I2C, and GPIO.

Connect Pi 3.3V power to the power rail of the breadboard, and connect the MCP VDD and RESET to 3V power. Be careful to connect the 3.3 volt and not 5 volt power to these pins!

Connect Pi ground to the ground rail of the breadboard, and connect the MCP VSS and address pins, one outer lead of the potentiometer, the LCD ground, and the LCD R/W pin to the ground rail.

Connect Pi 5V power to the other outer lead of the potentiometer, LCD power, and LCD backlight pins. Note that 5 volt and not 3.3 volt power is used to power the LCD!

Connect BeagleBone Black 3.3V power pin P9_3 to the power rail of the breadboard, and connect the MCP VDD and RESET to 3V power. Be careful to connect the 3.3 volt and not 5 volt power to these pins!

Connect BeagleBone Black ground pin P9_1 to the ground rail of the breadboard, and connect the MCP VSS and address pins, one outer lead of the potentiometer, the LCD ground, and the LCD R/W pin to the ground rail.

Connect BeagleBone Black 5V power pin P9_7 to the other outer lead of the potentiometer, LCD power, and LCD backlight pins. Note that 5 volt and not 3.3 volt power is used to power the LCD!

Note that the BeagleBone Black has two I2C interfaces and this wiring will use the/dev/i2c-1 interface. Make sure there aren"t any device tree overlays loaded which use these I2C pins for other purposes. The default BeagleBone Black device tree configuration with no overlays loaded will expose the necessary I2C interface for the wiring above.

The char_lcd_mcp.py file in the library"s examples folder demonstrates the usage of a character LCD (non-RGB version) with an MCP23017 IO extender. Run the script by executing this command inside the examples directory:

First the required modules are imported. Notice the addition of the Adafruit_GPIO.MCP230xx module (imported under the name MCP). This MCP230xx class will be used to talk to the MCP chip and interface with the LCD.

Next the LCD pins are defined in the script. Note that these pin numbers are the MCP chip GPIO pin numbers, and NOT Raspberry Pi/BeagleBone Black pin numbers!

Also note if you"re using an MCP23008 chip you can instead create an instance of the MCP23008 class. This class is exactly the same as the MCP23017 class, but only supports 8 GPIO pins.

Now the Adafruit_CharLCD class instance is created. The big difference with this line and previous examples is that the MCP23017 class (created with the name "gpio") is passed in as the gpio parameter. By passing in an explicit gpio parameter, the char LCD class will use that GPIO class for talking to the LCD instead of the default development board GPIO pins.

The rest of the example code is exactly the same as the non-MCP character LCD example. You only need to change the setup and initialization of the character LCD class to use the MCP IO extender with an LCD!

The character LCD plate is a great way to add a simple character LCD and buttons to your Raspberry Pi project. Because the character LCD plate is based on the MCP23017 IO expander, the character LCD library easily supports the character LCD plate!

To use this character LCD library with the plate, make sure the library is installed by following the steps on the usage page. Then connect the LCD plate to your Raspberry Pi and execute the char_lcd_plate.py script in the library"s examples folder:

Note that the example assumes an RGB character LCD is attached to the plate, however it will still run with a monochrome LCD (you just might see the backlight turn on and off in different ways as colors as displayed).

When you run the example you should see the backlight run through different colors, and then the display will tell you to press buttons. If you press different buttons on the LCD plate you should see the button name and a different color displayed. Try pressing buttons to see how the script reacts!

Examine the code for the char_lcd_plate.py script to see how to use the character LCD plate code. The usage of the LCD plate is very similar to RGB or monochrome LCD usage, with a few key differences.

The first difference is that you create and instance of the Adafruit_CharLCDPlate class. You don"t need to pass any parameters in to this class" constructor/init function because it is preconfigured for the LCD plate.

The second difference is that the Adafruit_CharLCDPlate adds a function to test if a button is pressed. Notice how the is_pressed function is called for each button, and if it returns True then the button press is detected.

For example to check if the select button is pressed you can call is_presssed(LCD.SELECT), or to check if the right button is pressed you can call is_pressed(LCD.RIGHT).

This new Adafruit Pi Plate makes it easy to use an RGB 16x2 Character LCD. We really like the RGB Character LCDs we stock in the shop. (For RGB we have RGB negative and RGB positive.) Unfortunately, these LCDs do require quite a few digital pins, 6 to control the LCD and then another 3 to control the RGB backlight for a total of 9 pins. That"s nearly all the GPIO available on a Pi!

With this in mind, we wanted to make it easier for people to get these LCD into their projects so we devised a Pi plate that lets you control a 16x2 Character LCD, up to 3 backlight pins AND 5 keypad pins using only the two I2C pins on the R-Pi! The best part is you don"t really lose those two pins either, since you can stick i2c-based sensors, RTCs, etc and have them share the I2C bus. This is a super slick way to add a display without all the wiring hassle.

This pi plate is perfect for when you want to build a stand-alone project with its own user interface. The 4 directional buttons plus select button allows basic control without having to attach a bulky computer.

The plate is designed for both Revision 1 and Revision 2 Raspberry Pi"s. It uses the I2C (SDA/SCL) pins. We have a special xtra-tall 26-pin header so the plate sits above the USB and Ethernet jacks. For Pi Model B+ and Pi 2, the resistors sit right above the new set of USB ports. To keep them from shorting against the metal, a piece of electrical tape must be placed onto the USB ports.

This product comes as a kit! Included is a high quality PCB and all the components (buttons, header etc). A 16x2 Character RGB positive LCD is included! Assembly is easy, even if you"ve never soldered before and the kit can be completed in 30 minutes. Check the product tutorial page for assembly instructions before purchasing

We also have some handy Python code to help you easily talk to the LCD and buttons You can also easily query the 5 keypad buttons to get input through the library, so you get extra buttons without using any more pins. The buttons are automatically de-bounced inside the library.

At this time, the code and plate can control the RGB backlight of our character LCDs by turning each LED on or off. This means you can display the following colors: Red, Yellow, Green, Teal, Blue, Violet, White and all off. There is no support for PWM control of the backlight at this time, so if you need to have more granular control of the RGB backlight to display a larger range of colors, this plate can"t do that (the I2C expander does not have PWM output).

The Serial Monitor is a convenient way to view data from an Arduino, but what if you want to make your project portable and view sensor values without access to a computer? Liquid crystal displays (LCDs) are excellent for displaying a string of words or sensor data.

This guide will help you in getting your 16×2 character LCD up and running, as well as other character LCDs (such as 16×4, 16×1, 20×4, etc.) that use Hitachi’s LCD controller chip, the HD44780.

When activated by an electric current, these liquid crystals become opaque, blocking the backlight that is located behind the screen. As a result, that area will be darker than the rest. By activating the liquid crystal layer in specific pixels, characters can be generated.

As the name suggests, these LCDs are ideal for displaying only characters. A 16×2 character LCD, for example, can display 32 ASCII characters across two rows.

If you look closely, you can see tiny rectangles for each character on the screen as well as the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

Character LCDs are available in a variety of sizes and colors, including 16×1, 16×4, 20×4, white text on a blue background, black text on a green background, and many more.

One advantage of using any of these displays in your project is that they are “swappable,” meaning that you can easily replace them with another LCD of a different size or color. Your code will need to be tweaked slightly, but the wiring will remain the same!

Before we get into the hookup and example code, let’s check out the pinout. A standard character LCD has 16 pins (except for an RGB LCD, which has 18 pins).

Vo (LCD Contrast) pin controls the contrast of the LCD. Using a simple voltage divider network and a potentiometer, we can make precise contrast adjustments.

RS (Register Select) pin is used to separate the commands (such as setting the cursor to a specific location, clearing the screen, etc.) from the data. The RS pin is set to LOW when sending commands to the LCD and HIGH when sending data.

R/W (Read/Write) pin allows you to read data from or write data to the LCD. Since the LCD is only used as an output device, this pin is typically held low. This forces the LCD into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD ignores activity on the R/W, RS, and data bus lines; when it is set to HIGH, the LCD processes the incoming data.

D0-D7 (Data Bus) pins carry the 8 bit data we send to the display. To see an uppercase ‘A’ character on the display, for example, we set these pins to 0100 0001 (as per the ASCII table).

The LCD has two separate power connections: one for the LCD (pins 1 and 2) and one for the LCD backlight (pins 15 and 16). Connect LCD pins 1 and 16 to GND and 2 and 15 to 5V.

Depending on the manufacturer, some LCDs include a current-limiting resistor for the backlight. It is located on the back of the LCD, close to pin 15. If your LCD does not contain this resistor or if you are unsure whether it does, you must add one between 5V and pin 15. It should be safe to use a 220 ohm resistor, although a value this high may make the backlight slightly dim. For better results, check the datasheet for the maximum backlight current and choose an appropriate resistor value.

Let’s connect a potentiometer to the display. This is necessary to fine-tune the contrast of the display for best visibility. Connect one side of the 10K potentiometer to 5V and the other to Ground, and connect the middle of the pot (wiper) to LCD pin 3.

That’s all. Now, turn on the Arduino. You will see the backlight light up. As you turn the potentiometer knob, you will see the first row of rectangles appear. If you have made it this far, Congratulations! Your LCD is functioning properly.

We know that data is sent to the LCD via eight data pins. However, HD44780-based LCDs are designed so that we can communicate with them using only four data pins (in 4-bit mode) rather than eight (in 8-bit mode). This helps us save 4 I/O pins!

Therefore, 4-bit mode is commonly used to save I/O pins. 8-bit mode, on the other hand, is best suited when speed is a priority in the application and at least 10 I/O pins are available.

The sketch begins by including the LiquidCrystal library. This library comes with the Arduino IDE and allows you to control Hitachi HD44780 driver-based LCD displays.

Next, an object of the LiquidCrystal class is created by passing as parameters the pin numbers to which the LCD’s RS, EN, and four data pins are connected.

In the setup, two functions are called. The first function is begin(). It is used to initialize the interface to the LCD screen and to specify the dimensions (columns and rows) of the display. If you’re using a 16×2 character LCD, you should pass 16 and 2; if you’re using a 20×4 LCD, you should pass 20 and 4.

In the loop, the print() function is used to print “Hello world!” to the LCD. Please remember to use quotation marks " " around the text. There is no need for quotation marks when printing numbers or variables.

The function setCursor() is then called to move the cursor to the second row. The cursor position specifies where you want the new text to appear on the LCD. It is assumed that the upper left corner is col=0 and row=0.

There are many useful functions you can use with LiquidCrystal Object. Some of them are listed below:lcd.home() function positions the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to the above function, use this inside a for loop for continuous scrolling.

lcd.display() function turns on the LCD display, after it’s been turned off with noDisplay(). This will restore the text (and cursor) that was on the display.

As previously discussed in this tutorial, a character is made up of a 5×8 pixel matrix; therefore, you must define your custom character within this matrix. You can define a character by using the createChar() function.

To use createChar(), you must first create an 8-byte array. Each byte in the array corresponds to a row in a 5×8 matrix. In a byte, the digits 0 and 1 indicate which pixels in a row should be ON and which should be OFF.

The CGROM stores the font that appears on a character LCD. When you instruct a character LCD to display the letter ‘A’, it needs to know which dots to turn on so that we see an ‘A’. This data is stored in the CGROM.

CGRAM is an additional memory for storing user-defined characters. This RAM is limited to 64 bytes. Therefore, for a 5×8 pixel LCD, only 8 user-defined characters can be stored in CGRAM, whereas for a 5×10 pixel LCD, only 4 can be stored.

Creating custom characters has never been easier! We’ve developed a small application called Custom Character Generator. Can you see the blue grid below? You can click on any pixel to set or clear that pixel. And as you click, the code for the character is generated next to the grid. This code can be used directly in your Arduino sketch.

After including the library and creating the LCD object, custom character arrays are defined. The array consists of 8 bytes, with each byte representing a row in a 5×8 matrix.

This sketch contains eight custom-characters. Take, for example, the Heart[8] array. You can see that the bits (0s and 1s) are forming the shape of a heart. 0 turns the pixel off, and 1 turns it on.

This is my first time working with LCDs and I am trying to get my code (see below) written for a PIC18f458 to display the ASCII characters "N" and "O" on a LCD; using a "check busy" flag ...

I am currently having an issue with trying to connect my pi pico with the I2c adapter (LCM1602 of my 1602LCD display. I tried the official example from the raspberry pi github page (It is using the c/...

I am writing to an LCD and have developed the drivers to accept a string input for the value. I have a variable called "cycles" that is a uint16. I need to convert that value to a string and ...

I have a MSP chip and a LCD screen - throughout my code I output messages to my LCD screen. 80% of the time it works but if I do a power cycle the screen will get stuck on "UART Baud: 9600". ...

I am trying to develop code for establishing I2C communication between PIC32MK1024MCM064 and I2C 16x2 LCD screen (via PCF8574 I2C expander). For now I am just trying to send any letter to get depicted ...

I"m having trouble wiring and coding this glcd to run on my pico. I cant find very much on the internet about getting these things to run on a pico. The places that I have looked, all have a different ...

I have a raspberry pi 4 (4GB) and a 2 inch Waveshare SPI LCD display. I’m trying to create animated eye expression just like the Vector Robot, but I have no clue on how to code the fluid animation (...

I am trying to make a random number generator that when a button is pressed will display a random number on a 16x2 LCD screen, but the button output always equals 1 even when the button is not being ...

I am trying to get an Arduino LCD screen to display some text. However, despite the wiring being done correctly, the LCD display doesn"t even turn on when I upload the code, let alone display text. I ...

I recently acquired a Microchip EVB USB7252. I can use it as a USB hub. There are some pins on the board, and I have been looking for ways to use these as an interface between my computer and other ...

Hello I am currently trying to connect my lcd display with my soil moisture sensor to display readings it is taking. Any ideas on how to get the code to do that. Currently I can operate the LCD and ...

I"m trying to use a LCD display 16x2 (based on Hitachi HD44780) with 4-bit I²C interface (based on PCF8574) on an ESP8266 NodeMCU V.3 (ESP-12E) and when I load the liquidcrystal.lua library (by ...

I have a problem with showing numbers on the LCD screen in Tinkercad. The time is counting down from 60 seconds. But when it counts until 9-1 the number has shown as 90-10. Eg: LCD screen shows 20 at ...

I have created a simple traffic lights situation with an LCD screen. The countdown time is set as 60 seconds in "Adruino for LCD", and I wish the traffic light runs normally at 59 to 11 ...

My project is to build a data logger. I"m using an ESP32 and a 2,8" SPI TFT-LCD with an ILI9341 controller and integrated SD-card slot along with some other sensors. I us the Arduino IDE because ...

The new IST3020-TX displays jumbled pixels instead of the OTI Saturn 6000 logo. The older version IST3020 displays perfectly. I need help identifying the problem with the newer versions and possible ...

while learning how to control a LCD 12864B from a PIC16F84A, I found an unexpected behaviour in init codes. I better explain the problem on a comment in the submitted code.

I have a custom lcd to drive with STM32L073VBTx"s internal lcd driver. Duty cyle is 1/4 and the bias is 1/3. The problem is the common pins are activated sequentially even the LCD"s RAM registers are ...

I am working on a simple AVR C project with an ultrasonic sensor (HC-SR04) and SPI communication between the ATmega328P (Arduino) and three cascaded MAX7219 LCD matrix. The ...

I"m trying to use 12864B 7920 LCD on a PIC16F environment (PIC16F84A). As I"m not so skilled in the microprocessor field, I took a generic 4-bit control program to learn about it. Following that, I ...

I am using a STM32F030F4P6 MCU and a LCD 2004 with PCF8574T I2C display driver. I have tried the library from this tutorial: https://controllerstech.com/interface-lcd-16x2-with-stm32-without-i2c/. I ...

The latest versions of these LCDs have a Qwiic connector. The previous versions did not. Some of the pictures in this tutorial are from the previous version of the hardware. However, because the change is rather minor, they are still relevant. The pinouts along the edge are still in the same order and position (except for the left-most cluster of 4 PTH pins).

The SparkFun SerLCD is an AVR-based, serial-enabled LCD that provides a simple and cost-effective solution for adding a 16x2 RGB on Black Liquid Crystal Display into your project. We"ve seriously overhauled the PCB design on the back of the screen by including an ATmega328P that handles all of the screen control, meaning a backpack is no longer needed! This display can now communicate in three different ways: serial, I2C, and SPI. This simplifies the number of wires needed and allows your project to display all kinds of text and numbers.

The on-board ATmega328P AVR microcontroller utilizes 11.0592 MHz crystal for greater communication accuracy with adjustable baud rates of 1200 through 1000000 but is default set at 9600. The firmware for this SerLCD is fully open-source and allows for any customizations you may need.

Note: Since the SerLCD is a 3.3V device, please make sure you convert to 3.3V logic depending on your chosen microcontroller or single-board computer. Otherwise, you may risk damaging the LCD.

This 16x2 SerLCD has a row of headers along the top side. This is where you can connect the power and your choice of communication protocol (Serial UART, I2C, or SPI). It also has 6-pin Arduino Serial port available for convenient firmware updates.

This screen can be powered by 3.3-9VDC. You have two-pin options for connecting up power. One is labeled "RAW" and the other (on the 3-pin JST) is labeled "3.3-9V".

We often get asked, "What"s your smallest display?". Crystalfontz specializes in small displays, in fact the majority of our displays are smaller than 5". To make it easier for you to find the smallest lcd display, we"ve compiled this list of the most tiny displays we have.

Grove - 16X2 LCD RGB Backlight is a full-color backlight 16x2 LCD display for Arduino. High contrast and ease of use make it a perfect I2C LCD display for Arduino and Raspberry Pi.

The traditional 16x2 LCD requires up to 10 I/O pins to display, and the 16x2 LCD with RGB backlight requires an extra 3 pins to control the backlight color. This will take up a lot of I/O pins on the main control board, especially for development boards with less I/O resources such as Arduino and Raspberry Pi. Grove - LCD RGB Backlight makes it totally different! With the help of Grove I2C connector, only 2 signal pins and 2 power pins are needed. You don"t even need to care about how to connect these pins. Just plug it into the I2C interface on Seeeduino or Arduino/Raspberry Pi+baseshield via the Grove cable. No complicated wiring, no soldering, no need to worry about burning the LCD caused by the wrong current limiting resistor. Easy peasy.

What"s more, this LCD module is not only a character LCD but also can display your DIY images, such as a heart and a smiling face. 16x2 means two lines and each line has 16 columns, 32 characters in total. Each character contains 5*8 pixels.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey