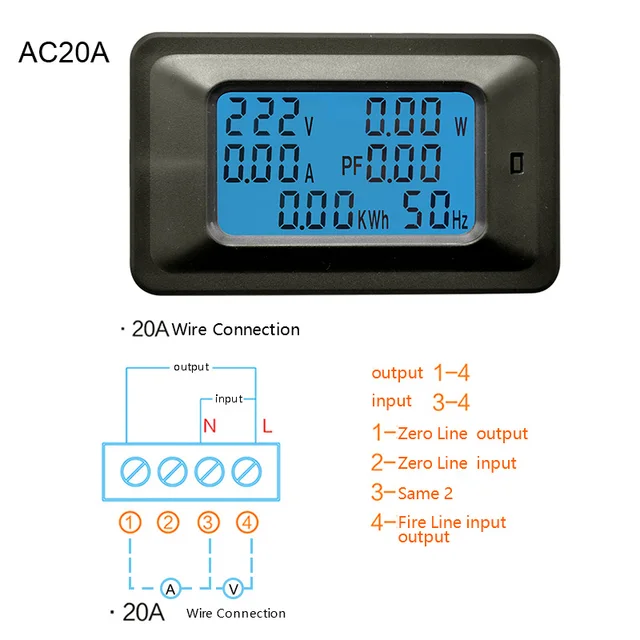

ac20a lcd panel power meter free sample

The PM135 is widely integrated in panel boards and SCADA systems. With the addition of the unique TOU module, the EH model answers the needs of revenue metering applications. It is also suitable for utility substation automation with its support of the industry standard DNP 3.0, Modbus RTU and IEC 60870-5-101/104 protocols, as well as its I/O capabilities (using the Digital Input/Output modules).

The PM135 series consists of two basic models providing digital measurements of more than 80 electrical parameters locally, and more than 100 electrical parameters via RS-485 interface.

The PM135 accurately measures over 100 parameters from basic frequency, voltages and currents, to all power parameters, four quadrant active, reactive and apparent energies, harmonics and time of use (TOU).

For the protection of low voltage distribution systems against direct lightning stroke into the overhead power supply line or outdoor lightning protection system (IEC 61024-1, IEC 61312-1).

6ES7313-5BF03-0AB0 Page 1 Product data sheet 6ES7313-5BF03-0AB0 SIMATIC S7-300, CPU 313C, COMPACT CPU WITH MPI, 24 DI/16 DO, 4AI, 2AO 1 PT100, 3 FAST COUNTERS (30 KHZ), INTEGRATED 24V DC POWER SUPPLY,

6ES7315-2AG10-0AB0 Page 1 Product data sheet 6ES7315-2AG10-0AB0 SIMATIC S7-300, CPU 315-2DP CPU WITH MPI INTERFACE INTEGRATED 24 V DC POWER SUPPLY 128 KBYTE WORKING MEMORY 2. INTERFACE DP-MASTER/SLAVE

6ES7316-2AG00-0AB0 SIMATIC S7-300, CPU 316 Technical / CAx data nmlkji Technical Data nmlkj CAx data As of 2010-01-24 Power supply Input voltage Rated value (DC) permissible range, lower limit (DC) permissible

Type: EASY719 DC RC Article.: 274119 Ordering information Relay outputs Quantity 6 Power supply V DC 24 V DC Description 12 digital inputs (4 inputs available as analog inputs) 6 relay outputs LCD display

Extract from the online catalog STEP-PS/1AC/12DC/1.5 Order No.: 2868567 DIN rail power supply unit 12 V DC/1.5 A, primary switched-mode, 1- phase Commercial data EAN 4046356292924 Pack 1 pcs. Customs tariff

Data sheet SIMATIC HMI, KTP700 BASIC DP, BASIC PANEL, KEY AND TOUCH OPERATION, 7" TFT DISPLAY, 65536 COLORS, PROFIBUS INTERFACE, CONFIGURATION FROM WINCC BASIC V13/ STEP7 BASIC V13, CONTAINS OPEN SOURCE

Page 1 of 11 DC UPS uninterruptible power supplies - DC UPS module 15 A Compact design, only 50 mm wide Absolutely interruption-free buffering of power failures through immediate electronic connection

Highlights & Features Protection Class II, Double Isolation (No Earth connection is required) Universal AC input voltage without power de-rating Efficiency > 87.0% @ 115Vac & 230Vac NEC Class 2 / Limited

Characteristics three-phase network control relay RM4-T - range 200..500 V Complementary [Us] rated supply voltage Output contacts Setting accuracy of time delay Delay at power up Measuring cycle Marking

The new generation of advanced test equipments for Relays, Energy meters, Transducers and Power quality meters Testing all relay technologies: electromechanical, solid state, numerical and IEC61850 Manual

The Sitras PRO combined DC protective unit and controller is used in the power supply for DC railways in mass transit and main-line systems up 3,000 V DC. It protects DC switch gear and contact line systems

Power Supply Unit, Primary Switched, Narrow Design MINI POWER provides: Extra narrow design with widths of 22.5 mm, 45 mm, and 67.5 mm (0.886, 1.772, and 2.657 in.) Global use due to a wide-range input

Characteristics multifunction voltage control relay RM35-U - range 15..600 V Complementary Reset time Maximum switching voltage [Us] rated supply voltage Supply voltage limits Power consumption in W Main

Product datasheet Characteristics HMIGTO4310 advanced touchscreen panel 640 x 480 pixels VGA- 7.5" - TFT - 96 MB Main Range of product Product or component type Display colour Display size Supply Magelis

Quick Connect quick - simple - efficient www.g-mw.de Phone: +49 9103 7129-0 Fax: +49 9103 7129-207 Innovative connection technology to plug three single-phase current transformers to multifunctional power

devices devices devices, electronic Type Page LED multifunction displays pulse, frequency, time (DC) Codix 524 240 pulse, frequency, time (AC+DC) Codix 544 243 LCD multifunction preset counters 1 or 2

Central 48 V DC Power Supplies for PoE-Components MICROSENS Description Active network equipment which is supporting the Power-over-Ethernet functions, typically requires a powerful 48 V DC power supply.

Power-monitoring unit PowerLogic System Technical data sheet 2003 Power Meter Series 800 Function and characteristics PB100313 The PowerLogic Power Meter Series 800 offers all the high-performance measurement

Automation Unit Flexible automation and telecontrol Power Transmission and Distribution Outstanding performance: Automate simply with Highly complex and yet fully transparent automation solutions are not

Panel Meters and Controllers Modular Panel Meter Type EDM 35 Modular digital panel meter, 3 1/2-digit Indicating or controlling current, voltage, resistance, temperature, tacho or frequency. Easy programming

Highlights & Features Protection Class II, Double Isolation (No Earth connection is required) Universal AC input voltage without power de-rating Efficiency > 87.0% @ 115Vac, > 89.0% @ 230Vac NEC Class

EtherNet/IP, Modbus TCP, or PROFINET slave Integrated Ethernet switch Supports 10 Mbps/100 Mbps 2 x M12, 4-pin, D-coded, Ethernet fieldbus connection 7/8" males, 5-pin, for power supply Separated power

Energy Management Energy Meter Type EM23 DIN Class 1 (kwh) according to EN62053-21 Class B (kwh) according to EN50470-3 Class 2 (kvarh) according to EN62053-23 Accuracy ±0.5 RDG (current/voltage) Energy

Data sheet Three-phase monitoring relay CM-PFE The CM-PFE is a three-phase monitoring relay that monitors the phase parameter phase sequence and phase failure in three-phase mains. 2CDC 251 005 S0012 Characteristics

Highlights & Features Protection Class II, Double Isolation (No Earth connection is required) Universal AC input voltage and full power up to 55 C Power will not de-rate for the entire input voltage range

Technical Data CompactLogix Power Supplies Specifications 1768 CompactLogix Power Supplies Catalog Numbers 1768-PA3, 1768-PB3 1769 Compact I/O Power Supplies Catalog Numbers 1769-PA2, 1769-PB2, 1769-PA4,

Flexible Counter Series in DIN size 24 x 48 mm high contrast 8-digit LCD display or brilliant 6-digit LED display 2 different supply voltages available: independent of mains supply with lithium battery

1SR 430 824 F9300 Features Monitoring of three-phase mains for phase sequence and failure Powered by the measuring circuit 2 c/o (SPDT) contacts 1 LED for status indication Approvals R: yellow LED - relay

Thyristor-controlled power supplies and battery chargers Input voltage: 115 / 230 VAC, single phase, 50 / 60 Hz or 208 / 400 / 480 VAC, three phases, 50 / 60 Hz Output voltage: 12 / 24 / 48 / 60 / 72 /

CHAPTER TWO THEORETICAL REVIEW OF LIGHT PROPAGATION AND INTERACTION WITH MATTER 15 Electromagnetic wave theory 15 Light wave fundamentals 22 Fermat s principle for reflection 22 Fresnel reflection 25 Theories of the bifurcated fibre probe 30 Principle of photo-detection 36 CHAPTER THREE EXPERIMENTAL APPARATUS AND PROCEDURES 41 Apparatus description 41 Light source 41 The probing fibre 42 Photodiode (818-SL) 43 Metex (M-3850D) 44 FIS-OV PM 46 The regulated 9 V d.c power supply 47 Samples 49 Experimental procedure and setup 50 Beam diameter verification 54 vii

CHAPTER FOUR RESULTS AND DISCUSSION 55 Surface reflectance (R) using transverse displacement of samples 55 Results obtained from the longitudinal displacement of the seven samples 63 Results obtained from the paracetamol tablets 72 The beam diameter verification 75 The 9 V power supply 76 Discussion 78 CHAPTER FIVE CONCLUSION AND RECOMMENDATION 83 Conclusion 83 Recommendation for future work 85 REFERENCES 86 viii

LIST OF TABLES Table Page 1 Input Limits 45 2 Average reflectance of the various samples for the three light sources used 61 3 Values of equation parameters for the three light sources used 70 4 Average reflectance values of the tablets of Letap A, B and M/G for the three light sources 74 5 A table showing the various measured a.c voltages at the transformer output and input as well as the regulated and unregulated d.c voltage 76 6 Summary of results 84 ix

13 Geometry of reflection and refraction at a plane interface 26 14 (a) Graphical representations of Brewster s angle and (b) the range of total internal reflection for reflections at an air-to-glass and glass-to-air interface 28 15 Lateral and frontal view of the transmitting and receiving ends of the fibre probe tip 30 16 The cone of light exiting the transmitting end of the fibre tip 30 17 Diagrams of circles representing (a) partial illumination (h < z a ) and (b) total illumination for h z a 32 18 Transfer function characteristic curve representing normalized power P N against normalized distance h N obtained through the geometrical approach 34 19 The characteristic graphs of the optical design depicting reflected intensity against (a) longitudinal and (b) transverse distances 35 20 A pn junction 37 21 A semiconductor junction photodiode energy band diagram 38 22 PIN photodiode in the reverse-bais 40 23 The circuitry diagram for the 9 V d.c regulated power supply 49 24 A sketch of the experimental setup 52 25 Setup for the beam diameter verification 54 26 A graph of average reflectance against transverse displacement of the plane mirror using the three light sources. The reflectance values for 850 and 1310 nm LED sources are the same 56 27 Graphs of average reflectance against transverse displacement for (a) Plane mirror, CD-R and CD-WR (b) Plane mirror, Steel xi

LIST OF PLATES Plate Page 1 The FIS OV-LS 42 2 The bifurcated multimode fibre used in the experiment 43 3 A cylindrical 818-Sl detector 44 4 M-3850 D Metex instrument with its connecting cable 46 5 The FIS OV-PM optical power meter 47 6 The opened power supply (blue arrow) connecting to the Variac (white arrow), DS06012A oscilloscope (orange arrow) and the voltmeter (yellow) 48 7 The experimental setup showing the He Ne laser, the microscope objective lens (MO), the bifurcated optical fibre, the sample stage, detector (818-SL), and the Metex instrument (M-3850D ) 52 8 Set-up showing the connection of the FIS OV-LS, FIS OV-PM bifurcated optical fibre probe and the sample stage 53 xiv

characterized by two most important parameters, namely reflectance and reflectivity. Reflectivity measures the fractional amplitude of the reflected electromagnetic field, while reflectance refers to the fraction of incident electromagnetic power that is reflected at an interface. Reflectivity is generally treated as a directional property that is a function of the reflected direction, the incident direction, and the incident wavelength. The reflectance is thus the square of the magnitude of the reflectivity. The reflectivity of a surface can be expressed as a complex number while reflectance always takes a positive or real value. A mirror provides the most common model for specular light reflection, and typically consists of a glass sheet with a metallic coating where the reflection actually occurs. Reflection is enhanced in metals by suppression of wave propagation beyond their skin depths. This is the depth to which electromagnetic radiation or waves can penetrate a conducting surface (Bekefi & Barret, 1977). In transparent material surfaces however, the amount of surface reflection depends on the different refractive indicies between the two materials with regards to wavelength of the light present. 4

all metals and most reflecting surfaces. Reflection also occurs at the surface of transparent media such as glass. The quantum interpretation is that when light waves incident on a material, induces small oscillations in the individual atoms causing each atom to radiate a weak secondary wave (in all directions). All of these waves add up to give the resulting reflection. The phenomenon of reflection is therefore inevitably important as its application extends from echoes in acoustics; studies of seismic waves in geology to VHF (Very High Frequency) for radio transmission and in all instances directly rely on the surface type of the materials in use. Surface Texture Surface types define the physical properties of a material including friction, density, reflectivity, depth of penetration, coating adherence etc (Wang & Kusiak, 2001). The relative specular and diffused components of a reflection of a given surface are determined by the characteristics of that surface on the order of the wavelength of the incident light signal. Surface texture sensing has been the focus of most recent research and a variety of sensing approaches have been examined which includes the most common technique which employs the use of surface profilometer. Surface profilometer (stylus) measures the surface topography electromechanically by moving a sample beneath a diamond-tipped stylus. This instrument measures and records vertical movement during surface scanning which reveals the topographical structure of the surface. One key disadvantage of surface profilometer technique is that it touches the surface it is inspecting, which can lead to contamination, damage or destruction of the part (Rideout, 2009). 6

Surface texture characteristics include roughness, waviness, flatness, contours and defects. Surface texture can also be measured in terms of fine and coarse aggregate when considering particles. The surface finish or roughness affects several functional attributes of the material and is characterized by such an important parameter as the R a, relative arithmetic mean roughness also known as the Center Line Average (CLA) which is the average roughness. This is the area between the roughness profile and its mean line, or the integral of the absolute value of the roughness profile height over the evaluation length and root-mean square (RMS) roughness. Guided Waves in Optical Fibres An optical fibre (or fibre) is a glass or plastic material that carries light along its length and hence is a medium through which information is carried. They usually consist of an inner core and outer cladding whose refractive indices are different. Light is kept in the core of the optical fibre on a path called a mode by a phenomenon of total internal reflection (TIR) illustrated in figure 5. This causes the fibre to act as a waveguide. Fibres are used instead of metal wires because signals travel along them with less loss, and they are also immune to electromagnetic interference. Fibres which support many propagation paths or transverse modes are called multi-mode fibers (MMF), have a core bigger in diameter and are used for applications where high power must be transmitted. Those which can only support a single guided mode are called single-mode fibres (SMF). Thus, at the operating wavelength, only one specific field distribution can propagate along the fibre with very little attenuation (Ghatak & Shenoy, 1994). 7

fibre on the light is also detected by a detecting system as shown in figure 7. The signal processing system then detects the changes introduced in the optical signal by the sensing area and then relates this to a change in the measurand field of interest, usually in the form of output intensity (power). The major parameters which influence the detected power are the reflectivity of the surface, the proximity of the sample surface, the angle of incidence of the light and the acceptance angle of the sensing fibre (Boyles, 1994). The sensing technique is therefore the Cinderella of the information age (Culshaw & Dakin, 1988). The inherent advantages of optical fibre sensing include their being resistant to electromagnetic interference, their small size nature which usually requires low power for its operation and their high sensitivity (Giallorenzi et al., 1982). Optical fibre link Coupled light source Sensor head / measurand field Detector unit Electronic signal processing unit Figure 6: Schematic diagram of a general optical fibre sensor system operating in the reflective mode 9

measurement point, which include resolution, responsivity, sensitivity, accuracy and reproducibility (Yeh, 1989). The fibre for sensing Many different types of fibres are used as medium for sensing different parameters. The graded index multimode optical fibre is the premier choice for maximizing the amount of power captured from light source in limited distance applications. Its large core and high NA provide excellent coupling efficiency over other fibres. Its varied applications include aerospace, defense and quality control. The bifurcated multimode optical fibre is a two way branched fibre or a Y-shaped assembly that has two fibres of the same diameter side-by-side in the common end, or the tail of the assembly referred to as the sensing area or the fibre probe tip in figure 8. From the nexus or the breakout of the assembly, the two fibres diverge into two arms. It allows light from a source through one arm to interact with an external reflecting surface and come out of the other arm after an inter-mixing of the reflected light and the light from source with less attenuation. Notably, either the input or the output arms could be used interchangeably based on the choice of purpose. There is no clear-cut restriction. Having high sensitivity to short distances, bifurcated optical fibre is well suited for position sensing application, gauging and surface assessment (Culshaw & Darkin, 1988). 11

Fibre probe tip (sensing area) Output arm Input arm Figure 8: A sketch of a bifurcated multimode optical fibre probe Sources and Detectors Light sources may be light emitting diodes (LED), laser, or broadband sources such as tungsten halogen lamp. The choice of light source depends on the application. In this work the source choice was characterized by the fact that scattering prevails over absorption between 600 nm - 1500 nm. Most importantly, LEDs are more suitable for linear systems than Laser diodes (LDs) because they exhibit a smooth (nearly linear) power/current relationship whereas the LDs exhibit non-linearity. The PIN photodiode is the most common detector used in optical systems. However, depending on the application and the detector characteristics such as detector sensitivity, active area, linearity, bandwidth, wavelength range of operation, and electrical biasing, a selection may be made. Silicon detectors are widely used in the 0.4 µm -1.0 µm wavelength range while germanium detectors are for measurements in the 0.8-1.7 µm range (Ghatak & Shenoy, 1994). 12

R(recordable compact disc), CD-RW(re-writable compact disc) and some locally manufactured paracetamol tablets. A comparison is made of their surface reflectance. An understanding is explored by using the mirror reflectivity as a standard parameter to evaluate optical sensitivity. The wavelengths of light sources used were He-Ne laser at 632.8 nm, LEDs at 850 nm and 1310 nm respectively. Arrangement of the thesis This thesis is organized as follows: chapter one begins with a general overview of surface reflection, the basics of light transmission in the fibre, the fundamental sensing mechanism and basic applications of the sensor. Chapter two discusses the literature review of the concept of surface reflection. This chapter also holds an overview of the various theories and models of light propagation and interaction with matter, the bifurcated optical fibre as well as operation at the detection point. Experimental procedures for the measurement of the intensities of surface reflection of the various samples used are discussed in chapter three. Analysis of experimental results and discussion are contained in chapter four. Chapter five gives the conclusion and recommendations for future work. 14

value of speed of light. The results confirmed light propagation as an electromagnetic phenomenon, thus making it clearer for its behaviour to be understood (Palais, 1992). Maxwell s four equations in their differential form (see equations (1) to (4)) treat light as an electromagnetic wave and also portray all the important features of light when carefully examined. E = ρ ε (1) 0 B = 0 (2) E B t (3) E B = μ 0 (J + ε 0 ) (4) t where E and B are macroscopic fields whereas ρ is the macroscopic charge density and J is the current density. The fields are high-frequency oscillating optical fields and so the response of electrons and ions are also considered at such high frequencies. This is an essential consideration since the parameters of a material are a function of the optical frequency (Guenther, 1990). For a Cartesian axes (as seen in figure 9), a typical sinusoidal solution is given by E= E o exp{i(ωt kz)} (5) B= B o exp{i(ωt kz)} 16

And when c < c 0, the ratio c c 0 is by definition the refractive index n of the medium and we have 1 2 n = ε R (11) Now ε R is a measure of the ease with which the medium can be polarized electrically by the action of an external electric field. This polarization depends on the mobility of the electrons within the molecule in the face of resistance by molecular force. Clearly then, ε R will depend on the frequency of the applied electric field since it will depend on how quickly these forces respond. Thus equation (11) will be true only if n and ε R refers to the same wave frequency, and that n is also frequency dependent. The parameters ε R and μ R are the relative permittivity and relative permeability factors respectively of the medium relative to those for free space, o and o (Culshaw & Dakin, 1988). Another essential solution is that of a wave which spreads from a point spherically (Gaussian distribution) given by E r = E 0 exp{i(ωt k. r)} (12a) r Here, the factor of 1 r in the amplitude is necessary to ensure energy conservation, for the total area over which the energy flux occurs is 4πr 2 so that the intensity drops as 1 r2 since intensity is directly proportional to the square of the amplitude. The electromagnetic theory leads to the following expression for the energy density (in SI units) associated with electric and magnetic fields in free space: (Smith & Thompson, 1988). U = 1 2 [ε 0E E + 1 μ 0 B B] (12b) 19

P Interface θ i O θ t Normal Q θ r n 1 n 2 S Figure 13: Geometry of reflection and refraction at a plane interface In figure 13, an incident light ray PO strikes at point O the interface between two media of refractive indexes n1 and n2. Part of the ray is reflected as ray OQ and part refracted as ray OS. The angles that the incident, reflected and refracted rays make to the normal of the interface are given as θ i, θ r and θ t respectively. The relationship between these angles is given by the law of reflection and Snell"s law. The fraction of the incident power that is reflected from the interface is given by the reflectance R and the fraction that is refracted is given by the transmittance T. Assuming the media to be nonmagnetic, the calculations of R and T depend on polarization of the incident ray. If the light is polarized with the electric field of the light perpendicular to the plane as shown in figure 13, then it is said to be s-polarized and the reflection coefficient is given by: R s = [ sin(θ 2 t θ i ) sin(θ t + θ i ) ] = ( n 2 1cosθ i n 2 cosθ t ) n 1 cosθ i + n 2 cosθ t 26

By extending the virtual incident cone of light beyond the mirror, so that the z-coordinate is aligned with the emitted light cone axis beginning at O and extending beyond the mirror surface. Following the representation in Figure 16, the coordinates of the center point q in the receiving end are coordinates of equation (35) where h is the distance under consideration which in this work is referred to as the longitudinal displacement. q { y = 2w a z = z a + 2h (35) Geometrically, assuming that the light intensity (irradiance) is constant for all points with the same z-coordinates inside the circular cross section of the cone and that there is no intensity outside of the cone, then Inside the cone I(z) = P E z > z a = { πw 2 (z) outside the cone I(z) = 0 (36) where P E is the optical power emitted by the transmitting fibre end and w is the cross section of the cone for the z-coordinate (current). Thus, w(z) = ztanθ a = z w a z a (37) The optical power collected at the tip of the receiving end may be obtained by evaluating the overlapping area of the circle of radius w(z) corresponding to the emitted light cone and the circle of radius w a corresponding to the collecting area of the receiving end. If centers of both circles are separated by 2w a, then in evaluating the overlapping area two different cases can be taken into account as depicted in figure 17. The first case is considered for small values of h where the receiving end is partially illuminated and secondly when the receiving end is completely illuminated occurring at larger values of h and 31

The power collected by the receiving fibre end is obtained by multiplying the illuminated area S by the light irradiance in equation (36). That is, P(z) = s I(z)ds = I(s)s(z) to give equation (41): P(z) = P E S(z) πw 2 (z) (41) The received optical power is the product of the collecting surface area 2 (S) πw a by the irradiance I(z). The irradiance of the emitted light does not remain constant over beam cross-sections, but rather decreases radially obeying an exponential law (Siegman, 1989). Therefore, in the case of total illumination that is h z a or w(z) < 3w a, we obtain equation (42). P(z) = P E w a 2 w 2 (z) (42) Equation (43) gives a summary of the two conditions as follows: { 1 for 0 h < z a ; P(z) = { P E α (z) π 2(z) sinα 2 (z) + ζ(z)[α 1 (z)ζ(z) sin α 1 (z)]} for h z a ; P E ζ 2 (z) (43) The dimensionless parameter ζ is dependent on the radius w(z) and the distance h given by ζ = w(z) 1 w a = 1 + 2h z a = 1 + 2h N (44) The plot of normalized collected power P N = P P max versus the normalized h N = h z a distance shows that power increases from zero to the maximum for small values of h and power falls off according to 1 ζ 2 law of values for h 33

higher than z a (as in figure 18). However, working within an effective distance h, an approximate value of about 1.0 from a surface, a characteristic curve can be displayed with a sketch as in figure 19(a) where maximum power occurs just before the receiving probe tip gets totally inside the light cone. Figure 19(b) is achieved when h is rather kept constant and the fiber probe tip moved across a surface. The fibre and light source properties as well as the reflecting material all affect these characteristic graphs. The amount of output power received does not only depend on the receiving fibre end but also largely on the type and properties of the detector used. Figure 18: Transfer function characteristic curve representing normalized power P N against normalized distance h N obtained through the geometrical approach 34

I/a.u I/a.u Longitudinal distance/ mm Transverse distance/ mm (a) (b) Figure 19: The characteristic graphs of the optical design depicting reflected intensity against (a) longitudinal and (b) transverse distances Two conflicting mechanisms take place as the longitudinal displacement (h) increases. Firstly for small values of h, is the increasing of the effective collecting area S as the fibre end (probe tip) gets progressively farther inside the light cone and secondly, the decreasing of the irradiance I as the probe tip collecting end moves away from the emitted light vertex when considering higher values of h. In the analysis of the sensitivity of the design, the derivative of the normalized power P N is evaluated with respect to h N. Sensitivity of the optical design then becomes the minimum amount of light that is detected within a specified range of displacement (Brandao, 1998). Thus sensitivity S becomes: S = P N h N (44) 35

Principles of Photodetection Although light can be detected by the human eye, it is not suitable for use in modern optical systems because of slow response, poor sensitivity to low-level signals and difficulty in processing its information electronically. Furthermore, the spectral response of the eye is limited to wavelengths between 0.4 and 0.7 µm, where even fiber losses are high. This section looks at the basic principles of devices that directly convert optical signals to electrical signals (either current or voltage) and respond quickly to changes in the power level (Palais, 1992). In semiconductor junction devices free charge carriers (electrons and holes) are generated by absorption of incoming photon. This mechanism is sometimes called the internal photoelectric effect. Three common devices which use this phenomenon are pn junction photodiode, the PIN photodiode and the avalanche photodiode. Important detector properties are responsivity, spectral response, and the rise time. The responsivity ρ is the ratio of the output current i of the detector to its optic input power P. It is ρ = i P (45) The unit of responsivity is amperes per watt. In some detector configurations the electrical output is a voltage. In this case the responsivity is given in units of volts per watt of incident power. The spectral response refers to the curve of detector responsivity as a function of wavelength. Because of the rapid change in responsivity with wavelength within either of the windows of the optical spectrum, the responsivity at a specific wavelength emitted by the source must be used when designing the receiver. The rise time is the time 36

for detector output current to change from 10 to 90% of its final value when the optical input power is in step. Semiconductor junction photodiodes are small, light, fast, sensitive and can operate with just a few bias volts. The simple pn photodiode, drawn in figure 20, illustrates the basic detection mechanism of a junction detector. When reverse biased, the potential energy barrier between the p and n regions increases. Free electrons (which normally reside in the n region) cannot climb the barrier, so no current flows. The junction refers to the region where barrier exists and because there are no free charges in the junction, it is called the depletion region or layer. Having no free charges, its resistance is high, resulting in almost all the voltage drop across the diode appearing across the junction itself. Hence electric forces are high in the depletion region and are negligible outside. hf p n Figure 20: A pn junction What happens when a photon is absorbed in the p or n regions outside the junction is that an electron hole pair is created. These free charges move slowly because of the weak electric forces outside of the junction. Most of the free charges diffuse through the diode and recombine before reaching the junction. These charges hence produce negligible current, thus reducing the detectors responsivity. 37

electron. The characteristic is described by the detector parameter called quantum efficiency η. This is defined by η = number of emitted electrons number of incident photons Because the optic power is the energy per second being delivered to the detector and hf is the energy per photon, then P/hf is the number of photons incident on the cathode. With quantum efficiency η, the number of emitted electrons per second is then ηp/hf. Since each electron carries charge of magnitude e, the charge per second (that is, the current) emerging from the cathode is i = ηep hf = ηeλp hc (48) The definition strictly refers to the external quantum efficiency of the device, which takes into account losses due to reflection at the detector surface. The detector responsivity from equation (45) therefore is given by (Perlin, 1989) ρ = i = ηe = ηeλ P hf hc (49) Hence the output voltage is v = ηepr hf = ρpr L (50) where current flows through the load resistor R L in the external circuit. The PIN diode has a wide intrinsic semiconductor layer between p and n regions, as illustrated in figure 22. The intrinsic layer has no free charges, so its resistance is high. Most of the diode voltage appears across it and the electrical forces within are also strong. Because the intrinsic layer is 39

CHAPTER THREE EXPERIMENTAL APPARATUS AND PROCEDURES In this work, light intensity was used to sense small displacements of objects from a reference point. The optical system seeks to examine material surfaces by measuring micro displacement of the target which is a reflective surface using light from a bifurcated optical fibre. Light is incident at one arm serving as the input arm of the fibre and the back reflected light after striking a target (reflective surface) goes through the other arm termed as the output arm which is connected to a detecting system for measurements to be recorded. Apparatus Description Light sources In this work three different light sources were used. A uniphase D- 8152 He-Ne laser of wavelength 633 nm with beam diameter of 1 mm and a guaranteed 4 mw minimum output power which generates a continuous wave was used. This laser produces a high optical quality light with a TEM00 Gaussian output profile. The laser housing has an adapter head which allows other accessories to be attached. The other two sources are incorporated in a single system. This system is an FIS OV-LS dual light emitting diode (LED) source which emits an 850 nm and 1310 nm wavelengths. The rated optical power for both wavelengths is -17 dbm (20.0 μw) which is very typical. The spectral bandwidth also typically is 45 nm at 850 nm and measures 170 nm at 41

1310 nm. It must also be stated that the temperature range of operation for this light source is + 14 0 to 122 0 F (-10 0 to +50 0 C). Depending on which wavelength one wants to operate, the SELECT SOURCE knob is pressed and a red light indicates on either source 1 or 2. Each source has an output port to aid connection to other accessories. For a continuous wave emission, the CW MODE button is pressed. The FIS OV-LS is powered by a 9 V DC regulated power supply which was built in this work order to get a stable delivery of power from the emitting light source. Output ports Plate 1: The FIS OV-LS The Probing Fibre The optical fibre probe consist of a glass bifurcated multimode optical fiber cable of diameter (100/140 m). The cable combines the input and the output arms into one assembly, in a random mix at the sensing point (fibre probe tip) and cylindrically housed in a brass case. It is an ideal configuration 42

for application that requires a compact sensing tip. The 100 μm core, 140 μm cladding diameter graded index multimode optical fibre has a numerical aperture (NA) of 0.29 ± 0.015 and attenuates at less than 4.0 db/km at 850 nm and less than 1.5 db/km for 1300 nm. The sensing point of the fibre operates with an active diameter of 50 μm. It has a robust and easy to use connectorize ends. Output arm Brass case Input arm Plate 2: The bifurcated multimode fibre used in the experiment Photodiode (818-Sl) The detector used was a silicon photodiode 818-Sl from Newport Company. It is housed in a cylindrical structure. The (818-SL) detector is actively sensitive to visible region detection even though it has a spectral range of 400 nm to 1100 nm. It uses the finest large-area, planar-diffused PIN silicon in its operation. Thus, its operation is generated by voltage across a p-n junction of a semiconductor. It is optimized for zero-bias operation to provide the low noise, high stability and uniformity in measurements. With an average 43

power maximum-w/o attenuator of 2 mw/cm temperature is 1 cm 2 2, the accuracy at constant 2% at 400 nm-1100 nm having an active area and diameter of and 1.13 cm respectively. Plate 3: A cylindrical 818-Sl detector Metex M-3850D This digital multimeter was manufactured and tested in accordance with IEC 1010 and DIN57411/VDE0411 part safety requirement for electronic measuring apparatus, safety class II by Geprutte Sicherheit in Germany. This is an analogue to digital converter. This instrument does not measure voltages greater than 1000 volts DC or 750 volts AC. It is also operated on a 9 V DC power supply. This avoids voltage drops which may heather to result in erroneous readings. Table 1 provides limit on inputs in order to ensure the safety working of this instrument to avoid damage when in use. 44

Table 1: Input Limits FUNCTION TERMINAL INPUT LIMIT V DC V/Ω + COM 1000V DC V AC V/Ω + COM 750V AC Ω V/Ω + COM 250V DC/AC m/a DC/AC ma + COM 400mA DC/AC 20A DC/AC 20 A + COM 20A DC/AC V/Ω + COM 250V DC/AC Freq. V/Ω + COM 750V DC/AC Logic V/Ω + COM 250V DC/AC By pressing the top-left red button, the instrument turns ON or OFF. To select a function, the rotary is switched to the appropriate switch position and the instrument is ready for normal operation. The back-lit display is operated by pressing the yellow button. It automatically turns off in seconds. There is also the SET/RESET button which can be pressed to enter, and then pressed again to exit. By automatically turning off the power extends to the life of the power supply if neither the rotary switch nor push button is operated for 10 minutes. 45

Plate 4: M-3850 D Metex instrument with its connecting cable FIS OV-PM This FIS OV-PM optical power meter devise has an easy to read LCD display. This detector has a 2 mm germanium PIN photodiode with a dynamic range of 70 db (+ 5 dbm to -65 dbm). Independent zero set function for each of the two available wavelengths conveniently allows storage of unique zero reference levels. The unit goes into the sleep mode if no keypad strikes are detected within 25 minutes and may reactivate by simply pressing the ON/OFF key. One important feature of this optical power meter is the rugged solid-rubber holster which provides protection for performance durability. By pressing the wavelength (λ) button, a selection of the particular wavelength to be detected is made. The available detection wavelengths are 850 nm, 1310 nm and 1550 nm. Measurements are recorded in units of either db or dbm and the selection is aided by the press of the db/dbm button. This comes along with the FIS OV-LS dual light source system to ease the output readout of the power. 46

Plate 5: The FIS OV-PM optical power meter The Regulated 9 Volt (DC) power supply The DC power supply was designed to produce a stable output voltage of 9 V and was purposely built to stabilize the mains voltage, thereby eliminating battery voltage drops which could affect measurements. It has a special feature of an external battery terminal which allows connection to a 12 V battery and subsequently gives out 9 V equivalent power supply for field work. The regulator switch allows selection between the mains and the external terminal whereas the toggle switch makes ON and OFF selection. The components used in the construction included the following: 9 V transformers (at 1.1 A), quick blow fuse (1 A), and a bridge rectifier. There was also the 470 μm electrolytic capacitor, a 100 μm electrolytic capacitor, time delay fuse (160mA), a toggle switch, pilot lamp, I C regulator, an insulating enclosure, slide switch, flush panel fuse holders and some wires. The circuit diagram was designed and transposed onto the Printer Circuit Board (PCB) and was etched in a concentrated hydrochloric acid for about three hours. It was then removed, 47

allowed to dry and cleaned. With the aid of a designed circuitry the various components were fixed by soldering. A heat sink was also incorporated into the system to conduct excess heat away. The completed circuit board was placed in a 12 12 8 cm insulation enclosure and covered. The power supply was tested by plugging its cable into a mains socket and the input terminal to a 230 V variac (shown with an arrow in plate 6) which varied the input voltage from 228 to 175 V and an Agilent Technologies oscilloscope (DS06012A) which monitored the input a.c transformer secondary voltage, output regulated and unregulated d.c voltage signals. Measurements were recorded as voltmeter readings for regulated and unregulated d.c voltages. Plate 6: The opened power supply (blue arrow) connecting to the Variac (white arrow), DS06012A oscilloscope (orange arrow) and the voltmeter (yellow) 48

Figure 23: The circuitry diagram for the 9 V d.c regulated power supply Samples A round protected silver mirror (PF10-03-P01) of diameter 25.4 mm and 6.0 mm thickness from Thorlabs was the standard mirror used. Other samples used in the experiment included a BK 7 rectangular glass block of diameter 4 cm by 2.5 cm by 0.8 cm, a clear glass ground edge microscope slide (CAT. NO. 7105) of 25.4 mm by 76.2 mm and thickness of 1.2 mm dimension from Sail Brand 10 (China) was also obtained from the School of Biological Sciences Laboratory. Adding to these samples were the Sony 700 MB CD-R and CD-WR (4x-24x high speed) which were both filled with 349.9 MB of data. A non galvanized hot-rolled steel plate of thickness 0.6 mm was also cut into a size of 3.5 cm x 4.0 cm. this was obtained from Sethi Brothers Ghana limited (Tema). A polished aluminium plate from Aluworks Ghana limited which was composed of 99.7% of pure aluminium was cut into a size of 3.8 cm x 2 cm (1mm thick). Some paracetamol tablets were also used. These are locally manufactured tablets which were obtained from the sales agent of the two manufacturing companies in Cape Coast (Nat and Sons Pharmacy). The Letap 49

and the M/G tablets are products of the Letap pharmaceutical and M&G pharmaceuticals Company limited respectively. These tablets were separately examined due to their relatively small size and for that matter small surface area within which measurement were taken. Two different types of the Letap were used. The differences came from their dates of manufacturing, expiration and sizes. Tablets categorized under Letap A both had a diameter of 12.1 mm and thickness of 4.7 mm and were manufactured in May 2007 and expired in March 2010 and come from one sachet under the label letapa1 and letapa2. Letap B comprises three different tablets from the same sachet labeled as Letap B1, B2 and B3, was manufactured in July 2009 and expires in July 2012. For the M/G, there was only one sachet (six tablets) of a sample which was manufactured in June 2009 and expires in July 2014. It was ensured that sample surfaces had no visible defect. Experimental setup In this work, the laser source (D-8152 He-Ne) was focused through a microscope objective (MO) lens of focal length 0.25 cm from Melles Griot into one arm of the bifurcated multimode optical fibre probe which was used as the input arm. The light travels along the length of the input arm of the fibre until it illuminates the surface of the plane mirror (PF10-03-P01). The microscope objective lens and the sample were separately and respectively mounted on translation stages (XYZ) to enable fine alignment so that a high percentage of the laser light was coupled into the input arm of the fibre. The emerging light was incident at 90 (normal incidence) on the mirror surface. Due to the reflective nature of the mirror, the light is reflected back almost in 50

Figure 24: A sketch of the experimental setup Detector Metex He-Ne Optical fibre MO Sample stage Plate7: The experimental setup showing the He-Ne laser, the microscope objective lens (MO), the bifurcated optical fibre, the sample stage, detector (818-SL), and the Metex multimeter instrument (M-3850D) 52

The experimental procedure was repeated using two other light sources which were both emitted by the FIS OV-LS system. In this setup the connectorize ends of the bifurcated fibre were connected directly to the FIS OV-LS and the FIS OV-PM with the input arm connected to the 850 nm source output port whiles the output arm went to the FIS OV-PM power meter. By this connection, coupling losses were terminated. Recordings were made from the power meter by selecting the required wavelength. The fibre input arm end was detached and connected into the 1310 nm port whiles maintaining the output arm connection. Measurements were taken for each of the samples. Due to multimode connector tolerances, the sharp point of an angled ferrule may crack the lens of many 850 nm LED source and cause erroneous readings. Therefore an angled-physical contact (APC) connector was installed into the 850 nm light source output port. (Giotta & Salamone, 1990) Plate 8: Set-up showing the connection of the FIS OV-LS, FIS OV-PM, bifurcated optical fibre probe and the sample stage 53

Beam diameter verification A verification of the laser beam diameter was conducted using the knife edge method. Here, a single-edged razor blade was attached to a micrometer driven translation stage to eclipse the laser beam. The intensity of the uneclipsed portion of the beam was measured with a detector. The experimental data was obtained by moving the translator and blade in small increments to gradually allow less and less of the laser beam to strike the detector, thus effectively eclipsing the beam with the blade. The points in the beam where the energy or power is 90% and 10% of the total respectively are used to calculate the Gaussian beam radius. Figure 25: Setup for the beam diameter verification 54

Table 2 gives the respective resulting average reflectance of seven of the samples obtained using the definition of reflectance given on page 24 of chapter two of this thesis. From the definition, the incident intensities of the various sources at the fibre probe tip were determined as follows: the 632.8 nm He-Ne laser was 0.341 V, 850 nm LED had 33.96 db and 39.62 db for 1310 nm. The reflected intensities were the recorded intensities from the receiving end of the fibre to the detector which was recorded as voltage readings on the Metex instrument for the He-Ne laser and on the FIS-OV-PM power meter in decibels (db) for the other two LED sources. From table 2, the plane mirror which was used as the standard sample proved to have the best reflectivity of approximately 70% of the 632.8 nm He-Ne laser, 99.5% of the 850 nm and 99.7% of the 1310 nm LED sources respectively. The corresponding reflectance values of the plane mirror were almost unity which means that the plane mirror reflected almost 100 % of the light from the 850 and 1310 nm LED sources and the values were very close thus an over-lap in the plotted results shown in figure 26. Table 2: Average reflectance of the various samples for the three light sources used Samples Average reflectance from the three light source wavelength 632.8 nm He-Ne 850 nm LED 1310 nm LED Plane mirror (PF10-03-P01) 0.68907 0.99592 0.99739 Glass block 0.48855 0.51469 0.63426 Microscope slide 0.55225 0.71109 0.81676 61

Results obtained from the longitudinal displacement of the seven samples. In figure 30, within the normalized displacement range of 0.1 to 7.0 the optical system could best detect (maximum sensitivity) the reflected light from the mirror. The response of the optical sensing design remained approximately linear with an error of ± 0.0001 within the operating displacement range of 0.1 to 7.26 as shown in figure (30b). For larger displacement movements, the rest position (which is the point at which detector sensitivity is minimum) of the mirror was 47.76 and 51.95 for the 850 nm and 1310 nm light sources respectively. The minimum sensitivity point of the mirror when the He-Ne laser was used was 40.99. From these points within the normalized reflected range of [40.0; 56.0], the sensing response also remained approximately constant. It could therefore be said that, since the operating point for minimum sensitivity corresponds to a higher reflected intensity which relates to a higher optical power level for that matter, it therefore means that operation of the optical design could be observed with less noise-sensitivity which may be advantage. (a) 63

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey