lcd display c code factory

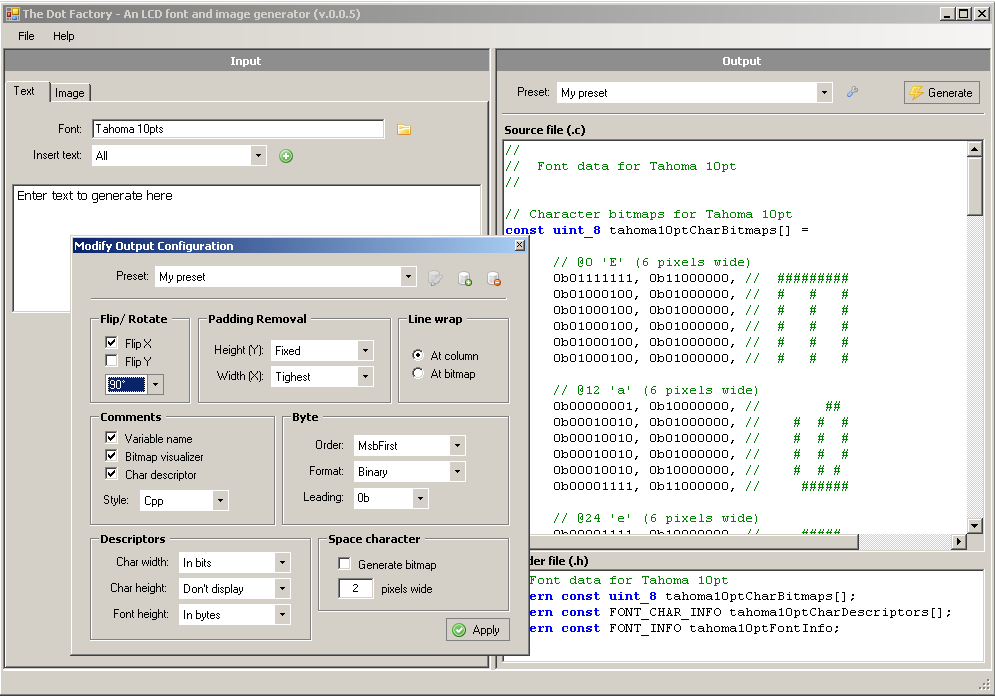

The Dot Factory is a small open source tool (MIT licensed) intended to generate the required C language information to store many fonts and images, as efficiently as possible, on a microcontroller. These fonts are then uploaded via the LCD driver (see the Drivers and Modules page for a few) to the actual dot matrix LCD. It is written in C# for Visual Studio 2008 and has been tested on Windows XP, 2003, Vista, 7 and Linux via Mono.

Working with dot matrix LCDs with microcontrollers, while not difficult, is tedious. The actual LCD controller allows us to upload simple visual data (dot on or dot off) into the LCD’s dot matrix, but not much else. It is up to our software to decide what to upload when we want to draw lines, circles and more importantly – text.

While there are software graphic libraries that allow us to generate a character “on the fly” using vector graphics (the character is described as a series of drawing commands that allow scaling and decoration) – these are much too complex and large to integrate in a microcontroller environment. Consequently, we must store the exact appearance of a character as a series of 1s and 0s, equivalent to a “dot on” “dot off” on the LCD, and upload this as a bitmap when we want to display text. While it is possible to generate this manually, it is desired to have a tool to do our grunt work by converting windows fonts (given a size and decoration) into a series of bitmaps.

TDF is comprised of two panes – the input pane on the left (what you want to generate) and the output pane on the right (the generated output, in C code). The input pane can accept either a font of your choice (for writing text to the LCD) or an image. When generating a font, you have the option of either generating all the available letters (by selecting “All” in the Insert Text box and clicking the plus button) or by typing in which letters, numbers or symbols you are actually using in your application (for example: 0123abcd). If you are writing a simple application that has only a few sentences, you can type them wholly in this box without fear of duplicating letters – TDF takes care of that by discarding any duplicates. This way only the letters you use will take up space.

Once you have completed setting up what it is you’d like to generate (be it an image or font), select the output method in the output pane. If you are using the LCD drivers on this website, you want it to generate an MSb first output, otherwise images will come out wrong. If you have a compiler that supports the “0b” binary specifier, you can select “binary” rather than “hex”. This will allow you to visually see the pixels you will set and allow for manual touch up by the user without having to calculate hex and experimentation. Click generate and your C code will be outputted to the text box below. Copy paste this into your application (it is recommended to put this in a separate module, not your LCD driver module, for organizational reasons).

Note that 5×7 and 5×8 fonts cannot be generated using this tool. While some TTF fonts can render characters this small they are usually distorted to the point of uselessness. You can download a ready made five by seven font here. I ripped this font from text file a while ago, so apologies to the uncredited author.

The character bitmap array: This holds the actual characters as a bitmap (only the characters selected in the input pane). Each byte represents a single vertical page sent to the LCD. All vertical padding is removed from the characters

The character descriptor array: Allows O(1) mapping between a character’s ASCII value and required meta information about the character – namely its width in bits and its offset into the character bitmap array. When the LCD driver needs to find where character X is located in the bitmap array, it will jump to index [X - font.startCharacter] in the descriptor array. The startCharacter is the first character (that is, the character with the lowest ASCII value) used for this font. By defining a startCharacter we can reduce the number of elements in the descriptor array.

The font information: This element is essentially the font descriptor for this font. It holds information regarding this font like the name of the character bitmap and descriptor arrays, the font start character and how many pixels wide a space character is for this font. The LCD driver will replace the space character with empty pixels (this saves both processing time, space in the character bitmap array and space in the character descriptor array – since the space is the first ASCII character and is commonly used).

The generated structures are generated with documentation, but you may want to see a sample bitmapDb header file for detailed info on the character descriptor array and font information structures. For image generation, only the image’s bitmap array and size descriptors are generated. Note that the height value is pixels (bits) and width values are in pages.

I usually release versions according to user demand. If you think TDF can use whatever feature, drop me a line. When enough users request something I invest the time to add it.

Version 0.1.2 (29may11): Fixed width/height being swapped. Added support for configuring image descriptor format (bits/bytes). Thanks geo for the heads up and suggestion

Version 0.1.1 (25may11): Added support for multiple descriptor arrays with a double lookup. Before this version TheDotFactory could generate Unicode characters but the lookup tables were usually too huge to be of any use. Using this feature, a double lookup is employed, allowing for fast lookups for characters residing at disparate ranges. See the video for an explanation (will be posted in the next few days). In addition to this, added support for specifying character ranges instead of inputing the actual characters. For example, <<100-120>> will generate characters for ASCII characters 100 to 120. Thanks a bunch to Archis Bhave for inputs and testing. Source is now distributed via github.

Version 0.1.0 (15dec10): Added support to format the generated variable names (thanks SpiralBrain), added end character indication to font information (thanks Nick Jensen), added the ability to save to clipboard from File menu and added the ability to save the source/header to file via file menu (don’t remember who, but someone wondered why this wasn’t in. I personally think all fonts should be in a single module and so I opted for copy/paste, but to each his own)

Version 0.0.8 (29may10): Fixed two unreported crashes (clicking generate without entering any text and when a newline existed in generated text), added the ability to copy the outputted text by using a context menu

Version 0.0.7 (28may10): Added ability to select whether character descriptor array is to be created and which character will be used to visualize the font (thanks Christian Treczoks), syntax coloring automatically disabled when generating large amounts of text (will be fixed properly next version), properly handled bitmaps with no black pixels in them (displays error instead of a crash), some minor cosmetics

Version 0.0.6 (03mar10): Bug fix for image generation (tried to save a temporary file for debugging in a custom directory) – thanks to Nir Shemeshfor pointhing this out!

Version 0.0.5 (23dec09): Added support for rotation (90 degree increments), space character generation, width (bit/byte) selection of character width and font height, optional generation of character height/width and font height, structures are now generated with documention, input text and font is persisted throughout invokations of the application, persistent preset management – add, edit, delete output configuration presets

Version 0.0.3 (30jul09): Added output configuration: hex/binary, MSb First/LSb first, configurable padding removal, comment control, flip X/Y and more

To run this executable, you must have the .NET framework installed. The stable binary has been in the wild for a month at least with no major bugs reported. Non stable binary contains new features and bug fixes (see revision history).

ESP chips can generate various kinds of timings that needed by common LCDs on the market, like SPI LCD, I80 LCD (a.k.a Intel 8080 parallel LCD), RGB/SRGB LCD, I2C LCD, etc. The esp_lcd component is officially to support those LCDs with a group of universal APIs across chips.

In esp_lcd, an LCD panel is represented by esp_lcd_panel_handle_t, which plays the role of an abstract frame buffer, regardless of the frame memory is allocated inside ESP chip or in external LCD controller. Based on the location of the frame buffer and the hardware connection interface, the LCD panel drivers are mainly grouped into the following categories:

Controller based LCD driver involves multiple steps to get a panel handle, like bus allocation, IO device registration and controller driver install. The frame buffer is located in the controller’s internal GRAM (Graphical RAM). ESP-IDF provides only a limited number of LCD controller drivers out of the box (e.g. ST7789, SSD1306), More Controller Based LCD Drivers are maintained in the Espressif Component Registry

LCD Panel IO Operations - provides a set of APIs to operate the LCD panel, like turning on/off the display, setting the orientation, etc. These operations are common for either controller-based LCD panel driver or RGB LCD panel driver.

esp_lcd_panel_io_spi_config_t::dc_gpio_num: Sets the gpio number for the DC signal line (some LCD calls this RS line). The LCD driver will use this GPIO to switch between sending command and sending data.

esp_lcd_panel_io_spi_config_t::cs_gpio_num: Sets the gpio number for the CS signal line. The LCD driver will use this GPIO to select the LCD chip. If the SPI bus only has one device attached (i.e. this LCD), you can set the gpio number to -1 to occupy the bus exclusively.

esp_lcd_panel_io_spi_config_t::pclk_hz sets the frequency of the pixel clock, in Hz. The value should not exceed the range recommended in the LCD spec.

esp_lcd_panel_io_spi_config_t::spi_mode sets the SPI mode. The LCD driver will use this mode to communicate with the LCD. For the meaning of the SPI mode, please refer to the SPI Master API doc.

esp_lcd_panel_io_spi_config_t::lcd_cmd_bits and esp_lcd_panel_io_spi_config_t::lcd_param_bits set the bit width of the command and parameter that recognized by the LCD controller chip. This is chip specific, you should refer to your LCD spec in advance.

esp_lcd_panel_io_spi_config_t::trans_queue_depth sets the depth of the SPI transaction queue. A bigger value means more transactions can be queued up, but it also consumes more memory.

Install the LCD controller driver. The LCD controller driver is responsible for sending the commands and parameters to the LCD controller chip. In this step, you need to specify the SPI IO device handle that allocated in the last step, and some panel specific configurations:

esp_lcd_panel_dev_config_t::bits_per_pixel sets the bit width of the pixel color data. The LCD driver will use this value to calculate the number of bytes to send to the LCD controller chip.

esp_lcd_panel_io_i2c_config_t::dev_addr sets the I2C device address of the LCD controller chip. The LCD driver will use this address to communicate with the LCD controller chip.

esp_lcd_panel_io_i2c_config_t::lcd_cmd_bits and esp_lcd_panel_io_i2c_config_t::lcd_param_bits set the bit width of the command and parameter that recognized by the LCD controller chip. This is chip specific, you should refer to your LCD spec in advance.

Install the LCD controller driver. The LCD controller driver is responsible for sending the commands and parameters to the LCD controller chip. In this step, you need to specify the I2C IO device handle that allocated in the last step, and some panel specific configurations:

esp_lcd_panel_dev_config_t::bits_per_pixel sets the bit width of the pixel color data. The LCD driver will use this value to calculate the number of bytes to send to the LCD controller chip.

esp_lcd_i80_bus_config_t::data_gpio_nums is the array of the GPIO number of the data bus. The number of GPIOs should be equal to the esp_lcd_i80_bus_config_t::bus_width value.

esp_lcd_panel_io_i80_config_t::pclk_hz sets the pixel clock frequency in Hz. Higher pixel clock frequency will result in higher refresh rate, but may cause flickering if the DMA bandwidth is not sufficient or the LCD controller chip does not support high pixel clock frequency.

esp_lcd_panel_io_i80_config_t::lcd_cmd_bits and esp_lcd_panel_io_i80_config_t::lcd_param_bits set the bit width of the command and parameter that recognized by the LCD controller chip. This is chip specific, you should refer to your LCD spec in advance.

esp_lcd_panel_io_i80_config_t::trans_queue_depth sets the maximum number of transactions that can be queued in the LCD IO device. A bigger value means more transactions can be queued up, but it also consumes more memory.

Install the LCD controller driver. The LCD controller driver is responsible for sending the commands and parameters to the LCD controller chip. In this step, you need to specify the I80 IO device handle that allocated in the last step, and some panel specific configurations:

esp_lcd_panel_dev_config_t::bits_per_pixel sets the bit width of the pixel color data. The LCD driver will use this value to calculate the number of bytes to send to the LCD controller chip.

esp_lcd_panel_dev_config_t::reset_gpio_num sets the GPIO number of the reset pin. If the LCD controller chip does not have a reset pin, you can set this value to -1.

More LCD panel drivers and touch drivers are available in IDF Component Registry. The list of available and planned drivers with links is in this table.

esp_lcd_panel_draw_bitmap() is the most significant function, that will do the magic to draw the user provided color buffer to the LCD screen, where the draw window is also configurable.

Commands sent by this function are short, so they are sent using polling transactions. The function does not return before the command transfer is completed. If any queued transactions sent by esp_lcd_panel_io_tx_color() are still pending when this function is called, this function will wait until they are finished and the queue is empty before sending the command(s).

Commands sent by this function are short, so they are sent using polling transactions. The function does not return before the command transfer is completed. If any queued transactions sent by esp_lcd_panel_io_tx_color() are still pending when this function is called, this function will wait until they are finished and the queue is empty before sending the command(s).

This function will package the command and RGB data into a transaction, and push into a queue. The real transmission is performed in the background (DMA+interrupt). The caller should take care of the lifecycle of the color buffer. Recycling of color buffer should be done in the callback on_color_trans_done().

Hello friend welcome to “Techno-E-Solution” in this article we are going to learn how to connect LCD display with Arduino Uno and print "Hello World!" on LCD using Arduino Uno. The 16x2 LCD is most popular LCD in electronics projects. In upcoming project we need this display in our project so it"s the beginners level tutorial learn this tutorial with fun. So friends let"s get started..........

A PCB Design Problems Detector, An Engineering Solution Provider Import the Gerber file with one click. No need for complicated file reading steps to review easily and improve efficiency.

For any microcontroller project, interfacing a display unit with it would make the project a lot easier and appealing for the user to interact with. The most commonly used display unit for microcontrollers is the 16×2 Alpha numeric displays. These types of displays are not only useful to display vital information to the user but can also act as a debugging tool during the initial developmental stage of the project. So, in this tutorial we will learn how we can interface a 16×2 LCD display with the STM32F103C8T6 STM32 Development board and program it using the Arduino IDE. For people who are familiar with Arduino this tutorial will just be a cake walk since they both are very similar. Also to learn more about STM32 Blue Pill Board follow our getting started tutorial.

As told earlier the Energia IDE provides a beautiful library which makes the interfacing a piece of cake and hence it’s not mandatory to know anything about the display module. But, would didn’t it be interesting to show what we are using!!

The name 16×2 implies that the display has 16 Columns and 2 Rows, which together (16*2) forms 32 boxes. One single box would look something like this in the picture below

A single box has 40 pixels (dots) with a matrix order of 5 Rows and 8 columns, these 40 pixels together forms one character. Similarly, 32 characters can be displayed using all the boxes. Now lets take a look at the pinouts.

Out of all these 16 pins, only 10 pins are to be used mandatory for the proper working of the LCD if you want to know more about these LCD display jump to this 16x2 LCD article.

As you can see the complete connection is made over a breadboard. We need a FTDI board to program the STM32 Microcontroller. So similar to our previous tutorial, we have wired the FTDI board to STM32, the Vcc and ground pin of the FDTI programmer is connected to the 5V pin and ground pin of the STM32 respectively. This is used to power the STM32 board and the LCD since both can accept can +5V. The Rx and Tx pin of the FTDI board is connected to the A9 and A10 pin of the STM32 so that we can program the board directly without the boot loader.

Next the LCD has to be connected to the STM32 board. We are going to use the LCD in 4-bit mode, so we have to connect the 4 data bit pins (DB4 to DB7) and the two control pin (RS and EN) to the STM32 board as shown in the STM32F103C8T6 LCD interfacing circuit diagram above. Further the table below will help you in making the connection.

As told in this tutorial we will be using the Arduino IDE to program our STM32 Microcontroller. But, the Arduino IDE by default will not have the STM32 board installed, hence we have to download a package and prepare the Arduino IDE for the same. This is exactly what we did in our previous tutorial getting started with STM32F103C8T6 using Arduino IDE. So if you have not installed the required packages fall back to this tutorial and follow it before you continue here.

Once the STM32 Board is installed in the Arduino IDE, we can start programming. The program is very similar to that of an Arduino board, the only thing that will change are the pin names since the notations are different for STM32 and Arduino. The complete program is given at the end of this page, but to explain the program I have split it into small meaningful snippets as shown below.

One noticeable advantage of using Arduino for programming our microcontrollers is that Arduino has readymade libraries for almost every famous sensors and actuators. So here we start our program by including the LCD library which makes the programming a lot easier.

In the next line we have to specify to which GPIO pins of the STM32 we have connected the LCD display control and data lines. To do this we have to check our hardware, for ease you can also refer to the table given at the top which lists the pin names of LCD against the GPIO pin of STM32. After mentioning the pins we can initialise the LCD using the LiquidCrystal function. We also name our LCD as “lcd” as shown below.

Next we step inside the setup function. Here first we have mention what type of LCD we are using. Since it is a 16*2 LCD we use the line lcd.begin(16,2). The code inside the void setup function gets executed only once. So we use it to display an intro text which comes on the screen for 2 seconds and then gets cleared. To mention the position where the text has to appear we use the function lcd.setcursor and to print the text we use the lcd.print function. For instance lcd.setCursor(0,0) will set the cursor at first row and first column where we print “Interfacing LCD” and the function lcd.setCursor (0,1) moves the cursor to second row first column where we print the line “CircuitDigest”.

After displaying the intro text we hold the program for 2 seconds by creating a delay so that the user the can read the intro message. This delay is created by the line delay(2000) where 2000 is the delay value in mill seconds. After the delay we clear the LCD using the lcd.clear() function which clears the LCD by removing all the text on LCD.

Finally inside the void loop, we display “STM32 –Blue Pill” on the first line and the value of seconds on the second line. The value of second can be obtained from the millis() function. The millis() is a timer which gets incrementing right from the time the MCU is powered. The value is in form of milli seconds so we divide it by 1000 before displaying it on our LCD.

Make the connections as show in the circuit diagram and use the code given below on Arduino IDE. Go to tools and make sure the right board is selected as done in getting started tutorial. Also, before uploading the program make sure the boot 0 jumper is set to 1as shown in the image below and press the reset button. When the upload button is pressed is code should get uploaded and the message will be shown on LCD as show in the image below.

As discussed in the above paragraph you should be able to notice the output as soon as the code is uploaded. But this program will not work the next time when you power up the board, since the board is still in programming mode. So once the program is uploaded the jumper on boot 0 should be changed back to 0 positions as show below. Also now since the program is uploaded to the STM32 board already we do not need the FTDI board and the whole set-up can be powered by the micro-USB port of the STM32 board as well as shown below.

This is just a simple interfacing project to help use the LCD display with STM32 board, but further you can use this to build cool projects. Hope you understood the tutorial and learnt something useful from it. If you had faced any problem in getting it to work, please use the comment section to post the problem or use the forums for other technical questions. The complete working of LCD display with STM32 can also be found as a video given below.

In this digital age, we come across LCDs all around us from simple calculators to smartphones, computers and television sets, etc. The LCDs use liquid crystals to produce images or texts and are divided into different categories based on different criteria like type of manufacturing, monochrome or colour, and weather Graphical or character LCD. In this tutorial, we will be talking about the 16X2 character LCD Modules.

The 16x2 LCDs are very popular among the DIY community. Not only that, but you can also find them in many laboratory and industrial equipment. It can display up to 32 characters at a time. Each character segment is made up of 40 pixels that are arranged in a 5x8 matrix. We can create alphanumeric characters and custom characters by activating the corresponding pixels. Here is a vector representation of a 16x2 LCD, in which you can see those individual pixels.

As the name indicates, these character segments are arranged in 2 lines with 16 characters on each line. Even though there are LCDs with different controllers are available, The most widely used ones are based on the famous HD44780 parallel interface LCD controller from Hitachi.

The 16x2 has a 16-pin connector. The module can be used either in 4-bit mode or in 8-bit mode. In 4-bit mode, 4 of the data pins are not used and in 8-bit mode, all the pins are used. And the connections are as follows:

Vo / VEE Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backwards to adjust the LCD contrast.

EnableSends data to data pins when a high to low pulse is given; Extra voltage push is required to execute the instruction and EN (enable) signal is used for this purpose. Usually, we set en=0, when we want to execute the instruction, we make it high en=1 for some milliseconds. After this we again make it ground that is, en=0.

The 16x2 LCD modules are popular among the DIY community since they are cheap, easy to use and most importantly enable us to provide information very efficiently. With just 6 pins, we can display a lot of data on the display.

The module has 16 pins. Out of these 16 pins, two pins are for power, two pins are for backlight, and the remaining twelve pins are for controlling the LCD.

If you look at the backside of the module you can simply see that there are not many components. The main components are the two controller chips that are under the encapsulation. There is an onboard current limiting resistor for the backlight. This may vary from different modules from different manufacturers. The only remaining components are a few complimentary resistors for the LCD controller.

In the module PCB, you may have noticed some unpopulated footprints. These footprints are meant for charge pump circuits based on switched capacitor voltage converters like ICL7660 or MAX660. You can modify your LCD to work with 3.3V by populating this IC and two 10uF capacitors to C1 and C2 footprint, removing Jumper J1 and adding jumper J3. This modification will generate a negative contrast voltage of around 2.5V. This will enable us to use the LCD even with a VCC voltage of 3.3V.

Another issue to be concerned about is the oscillator frequency, i.e. when the supply voltage is reduced, the built-in clock frequency will also get reduced. The Rosc should be changed to a suitable value if any timing issues or command execution issues occur. The typical value of the Rosc for 5V VCC is 91KOhms.

To test whether a 16x2 LCD works or not, connect the VDD, GND and backlight pins to 5v and GND. Connect the centre terminal of a 10K variable resistor to the VEE pin. Connect the other two terminals to VCC and GND. Simply rotate the variable resistor you will see that the contrast will be adjusted and small blocks are visible. If these rectangles are visible, and you were able to adjust the contrast, then the LCD is working

There are 16 pins on the display module. Two of them are for power (VCC, GND), one for adjusting the contrast (VEE), three are control lines (RS, EN, R/W), eight pins are data lines(D0-D7) and the last two pins are for the backlight (A, K).

The 16x2 LCD has 32 character areas, which are made up of a 5x8 matrix of pixels. By turning on or off these pixels we can create different characters. We can display up to 32 characters in two rows.

Yes, we can. We can store up to eight custom characters in the CGRAM (64 bytes in size) area. We can create load the matrix data for these characters and can recall when they need to be displayed.

Controlling the LCD module is pretty simple. Let’s walk through those steps. To adjust the contrast of the LCD, the Vo/ VEE pin is connected to a variable resistor. By adjusting the variable resistor, we can change the LCD contrast.

The RS or registry select pin helps the LCD controller to know whether the incoming signal is a control signal or a data signal. When this pin is high, the controller will treat the signal as a command instruction and if it’s low, it will be treated as data. The R/W or Read/Write pin is used either to write data to the LCD or to read data from the LCD. When it’s low, the LCD module will be in write mode and when it’s high, the module will be in reading mode.

The Enable pin is used to control the LCD data execution. By default, this pin is pulled low. To execute a command or data which is provided to the LCD data line, we will just pull the Enable pin to high for a few milliseconds.

To test the LCD module, connect the VDD, GND, and backlight pins to 5v and GND. Connect the center terminal of a 10K variable resistor to the VEE pin. Connect the other two terminals to VCC and GND as per the below connection diagram-

Simply rotate the variable resistor you will see that the contrast will be adjusted and small blocks are visible. If these rectangles are visible, and you were able to adjust the contrast, then the LCD is working.

Let’s see how to connect the LCD module to Arduino. For that first, connect the VSS to the GND and VDD to the 5V. To use the LCD backlight, connect the backlight Anode to the 5V and connect the backlight cathode to the GND through a 220Ωresistor. Since we are not using the read function connect the LCD R/W pin to the GND too. To adjust the contrast, connect the centre pin of a 10KΩ trimmer resistor to the VEE pin and connect the side pins to the VCC and GND. Now connect the registry select pin to D12 and Enable pin to D11.

Now let’s connect the data pins. The LCD module can work in two modes, 8-bit and 4-bit. 8-bit mode is faster but it will need 8 pins for data transfer. In 4-bit mode, we only need four pins for data. But it is slower since the data is sent one nibble at a time. 4-bit mode is often used to save I/O pins, while the 8-bit mode is used when speed is necessary. For this tutorial, we will be using the 4-bit mode. For that connect the D4, D5, D6 and D7 pins from the LCD to the D5, D4, D3 and D2 pins of the Arduino.

Here is the actual circuit. It is built as per the connection diagram provided. All the connections are made using standard male to male jumper wires.

The following Arduino 16x2 LCD code will print Hello, World! on the first line of the display and the time the Arduino was running in seconds on the second line.

Now let’s discuss the code. As usual, the sketch starts by including the necessary libraries. For this tutorial, we will be including the LiquidCrystal library from Arduino. This library is compatible with LCDs based on the Hitachi HD44780, or any compatible chipset. You can find more details about this library on the Arduino website.

Let’s create an object to use with the LiquidCrystal library. The following line of code will create an object called lcd. We will be using this object in the entire code to access the library functions. The object is initialized with the pin numbers.

Now let’s look at the setup()function. The lcd.begin function is used to initialize the LCD module. This function will send all the initialization commands. The parameters used while calling this function are the number of columns and the number of rows. And the next function is lcd.print. with this function, we have printed the word Circuit Digest! to the LCD. Since the LCD cursor is set to home position within the lcd.begin, we don’t need to set any cursor position. This text will stay there for two seconds. After that, the text will scroll from left to right until the entire text is out of the display. To scroll the display to the right, we have used the function lcd.scrollDisplayRight. After that, to clear display, we used lcd.clear, this will clear any characters on the display.

Now let’s look at theloop function. The for loop will count from 0 to 9, and when it reaches 9, it will reset the count and repeat the process all over again. lcd.setCursor is used to set the cursor position. lcd.setCursor(8, 1) will set the LCD cursor to the eighth position in the second row. In the LCD, the first row is addressed as 0 and the second row is addressed as 1. And the lcd.print(i) will print the count value stored in the variable i to the display.

Wrong characters are displayed: This problem occurs usually when the LCD is not getting the correct data. Make sure you are sending the correct ASCII value. If you are sending the correct ASCII characters, but still showing the wrong one on the LCD, check your connections for loose contact or short circuits.

Display shows Black boxes or does not show anything: First thing to do in these situations is to adjust the contrast voltage by rotating the variable resistor. This will correct the contrast value and will give you a visible readout.

Contrast is Ok, but still no display: Make sure to provide a sufficient time delay in between sending each character. Because if you don’t give enough time to process the data the display will malfunction.

Contrast and delay are ok, but still no display: Make sure you are powering the LCD from a 5V source. By default, these displays won’t work with a supply voltage below 5V. So if you are using the display with a 3.3V microcontroller make sure to power the display from 5V and use level shifters in between the display and the microcontroller.

In this project we will provide the input voice using Google Voice Keyboard via a Android App (BlueTerm) and print the text on 16x2 LCD using Raspberry Pi.

In this tutorial we are interfacing a Liquid Crystal Display (LCD) module with the Raspberry Pi Pico using Micropython to display strings, and characters on the LCD.

We used some Python scripts to find the local IP address of your Raspberry Pi on the network and display it on the 16x2 LCD Screen. We also added the script in the Crontab so that it can be run on every 10 minutes and we will have the updated IP address every time.

The following is a tutorial on using the ST7920 LCD with the ATmega328 microcontroller using Atmel Studio via the SPI interface. I have used the U8g2 Library, https://github.com/olikraus/u8g2

There are many tutorials on how to control the LCD using an Arduino, but I couldn"t find many on how to use the LCD in Atmel Studio. There was a great one here, https://github.com/olikraus/u8g2/wiki/u8g2as7 which I used to learn how to do this, but several fine details were missing, which made it hard to follow.

I assume that you have the microcontroller working in Atmel Studio. There are plenty of tutorials on how to set up the ATmega328 on a breadboard and get a simple blink program working in Atmel Studio. These are some great ones:

I have my ATmega328 operating at 8MHz using an internal crystal, set by changing the fuse bits from the factory default 1MHz. I use the following to set fuse bits: https://github.com/zkemble/AVRDUDESS, it is a clean interface and provides all necessary functionality. Careful when fusing bits - once again, many tutorials out there if you want to set your microcontroller to operate at a desired frequency.

We are using SPI communication, so we select that setup line and paste it into the Atmel main function as shown in the last image. The following line is copied into the main function, replacing the original setup line.

2. If the LCD does not have a potentiometer soldered to the back, attach a resistor with a value of between 200 to 10000 ohms to pin VO as seen above. Adjust the value of the resistor to achieve an optimal contrast. Alternatively, a potentiometer could be used to adjust the contrast.

The CFA533-***-KC series is a 16x2 I2C LCD with keypad. The I2C interface allows you to use just two lines (SDA & SCL) to have bi-directional communication with the I2C LCD. Other devices can also share those two I2C control lines with the LCD. Only 4 wires are needed to connect this I2C LCD: power, ground, SDA (I2C Serial DAta) and SCL (I2C Serial CLock).

The CFA533 can run on 3.3v to 5.0v directly, with no changes needed, so you do not need to do any level translation between your embedded processor and the I2C LCD. Simply power the CFA533 from the same supply as your processor and the I2C signal levels will match up.

Using only one address on your I2C bus, you can add all the elements that you need for your front panel. The CFA533 I2C LCD can also read up to 32 DS18B20 digital temperature sensors, giving you an easy way to integrate temperature sensing over the I2C bus. No additional firmware or pins are needed on the host system.

This CFA533-TFH variant features crisp dark letters against a white, backlit background. The keypad has a matching white LED backlight. Since the LCD is a backlit positive FSTN, the CFA533-TFH I2C LCD is readable in direct sunlight, as well as complete darkness.

The original example code is a bad implementation of how to handle a PIN, and adding the printing of the key when a digit position is correct makes it even worse.

This requires no coding ability, no coding skills, or any software or hardware since it just defining the high level functionality of how it should work.

Or it could require telling it you have entered the PIN by doing something like pressing a key like #. But then you must figure out how to handle things when they type more than the number of buttons. i.e. does it start over or does it rotate through the PIN positions queued up or does it shift the PIN buttons in the que to allow using the most recent N buttons.

You could have a timeout that turns off the backlight to preserve the life of the backlight save power that triggers after a certain amount of time with no button pressed.

The most secure is only provide feedback when something is pressed but no feedback when a button is correct or incorrect for the PIN until entering the final PIN position.

If it is fixed pin that can be modified, then there would need to be a sequence to enter the existing pin to allow changing the pin. And then there must be a way to set the PIN back the "factory default" that is hard coded in the source code.

I would suggesting spending some time thinking about how you want your system to work and then when you have a design, come back to code implementation.

The LCD BoosterPack Text example is an application that demonstrates the use of the Kentec QVGA BoosterPack to display text on an LCD screen with a variety of different styling configurations. The user has the ability to display a variable text message of their choice and change the font size, font color, text position, and background color. This code example leverages the MSP432 Graphics Library that is shipped with the SimpleLink MSP432 SDK.

The LCD BoosterPack Text code example requires the standard configuration of an MSP-EXP432P401R LaunchPad with an attached BOOSTXL-CC2650 BoosterPack. Additionally, a Kentec QVGA BoosterPack must be stacked on top of the CC2650 BoosterPack. This hardware configuration is shown in the below image:

This code example has been tested with IAR Embeded Workbench 7.80.3 and Code Composer Studio v7.1. For more information on how to import this project into your IDE workspace and build/run, please refer to the main user’s guide.

Once the LCD BoosterPack Text code example starts, the LCD will turn to a black background with the text “Simplelink MSP432 SDK Bluetooth Plugin” displayed on the screen.

By default, this code example starts with BLE advertisement enabled indefinitely. Using your BLE client of choice, search for the “MSP432 LCD” device and connect:

Once connected, scroll down past the product information (this might be different depending on your client) and there should be a list of six different characteristics and their corresponding properties/values (these are described in detail in the following sections):

The text string characteristic will change the value of the text that is displayed on the screen. From your client application, write any desired string value to this characteristic and the displayed text on the LCD will change:

The text color characteristic is a three byte value that controls the RGB value of the font display. The byte order is in the format of BB GG RR. For example, writing a value of 0000FF to the characteristic would change the text color to full red.

The X Position characteristic is the position of the beginning of the text string starting from the left side of the screen. The position is limited by the X resolution of the LCD screen (320) and a value from 0 to 320 can be used. A value of 160 will roughly put the text in the horizontal center of the screen.

The Y Position characteristic is the position of the top of the text starting from the top side of the screen. This value is limited by the Y resolution of the LCD screen (240) and a value from 0 to 240 can be used. A value of 120 will roughly put the text in the vertical center of the screen.

The text size characteristic changes the font size of the text on the screen. This code example has a total of eighteen different fonts (0 being the smallest, 17 being the largest). Changing the value of this characteristic will change the font size of the displayed string:

The last characteristic controls the background color of the LCD. The format of this characteristic is identical to the format of the text color characteristic (six byte BB GG RR value). Write to this value to change the background color:

Updating the firmware on the CC2650 BoosterPack uses the SBL libraries to invoke the CC2650’s bootloader and transfer the new firmware over serial. For LCD BoosterPack Text, the method to trigger this invocation is to hold down both S1 and S2 buttons on the LaunchPad for a duration of at least three seconds. Note that in order to trigger the firmware update, no active BLE device can be connected. Once S1 and S2 are held down for two seconds, LED2 on the LaunchPad will toggle bright blue to signal the BSL start:

The console screen will print the status of the firmware update as well as signal when the update has finished. At the end of the update the status of the update will be printed over the serial port and the MSP432 will reboot itself:

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey