tft lcd manufacturing process supplier

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD(Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

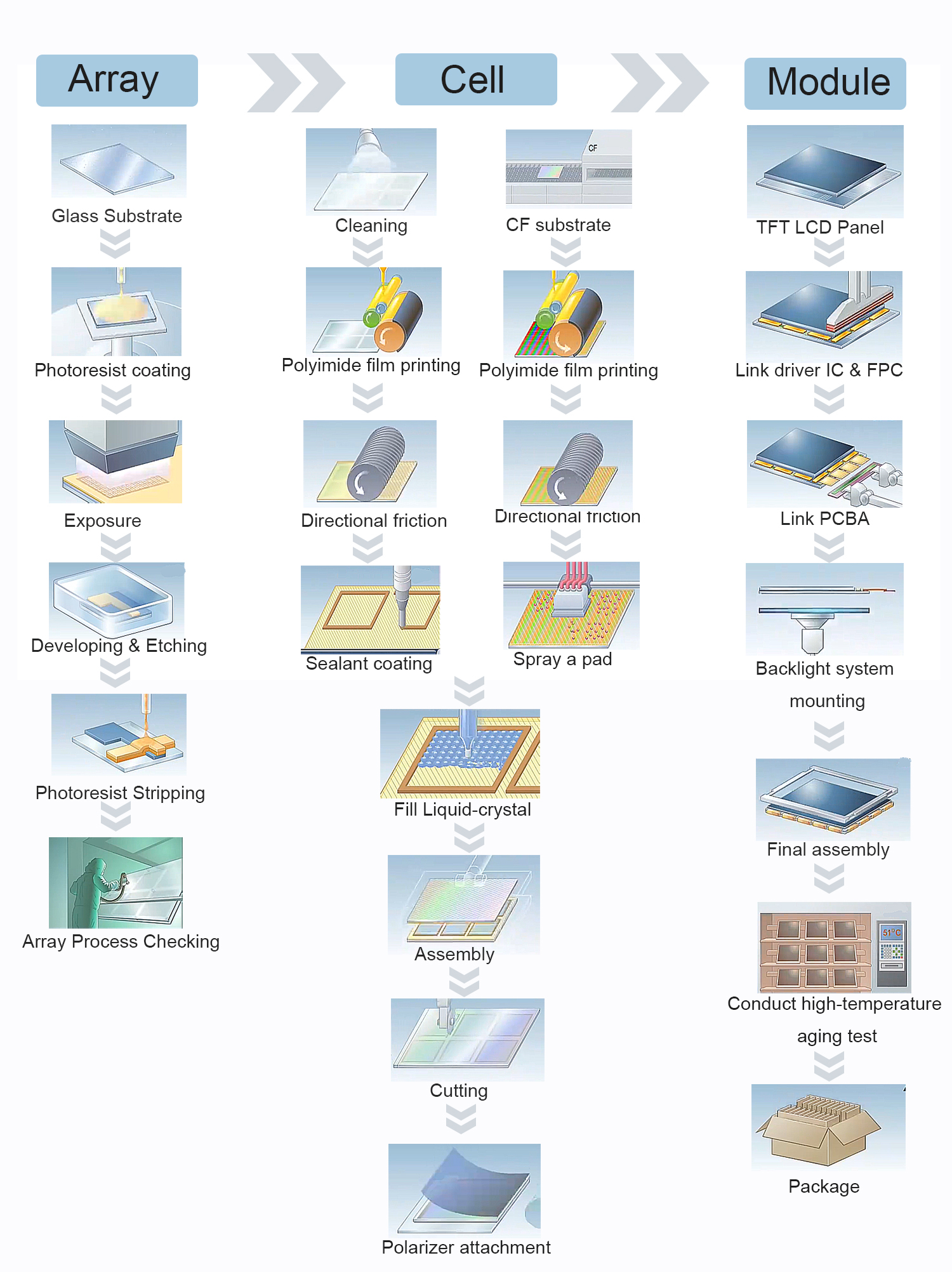

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

This marks the end of this post. If you find it useful or want to know more about TFT LCD, just leave your comment below or contact us. We’re hearing!

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

Microtips also provides value-added services to all its clients. The company’s Electronic Manufacturing Services team gives product suggestions and shares insights on how clients can successfully manage their projects.

Taiwan and Mainland China are two Asian countries where Microtips set up their manufacturing plants. The factories boast of modern equipment, high-quality raw materials, and stringent quality control measures. Microtips even earned ISO9001 and ISO14001 certifications for excellent quality management.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

LXD has research centers and factories in both the United States and China. The US-based headquarters feature a massive 30,000 square feet of manufacturing and research development centers. Meanwhile, LXD’s Chinese facilities feature a large 5,000 square meters of cleanrooms for manufacturing modular and glass products.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

Distributor of component LCDs for equipment which provide high-contrast ratio, color saturation, luminance and performance enhancements such as advanced wide viewing (AWV) for true color fidelity, super-high brightness (SHB) and wide temperature range. Focus on industrial, instrumentation, hand-helds, medical and other low-to-medium volume markets. High-bright LED backlights for outdoor use. LVDS interfaces decrease EMI. Factory installed touch screen solutions. 3.5" to 12.1" QVGA, HVGA, VGA, WVGA, SVGA, XGA, WXGA. Also distributes other related products including LED drivers, lamps, indicators, LED assemblies, segment displays, LED mounts, LEDs, and light pipes. Distributor of electronic components, hardware and fasteners and provides design/value engineering support, fulfillment strategies, procurement services and transactional models to meet specific needs and priorities.

![]()

For over 20 years we"ve been helping clients worldwide by designing, developing, & manufacturing custom LCD displays, screens, and panels across all industries.

Newhaven Display has extensive experience manufacturing a wide array of digital display products, including TFT, IPS, character displays, graphic displays, LCD modules, COG displays, and LCD panels. Along with these products, we specialize in creating high-quality and affordable custom LCD solutions. While our focus is on high-quality LCD products, we also have a variety of graphic and character OLED displays we manufacture.

As a longtime leader in LCD manufacturing, producing top-quality LCD modules and panels is our highest priority. At Newhaven Display, we’re also incredibly proud to uphold our reputation as a trusted and friendly custom LCD manufacturing company.

As a custom LCD manufacturing company, we ensure complete control of our custom displays" reliability by providing the industry"s highest quality standards. Our design, development, production, and quality engineers work closely to help our clients bring their products to life with a fully custom display solution.

Our excellent in-house support sets Newhaven Display apart from other display manufacturers. Modifications in the customization process are completed at our Illinois facility, allowing us to provide an exceptionally fast turnaround time.

Customer support requests sent by phone, email, or on our support forum will typically receive a response within 24 hours. For custom LCD project inquiries, our response time can take a few days or weeks, depending on the complexity of your display customization requirements. With different production facilities and a robust supply chain, we are able to deliver thefastest turnaround times for display customizations.

Our excellent in-house support and custom display modifications set Newhaven Display apart from other LCD display manufacturers. From TFTs, IPS, sunlight readable displays, HDMI modules, EVE2 modules, to COG, character, and graphic LCDs, our modifications in the customization process are completed at our Illinois facility, allowing us to provide quality and fast turnaround times.

As a display manufacturer, distributor, and wholesaler, we are able to deliver the best quality displays at the best prices. Design, manufacturing, and product assembly are completed at our headquarters in Elgin, Illinois. Newhaven Display International ensures the best quality LCD products in the industry in this newly expanded facility with a renovated production and manufacturing space.

With assembly facilities in the US, manufacturing facilities in China, and distribution channels worldwide, we pride ourselves on delivering high-quality custom display solutions quickly to locations worldwide.

PalmTech devotes ourselves to developing new items such as LCD, LCD module, TFT, and Touch Panel. Our products can apply to wearable devices, medical categories, industrial fields, automotive areas, etc.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Customer service is another element we are particularly proud of. To facilitate the pre-production and product development process, thousands of standard solutions are stored in our warehouses. This ensures efficient order realization which is a recipe to win the hearts of customers who chose Orient Display. We always go to great lengths to respond to any inquiries and questions in less than 24 hours which proves that we treat buyers with due respect.

To become the stage of realizing dreams of our employees! To build a happier, more united and extra professional workforce! To reach a mutual advantage of our prospects, suppliers, the society and ourselves for Tft Lcd Touchscreen Display, Face Recognition Tft-Lcd Screen, Wireless Touchscreen Monitor, Monochrome Lcd Display,Monochrome Lcd Display. Welcome your enquiry, greatest service is going to be provided with full heart. The product will supply to all over the world, such as Europe, America, Australia,Jersey, Estonia,Luxemburg, Angola.We"ll supply much better products with diversified designs and expert services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

We also supply merchandise sourcing and flight consolidation companies. We now have our very own manufacturing facility and sourcing business. We could present you with almost every kind of product relevant to our solution array for Advantages Of Tft Display, Liquid Crystal Module, Round Lcd, Rugged Military Lcd Display,Stone Tft Display. Our products are new and old customers consistent recognition and trust. We welcome new and old customers to contact us for future business relations, common development. Let"s speeding in the dark! The product will supply to all over the world, such as Europe, America, Australia,Croatia, San Francisco,Berlin, Frankfurt.The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer"s trust and support! In the future, we are going to continue with the most qualified and high quality service to offer the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

ADI provide a complete line of products and services for our quality computer & PC peripherals, electronic & electrical components, including liquid crystal displays, commercial open frames, industrial open frames, LCD TV, LCD panels, thin client displays, LCD monitors, LCD module, LCD flat panel displays, LCD screens, LCD displays, TFT LCD displays, CRT displays, touch screen monitors etc. Obtained ISO 9001 & ISO 14001 certifications.

Manufacturer of car TFT monitors, car DVD player, portable DVD players, TFT LCD TV, digital TV, portable multimedia player and other related products. It was founded in 2001, and seriously carries out ISO9001 & ISO4000 quality management system to ensure good quality. The product widely covers America, Europe, Middle East, Africa, Southeast Asia and Chinese mainland, etc..

AU Optronics Corp. ( AUO) is Taiwan"s largest and a worldwide top 3 manufacturer of TFT LCD panels. AUO was formed in September 2001. In October 2006, AUO merged with Quanta Display Inc. to create a larger TFT-LCD manufacturer with more than 20% of the world"s large-sized TFT-LCD market. Additionally, the amassed production of company"s G6 reached worldwide top 1. Additionally, AUO is the first pure TFT-LCD manufacturer to successfully list at the NYSE. AUO is able to provide customers a full range of panel sizes and comprehensive applications, offering TFT-LCD panels in sizes ranging from 1.5 inches to greater than 65 inches. AUO generated NT$423 billion ( US $12.9 billion) in sales revenue in 2008 and now houses the staff of more than 38,000 employees throughout its global operations spreading...

Manufacturer of electronic & electrical components, computer & PC peripherals, including liquid crystal displays, LCDTV, LCD displays, TFT LCD TVs, LCD monitors, LCD screens, LCD displays, multifunction displays, electronic display devices, etc. Obtained ISO 9001 & ISO 14001 certifications.

Daxian Company Limited, is engaged on OEM/ODM telecom products for many years. Our product ranges include VoIP/ Skype DECT, DECT phone, mobile phones, VoIP/ SIP phones, WiFi phones, walkie talkies, media converters, digital picture frames, PMP, etc. Stable quality is vital for the survival and the development of our company. We keep strict quality control from incoming materials to outgoing complete products. We only use materials from our approved suppliers. It puts the the ISO 9001 system into effect. For in process quality control, we adopts the SPC (Special Process Statistical) to monitor the capability and critical parameters. All of our products are approved by the major approval bodies: FCC and UL_USA, European CE l and China Authority Approval. In our factory in Shenzhen, China, our...

HannStar Display Corporation ( "HannStar®") was established in June 1998. We are specialized in the manufacturing of TFT-LCD products and these main applications are in notebook computer displays and desktop computer monitors. At the beginning of our establishment, we have built up a clear operation concept, i.e., providing human beings with the most healthy visionary environment and dedicated to the R&D, manufacture and sales of low-radiation, low power consumption and compact & convenient TFT-LCD. HannStar now has one LCD fabrications and one LCM fabrication. Through technology transfer from Toshiba and Hitachi, HannStar acquired the state-of-the-art TFT-LCD manufacturing technology with the highest efficiency for mass production. Our customers include leading electronics companies...

Chi Mei Corporation established Chi Mei Optoelectronics (CMO) in 1998. Company shares began trading on the Taiwan Stock Exchange in August of 2002. Our main products are LCD TV panels and LCD panel displays for desktop and notebook computers, delivered to IT and home electronics vendors worldwide. CMO is a global industry leader in TFT- LCD manufacturing. In its perseverance to promote LCD TV and LCD panels in universal applications, CMO has earned the industry"s trust and respect as a first-rate manufacturer with world-class display technology. With production facilities are based in Southern Taiwan Science Park, we are currently operating one 3.5G, 4G, 5.5, 6G, and G7.5 plant each, as well as two 5G plants. Besides producing LCD panels for nearly every specification on the market, capacity...

Manufacturer of computer & PC peripherals, electronic & electrical components, including liquid crystal displays, LCD panels, LCD monitors, LCD modules, character LCD modules, TFT LCD, LCD displays, LCD TV, LCD monitor, TFT LCD panels, TFT LCD modules, etc. Products are exported to Europe, Mainland China, Brazil, South America, North America. OEM order are accepted.

Manufacturer of electronic & electrical components, computer & PC peripherals, including semiconductor material business divisions, engineering plastic materials, electronic machinery, LCD TV, TFT LCD panel, TFT LCD module, LCD monitor, LCD screens, liquid crystal displays, LCD display, LCD TV, light guiding plate, liquid crystal, OLED materials, pick-up heads, etc. Obtained ISO 9001:2000 certification.

Manufacturer of electrical & electronic parts, computer & PC peripherals, including liquid crystal displays, LCD panels, LCD monitors, character LCD modules, LCD displays, TFT LCD, LCD TV, PDP display, PDP TV, digital light processing projector, rear-projection TV, backlight modules, etc. Certificated by ISO 9001 & ISO 14001. OEM orders are welcome.

Manufacturer of electronic & electrical components, computers & PC peripherals, including liquid crystal displays, TFT LCD panels, TFT LCD modules, LCD monitors, LCD TV, TFT LCD monitors, LCD TV, color STN LCD, LCD flat panels monitors, graphic LCD modules, color monitors, etc. Obtained ISO 9001, ISO 14001, TL 9000 certifications.

Manufacturer of electronic, electrical parts & components, computers & PC peripherals, including LCD drives, control IC, video displays, commercial & IM products, TFT LCD mobile phone drivers, TFT LCD source drivers, TFT LCD gate drivers, LCD monitor controllers, USB keyboard controllers, dual-channel flat panels TV controllers, LVDS transmitters, etc. Obtained ISO 9001 certification.

Manufacturer of electrical, electronic parts & components, computer & PC peripherals, including TN LCD panel & modules, PLED modules & panels, TFT LCD panels & modules, STN LCD panels & modules, rear projection TV, multimedia projectors, desktop computers, notebook computers, driver IC, control IC, LCD drivers, printers, digital photographs, home entertainments, scanners, personal photo labs, etc.

Manufacturer of electronic, electrical parts & components, computer & PC peripherals, including IC designing, software embedded memory, analog IP, wireless communication, microcontrollers, LCD drivers, sound processors, consumer IC, communication IC, LCD drivers IC, graphic color STN LCD drivers, USB controller, keyboard & mouse controllers, etc. Certificated by ISO 9001.

Manufacturers of electronic, gift items, giftware, include novelty, China ( Chinese) gifts, digital photo frame, digital picture frames, LCD digital photo frames, LCD digital photo picture frames, promotional premiums, digital photo frames and albums, TFT LCD advertising displayers, multimedia TV. OEM & ODM are welcomed.

Casing Macron Technology Co. was founded with the mission to be the full-service vendor of computing products. Since our established in 1994, firstly focused our core business on computer PC chassis and switching power supply, now we expend our product line to other peripheral advices such as card reader, mouse, speaker and barebone system. Our major products include computer cases, power supply, digital photo frames, MP3/ MP4/ MP5 players, memory card readers, etc. CASING aims to be the first and foremost name that comes to mind for companies around the world seeking case and enclosures of personal computers. We dedicated ourselves to delivers value to the PC industries by designing, manufacturing, marketing, selling high quality products and providing efficient services to its customers....

Established in 1971, Delta Group is the world"s largest provider of switching power supplies and brushless fans. As a global leader in power electronics. Our mission is- To provide innovative energy-saving products for a better quality of life. Our design process is based on Product Life Cycle Management (PLM) providing a stringent and accelerated design cycle while ensuring product quality and reliability. Our manufacturing facilities are ISO-9001 and ISO-14001 certified, and all share common quality and measurement systems. In recent years we have developed high-density and high-efficiency telecommunication power systems, UPS ( uninterruptible power supply) with advanced interfaces, computer networking components and products with high software content, microdisplay PTVs, and many others....

CPT being the pioneer of TFT-LCD mass production technology leads in the domestic industry with the most complete product lines- (1) TFT products: TFT LCD display & monitor, TFT LCD TVs. (2) CRT products: color picture tubes, monochrome display tubes, projection tubes. We plan to build an LCD module ( LCM) plant in Xiamen, China.

K-Bridge Electronics has three primary manufacturing divisions- (1) LCD Monitor Division: design LCDs, auto ( car, vehicle) audio and video systems, TFT LCD, touch LCD computers, large LCDs, intelligent LCD TVs for cars and intelligent liquid crystal AD machines. (2) Backlight Division: Backlight Module, LCD Backlight, LCD Backlight Module. (3) PCB Division: OEM production for double sided & multi-layers printed current board.

STARVF Optical and Electronic Technology Co., Ltd is a modern enterprise advocating combination of technology and human culture. Boasting abundant capital, advanced equipments and sound management, we have been long devoting to the development and distribution of video-information products, with the main of which are LCD monitors, LCD TVs, all-in-one pc desktop and other portable digital products. Our core is innovation and creativity in new technology. We have a group of excellent engineers who have been endeavoring in LCD field for years and have been command of many important ODM projects from home and abroad. Relying on their many-year experience, the advantages in technology and their relationship with the foreign enterprises, they are doing their best to develop LCD displaying application...

Manufacturer of TV lartern, B/W series, mini color TV, portable DVD, TFT LCD televison, car LCD TFT monitor, digital photo frame, security monitor. Its products have been passed almost all safety/quality certifications in the world, like UL, GS, CE, FCC, FDA, etc. Besides, the company is also a ISO9001:2000-approved enterprise.

Established in 1998, DSW Audio & Security Co., Ltd. has specilized in manufacturing Piezo siren & Alarm, Electrical siren, Battery backup siren, Outdoor Siren, Home Alarm, strobe light, magnetic contacts, reed switches, Moled Speaker Box, Car Speaker, Loudspeaker and PIR sensor, motion detector sensor, control panel, Power supplier, CCTV power supplier as well as innovation electronic items in China. With over 10 years combined experience the DSW staff can offer you the support it needs for state of the art design and now there are 20 staff work for DSW including technicians and engineers. It is usually takes 30 days to develop a new design and develop 20-30 new model each year. Our annual investment in R&D accounts for 6.5% of sales. More than 30% raw material is imported from Japan and Korea...

Manufacturer of bluetooth mirror hands free car kits, TFT LCD TVs, LCD monitors, speakers, headphones, SD cards. It was established in 1988. All its products are reliably compliant with CE, FCC, UL and CB standards.

Manufacturer of touch screem monitor, touch screen monitors, car TFT LCD monitors/ Tv, portable AV products, car DVD players and other Mutil-Media electronical products. The company was ISO-9000 certified.

Manufacturer of touch screen monitor, touch screen monitors, multi touch screen, multi touch screens, TFT LCD monitors, TVs. It can provide OEM/ODM service.

Manufacturer & exporter of mobile audio-visual products. Base on our R&D department, we develop many kinds of new products such as VGA TFT LCD touchscreen monitors, car PCs & media players, VGA TFT LCD touch monitors, in-car TFT LCD TV monitors, rearview mirror TFT LCD monitors, digital picture frames, IP network cameras, video cameras, waterproof color CMOS cameras & DVB-T. We have more than 5 yeares experience in OEM of VGA Touch screen TFT LCD monitor and car PC for worldwide customers. Moving steadfastly forward, we can assure you of our high quality outputs. Neway welcomes companies to join forces in pursuit of business opportunities and form win-win partnerships.

Manufacturer of touchscreen VGA monitors, stand alone wide screen touchscreen VGA monitors, desktop/wall-mount TFT-LCD touchscreen VGA monitors, stand-alone TFT-LCD touchscreen VGA monitors, digital photo frames, touchscreen GPS systems, TFT LCD small TVs, oscillographs, TFT LCD monitors, wide screen headrest/stand-alone TFT-LCD monitors, photo browsing with music background.

Manufacturer of LCD flat screen TVs, LCD displays, LCD TV PC monitors, LCD TVs, LCD Monitors, TFT LCD, shoes, case & bags, festival lights, LCD and ceramic & porcelain products.

Manufacturer of open frame touch monitor, open frame touch monitors, TFT LCD monitors, TV, digital LCD AD players, monitor brackets, waterproof cameras.

Manufacturer of miniIP platform, hot IP, memory IPs, ethernet controller, memory compiler architecture, memory compiler, physical library, media composer, audio platform, TFT LCD platform. Receivied by ISO 9001 certification.

With a strong R&D team, Apex designs the product developments for its entire Opto-Electronics Department, from components, modules, to systems in 2000. Apex focuses on three main fields: infrared products, visible-light LED products, application module, LCD modules, TFT LCD display module, color STN module, LED lighting modules etc. Obtained ISO 9001 Quality Approval in 2002.

In recent years, the TFT LCD display industry has become more and more complex. Upstream panel manufacturers and chip manufacturers are all oligopoly, while TFT LCD display manufacturers are basically in the crack of survival. How to find a way to survive in the fiercely competitive market is a breakthrough that every TFT LCD display manufacturer is looking for. The following is Proculus"s views on this topic.

Good production technology is the core competitiveness of the TFT LCD screen. Only by continuously optimizing the production process can the products become more competitive. This can promote the production industry and indirectly reduce costs.

Cost is critical for the LCD screen factory. Everyone knows that in the upstream of TFT liquid crystal display manufacturers, many panel manufacturers and IC manufacturers belong to monopoly industries and require cash transactions. This has brought many problems to TFT LCD manufacturers. Therefore, in the face of such a severe market situation, it is also very important to reduce costs and improve cost performance. Both the quality and price of the end product are very important.

The stagnant TFT liquid crystal display manufacturers will eventually be eliminated by the trend of the times, while potential TFT liquid crystal display manufacturers will focus on innovation. In view of our own shortcomings, we must make changes and make breakthroughs. There must be a sense of innovation in products and services in order to keep up with the pace of the times. Good TFT LCD display manufacturers should have excellent qualities, and create a virtuous development and virtuous circle of the industry atmosphere, and be manufacturers that love the industry.

TFT-LCD technology is based on semiconductor IC manufacturing processes, and is unique in that it uses glass substrates rather than traditional silicon wafers. For the TFT manufacturing process, thin film formation, such as CVD and PVD processes, is a very important part. The ODF process has been developed for the assembly of color filters and TFT substrates, and is used in large size LCDs.

First of all, the movement and arrangement of liquid crystal molecules need electrons to drive, so in the carrier of liquid crystal – TFT glass, there must be able to conduct the part to control the movement of liquid crystal, here will use ITO (Indium TIn Oxide, transparent conductive metal) to do this thing. ITO is transparent, also known as thin film conductive crystal so that it will not block the backlight.

The different arrangement of liquid crystal molecules and the rapid movement changes to ensure that each pixel accurately display the corresponding color, and the image changes precisely and quickly, which requires precision control of the liquid crystal molecules. ITO film requires special processing, as if printed circuitry on a PCB board, drawing conductive lines throughout the LCD board.

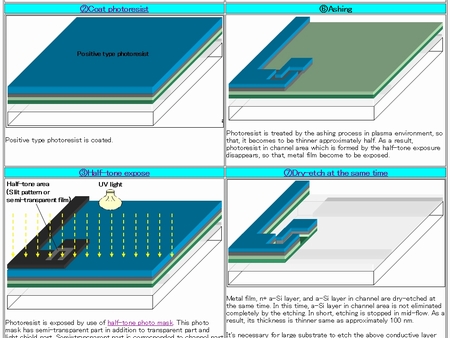

For array panels with back-channel etched TFT structure.The main process can be divided into 5 steps (5 lightings) according to the sequence of the layers to be made and the interrelationship between the layers.

The process includes: Gate layer metal sputtering, Gate lithography, Gate wet lithography, and other processes. After these processes, scan lines and gate electrodes are formed on the glass substrate, i.e. gate electrodes. The graphical representation of the completed process is shown in the following figure.

Photolithography is the process of copying Mask graphic structures onto the glass substrate to be etched. There are three main processes: photoresist coating, exposure, and development

Dry lithography: The chemical reaction between the process gas and the film, as well as the bombardment of the film by the plasma, is used to remove the film layer.

The process includes: PECVD triple layer continuous film formation, island lithography, island dry lithography and other processes. After these processes, the final amorphous silicon island for TFT is formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

Specific processes include: S/D metal layer sputtering into a film, S/D lithography, S/D wet lithography, channel dry lithography and other processes. After these processes, the source, drain, channel and data lines of the TFT are finally formed on the glass substrate. At this point, the TFT has been produced. The graphics obtained after the process is completed are shown in the following figure.

The process includes PECVD, photolithography, and dry lithography of vias. After these processes, the final TFT channel protective insulation layer and guide through the hole are formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

Specifically, the process includes: sputtering of ITO transparent electrode layer, ITO photolithography, ITO wet lithography and other processes. After these processes, the transparent pixel electrode is finally formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

At this point, the whole array process is completed. In short, the array process of 5 times of light is: 5 times of film formation + 5 times of etching

Color filters can be produced by various methods; photolithography is a typical method. In photolithography, color filters are produced by exposing a glass substrate coated with a photographic color resist through a photomask. The resist is hardened to form the RGB pattern of the LCD.

When making LCD panels it is impossible to produce them one by one, which is too inefficient, so multiple pieces are processed at once and separated by cutting.

After that is bonding IC and FPC; assembling backlight module, the whole machine shell and other processes, relative to the front of the high-precision process to be simpler.

In addition to the above main process, there are some auxiliary processes in the module section, such as: laser cutting, electrical testing after cutting, electrical testing after bonding, electrical testing after assembly, microscopic inspection after cutting, microscopic inspection or automatic optical inspection after binding, shear force peel test after IC bonding, tensile peel test after FPC bonding, electrical aging after assembly, packaging and shipping, etc.

Although we are not process processing personnel, but we still need to understand the relevant things, because in the interface with other departments or personnel in order to be more comfortable. Problems can be considered in many aspects, if you do not know the process related knowledge, encounter problems simply will not think of here, so the process of understanding or necessary.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

Beijing STONE Technology co., ltd was established in 2010 and devoted itself to manufacturing and developing high-quality intelligent TFT LCD display modules.

Our core TFT LCD display modules integrate a CPU, flash memory, and touch screen in the hardware unit. Paired with an easy-to-use free GUI design software and complete instruction set, customers can avoid time-consuming accessories selection and system integration tasks. These units greatly reduce the workload in HMI development and make the entire process faster and easier.

The modules come with a UART TFT serial interface that can be controlled by any MCU through the simple but powerful instruction set like the 8051 series, AVR series, MSP430 Series, STM32 series, MC9S12, and Arduino series, among others.

Each TFT display LCD module has a wide range of applications, such as automated system control, vending machine functionality, intelligent lockers, electricity equipment (oiling machine, EV charger), elevators, smart home and office, precision instruments, and much more.

To date, we have delivered custom display solutions to over 3000 customers around the world. Our TFT LCD modules have been widely praised for their quality and performance and that is in large part thanks to our partners, including NI, Siemens, ThyssenKrupp, and many others. These long-term cooperative relationships have been mutually beneficial and we hope to continue a long history of success.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

The TFT-LCD panel generally speaking is a liquid crystal layer that is sandwiched between two glass substrates, the upper glass substrate is combined with a color filter, and the lower glass is embedded with transistors. The upper glass is bonded with the color filter so that each pixel (Pixel) contains three colors red, blue, and green, and these red, blue and green pixels constitute the image on the panel.

Front Array, Middle Cell, Cell is the glass of the front Array as the substrate, combined with the glass substrate of the color filter, and between the two glass substrates Filled with a liquid crystal (LC). The rear module assembly process is the final assembly process of the glass after the Cell process and other accessories such as backlight panels, circuits, and outer frames.

Please check the following picture which shows the whole process of making a TFT LCD. This picture will introduce the whole manufacturing process to you with simple text and a picture description.

6) To form a usable thin film transistor, it is necessary to repeat the processes of cleaning, coating, photoresist, exposure, development, etching, photoresist removal, etc. Generally speaking, to manufacture TFT-LCD, it is necessary to repeat 5 to 7 times.

1) After completing the thin film transistor glass substrate, we will combine the liquid crystal panel. The liquid crystal panel is composed of a transistor glass substrate and a color filter. First, we must wash the glass first, and then proceed to the next step. a step. The entire manufacturing process of TFT-LCD must be in a clean room, so that there will be no impurities inside the display.

3) In the whole process of combination, firstly, we need to coat a layer of chemical film on the glass and color filter covered with transistors, and then perform the alignment action.

5) After sealing the frame, put the LCD panel into the vacuum chamber, pump the air out of the LCD panel through the gap just reserved, and then pour the liquid crystal into the liquid crystal with the help of atmospheric pressure, and then close the gap. A compound substance between solid and liquid, with the characteristics of regular molecular arrangement.

1) After the polarizer is attached, we start to install DRIVE IC on both sides of the LCD panel. DRIVE IC is a very important driving part, which is used to control the color and brightness of the LCD.

3) The light of the LCD panel is emitted from the backlight. Before assembling the backlight, we will first check whether the assembled LCD panel is complete, and then assemble the backlight. The backlight is the light source behind the LCD panel.

5) Then we enter the final key test process, and do the aging test on the assembled modules, and screen out the products with poor quality in the state of electrification and high temperature.

We provide wholesale and customization of common 1.3″-24″ TFT LCD panels, if you have any projects that need these products, welcome to contact us, besides, we have different size of FLCOS and OLED mini micro-displays in stock, some mall ads bar type LCD display we also could provide, and welcome a bulk production wholesale inquiry.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey