tft lcd manufacturing process quotation

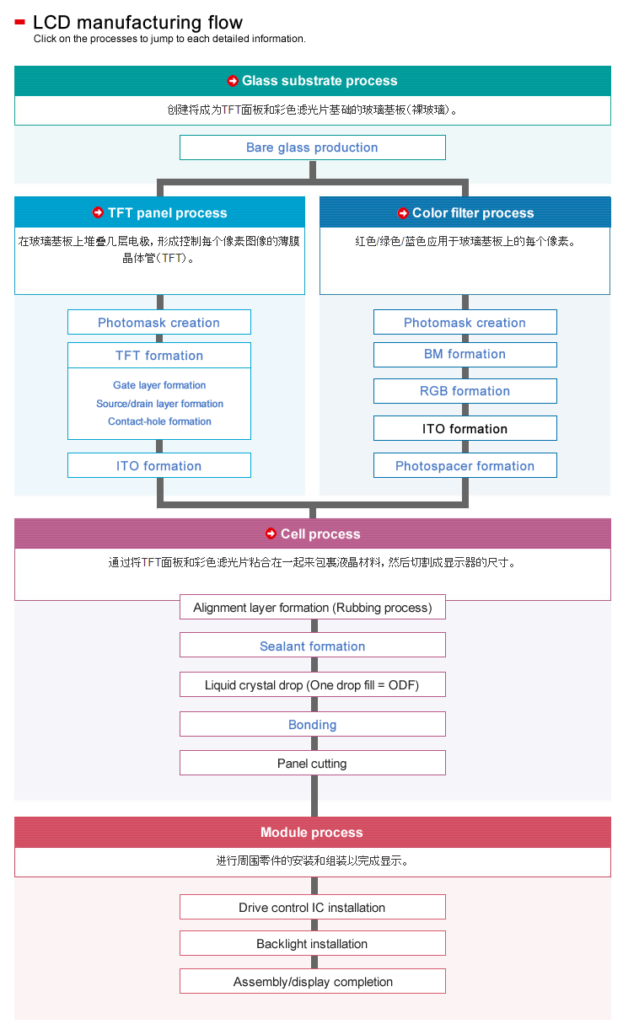

TFT-LCD technology is based on semiconductor IC manufacturing processes, and is unique in that it uses glass substrates rather than traditional silicon wafers. For the TFT manufacturing process, thin film formation, such as CVD and PVD processes, is a very important part. The ODF process has been developed for the assembly of color filters and TFT substrates, and is used in large size LCDs.

First of all, the movement and arrangement of liquid crystal molecules need electrons to drive, so in the carrier of liquid crystal – TFT glass, there must be able to conduct the part to control the movement of liquid crystal, here will use ITO (Indium TIn Oxide, transparent conductive metal) to do this thing. ITO is transparent, also known as thin film conductive crystal so that it will not block the backlight.

The different arrangement of liquid crystal molecules and the rapid movement changes to ensure that each pixel accurately display the corresponding color, and the image changes precisely and quickly, which requires precision control of the liquid crystal molecules. ITO film requires special processing, as if printed circuitry on a PCB board, drawing conductive lines throughout the LCD board.

For array panels with back-channel etched TFT structure.The main process can be divided into 5 steps (5 lightings) according to the sequence of the layers to be made and the interrelationship between the layers.

The process includes: Gate layer metal sputtering, Gate lithography, Gate wet lithography, and other processes. After these processes, scan lines and gate electrodes are formed on the glass substrate, i.e. gate electrodes. The graphical representation of the completed process is shown in the following figure.

Photolithography is the process of copying Mask graphic structures onto the glass substrate to be etched. There are three main processes: photoresist coating, exposure, and development

Dry lithography: The chemical reaction between the process gas and the film, as well as the bombardment of the film by the plasma, is used to remove the film layer.

The process includes: PECVD triple layer continuous film formation, island lithography, island dry lithography and other processes. After these processes, the final amorphous silicon island for TFT is formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

Specific processes include: S/D metal layer sputtering into a film, S/D lithography, S/D wet lithography, channel dry lithography and other processes. After these processes, the source, drain, channel and data lines of the TFT are finally formed on the glass substrate. At this point, the TFT has been produced. The graphics obtained after the process is completed are shown in the following figure.

The process includes PECVD, photolithography, and dry lithography of vias. After these processes, the final TFT channel protective insulation layer and guide through the hole are formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

Specifically, the process includes: sputtering of ITO transparent electrode layer, ITO photolithography, ITO wet lithography and other processes. After these processes, the transparent pixel electrode is finally formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

At this point, the whole array process is completed. In short, the array process of 5 times of light is: 5 times of film formation + 5 times of etching

Color filters can be produced by various methods; photolithography is a typical method. In photolithography, color filters are produced by exposing a glass substrate coated with a photographic color resist through a photomask. The resist is hardened to form the RGB pattern of the LCD.

When making LCD panels it is impossible to produce them one by one, which is too inefficient, so multiple pieces are processed at once and separated by cutting.

After that is bonding IC and FPC; assembling backlight module, the whole machine shell and other processes, relative to the front of the high-precision process to be simpler.

In addition to the above main process, there are some auxiliary processes in the module section, such as: laser cutting, electrical testing after cutting, electrical testing after bonding, electrical testing after assembly, microscopic inspection after cutting, microscopic inspection or automatic optical inspection after binding, shear force peel test after IC bonding, tensile peel test after FPC bonding, electrical aging after assembly, packaging and shipping, etc.

Although we are not process processing personnel, but we still need to understand the relevant things, because in the interface with other departments or personnel in order to be more comfortable. Problems can be considered in many aspects, if you do not know the process related knowledge, encounter problems simply will not think of here, so the process of understanding or necessary.

Keywords: departments in a Taiwanese high-tech company, which is a top global producer of TFT-LCD equipment.

TFT-LCD industry The cross-fold validation method is applied to measure model performance, reliability, and prediction

Manufacturing ease. Through comparison of various performance indices, the Hi method outperforms MRA, ANNs and

were cathode ray tubes (CRTs) in 1999. However, more than 60% The TFT-LCD industry, promoted by Taiwan’s government in

of displays are now flat panels (e.g., liquid crystal displays (LCDs), the Two Trillion Twin Stars plan, has developed rapidly in recent

plasma screens). The global market for panels, which was worth years. The TFT-LCD industry is second only to the semiconductor

2011 (ITIS, 2008). Therefore, thin-film transistor-LCDs (TFT-LCDs) production involves hundreds of complex processes. Each panel

(Menozzi et al., 2001), as TFT-LCDs have excellent features such as production lines requiring diverse manufacturing equipment with

the engineer-to-order manufacturing industry still face problems The remainder of this paper is organized as follows. Literature

Thomasson et al., 2006; Toussaint and Cheng, 2006), process commonly used to estimate cost early in a project’s lifecycle when

knowledge of the TFT-LCD manufacturing process. By applying operations, or activities (PMI, 2004). Activity-based costing (ABC),

combined with business process modeling and an analytical ging. (Berlin et al., 2009; Cavalieri et al., 2004; Chou, 2009a). Fig. 1

in the following section) were employed to develop cost output rithms with an iterative and time-intensive process. NeuralTools

where Similarityðf I ,fiR Þ represents the case similarity measure industry report indicates there will be 1.2 billion LCD TVs in 2015

equipment layouts were acquired from the engineering & design and test sets in modeling processes; however, some confusion exists

manufacturing process. These features must be identified based on mutually exclusive subsets of roughly equal size to minimize bias

process, and equipment type); these features can be accessed easily samples. All models were trained and validated ten times, and each

machines. The manufacturing processes include TFT, CF, LCD, and where n is the number of validation data, Yi is the equipment

8. Manufacturing process (TFT, CF, LCD, LCM) Dummy (D9, D10, D11) X8 String

terms of single techniques and MAER. costs for equipment used to manufacture TFT-LCDs. Field inter-

timely manner, thereby leading to organizational losses. AI-based techniques for estimating cost of developing TFT-LCD

hybrid AI-based technique outperformed MRA, implying that the manufacturing based on the complex machining features. Int J Adv Manuf

method developed in this study were adequate in predicting the estimation of process vessels. International Journal of Production Economics

TFT-LCD panels are currently a global trend and users have forecasting. Civil Engineering and Environmental Systems 22, 71–81.

PMs of TFT-LCD manufacturing equipment an effective and De Barcelos Tronto, I.F., Simoes Da Silva, J.D., Sant’Anna, N., 2007. Comparison of

environmental protection, are adopted, or new manufacturing prediction of total construction costs. Construction Management and

Albright, S.C., Winston, W., Zappe, C.J., 2006. Data Analysis & Decision Making with sourcing process–The case study of Taiwan’s TFT-LCD industry. International

model using experience by analytic hierarchy process. Building and Environ- novel LCD color filter repair machine with fully dry process, IDW/AD’05—

Information & Management 34, 33–40. Lin, J.T., Chen, T.-L., Lin, Y.-T., 2009. Critical material planning for TFT-LCD

hypermedia project cost estimation. International Journal of Web Engineering design. International Journal of Computer Integrated Manufacturing 15,

Menozzi, M., Lang, F., Napflin,¨ U., Zeller, C., Krueger, H., 2001. CRT versus LCD: Smith, A.E., Mason, A.K., 1997. Cost estimation predictive modeling: regression

performance. Displays 22, 79–85. Smith, J.R., 2005. LCD Modules, Programming the PIC Microcontroller with

Science and Engineering 128, 563–575. modeling for cost-conscious product design: a case study in a manufacturing

repairing ITO film on LCD board. Guangdian Gongcheng/Opto-Electronic Toussaint, J., Cheng, K., 2006. Web-based CBR (case-based reasoning) as a tool with

early manufacturing cost estimation. International Journal of Advanced Tsai, K.-m., Wang, S.-c., 2009. Multi-site available-to-promise modeling for

Manufacturing Technology 13, 618–629. assemble-to-order manufacturing: an illustration on TFT-LCD manufacturing.

Pardo, P.J., Pe!rez, A.L., Suero, M.I., 2004. Validity of TFT-LCD displays for colour metal parts using multiple regression and artificial neural networks: A case

Park, N.K., Yoo, S.I., 2009. Evaluation of TFT-LCD defects based on human visual Witten, I.H., Frank, E., 2005. Data Mining: Practical Machine Learning Tools and

Factors that may influence the price of a certain type of LCD include: screen size, viewing angle, maximum brightness, color display,resolution and frame rate.

Screen size: larger size display more, and larger size cost more, these’re common sense. For example, in last year’s iPhone 8P which used a 5.5-inch LCD screen, the display (including touchscreen) cost 52.5 dollars, while a 43-inch LCD TV cost 128 dollars.

Viewing angle: it’s the maximum angle at which a display can be viewed with acceptable visual performance. It’s measured from one direction to the opposite, giving a maximum of 180° for a flat, one-sided screen. Early LCDs had strikingly narrow viewing angles, for now most of the manufacturers have improved them to more than 160°.

Color display: in early or simple LCDs, only two or very few colors can be displayed. As the technology advances, TFT LCD can display up to 65536 colors.

As the diagram shows above, LCD module covers the most part of the cost of a LCD TV. Within LCD module, there’re still many components. In the following diagram we’ll show you the price breakdown of these components.

The third quarter in the year is usually the demand season of LCD module, as a result the price will be the highest. However, situation varies in different market.

Due to the massive investment and low cost of Chinese mainland manufacturer, the capacity of LCD module for TVs increases significantly, so the price of these modules stay pretty low for the past year.

In another aspect, technology innovations keep push the price of high-end LCD to a higher level. For many users that are planning to replace their old TVs, these high-end LCDs are tempting choices.

Actually, though LCD screen has many advantages, its average price is keep decreasing in the past years. New technology brings lower cost is one reason, a strong competitor called OLED is another.

Main difference between OLED and LCD is OLED can give out light itself, that is to say OLED screen can run at a lower load compared to LCD screen, at least it doesn’t need a backlight system.

In the high-tech industries, on-line quality monitoring on each workpiece under processing is required to ensure process stability and improve yield rate. However, conducting workpiece-by-workpiece actual metrology is very expensive and time-consuming. In this case, a novel idea is to use “virtual metrology” (VM) that conjectures workpiece quality based on process data collected from production equipment with a slight supplement of actual metrology data. The purpose of this tutorial paper is to select the thin film transistor-liquid crystal display (TFT-LCD) manufacturing processes as the illustrative examples for demonstrating the methodology of fab-wide implementation of the VM technology systematically. To begin with, a survey of VM-related literature is performed. Then, the features of an effective and refined VM system are presented with the automatic VM (AVM) system developed by the authors as a case study, followed by introduction of the TFT-LCD production tools and manufacturing processes. After that, the generic deployment schemes of the VM technology for the TFT-LCD tools are proposed. Finally, illustrative examples with the AVM system as a case study are presented to show how the VM technology applies to TFT-LCD manufacturing.

The fabrication of TFT-LCD panel includes the growing and etching of a-silicon and silicon nitride films. These fabrication processes utilize significant amounts of silane, phosphine, ammonia, chlorine, boron trichloride, nitrogen trifluoride, fluorine, and hydrogen which are highly flammable, reactive, corrosive, and/or toxic. The amount used and scale of the supply system for these gases are far larger than for other tech industries such as the semiconductor and photovoltaic industries…Expand

Transform your design into an innovative product with our electronics manufacturing services. Scale your product with the help of a reliable manufacturing partner.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

Microtips also provides value-added services to all its clients. The company’s Electronic Manufacturing Services team gives product suggestions and shares insights on how clients can successfully manage their projects.

Taiwan and Mainland China are two Asian countries where Microtips set up their manufacturing plants. The factories boast of modern equipment, high-quality raw materials, and stringent quality control measures. Microtips even earned ISO9001 and ISO14001 certifications for excellent quality management.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

LXD has research centers and factories in both the United States and China. The US-based headquarters feature a massive 30,000 square feet of manufacturing and research development centers. Meanwhile, LXD’s Chinese facilities feature a large 5,000 square meters of cleanrooms for manufacturing modular and glass products.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey