atmega328p arduino spi problems tft display supplier

Is there a difference between the NANO and MEGA that would account for ST7735 displays working on NANO and not working on MEGA? I"m using the same pins on both....

Please always post a link to your display. It answers many questions. Even when descriptions are dishonest we can identify most displays from the pictures of the pcb.

It"s a little bit embarrassing, the Microprocessor (ATMega328P) was fault. I had 4 unprogrammed AVR"s in my box and burned the Bootloader to one and used this new Processor to test it. And now it works just fine.

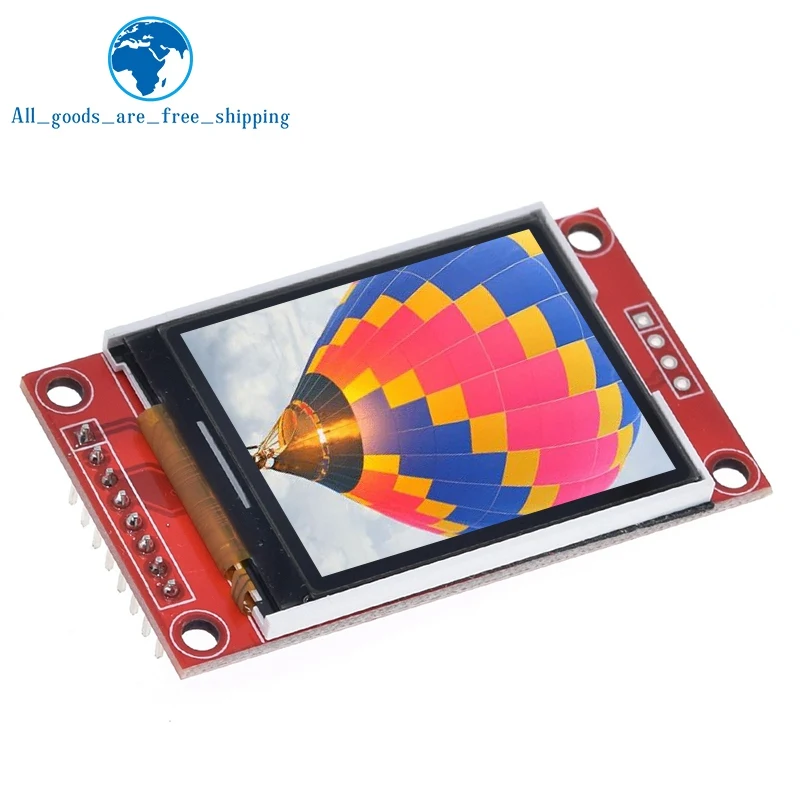

Find many great new & used options and get the best deals for 1.8" Serial 128x160 SPI TFT LCD Modul Display PCB Adapter SD Socket 4 Arduino at the best online prices at eBay! Free delivery for many products!

The ebay URL you supplied contains a download link to a file that appears to contain an Arduino library and example sketches for the device. The example sketches are .pde extension instead of .ino so the libraries may need modifying to work with Arduino IDE v1.0+

No the ST7735 driver is an SPI device only. The more expensive of the two form OP"s post is identical to one from Adafruit to the SD card and footprint for the 8 pin eprom on the back side. the real difference is the $15.00 price difference.

I notice when you send data to the screen it stays until something is written over it. When sending variable data text strings to the TFT, the results just keep overlaying each other. Sending tft.fillScreen(ST7735_BLACK); is very slow and it seems pointless re-writing any static text also.

By these two functions, You can find out the resolution of the display. Just add them to the code and put the outputs in a uint16_t variable. Then read it from the Serial port by Serial.println();. First add Serial.begin(9600); in setup().

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big (7" diagonal) bright (14 white-LED backlight) and colorfu 800x480 pixels with individual pixel control. As a bonus, this display has a optional capacitive and resistive touch panel attached on screen by default.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (UNO/Due/Mega 2560).

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

For 7 inch screen,the high current is needed.But the current of arduino uno or arduino mega board is low, an external 5V power supply is needed. Refer to the image shows the external power supply position on shield ER-AS-RA8875.

If you"ve had a lot of Arduino DUEs go through your hands (or if you are just unlucky), chances are you’ve come across at least one that does not start-up properly.The symptom is simple: you power up the Arduino but it doesn’t appear to “boot”. Your code simply doesn"t start running.You might have noticed that resetting the board (by pressing the reset button) causes the board to start-up normally.The fix is simple,here is the solution.

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big (5" diagonal) bright (18 white-LED backlight) and colorfu 800x480 pixels with individual pixel control. As a bonus, this display has a optional resistive touch panel attached on screen by default.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (UNO/Due/Mega 2560).

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

If you"ve had a lot of Arduino DUEs go through your hands (or if you are just unlucky), chances are you’ve come across at least one that does not start-up properly.The symptom is simple: you power up the Arduino but it doesn’t appear to “boot”. Your code simply doesn"t start running.You might have noticed that resetting the board (by pressing the reset button) causes the board to start-up normally.The fix is simple,here is the solution.

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

In electronic’s projects, creating an interface between user and system is very important. This interface could be created by displaying useful data, a menu, and ease of access. A beautiful design is also very important.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

In this article, we have used libraries and advanced technics to display data, charts, menu, etc. with a professional design. This can move your project presentation to a higher level.

Size of displays affects your project parameters. Bigger Display is not always better. if you want to display high-resolution images and signs, you should choose a big size display with higher resolution. But it decreases the speed of your processing, needs more space and also needs more current to run.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The display driver will typically accept commands and data using an industry-standard general-purpose serial or parallel interface, such as TTL, CMOS, RS232, SPI, I2C, etc. and generate signals with suitable voltage, current, timing and demultiplexing to make the display show the desired text or image.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

By these two functions, You can find out the resolution of the display. Just add them to the code and put the outputs in a uint16_t variable. Then read it from the Serial port by Serial.println(); . First add Serial.begin(9600); in setup().

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We created a function which accepts numbers as input and displays them as a pie chart. We just use draw arc and filled circle functions.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

while (a < b) { Serial.println(a); j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 255, 255)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

while (b < a) { j = 80 * (sin(PI * a / 2000)); i = 80 * (cos(PI * a / 2000)); j2 = 50 * (sin(PI * a / 2000)); i2 = 50 * (cos(PI * a / 2000)); tft.drawLine(i2 + 235, j2 + 169, i + 235, j + 169, tft.color565(0, 0, 0)); tft.fillRect(200, 153, 75, 33, 0x0000); tft.setTextSize(3); tft.setTextColor(0xffff); if ((a/20)>99)

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

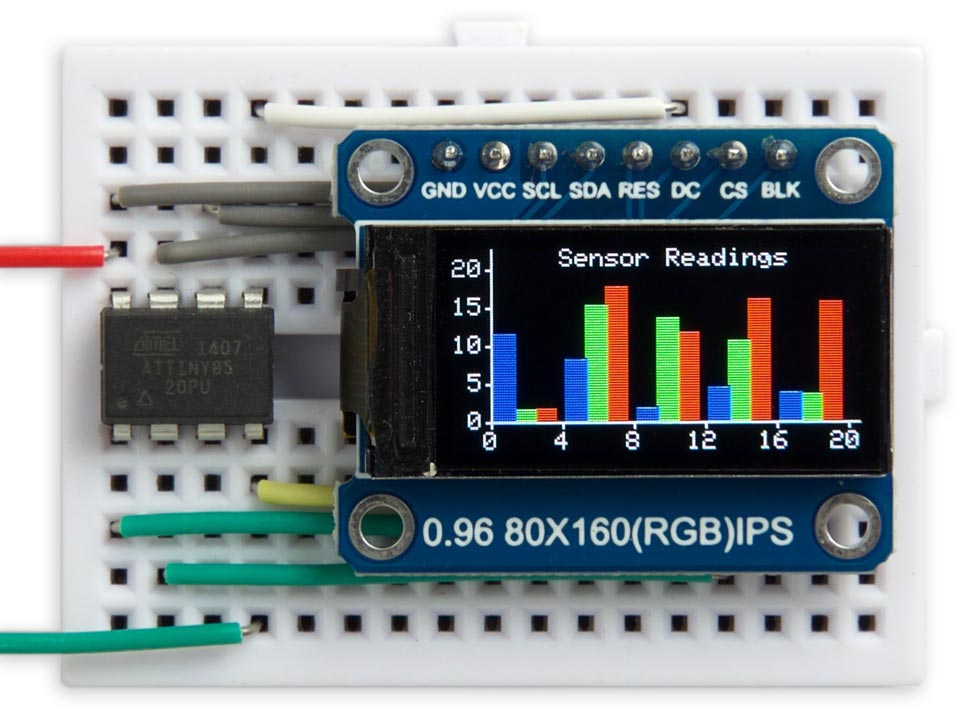

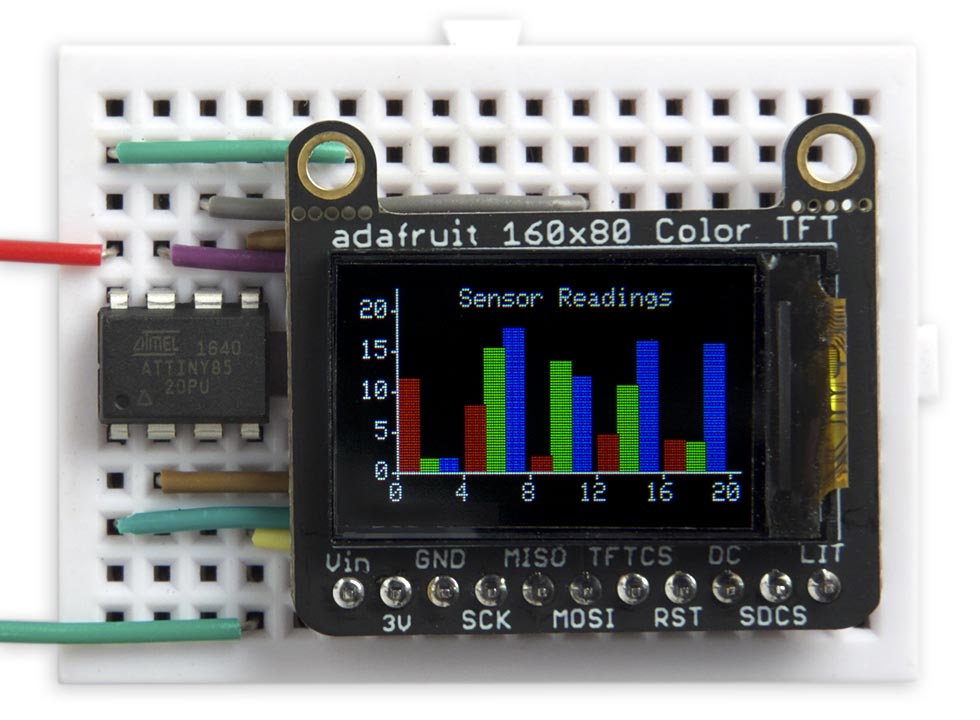

This is a graphics library for the family of small colour TFT displays based on the ST7735 and ST7789 driver chips. These are really nice displays; bright, colourful, available in a variety of useful sizes, and available at low cost from suppliers like Adafruit, AliExpress, or Banggood:

This library allows you to plot points, draw lines, draw filled rectangles, and plot text with an optional scale factor. I"ve included a demo histogram-plotting program that adjusts itself to fit each of the displays I"ve supported.

Unlike most other TFT display libraries this one doesn"t require a memory buffer, allowing it to be run on any processor down to an ATtiny85. The displays are SPI and require four pins to drive the display, leaving one pin free on an ATtiny85 to interface to another device, such as a temperature sensor. If you need more pins choose a larger chip, such as the ATtiny84; see Using the library with other AVR chips at the end of the article for information about how to convert the code for different chips.

I"ve published a library for a colour OLED display in a previous article: Colour Graphics Library. The main difference between the colour TFT displays and the colour OLED displays is that the TFT displays are not self-illuminating, and so need a backlight; they therefore have a slightly higher power consumption. However, they are exceedingly cheap, and they are available in larger sizes than the colour OLED displays.

This library will work with displays based on the ST7735 which supports a maximum display size of 132 (H) x 162 (V), or the similar ST7789 which supports a maximum display size of 240 (H) x 320 (V).

The display driver interfaces to the displays with the longer side as the vertical dimension, which is why the rectangular displays are usually listed with the longer dimension second. My library allows you to rotate the image for any desired orientation.

All the Adafruit breakout boards for these displays include level-shifting circuitry, so they will work with either 5V or 3.3V microcontroller boards. They also include an SD card socket, if that"s of interest to you. The Adafruit boards have pullups on the backlight and reset pins, so the display will work if you leave these pins unconnected.

The pullup resistor from the display"s CS pin is optional; it holds the chip select high to prevent the display from being affected by the ISP signals while programming the ATtiny85.

The different displays are catered for by six constants which specify the size of the display, the offsets relative to the area supported by the display driver, whether the display is inverted, and the rotation value; for example:

Note that on some displays you may also have to change the xoff or yoff value when rotating the display. For example, to rotate the image on the 240x240 displays by 180° use the settings:

To check or adjust the values for each display I ran this program, which draws a one-pixel border around the display area, and plots an "F" to show the orientation:

The ATtiny85 and other AVR processors supports toggling of one or more bits in a port, so provided you set all the pins to their disabled state at startup, for speed the display access routines can simply toggle the appropriate pins to enable or disable them.

The InitDisplay() routine first defines the four display pins as outputs, and takes the SCK, DC, and CS pins high (inactive). It then sends the essential configuration commands to the display.

The display memory stores 18 bits per pixel: 6 bits per colour. However, you can write to the display in three alternative modes, with 12, 16, or 18 bits per pixel. I chose the 16 bit mode, which assigns 5 bits to red, 6 bits to green, and 5 bits blue. It"s the most convenient one to work with as you simply send two bytes to define the colour of each pixel.

To clear the display the ClearDisplay() routine sends the appropriate number of zero bytes. The routine temporarily switches to 12-bit colour mode, which reduces the time to clear the display by 25%:

The library includes basic graphics routines for plotting points and drawing lines. These work on a conventional coordinate system with the origin at lower left. For example, on the 80x160 display:

My first version of PlotChar() plotted characters by calling PlotPoint() for each pixel. However, I then tried the following alternative approach which defines an area of the display using the CASET (Column Address Set) and RASET (Row Address Set) commands, and then sends a stream of the appropriate bytes to define the character. This turned out to be over three times faster!

14th January 2020: Tested the program with the Adafruit 1.3" 240x240 TFT display, and updated the program to correct a problem when rotating the image on that display.

Amateur Radio Single Sideband Transceiver Controller for Arduino and SI5351 Clock generator. Includes Dual VFO, single or double band support for 20 and 40 meter bands, CAT control, optional S-meter, multiple supported displays including options include 20x4 LCD, Color TFT, and 2.8" Nextion Touch Screen

The Arduino Uno is probably the most popular Arduino board, and for good reason. It’s relatively small, very inexpensive (especially clone boards) and has a wealth of support code and documentation. It’s also likely the first Arduino board you started working with, for some of you it may even be the only Arduino board you own.

You’ll find that the majority of projects and demonstrations that I perform on this website and on the YouTube channel use an Arduino Uno. It’s also my favorite Arduino board.

But the real value of the Arduino Uno is as a development or prototyping board. With an Arduino Uno and a solderless breadboard you can quickly bring ideas and concepts to life, its connectors work well with jumper wires and the wealth of code available for the Arduino platform makes development tasks a breeze.

After you finish you’ll have a working project but it may not be a practical one to use in the real world. It has no enclosure and as it consists of an Arduino Uno, a solderless breadboard and various wires, modules, and components. It’s actually pretty fragile.

One big thing that you’ll need to factor into your decision is the Arduino Uno itself. It may be perfect for your permanent project, but again, it may not be.

The Arduino Uno is a wonderful device. With a generous helping of digital I/O ports, 8 analog-to-digital converters, I2C, Serial and SPI interfaces and onboard voltage regulation it is suitable for powering a wide variety of devices. It has a built-in USB port and onboard LEDs and can provide both 5-volt and 3.3-volt low-current power supplies for your peripheral devices.

The Arduino Nano– This small board can do everything an Arduino Uno can, it even has two additional analog to digital converters. It has a mini USB connector instead of the bulky Type B connector used on the Arduino Uno. Cost wise it’s a bit less expensive.

The ATmega328– This is the solution you’ll be reading about in this article. It’s the microcontroller that powers the Arduino Uno, and it can be used all on its own.

The original Arduino Uno and its clones used the 28-pin DIP (Dual Inline Package) version of the ATmega328. Other clones and boards like the Nano and Pro Mini make use of surface mount versions, this explains why the Nano and Pro Mini have two additional analog to digital converters.

As you can see from the diagram above the ATmega328 has several pins that have two, or even three, functions. You can change the functions of these pins programmatically within your sketch, the same is true of the Arduino Uno (which makes perfect sense as the Uno is based upon the ATmega328).

When converting your design from an Arduino Uno to a raw ATmega328 chip it is helpful to be able to relate the pinouts on the ATmega328 to the connections on an Arduino Uno. The following pinout diagram has been relabeled to show the Arduino Uno equivalent functions:

An example might be helpful to help you equate the pins on an Arduino to those on an ATmega328. For that reason, I’ve put together a very simple project that can be quickly prototyped on an Arduino Uno. We will then look at what is required to move our simple project to an ATmega328.

After building this you’ll realize that using an entire Arduino Uno is a real overkill, as only three digital I/O pins are put to use. It also would lend itself well to being mounted into a Star Wars toy or a custom 3D-printed enclosure.

I took the easy road and used an excellent sketch that has been on GitHub for over 6 years. It is theArduino Song sketch by Nick Sort, you can take a look at it here:

If you look closely an an Arduino Uno board you’ll notice that aside from the ATmega328 there really are not very many components. Most of the “extra” parts have to do with either the USB to serial interface or with the internal 5-volt and 3.3-volt regulators.

In actual fact, you can put together a functional equivalent of an Arduino Uno using only an ATmega328 and five parts. You can even wire on up without any additional parts if you are willing to run it at a lower clock frequency.

A “bootloader” is code that is burned onto the ATmega328 chips EEPROM. This code is loaded when the processor is powered up or reset and it sets up things like the clock frequency and a number of the internal registers. It also gets the ATmega328 ready to accept programs from the Arduino IDE on its serial RX and TX pins.

The Arduino Bootloader is essentially what makes an ATmega328 into an “Arduino”. It is open source code that is already available in your Arduino IDE, and you can use the Arduino IDE to load a bootloader into a blank ATmega328 chip.

You might not need to do this though. You can purchase an ATmega328 with the bootloader already installed. That is what I did for this project. Look for an ATmega328 chip that has the letters “PU” at the end of the part number, i.e. ATmega328P-PU.

If you do need to burn your own bootloader there are many resources that will show you how, including the one on theofficial Arduino website. You can also get dedicated devices that burn bootloaders automatically, useful if you have dozens or hundreds of chips to set up.

Assuming that you have an ATmega328 with a bootloader burned onto it you are now ready to wire it up. You will need a few extra components for your “homemade Arduino”.

You can use an Arduino Uno to load the sketch onto the ATmega328, but only if you have the right kind of Arduino Uno. Let me explain what I mean by “right kind”:

The original Arduino Uno, as well as several clones, use a 28-pin DIP version of the ATmega328. The same type of ATmega328 that we are going to be programming.

This chip was mounted in an IC socket and thus can be removed. And the ability to remove the chip from its socket provides us with two methods of using the Arduino Uno to program an ATmega328 for our stand-alone configuration.

Of course, if your Arduino Uno clone uses a surface mount chip then you’re out of luck. But fear not, there is a third method of programming an ATmega328 that doesn’t require an Arduino Uno at all.

Simply use the Arduino Uno as you normally would and program your sketch onto it. Then carefully remove the ATmega328 from your Arduino Uno and use it on the breadboard, wired as we have seen earlier.

The IC socket on the Arduino Uno is not really made for repeated removals and insertions. Eventually, you will degrade or damage it if you do this a lot.

The second method also requires an Arduino Uno that has a 28-pin DIP version of the ATmega328. As with the first method you’ll need to remove the processor from the Arduino board. Unlike the first method, however, you will just be putting the ATmega328 aside. After we are done you can put it back into the IC socket.

This method will make use of the USB to serial converter that is built into the Arduino Uno. The outputs of this converter are always available on pins 0 and 1 of the Uno’s digital I/O connecter. With this method we will just send those outputs to our ATmega328 on a breadboard.

Again remember,although it isn’t shown in the diagram above you need to have all of the other wiring to the ATMega328 as well. This diagram only shows theadditional connections you need to make using the Arduino Uno!

What you are doing is tying the RX (receive) pin of the Arduino Uno to the RX pin on the ATmega328 (pin2). You are also connecting the TX (transmit) pin on the Uno to the ATmega328 TX pin (pin 3). And, finally, the Reset pin on the Arduino Uno is connected to the Reset pin on pin 1 of the ATmega328.

There seems to be a lot of conflicting advice on the web regarding how you setup the Arduino IDE to program your ATmega328 using this method. Some suggest that you change the board type.

I have not found that to be necessary. I just leave my Arduino IDE set exactly as it was when programming my Arduino Uno normally. And it worked every time.

When you are loading your sketch you should notice that a few of the LEDs on the Arduino Uno wil blink, just like they do normally. It’s a good indication that everything is working properly.

But what do you do if your Arduino clone uses a surface mount chip, or if you just don’t want to pull the chip out of the socket on your board? Let’s look at another method that doesn’t use an Arduino Uno at all.

The FTDI Adapter is a USB to serial convertor that is commonly used to program an Arduino Pro Mini and other microcontrollers that do not have a USB port. The “FTDI” abbreviation comes from the original manufacturers’ name, a Scottish company calledFuture Technology Devices International.

Also, note that unlike the previous method which used the Arduino Uno the FTDI method requires you to reverse transmit and receive. So the RX output from the FTDI adapter connects to the TX pin (pin 3) on the ATmega328 and the TX output from the FTDI adapter is attached to the RX pin (pin 2) on the ATmega328.

Once again I found I didn’t need to make any changes in my Arduino IDE, it just worked as it always did. One thing to note however is that the computer in my workshop is LINUX (Ubuntu 16.04) and if you are using a Windows computer you may need to install a driver to use the FTDI adapter.

This method of programming an ATmega328 has a lot of advantages once you get it working, the primary one being that it is completely independent and does not require you to modify an Arduino Uno.

Learn how to transfer your Arduino Uno projects to an ATmega328 chip so you can create a permanent version in a custom enclosure. Uses a Star Wars music box as an example.

The Arduino reads temperature & humidity & pressure values from the BME280 sensor and print them (respectively in °C & RH% & hPa) on ST7735 color TFT display.

The ST7735 TFT used in this project is a color display which has a resolution of 128×160 pixel and it communicates with the master device using SPI (Serial Peripheral Interface) protocol.

Also, if we’re working with a 5V system (development board, microcontroller …) like the Arduino UNO board (ATmega328P microcontroller), we’ve to use a voltage level shifter (level converter) which converts the 3.3V (comes from the BME280 chip) into 5V (goes to the ATmega328P) and vice versa. This level shifter is for the I2C bus lines (clock and data).

Generally, the BME280 module has at least 4 pins because it can work in SPI mode or I2C mode. For the I2C mode we need 4 pins: VCC, GND, SDA and SCL where:

Normally the ST7735 display works with 3.3V only, but many boards of this display have a built-in 3.3V regulator (AMS1117 3V3) like the one shown in the circuit diagram. This regulator supplies the display controller with 3.3V from 5V source.

All Arduino UNO board output pins are 5V, connecting a 5V pin directly to the ST7735 display board may damage its controller circuit. To avoid that, I connected each control line of the display to the Arduino board through 1k ohm resistor.

The ST7735 TFT display is connected to Arduino hardware SPI module pins (clock and data), the other pins which are: RST (reset), CS (chip select) and DC (data/command) are defined as shown below:

As any other I2C device, the BME280 sensor has an I2C slave address which may be 0x76 or 0x77. This address depends on the connection of the SDO pin (used for SPI mode as serial data out or MISO), if the SDO pin is connected (directly or through resistor) to VCC (3.3V) the address will be 0x77, and if it’s connected to GND the address will be 0x76.

I am working on a simple AVR C project with an ultrasonic sensor (HC-SR04) and SPI communication between the ATmega328P (Arduino) and three cascaded MAX7219 LCD matrix. The objective of the system is to detect and measure the distance using the ultrasonic sensor and display an appropriate message on the LCD matrix simultaneously.

I can perform the main functionality of both components separately. I can detect and measure distance with the HC-SR04 and I can display the text on the LCD matrix and scroll the text as well. The HC-SR04 repeatedly measures the distance roughly every 5ms.

The problem rises when I want to perform both functionalities simultaneously. What happens is that the text message is displayed repeatedly on the LCD matrix but not in full. I understand this is because I repeatedly measure the distance using the ultrasonic sensor. My guess would be interrupts, however I am not sure how to tackle this issue.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey