tft display vs oled factory

A new form of display technology called Organic Light-Emitting Diode (OLED) is sweeping the display world today. Let’s take a look at what TFT display VS OLED display and how it stacks up to TFTs.

OLED display uses a light-emitting diode (LED) that features an organic compound as its emissive electroluminescent layer. Electric current is applied to the diode, activating the organic compound film and giving off light as a result. The organic compound film is typically situated between two electrodes, one of which is transparent.

OLEDs are mostly used in smartphones and limited releases of high-end smart televisions. It can also be used in computer monitors and handheld game consoles.

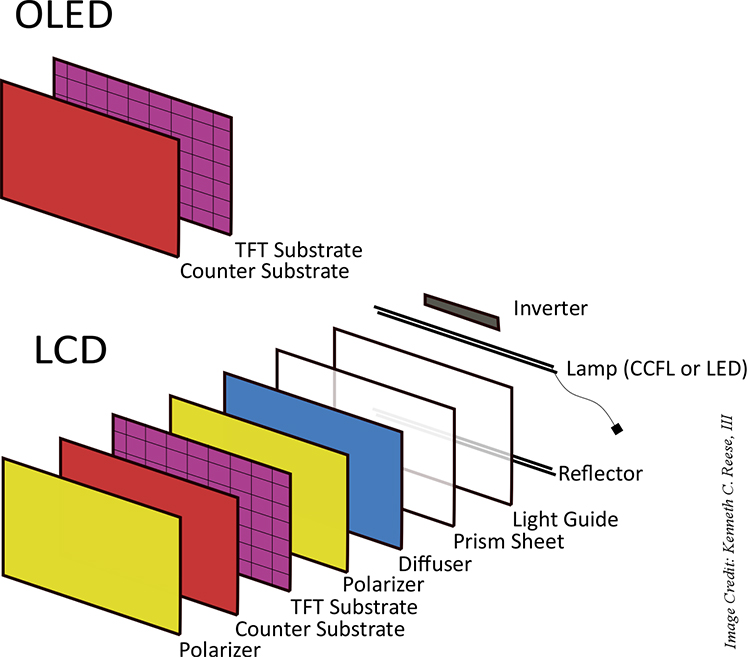

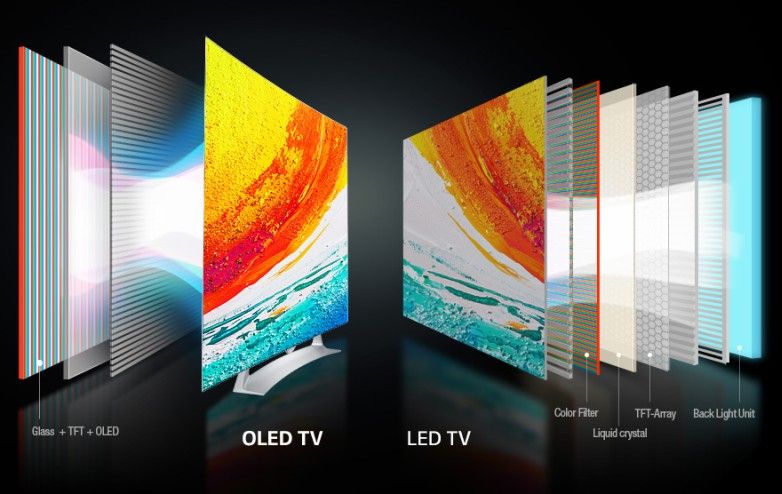

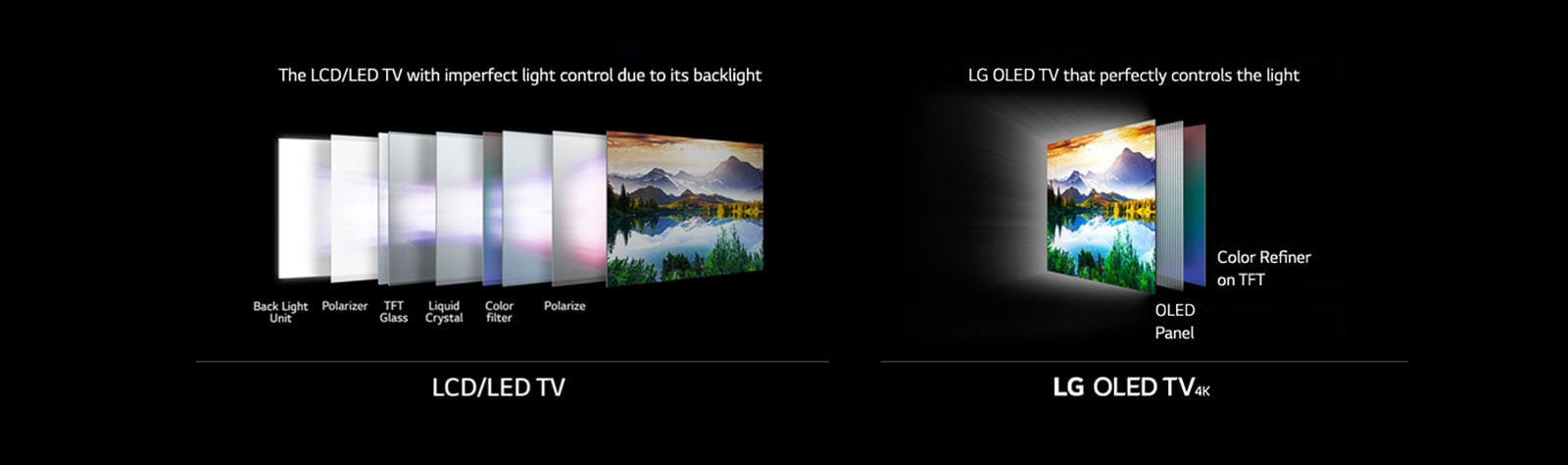

OLED displays naturally emit light, so using them on a display panel doesn’t require a backlight. Meanwhile, LCDs need backlights because the liquid crystals cannot create light on their own. OLED’s natural light emission also paves the way for creating lighter screen devices than those using TFT LCD display.

LCD displays are brighter than OLED. This is due to the LCD’s use of backlights that can brightly light up the entire screen. While OLEDs emit good brightness levels from their light, they can never match the brightness that LCD backlights have.

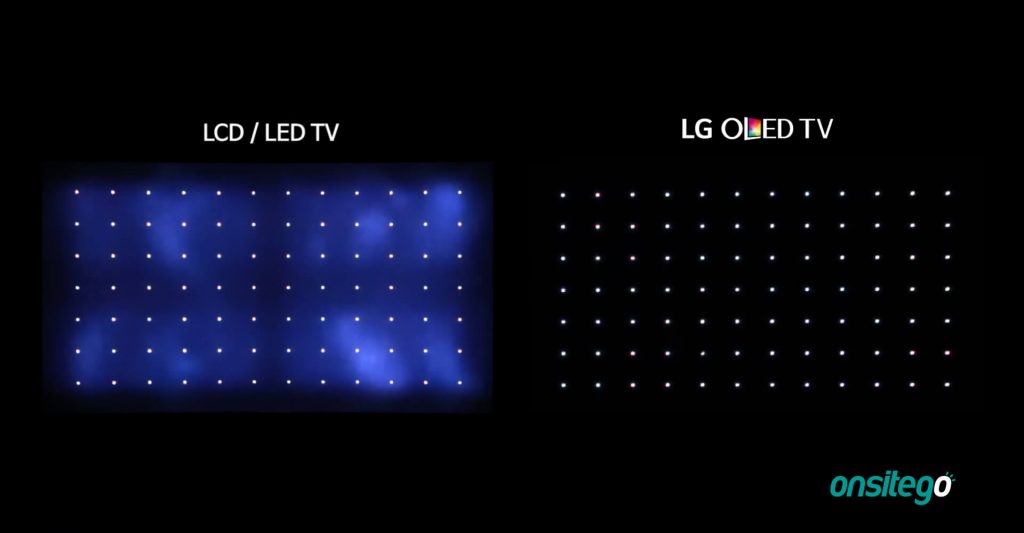

OLED wins in the black levels feature. It’s because OLEDs can perfectly turn off a pixel, causing it to become completely black. LCDs can’t create perfect black screens even with their full-array local dimming feature. LCDs are also prone to blooming, where a bright part spoils the darkness of an adjacent black area.

OLED screens have better viewing angles than LCDs display. Some LCDs improve their viewing angles by using in-plane switching panels (IPS). However, the clarity of images and videos can’t match that of OLEDs when viewed from extreme side angles. This is because LCDs inherently block light due to their filtering layers, and that creates added depth which makes LCD viewing angles limited.

LCD displays are a bit more energy-efficient than OLEDs. Energy consumption in OLED displays depends on the screen brightness. Less brightness used means lower power consumption, but this may not be ideal because the contrast ratio will suffer when brightness is reduced. This is not ideal if, for instance, you’re using an OLED smartphone under bright sunlight.

Meanwhile, the backlights form the bulk of power consumption in TFT displays. Putting the backlight to a lower setting significantly improves the energy efficiency of TFT displays. For instance, reducing the backlight brightness of an LCD TV with a LED backlight won’t affect the picture quality but will draw less power consumption than an OLED TV.

Both OLED and LCD create high-quality images with a wide color gamut on a screen. OLED display wins over TFT display regarding blackness levels and viewing angle. However, the TFT display takes the cake for brightness and energy efficiency.

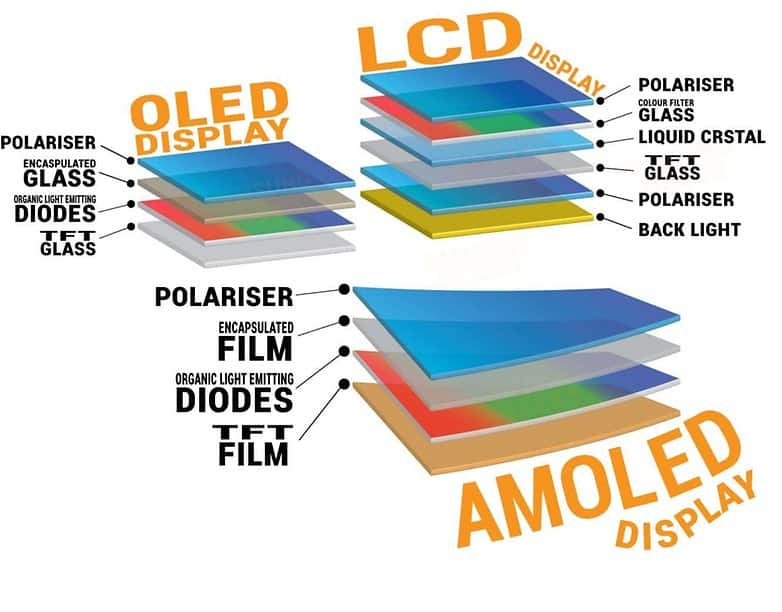

AMOLED is another emerging display technology lately. It stands for Active Matrix Organic Light-Emitting Diodes. AMOLED is a type of OLED display used in several smartphones, digital cameras, televisions, and media players.

Thin film transistors (TFTs) and capacitors are attached to each pixel LED component of the panel. At least two TFTs are attached to one pixel – one to control the capacitor’s charging and another to give a voltage source.

AMOLED displays have better color accuracy than LCDs. What makes the color more accurate in AMOLED displays is largely due to the precise pixel control achieved by AMOLED panels.

Whites and blacks appear perfect in AMOLED displays. Whites produced by LCDs may carry a bluish tint due to the backlight. Blacks don’t completely appear dark in LCDs, too.

AMOLED provides a greater color gamut than LCDs. AMOLEDs (and all OLED displays in general) have additional blue and green saturation. While these hues greatly widen AMOLED’s color options, some people find the resulting colors a bit unnatural to look at.

Meanwhile, LCDs have subdued greens and quite compelling red hues. Its color gamutmay not be as wide as AMOLED’s, but many people still find it satisfying. That’s because LCD’s color range closely matches the Standard RBG color gamut profile, the one most utilized in videos and images.

LCD’s backlights help maintain the color balance of the entire screen. The backlights ensure that color balance remains consistent across the display. Meanwhile, AMOLED tends to suffer from very slight color balance drifts because of variances in the diodes’ light-emitting capacity over time.

LCDs often have a lower contrast ratio and are prone to light bleeds. That’s due to the backlights remaining open even if light has been blocked and the pixels are supposed to show black color. This is not a problem with AMOLED displays because the panel can simply switch off the pixel to create a pure black color. AMOLEDs have a better contrast ratio as exhibited by their pure black and white levels.

Since AMOLED displays do not require filtering layers and backlights, they’re more suited for use in handheld mobile devices such as smartphones and gaming consoles. LCD may be used in mobile devices as well, but the filtering layers and backlights tend to add a slight bulk to the device. Hence, many manufacturers are now switching to thinner and lighter AMOLED displays.

To sum up this part, AMOLED displays fare better than LCDs in terms of color gamut, accuracy, contrast, and mobile device suitability. However, LCDs have the potential for longer lifespans and carry a better color balance across the display device.

Display P3 is an Apple-developed color space heavily used in American films and digital movie projection. It allows devices to display richer, vibrant, and more lifelike colors that are demanded in videos and movies. It’s also created for adapting to computer displays.

Display P3 has a color space based on the DCI-P3 primaries. It uses the D65 white point which is typically used in color spaces for computer displays. Display P3 also utilizes the sRGB transfer curve in place of the DCI-P3’s 1/2.6 pure gamma curve.

If you compare color LCD vs Display P3, you’ll find a significantly wider color range in Display P3 than the typical sRGB used in color LCDs. LCD monitors, especially those used in computers and laptops, are configured to accurately represent the sRGB gamut as precisely as possible. Meanwhile, Display P3 has been consistently used in Apple products since 2015, starting with the iMac desktop.

Display P3 is not limited to Apple devices, though. Several devices have been configured to support Display P3 as well. These include smartphones from Samsung, OnePlus, Google, and HTC. Even Windows-based laptops from Acer and Asus support Display P3 color gamut.

That’s all the basic information you need to know about LCD display screens. And the difference between TFT Display VS OLED Display. Now, you know How LCD Works, its possible lifespan, components, and how it compares to other display technologies.

Armed with this information, you can better appreciate and take care of your LCD display devices. And in case you’re planning to add display devices to your business, the information you’ve learned will help you make educated choices regarding the display technologies you’ll utilize.

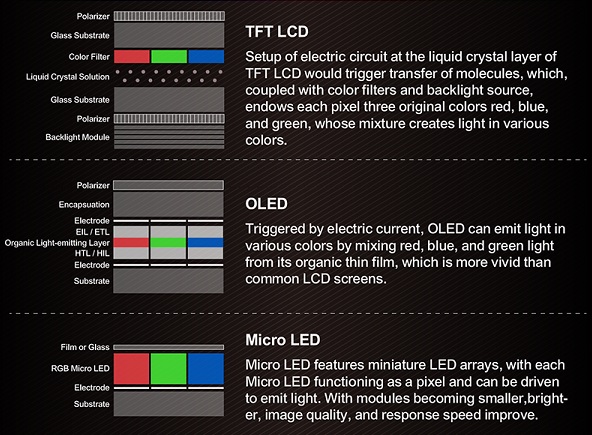

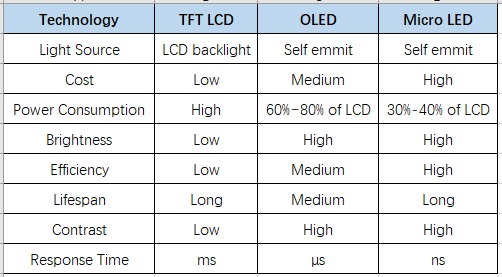

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Low power consumption and flexible: OLED doesn"t rely on backlight and consumes less power. OLED is essentially created on plastic film. It is bendable and easy to process.

High contrast and vivid color: OLED emits light itself, can produce very bright image with beautiful color. And because OLED can be turned off, it can produce true black.

Stroboscopic effect: most OLED screen uses PWM dimming technology. Some people who are easy perceive stroboscopic frequency may have sore eyes and tears.

Micro LED, sometimes called μLED is made up of tiny LED, measure less than 100μm. Another way of looking at this is that MicroLEDs are simply traditional LEDs shrunk down and placed into an array.

Replacing organic material with inorganic GaN material eliminates the need of polarizing and encapsulation layer, found in OLED. Micro LED is smaller and thinner, consumes less power.

TFT displays are also known as an “Active Matrix TFT LCD module” and have an array of thin film transistors fabricated on the glass that makes the LCD. There is one of these transistors for each pixel on the LCD. See our blog post RGB and Color Depth for more on how TFTs show color.

LCDs use voltage applied to a field of microscopic liquid crystals to change the crystal’s orientation. The orientation of the crystals changes the polarization of the liquid crystal creating light or dark pixels on the display.

These pixels are arranged to create characters or graphic images. This type of display may be sunlight-readable and may have a backlight, which allows it to be viewed in dark areas.

Beautiful, complex images: All of our TFT modules are full-color graphic displays. Unlike standard monochrome character displays, you can create complex images for an imaginative user experience.

Thin and light: These are ideal display modules for handheld devices, communications equipment, information displays, and test and measurement equipment.

Single Supply: Most of the TFTs use an integrated controller with built-in voltage generation so only a single 3.3v supply is needed for both the panel power and logic voltage.

Many of the LCD controllers on board our graphic LCD display modules also include a CGROM (character generator ROM) which allows for easy character information as well as full bit-mapped graphic information to be shown.

Some of the graphic LCD displays have the ability to render graphics in grayscale, enabling you to show images and elements of your UI (user interface) with more depth and definition.

Because OLEDs are emissive, these displays can always be used in dark environments. There is usually a software command or hardware setting that will allow OLEDs to be dimmed.

Some OLED displays are bright enough to be sunlight readable–these models will typically take more current and may have a shorter rated lifetime. Additionally, OLEDs have extremely wide viewing angles.

What makes OLEDs useful for display construction is that they can be fabricated in bulk. Using OLED fabrication techniques, all the diodes can be made at the same time, at a much lower cost. OLEDs also come in a wide variety of colors.

In market, LCD means passive matrix LCDs which increase TN (Twisted Nematic), STN (Super Twisted Nematic), or FSTN (Film Compensated STN) LCD Displays. It is a kind of earliest and lowest cost display technology.

LCD screens are still found in the market of low cost watches, calculators, clocks, utility meters etc. because of its advantages of low cost, fast response time (speed), wide temperature range, low power consumption, sunlight readable with transflective or reflective polarizers etc. Most of them are monochrome LCD display and belong to passive-matrix LCDs.

TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy without running out of operation.

Normally, we say TFT LCD panels or TFT screens, we mean they are TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology. TFT is active-matrix LCDs, it is a kind of LCD technologies.

TFT has wider viewing angles, better contrast ratio than TN displays. TFT display technologies have been widely used for computer monitors, laptops, medical monitors, industrial monitors, ATM, point of sales etc.

Actually, IPS technology is a kind of TFT display with thin film transistors for individual pixels. But IPS displays have superior high contrast, wide viewing angle, color reproduction, image quality etc. IPS screens have been found in high-end applications, like Apple iPhones, iPads, Samsung mobile phones, more expensive LCD monitors etc.

Both TFT LCD displays and IPS LCD displays are active matrix displays, neither of them can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to make LCD showing colors. If you use a magnifier to see your monitor, you will see RGB color. With switch on/off and different level of brightness RGB, we can get many colors.

Neither of them can’t release color themselves, they have relied on extra light source in order to display. LED backlights are usually be together with them in the display modules as the light sources. Besides, both TFT screens and IPS screens are transmissive, it will need more power or more expensive than passive matrix LCD screens to be seen under sunlight. IPS screens transmittance is lower than TFT screens, more power is needed for IPS LCD display.

TFT stands for ‘Thin Film Transistor’ – it is a type of LCD that gives higher resolution and better image quality than standard LCDs. These are usually coloured, but Mono is becoming more popular and therefore more readily available.

OLED stands for ‘Organic Light Emitting Diode’. It has a layer of organic compound that emits its own light eliminating the requirement for a backlight. They are super thin, have a really wide viewing angle with exceptional contrast ratios. Some can also be curved, creating all sorts of interesting new applications for example LG’s new ‘wallpaper TV’.

Displays are measured using ‘lumens’, which are also known as ‘nits’. The brightness should be measured in 5 different points on the front of the display to give you an average reading. Adding filters, touch screens or lenses will all decrease the overall brightness of a display so it should always be measured after these add-ons. Some displays are now as bright as 1500 nits or lumens.

This depends on the application and what you want to achieve, this is a very subjective question. LCDs can be very cheap – the older green and black ones (think calculators for example) can be extremely cheap, but they are not as colourful or easy to read as newer technologies. TFTs will give you full colour and a higher solution than an LCD, but they are more difficult to drive and tend to be more expensive. OLED is a relatively new technology. OLEDs are lower power than TFT and offer very good viewing, but have lifetime issues and are only available in smaller sizes.

Capacitive touch is most commonly used in products such as smartphones. It’s used in all sorts of applications currently but it’s difficult to get working. Capacitive is a lot more expensive than resistive but it does enable nice gesture features and has the ability to have a cover lens. Resistive touch screens are much cheaper and easier to drive, but do suffer from a mottled effect over the display and can be damaged easily as there is no cover lens.

OLEDs currently range from 1” to 6” – Please note manufacturers such as LG have much bigger OLED televisions but these are a different technology to those available in the industrial market.

For LCD and TFT displays, most power is consumed by the backlight. If you turn the backlight off on a standard LCD, the display itself can run from batteries for many days.

Nearly all TFTs need to have their backlight on to be able to work, which is why your tablet or phone shuts down the backlight quickly when it detects you are not using it. There are some TFTs that can work with no backlight, but they are unique and expensive.

An OLED is self-emitting, so has no backlight. With an OLED, power consumption is controllable by the user – if you want the battery to last longer then dim the display, or show fewer dots as each dot consumes power.

An LCD will work very well in direct sunlight. We actually use the sunlight as the backlight, as it bounces off the rear and becomes part of the display.

We can also achieve this in TFT by adding special films - it does decrease the overall brightness of the display but enables it to be run in direct sunlight.

We all use and handle TFTs in our daily lives with phones, monitors, laptops etc. All of these use TFT displays, but they are very different to TFTs we may use in industrial applications. Why is this?

Consumer electronics have a different specification requirement to those of us in the industrial world. From the outside, they may well look the same with the same TFT cell and white LED backlights, but the differences then start to show. Laptop screens for example are designed to be as thin and lightweight as possible – often just 3mm thick and very susceptible to physical damage, not something you would want in an industrial application.

Consumer TFTs are also designed for typically one product, and when the next one is launched their specification will change to meet the requirements of that next generation, often meaning things like mounting holes and connector positions have changed in the space of a few months.

Interfaces to consumer displays also tend to use protocols designed for highly integrated systems like mobile phones and the ability to drive them requires you to use the latest mobile platform’s chipset.

Industrial displays have been designed and developed to overcome all of these issues. They use fixed rigid mounting holes, the interfaces are industry standard and most importantly they have a guaranteed lifetime of at least 5 years, so you can guarantee you will not have to redesign your own product due to TFT changes.

Intelligent Display Solutions (IDS) has recently introduced a whole family of industrial TFTs into RS Components, all incorporating the latest technology and all available for 5 years minimum.

All of this, with the latest high resolutions and bright backlights, means these displays are the best you can currently buy as an industrial product.

Intelligent Display Solutions (IDS) is a division of Intelligent Group Solutions Ltd. (IGS), a well-established respected industry-leading Optoelectronics solutions provider since 2001.

It"s an organic light-emitting display. OLED display technology is different from the traditional LCD display mode, without backlight. It uses a very thin coating of organic materials and a glass substrate, which emit light when an electric current passes through. Moreover, OLED screen module can be made lighter and thinner, with larger viewing angle, and can significantly save power.

AMOLED is panel-self luminous. The TFT is illuminated on the LCD panel by backlight. AMOLED effect is more colorful and brighter. The screen can be seen clearly outside during the day. The most important is that the power consumption of AMOLED is much lower. AMOLED screen is more expensive than TFT LCD touch screen. The life of AMOLED screens is also longer.

AMOLED, after all, is a new technology, which has a bright future. TFT LCD touch screen can be thinned, and LTPS technology is still relatively stable. AMOLED module has low qualified rate and long lead time. So if the size and resolution are the same, buy the cheapest one.

Kingtech LCD is one of the leading TFT LCD OEM / ODM LCD display manufacturers in China. Customizing industrial equipment, medical, POS, logistics equipment, smart home applications and other projects is allowed.

OLED relies on its own light to display images, does not need to use backlight, and is not affected by the surrounding light. Its general life is about 5000 times. TFT is an active matrix liquid crystal, and needs to use the brightness of backlight to display images, which is affected by the surrounding light, and its general life is about 20000 times.

OLED display is essentially different from traditional LCD display, that is, it does not need backlight. It uses very thin organic material coating and glass substrate. When there is current, these organic materials will emit light. Therefore, OLED LCD screen can be made lighter and thinner, with a larger viewing angle and more power saving at the same time. However, it has a short service life and can"t make the screen bigger. OLED is mostly used for folding mobile phone screen.

TFT thin film transistor (TFT) is the current material LCD screen. It belongs to the active matrix type LCD screen. There is a special lamp on the back, which can "actively" control each independent pixel on the screen. This is what we often call active matrix TFT. The reaction time is relatively fast, about 80 ms, and the visual angle is large, usually about 130 degrees, It is used in some high-end models. Because the arrangement of TFT LCD has memory, it will not recover immediately after the current disappears, which effectively improves the ability of playing dynamic pictures. The disadvantages are power consumption and high manufacturing cost.

OLED color screen is 30% more expensive than TFT color screen of the same size! The big difference between true color OLED screen and TFT screen is that OLED true color screen has high screen contrast and fuller color restoration, and OLED true color screen is better than TFT screen in backlight and brightness.

If you’re designing a display application or deciding what type of TV to get, you’ll probably have to choose between an OLED or LCD as your display type.

Not sure which one will be best for you? Don’t worry! We’re here to help you figure out the right display for your project or application. In this post we’ll break down the pros and cons of these display types so you can decide which one is right for you.

LCDs utilize liquid crystals that produce an image when light is passed through the display. OLED displays generate images by applying electricity to organic materials inside the display.OLED and LCD Main Difference:

These different technological approaches to display technology have big impact in some features including contrast, brightness, viewing angles, lifespan, black levels, image burn-in, and price.

Everything from the environment your display will be used in, your budget, to the lighting conditions and the required durability will play a part in this decision.

Contrast refers to the difference between the lightest and darkest parts of an image. High contrast will produce sharper images and more easily readable text. It’s a crucial quality for high fidelity graphics and images or to make sure that a message on a display is very visible.

graphics and images visible. This is the reason you’re still able to see light coming through on images that are meant to be dark on an LCD monitor, display, or television.

OLEDs by comparison, deliver a drastically higher contrast by dynamically managing their individual pixels. When an image on an OLED display uses the color black, the pixel shuts off completely and renders a much higher contrast than that of LCDs.OLED vs LCD - Who is better at contrast?

Having a high brightness level is important if your display is going to be used in direct sunlight or somewhere with high ambient brightness. The display"s brightness level isn"t as important if it’s going to be used indoors or in a low light setting.OLED vs LCD - Who is better at Brightness?

This means the display is much thinner than LCD displays and their pixels are much closer to the surface of the display, giving them an inherently wider viewing angle.

LCDs with IPS are significantly brighter than standard LCDs and offer viewing angles that are on-par with OLEDs.OLED vs LCD - Who is better at Viewing Angles?

LCDs have been on the market much longer than OLEDs, so there is more data to support their longevity. On average LCDs have proven to perform for around 60,000 hours (2,500) days of operation.

With most LCDs you can expect about 7 years of consistent performance. Some dimming of the backlight has been observed but it is not significant to the quality of the display.

OLEDs are a newer technology in the display market, which makes them harder to fully review. Not only does OLED technology continue to improve at a rapid pace, but there also hasn’t been enough time to thoroughly observe their performance.

You must also consider OLED’s vulnerability to image burn-in. The organic material in these displays can leave a permanent afterimage on the display if a static image is displayed for too long.

So depending on how your OLED is used, this can greatly affect its lifespan. An OLED being used to show static images for long periods of time will not have the same longevity as one displaying dynamic, constantly moving images.OLED vs LCD - Which one last longer?

There is not yet a clear winner when it comes to lifespans between LCD and OLED displays. Each have their advantages depending on their use-cases. It’s a tie!

For a display application requiring the best colors, contrast, and viewing angles – especially for small and lightweight wearable devices – we would suggest an OLED display.

Engineers should choose TFT vs OLED for new designs…and here’s why. OLED (organic light-emitting diode) technology continues to increase in popularity, but its growth has really exploded in the last few months due to such large-scale mass production of consumer products such as: e-cigarettes (personal vaporizers), smart-watches, cell phones and other wearables.

But these advantages have worked against OLEDs in new products as more and more new designs have incorporated OLEDs, increasing demand, while the supply side of this technology has failed to keep pace.

“There are only a handful of factories here in Shenzhen that produce OLED screens,” says Alex Liu, President of EC Supply Inc., a leading distributor of vape and electronic cigarette products. “These factories are extremely understaffed for the tens of millions of OLED screens that are in demand, yet everyone wants to jump on board the wearable technology craze. These factories simply lack the work force and raw materials to keep up with production of wearables, let alone fulfill relatively small orders for the vape industry in time for the holiday season.”

Adding to the OLED supply nightmare is the labor shortage in China coupled with many OEM customers increasing their order quantities in a race to beat the Chinese New year shut down.

“I strongly recommend customers purchase any MODs with OLED screens through a trusted source that can guarantee inventory.” – Alex Liu, President of EC Supply Inc.

TFT technology has been in production for several years and is here to stay. There are several TFT glass suppliers to support current demand and they have a great deal of capacity for increased demand.

Focus Displays carries TFT Displays as a standard stock item and can be shipped the same day from our online store as well as from distributor: Allied Electronics

OLED stands for Organic Light Emitting Diode and is made up of individual image elements called pixels comprised of organic chemical compounds which emit light when an electric current is applied between a anode and cathode of each pixel. This process is similar in operation to a standard LED operation where light emission is through the recombination of electrons and holes from the cathode and anode.

OLEDs and LCDs are used in display devices but are very different in how they present their display information. An OLED is an emissive type of display meaning it’s self-illuminating. An LCD, however, presents information via transmissive or transflective methods, which means that image illumination is supplied with methods such as a backlight and room light or the sun.

PMOLED stands for Passive Matrix OLED and is fabricated of emitting OLED pixel arrays configured in columns and rows with each pixel intersecting at a column row. These OLED pixels are arranged where their anodes are current driven by an electronic controller chip which also controls the cathode turn on to produce the desired display image.

The controller electronic continually scans the entire OLED column and row array at a set frame rate to produce an image. Because of this, the most power efficient display designs are best in smaller display sizes of 3” or less.

AMOLED stands for Active Matrix OLED and is fabricated similarly to a TFT display with each individual pixel element being addressable unlike the row and column design of a PMOLED. PMOLED displays are good for displaying text but fall short when displaying moving images due to the time needed to scan the rows and columns which can cause a perceived ghosting.

On the contrary, with an AMOLED, each individual OLED pixel can be turned on individually without the need to scan an entire array making them far superior for moving images. This allows the AMOLED to produce an image without any ghosting. This individually pixel design also allows for better illumination control for a brighter, higher contrast, more power efficient display. AMOLED displays are much faster the LCDs which makes them more attractive for video displays.

OLED displays have an advantage over other displays such as TFT LCDs since they are a self emitting light source and do not need a separate external light source in order to display an image. Therefore, they are more efficient. This self-illumination allows OLED displays to be much thinner than other technologies and can even be used in flexible displays as well. Some other advantages are:

Shorter lifetime then some other display technologies. This shorter lifetime is mainly due to the blue organic material but lifetime gets better all the time but is also due to moisture migration.

The current production processes make it difficult and costly to produce large displays so most are limited to handheld devices, but like the lifetime issue this eventually will be improved.

OLED displays have found their way into many handheld products since their onset and continue to be popular in the mobile market. OLED displays can also be found in gaming applications and audiovisual applications such as programmable push button switches. OLED displays can also be found in cameras, PDA’s, and a few small TV’s.

AMOLED and TFT are two types of display technology used in smartphones. AMOLED (active-matrix organic light-emitting diode) displays are made up of tiny organic light-emitting diodes, while TFT (Thin-Film Transistor) displays use inorganic thin-film transistors.

AMOLEDs are made from organic materials that emit light when an electric current is passed through them, while TFTs use a matrix of tiny transistors to control the flow of electricity to the display.

Refresh Rate: Another key difference between AMOLED and TFT displays is the refresh rate. The refresh rate is how often the image on the screen is updated. AMOLED screens have a higher refresh rate than TFT screens, which means that they can display images more quickly and smoothly.

Response Time: The response time is how long it takes for the pixels to change from one colour to another. AMOLED screens have a shorter response time than TFT screens..

Colour Accuracy/Display Quality: AMOLED screens are more accurate when it comes to displaying colours. This is because each pixel on an AMOLED screen emits its own light, which means that the colours are more pure and true to life. TFT screens, on the other hand, use a backlight to illuminate the pixels, which can cause the colours to appear washed out or less vibrant.

Viewing Angle: The viewing angle is the angle at which you can see the screen. AMOLED screens have a wider viewing angle than TFT screens, which means that you can see the screen from more angles without the colours looking distorted.

Power Consumption: One of the main advantages of AMOLED displays is that they consume less power than TFT displays. This is because the pixels on an AMOLED screen only light up when they need to, while the pixels on a TFT screen are always illuminated by the backlight.

Production Cost: AMOLED screens are more expensive to produce than TFT screens. This is because the manufacturing process for AMOLED screens is more complex, and the materials used are more expensive.

Availability: TFT screens are more widely available than AMOLED screens and have been around for longer. They are typically used in a variety of devices, ranging from phones to TVs.

Usage: AMOLED screens are typically used in devices where power consumption is a concern, such as phones and wearable devices. TFT screens are more commonly used in devices where image quality is a higher priority, such as TVs and monitors.

AMOLED and TFT are two different types of display technology. AMOLED displays are typically brighter and more vibrant, but they are more expensive to produce. TFT displays are cheaper to produce, but they are not as bright or power efficient as AMOLED displays.

The display technology that is best for you will depend on your needs and preferences. If you need a screen that is bright and vibrant, then an AMOLED display is a good choice. If you need a screen that is cheaper to produce, then a TFT display is a good choice. However, if you’re worried about image retention, then TFT may be a better option.

Nauticomp Inc.provides world-class fully customizable touchscreen displays for commercial and industrial settings. With features like sunlight readability, brightness adjustability, infrared lighting, full backlighting, all-weather capabilities, etc., our displays are second to none. Contact us today to learn more.

LCD is the abbreviation for liquid crystal display. An LCD basically consists of two glass plates with a special liquid between them. The special attribute of this liquid is that it rotates or “twists” the plane of polarized light. This effect is influenced by the creation of an electrical field. The glass plates are thus each coated with a very thin metallic film. To obtain polarized light, you apply a polarization foil, the polarizer, to the bottom glass plate. Another foil must be applied to the bottom glass plate, but this time with a plane of polarization twisted by 90°. This is referred to as the analyzer.

Liquids that twist the plane of polarized light by 90° are referred to as TN (Twisted Nematic). STN (Super Twisted Nematic) liquids twist the plane of polarized light by at least 180°. This gives the display improved contrast. However, this technology does color the display to a certain extent. The most common colors are referred to as yellow-green and blue mode. There is also a gray mode, which in practice is more blue than gray, however.

In order to counteract the undesired color effect, the FSTN technology uses an additional foil on the outer side, but this causes a loss of light and means that this technology is only effective with lit displays.

However, the different colors occur only in displays that are either not lit or that are lit with white light. If there is any color in the lighting (e.g. yellow-green LED lighting), it overrides the color of the display. A blue-mode LCD with yellow-green LED lighting will always appear yellow-green.Static or multiplex driving method

Small displays with a small viewing area are generally statically driven. Static displays have the best contrast and the largest possible angle of view. The TN technology fulfills its purpose to the full here (black and white display, reasonably priced). The bigger displays get, however, the more lines become necessary in static operation (e.g. graphics 128x64=8192 segments =8192 lines). Since there is not enough space on either the display or a driver IC for so many lines, multiplexing is used. The display is thus divided up into rows and columns, and there is a segment at each intersection (128+64=192 lines). Scanning takes place row by row (64x, in other words a multiplex rate of 1:64). Because only 1 row is ever active at any one time, however, the contrast and the angle of view suffer the higher the multiplex rate becomes. This makes it essential to use STN.Angle of view 6°°/12°°

Every LCD has a preferred angle of view at which the contrast of the display is at its optimum. Most displays are produced for the 6°° angle of view, which is also known as the bottom view (BV). This angle corresponds to that of a pocket calculator that is lying flat on a desktop.

12°° displays (top view, TV) are best built into a table-top unit. All displays can be read vertically from the front.Reflective, transflective, transmissive

However, the lighting also determines the optical impression made by the display, and the display mode; blue or yellow-green – does not always have an influence. Below you can see the EAP162-3N display with different types of lighting by way of example:Lighting

Standard LCDs have a temperature range of 0 to +50°C. High-temperature displays are designed for operation in the range from -20 to +70°C. In this case, however, additional supply voltage is generally required. Since the contrast of any LCD is dependent on the temperature, a special temperature-compensation circuit is needed in order to use the entire temperature range, and this is particularly true for high-temperature displays (-20 to +70°C). Manual adjustment is possible but rather impractical for the user.

However, the storage temperature of a display should never be exceeded under any circumstances. An excessively high temperature can destroy the display very quickly. Direct exposure to the sun, for example, can destroy an LCD: This is because an LCD becomes darker (in positive mode) as it gets hotter. As it gets darker, it absorbs more light and converts it to heat. As a result, the display becomes even hotter and darker... In this way, temperatures of over 100°C can quickly be reached.Dot-matrix, graphics and 7-segment displays

The first LCDs were 7-segment displays, and they are still found today in simple pocket calculators and digital watches. 7 segments allow all of the digits from 0 to 9 to be displayed.

Text displays require what is known as a dot matrix, an area consisting of 5x7=35 dots, in order to display all of the letters in the alphabet as well as various special characters. Graphics displays have a similar structure to text displays. In this case, however, there are no spaces between the lines and characters.Display drivers and controllers

The semiconductor industry now offers a very large range of LCD drivers. We generally distinguish between pure display drivers without intelligence of their own, controllers with a display memory and possibly a character set, and micro-controllers with integrated LC drivers.

Pure display drivers work in a similar way to a shift register. They generally have a serial input. They require an external pulse, and in multiplex operation with high frequency they require new display data continuously in order to achieve a refresh frequency that is as high as possible (MSM5219, UPD7225, HD44100, LC7942, etc.). An example of a genuine controller is theHD44780 for dot-matrix displays: Once it has received the ASCII code, the controller manages its character set, memory and multiplexing entirely on its own. The following controllers are widely used for graphics displays: HD61202/3, HD61830, SED1520, SED1330, T6963.

Many ask themselves, "What is the difference between an LCD display and a TFT display?" or "What is the difference between a TFT and an OLED display?". Here are these 3 sometimes extremely different display technologies briefly explained. LCD vs. TFT vs. OLED (comparison).

- The LCD (Liquid Crystal Display) is a passive display technology. The operation and the structure are described above. Passive means that an LCD can only darken or let out light. So it always depends on ambient light or a backlight. This can be an advantage because the power consumption of a LCD display is very, very low. Sometimes even less than the accumulated power consumption of an E-paper display, which in static operation requires absolutely no energy to maintain the content. To change the contents, however, a relatively large amount of power is required for an E-paper display.

LCDs can also be reflective, so they reflect incident light and are therefore legible even at maximum brightness (sunlight, surgical lighting). Compared to TFT and also OLED, they have an unbeatable advantage in terms of readability and power consumption :; the "formula" is: Sunlight = LCD.

- A TFT display (of Thin-Film Transistor) is usually a color display (RGB). From the construction and the technology it corresponds to the LCD. It is also passive, so it needs a backlight. This is in any case necessary except for a few, very expensive constructions. However, a TFT needs much more light than the monochrome relatives, because the additional structures on the glass as well as the additional color filters "swallow" light. So TFTs are not particularly energy-efficient, but can display in color and at the same time the resolution is much higher.

- OLED displays (by Organic-Light-Emitting-Diode) are as the name implies active displays - every pixel or sign generates light. This achieves an extremely wide viewing angle and high contrast values. The power consumption is dependent on the display content. Here OLEDs to TFTs and LCDs differ significantly, which have a nearly constant power consumption even with different display contents. Unfortunately, the efficiency of converting the electric current into light energy is still very poor. This means that the power consumption of OLEDs with normal content is sometimes higher than that of a TFT with the same size. Colored OLEDs are increasingly used in consumer devices, but for the industry, due to their availability and lifetime, currently only monochrome displays are suitable (usually in yellow color).

In the reaction time, the OLEDs beat each TFT and LCD by worlds. Trise and Tfall are about 10μs, which would correspond to a theoretical refresh rate of 50,000 Hz. Possibly an advantage in very special applications.

Finally the question "What is better, LCD, OLED or TFT?" Due to the physical differences you can not answer that blanket. Depending on the application, there are pros and cons to each individual technology. In addition to the above differences, there are many more details in the design and construction that need to be individually illuminated for each device. Write us an e-mail or call us: we have specialists with some 20- and 30-year experience. We are happy to compare different displays together with you.AACS and IPS technology

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

Reports suggest that Apple is getting closer to implementing MicroLED in its future product releases, including the Apple Watch, with the display technology potentially offering a number of benefits compared to other methods. AppleInsider explains how the current TFT and OLED display technologies work, and how MicroLED differs.

MicroLED shows promise as a display technology, potentially offering power savings and a reduced screen thickness when put beside current-generation display panels. Apple has recognized the potential, and has invested heavily into developing the technology over the last few years, with a view to using it in the company"s future products.

To understand fully how MicroLED can benefit Apple, it is worth understanding how the commonly-used display technologies work in the first place, before examining how different MicroLED really is in a comparison.

The most common display technology used by consumer products today, and the oldest of the technologies examined in this article, TFT"s full name of TFT LCD stands for Thin-film-transistor liquid-crystal display. This technology is extensively used by Apple in its products, found in iPads, iPhones, MacBooks, and iMac lines.

The LCD part relates to the concept of defining small translucent or transparent areas in a thin and flexible liquid crystal-filled panel, like the displays used in calculators. Passing current through the segment changes the molecular properties of the defined segment area, allowing it to switch between being see-through or opaque.

TFT takes this a stage further, by effectively covering an entire panel with a grid of isolated liquid crystal segments, which again can vary between opaque and transparent based on the level of electrical current. In this case, there are far more segments needed to make up the display than with a normal calculator.

Polarizing filters on either side of the TFT display sandwich are used to prevent light from passing through directly, with the liquid crystal reaction of each segment affecting polarized light passing through the first filter to go through the second.

Sometimes these types of display are known as "LED," but this somewhat of a misnomer, as this actually refers to the use of Light Emitting Diodes as a light source. The LED backlight shines light through the various layers making up the TFT LCD.

Displays that use collections of LEDs as individual pixels do exist, but it isn"t usually found in consumer products. LED screens are commonly used for billboards, in attractions, and as a large-scale display for events.

TFT LCD screens continue to be widely used in production for a number of reasons. Manufacturers have spent a long time perfecting the production of the display panels to make it as cheap as possible, while its high usage allows it to benefit from economies of scale.

Used in consumer devices in a similar way to TFT LCD, OLED (Organic Light-Emitting Diode) is a display technology that is similar in the basic concept, but differs considerably in its execution. Again, the idea is for a thin panel to be divided up into segments, with charge applied to each section to alter its molecular properties, but that"s where the techniques diverge.

As the name implies, OLED uses an organic compound film that is put between two electrodes, which are used to provide charge. Instead of the charge changing how light passes through, the current instead causes the emissive electroluminescent layer to emit light, without the need for a rear light source.

These self-emitting pixels gives OLED a considerable advantage over LCD-based systems in a number of areas. Most obviously, by not needing a backlight, OLED panels can be made far thinner than an equivalent LCD-based display, allowing for the production of thinner devices or more internal area for other components, like a larger battery.

The power efficiency of OLED panels can be far greater, as while a TFT screen requires an always-on backlight, the brightness of OLED pixels themselves determine power usage, with a black pixel consuming no power at all. OLED screens are also faster to respond than LCD displays, making them more useful for VR displays, where response time needs to be as rapid as possible.

This also allows OLED to provide superior contrast ratios compared to TFT, as the lack of backlight bleed-through that occurs in TFT simply doesn"t happen in OLED.

OLED also can be produced on plastic substrates instead of glass, allowing it to be used to create flexible displays. While this is currently embodied in curved and other non-flat screens in some devices, it has the potential to be employed in foldable smartphones or rolled up for storage, an area Apple is also allegedly examining.

Despite the advantages, OLED is still lagging behind TFT in terms of adoption. The cost of production is far higher, in part due to the need for extremely clean environments, as a single speck of dust can potentially ruining a display during fabrication.

OLED panels are also affected by the presence of water, both in production and in use. Small amounts of water contacting the organic substrate can cause immediate damage to the display, rendering parts of the screen useless.

So far, Apple"s usage of OLED consists of the premium iPhone X and the Apple Watch. As the cost of production drops down, it is plausible for Apple to use OLED in more future products, providing a better screen for customers to use.

Thought to be the next big thing in display technology, MicroLED basically takes the idea of using LEDs for pixels in a large stadium-style screen and miniaturizes it all.

Using extremely small LEDs, three MicroLEDs are put together to create each pixel, with each subpixel emitting a different color from the usual red, blue, and green selection. As each LED emits light, there is no need for a backlight as used in TFT screens.

MicroLED doesn"t use an organic compound to produce light, making it less susceptible to failure compared to OLED. Just like OLED, it can be applied onto a flexible material, allowing it to be used for curved displays or non-stationary components, like a watch strap, and can result in an extremely thin display panel.

MicroLED offers the same lower power consumption and high contrast ratio benefits as OLED when compared to TFT. However, MicroLED is also capable of producing a far brighter image than OLED, up to 30 times brighter, and is in theory more efficient in converting electricity into light.

As a relatively new and in-development technology, the cost of MicroLED production is extremely high in comparison to the more established OLED and TFT mass production lines, in part due to lower than required yields. Manufacturing equipment vendors have produced hardware for MicroLED production that cuts defects in half and reduces deposition deviance from 3 nanometers down to 1 nanometer, but it is unclear if this is enough to help mass production move forward.

While MicroLED is an attractive proposition for Apple, it is not the only technology under development by the company"s engineers. Apple has previously filed patent applications for a technology described as "Quantum Dot LED and OLED Integration for High Efficiency Displays."

Quantum Dots are photoluminescent particles included in an LED-backed TFT display that can produce brighter and more vibrant colors, with the colors produced depending on their size. While available in current QLED televisions, the technology is only really being used to enhance the backlight, rather than being used to illuminate individual pixels.

Image: Lee, Changhee & BAE, Wanki & KWAK, Jeonghun. (2014). "Quantum Dot LED (QLED) Emerging as a Next-generation Display Technology" in Physics and High Technology

The technology in theory can create an even thinner display than OLED, along with a more streamlined manufacturing process. True QD displays are also capable of high pixel densities of up to 1,000ppi, multiple times the density required to be called a Retina-quality display, and based on Apple"s hybrid invention, will also boast the response times of OLED technology.

The QD patent application certainly shows Apple is thinking about display technology in multiple ways, and how it can be applied to future devices, but short of getting firm supply chain information or an official announcement from Apple directly, it is difficult to confirm which direction it will be heading.

Apple has been interested in using the technology for some time now, with the first notable sign being its acquisition of LuxVue in May 2014, alongside assorted related patents. A MicroLED specialist, LuxVue was rumored to have been the display producer for the ill-fated Google Glass headset, but was also the holder of assorted patents in the LED display field, including MicroLED.

At the time, the acquisition was thought to be an attempt by Apple to bring part of its display technology development in-house, with suggestions the MicroLED technology would be used in another rumored-at-the-time device, the Apple Watch. A more recent report suggests Apple is working with TSMC to make small panels for a future premium Apple Watch, potentially starting mass production by the end of the year.

Apple has also reportedly set up a secret facility just 15 minutes away from Apple Park, believed to be used for developing MicroLED. The 62,000 square-foot facility is thought to house around 300 engineers on a project named "T159," relating directly to the technology"s development.

The facility is also claimed to be sufficient in size to perform small scale manufacturing of display panels, allowing the company to keep development and testing in-house without involving third-parties. Considering Apple"s previous history in developing technologies before issuing information to manufacturing partners, it is possible that Apple is trying to work out the kinks in production before suppliers even attempt to make MicroLED panels.

The rumored small screen production may be for the Apple Watch now, but it may also benefit another often-rumored device, namely the VR or AR headset. This type of hardware relies on light components to keep the weight off the user"s head and neck, as well as displays with a high refresh rate and as close to perfect color reproduction as possible.

Apple is also apparently planning to use the technology in larger displays, said to be bigger in size than those in the MacBook Pro lines. This could be an iMac or iMac Pro, or even an external display, but ultimately there"s no real indication of Apple"s plans at this point, regardless of the scale of the screen.

Reports from last year also suggest Apple"s investment in MicroLED was a cause for concern for Samsung, LG, and other South Korean suppliers who provide display panels for the company"s products. Owning the process for MicroLED manufacturing could allow Apple to migrate away from its existing display suppliers in the coming years, reducing revenues and profits.

Aside from Apple"s development, there has been little in the way of announcements from other firms for products using the technology that could be bought by consumers in the coming months. The exception is Samsung, Apple"s main rival in the mobile marketplace and a major supplier of display panels, but its usage of MicroLED is not aimed at producing smaller screens.

At CES 2018, Samsung introduced The Wall, a 148-inch TV claimed to be the "world"s first consumer modular MicroLED" television. According to the South Korean electronics giant, The Wall"s modularity meant consumers would be able to customize their television"s size and shape to suit their needs.

The impending use of the technology in a high-priced consumer product could be considered proof that MicroLED display technology is maturing enough for use in devices. If the reports claiming Apple is getting close to mass producing panels is true, the inclusion of MicroLED in the Apple Watch could end up being the first mainstream usage of the technology.

The viewfinder in the E-m10 mark II/III/IIIs/IV, Pen-F, and E-m5 mark III is an OLED viewfinder. The viewfinder in the E-m5 mark I/II, E-m1 mark I/II/II, E-m1x, Stylus-1, and the VF-2/VF-3/VF-4 viewfinders is a TFT LCD viewfinder. They have different characteristics:

In general an OLED viewfinder does not have issues if you look at the viewfinder while wearing polarized sunglasses and shooting in horizontal orientation. Most of the TFT LCD viewfinders have horizontal waves alternating between no distortion and heavy distortion (you can select the focus point if you concentrate on the areas where there is no distortion, but you would not be able to manually focus). However, the E-m5 mark II is different that when I"ve tried it, the viewfinder is completely opaque. Note, if you shoot in vertical orientation, there is not degradation.

In general, TFT viewfinders can refresh their images much faster that OLED displays can. I suspect this is the reason Olympus uses TFT viewfinders in the modern pro cameras.

Generally I find that the OLED viewfinder supersaturates the image compared to the TFT LCD viewfinder. This i

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey