lcd panel edge connector repair quotation

TV repair costs between $60 and $350 with most spending $207 on average for LCD, LED, plasma, and 4K TVs; costs are higher if repairing older DLP, projection, and HD TVs. TV problems like display issues, powering-on problems, or sound issues can be fixed. Pickup and delivery fees may apply.

The cost to repair a TV will include the price of parts and labor costs, plus other associated costs. Additional charges include a trip fee for a technician to come to your home, a fee to transport your TV to and from a repair shop, and the diagnostic fee to determine what needs to be replaced.

The cost to repair a TV screen can be significantly more than the cost of purchasing a new TV. For this reason, replacing or repairing a broken TV screen is not considered feasible.

For example, the price of a new Samsung 40-inch LED TV is about $400, yet the cost of a replacement display panel for this model is about $380. This price is only for the replacement part and does not cover diagnostic costs, labor costs, or travel or shipping fees.

Broken TV screen repair is not a service offered by most TV or electronics repair companies. For example, BestBuy"s 90-day warranty, does not list broken TV screen repair as one of the problems they service.

Unless you are trying to fix a TV from the ’80s or earlier, cracked TV screen repair is not feasible; the entire display panel must be replaced instead. The cost of a replacement TV display panel is more than the cost of buying a new TV, and that’s before labor and other service costs.

TV manufacturers do keep replacement TV screen panels on hand to support products under warranty in case the screen malfunctions, due to manufacturer defect.

If you still want to replace a damaged or malfunctioning TV screen, your best option is to find a used replacement panel or a broken TV of the same model on which the screen is still functional. You might find one on eBay, and you can hire a technician to change out the panel.

The cost of a used replacement TV panel ranges from $50 to $350 or more, excluding shipping, depending on the brand and size. Note that the chances of finding exactly the part you need in excellent condition are slim, and the cost excludes the cost of installation by a repair shop.

Whether your TV is LCD, LED, plasma screen, or 4K (Ultra HD), the cost to fix common problems ranges from $60 to $350, depending on the repair type and the brand of TV being repaired.

These repair problems could have more than one possible source, so a technician should take time to narrow down the exact problem. TVs are repaired by replacing faulty components.

A TV inverter repair costs $104 to $171, including parts and labor, with an average cost of $138 for a TV with one inverter board or $178 for two. Parts range from $7 to $74, and the average labor cost for TV inverter repair is $97 per hour.

When an inverter component goes bad, it is usually replaced rather than repaired. In some cases, the capacitors on a converter board fail, and a technician can fix it by replacing the capacitors rather than replacing the entire inverter component. However, if an entire inverter board replacement is not available for the model of TV being repaired, replacing the capacitors may be the only option for TV inverter repair.

If an older model LCD TV or projection TV powers on and has sound but no picture, this may be due to lamp burnout, which is both common and expected. In this case, replacing the bulb will fix the problem. An experienced technician should be able to replace the bulb quickly and easily.

TV backlight repair costs $100 to $122, including replacement parts and labor, at a repair shop. In-house repair costs are more due to trip fees. The price of backlight replacement parts averages around $2.50for each LED and between $20 and $25 for each CCFL strip.

A new inverter may be needed to power the LEDs, costing between $7 and $74before labor, or an average of $40. In some cases, a repair shop can convert a CCFL backlight to LED without installing a new inverter.

Repairing a TV power supply board costs $23 to $234 for parts alone. Completely replacing the power supply board costs $250 for parts and labor. If one capacitor has failed, the cost for replacement capacitors is low. However, it’s more cost-effective for the technician to replace the entire board rather than spend time trying to diagnose and replace faulty capacitors one by one.

TV capacitor repair costs $60 to $129, including parts and labor. The cost for the replacement part ranges from $0.06 to $14, with the labor portion ranging from $60 to $125 per hour. TV capacitors protect the circuit from getting too much power, filter signals, and facilitate changing channels.

Flat screen replacement glass is not available. The only option for flat-screen TV glass repair is to try optical glass glue, which costs $1.70 for a 5-ml. tube. This may be an option for TV glass repair if the crack is only a few inches or less. TV panels are built as one unit at the factory, with the glass adhered to the display panel.

In-home CRT repair ranges from $199 to $249. The cost of repairing a CRT picture tube ranges from $199 for a TV that is 27 inches or smaller to $249 for a TV that is 28 inches or larger.

A TV fuse repair costs between $61 and $136, with most spending $99 on average. The cost of the replacement fuse itself is $1.50 to $11, while labor ranges from $60 to $125 per hour. Additional fees may apply.

LCD flat-panel repair is not considered cost-effective. If the glass is cracked or the display is physically damaged, it is cheaper to replace the entire TV than to repair or replace the display panel.

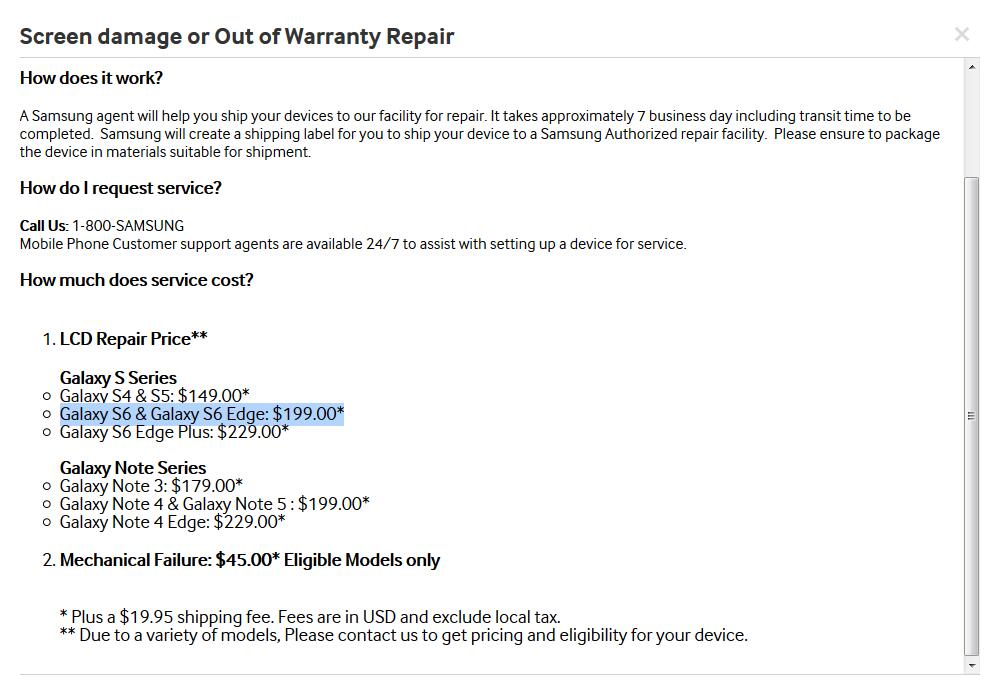

Estimating TV repairs costs by brand is not something TV repair shops offer, however, there are general prices by type. When looking for specific repair costs for your TV, you’ll find them in the common repairs price list above. Pricing applies to brands such as Samsung, LG, Sanyo, TCL, Insignia, HiSense, Sony, Toshiba, Pioneer, and Vizio.

More popular TVs are usually less expensive to repair because repair shops order replacement parts for them in bulk, which allows them to buy those parts at a lower cost.

The cost of flat-screen TV repair ranges from $42 to $359. You cannot fix a broken screen, but the price of a new flat-panel TV starts from around $249 for a 1080-mp (non-4K) LED TV from LG to as much as $14,999 for an 85-inch 8K LED TV from Samsung. A TV referred to as a “flat TV” or “flat-screen” TV might be any of the following:

LCD TV repair typically costs $60 to $85 for diagnostics testing, and $200 to $300 to perform repairs. LCD TVs use backlighting, which may fail. Newer LCD TVs use LED strips for backlighting. Older ones might use CCFL. If CCFL backlighting fails, a technician can replace it with LED backlighting.

An LED TV is just an LCD TV that uses LED backlighting, which all newer models do (older models use CCFL backlighting). The cost to replace one LED backlighting strip ranges from $100 to $122, including parts and labor.

The cost to replace the motherboard, inverter, or LED"s in a 4K TV ranges from $100 to $275 or more depending on the brand and model. The cost for screen repair for a 4K TV is irrelevant because it cannot be fixed or replaced at a cost that is lower than the cost of a new 4K TV.

Digital light processing (DLP) TVs are also known as projection TVs. DLP big screens have not been made since 2012, and DLP TV repair is usually not worth the cost except for a lamp burnout, in which the bulb can be replaced. The cost to replace bulbs ranges from $60 to $115.

TV repair shops charge an average $60 to $125 per hour, or a flat rate of $50 to $250, which includes the diagnostic fee. Additional costs after that depend on the repairs needed and the brand and type of TV. However, most stores will have a minimum charge of about $90.

Best Buy TV repair is provided through the Geek Squad TV & home theater service. Geek Squad TV repair starts at a base cost of $100 for a diagnostic fee. TV repair is covered under Best Buy’s protection plan, which costs $280 per year when you purchase a TV from Best Buy at the time of purchase, or within the return period printed on your receipt.

The brand and model of your TV will dictate the final repair cost, with more expensive brands and larger TVs costing more to repair. Consider the remaining lifespan of the TV before paying for repairs. You can now buy bigger TVs with more features and better displays for a TV that won’t need repairs for a while and probably comes with a warranty.

The cost of labor to fix a TV ranges from $60 to $125 per hour, or a flat rate of $90 to $299. If the work is performed in your home, the cost ranges from $25 to $125 per hour plus the trip fee. Most TV repairs take 1 to 3 hours if the repair specialist has the parts already.

If you live in a remote area, you may need to ship your TV to a repair facility, costing $99 to $175. Be sure to choose a delivery service that allows you to track the shipment and confirm delivery. When sending your TV into a service center for repair, you will be contacted regarding the associated costs and asked to process payment before the repair is completed, which usually takes two weeks including the shipping time.

Many TV repair shops charge a diagnostic fee that ranges from $20 to $60, depending on whether it is done in your home or the repair shop. Some shops charge a flat fee that ranges from $50 to $250that covers both the diagnostic cost and labor cost. In many cases, the initial diagnostic fee will be applied to the repair cost if you have the shop do the repair.

The more expensive a TV is, the more sense it makes to purchase an additional warranty to defray the potential for costly repairs. Best Buy offers an $89 five-year extended warranty for entry-level TVs. On larger TVs such as the 85-inch Samsung QLED 8K TV, which costs $14,998, the five-year warranty from Geek Squad costs an additional $1,699—11.33% of the cost of the TV.

With modern TVs, repair entails component replacement or replacement of capacitors, for which high levels of certification are not necessary. Generally, TV repair shops will let you know if their employees have certification.

Satellite dish repair is either covered by your satellite service company or the cost for a technician to fix it ranges from $80 to $150. Repairs may also be billed at an hourly rate of $50 to $65.

There are various ways you might be able to save money on TV repair. These include transporting your TV to a repair shop, using a shop that charges in 15- or 30-minute increments, diagnosing the problem yourself, using salvaged parts, and doing the repair work on your own.

You can also consider the cost of TV repair when purchasing a new TV. More popular TV models are less expensive to repair because repair shops buy parts for the most common TVs in bulk and are therefore able to get them at lower prices.

Circuit breaker - Check the circuit breaker for the power outlet that the TV plugs into. You can check the breakers by opening the door to your breaker panel and looking for circuit breakers that are in the OFF position.

Lamp burnout -In a projection TV or older LCD TV, no picture may be caused by lamp burnout. In this case, a technician can replace the bulb quickly and easily.

The primary way to save money on TV repair would be to perform the work yourself. This may require you to purchase and get familiar with various tools such as soldering tools, and methods for replacing a capacitor or some other component.

The right parts - It can be complicated to determine which component of a TV is failing and causing the TV not to work correctly. If you buy a replacement part and perform the repair yourself, the TV may still not work, either because you replaced the wrong part, the part was old and not working properly to begin with, or you did not perform the work correctly. Buying multiple replacement parts can become costly.

Lack of experience – you might cause more damage to the TV due to your lack of knowledge and experience, and you might also end up causing a fire with your soldering iron or being electrocuted.

The cost of repairing a TV could be as much as $500 if multiple repairs are needed. Consumer Reports recommends not to spend more than 50% of the cost of a new TV repairing the old one.

If you have a newer TV that cost thousands of dollars, having it repaired would most likely be cost-effective. If the TV only cost a few hundred dollars to begin with, replacing the TV is more likely to be the best option.

In most cases, a flat-screen TV can be fixed. The exception is a physically damaged display panel or screen. Most other issues including failing speakers, backlights, or power supply. Burned out fuses and damaged input ports can also be repaired.

If the screen is not physically damaged but is not showing a picture or is displaying “snow’” or vertical or horizontal lines, a technician can repair the TV by replacing failed components. If the screen is physically damaged, it cannot be repaired.

If you live in a remote area, you may need to ship your TV to a repair facility, costing $99 to $175. Be sure to choose a delivery service that allows you to track the shipment and confirm delivery.

This instructable came about from a broken LCD control module out of a modern VW Camper Van. The LCD module is part of a control unit which was virtually unreadable and a replacement for a new unit was £400+. It really was a no lose option, either have a go at fixing it or end up buying a new unit.

The fault of the LCD was that it only displayed a couple lines of output on the LCD. The symptoms are caused by poor location of the LCD ribbon in manufacture and also the poor position of the whole module in the vehicle which exposes it to heat and is subject to vibration within the vehicle. This causes the ribbon to fail eventually and is a known common fault.

The ribbon in this display actually controls the Rows of the LCD matrix and the Columns were handled by a rubber standoff connection on the longest side of the LCD. There were no problems with the rubberized connection.

Some re-work on the LCD ribbon had already been tried with a little improvement but the poor registration of the ribbon pushed me to try a new attachment.

From the photos below you can see the LCD control unit and the state of the LCD ribbon before repair. You can just make out the offset placement and poor registration of the ribbon before repair.

Do not under estimate the patience required for this repair as some delicate and nimble work is required and i cannot stress how important it is to take your time and not rush. You may only get one chance with this sort of repair.

The registrations of the LCD ribbon in this repair was difficult. It took me and my friend 20 minutes just to line up the ribbon for re-attachment. The ribbon in this case is sub 1mm pitch OR less than 25.4 thousands of an inch. You may want to try a simpler ribbon repair on an old LCD clock for example before jumping in head first with fine pitch.

Also the removal of the LCD ribbon is a delicate process as you do not want to tear what is a good ribbon or damage the carbon printed lines. Also the PCB must be respected to avoid introducing other faults and the the re-attachment may need an extra pair of hands.

You may also want to review the last step for results and lessons learned from this instructable before jumping in head first but i believe this will give a you a good insight to some important factors of LCD ribbons and possible success.

Other favorites of reworking the LCD connection that i have read here are the tinfoil on a heat gun. This has good temperature management but not so good in tight spaces. The solder iron with flat blade and tin foil is more precise but a 25 Watt iron can be too brutal on the ribbon.

In the photos below you can see the available ribbon length was generous enough but do watch for mechanical constraints. In some cases you could find yourself not being able to lay down the LCD back down as it is too tight a radius to sit down.

You do not want to pull at the ribbon as you will most likely damage what you already have. In my instance it was best to cut the ribbon free as close to the PCB pads as possible.I used a scalpel to slice parallel to the PCB board to remove the ribbon. Do make a good job of this as you may need to preserve as much extra ribbon to re-attach the LCD module.

The LCD assembly was lifted off and put in safe place to avoid damage. The ribbon was then gently lifted and peeled back with tweezers to remove the bulk. You must not use force to remove the remainder ribbon especially if your PCB is off a cheap quality OR single sided cardboard type variety. The PCB pads can come off with the ribbon! If you have a double sided PCB of FR4

If you have a half decent PCB the connecting pads may be gold flashed (actually called Electroless Plated gold). This gold flashing is good as it provides a very good flatness to the PCB pads but they are not as mechanically strong as gold edge connectors (like you see on old PC adapter cards) which is a hard gold . The gold plate here is soft and also micrometer thin on the surface.

The trick to get good alignment is to allow some the gold pad fingers toes of the PCB to be visible just beyond the carbon lines of the ribbon. You then get the pads toes to line up with the carbon lines of the LCD ribbon.

The photos below show how i handled the PCB and LCD and clamped the ribbon in place. The LCD display is being held by a plastic clamp above the PCB assembly. The PCB below which has components both sides is laying on some foam (try polystyrene). This allowed me to nudge the PCB under the ribbon into position. The plastic ruler acts as a LCD ribbon clamp. When you have got the registration get a steady handed friend to hold the ruler as a ribbon clamp in place so you can then apply the heat to stick the ribbon back down.

In our case the LCD ribbon was not only glued to the PCB pads but there was some additional tape at the heel of the ribbon to hold the ribbon in place. By holding at the heel the ribbon you get some good extra mechanical support.

I did not go further with more re-work as the VW LCD module was considered a good enough result and some other time pressures intervened. It was concluded that we could read the display well enough and operate items from the controller. It was also considered as one of those quit while your ahead things!

The technique for LCD ribbon removal and re-attachment are achievable certainly on simpler ribbons and fine pitch ribbons with careful preparation and thought. I hope this instructable is comprehensive enough for people to get some good results.

The material bonds at 180 DegreeC. Direct Ribbon connection is used for economy (i.e. no fancy connectors) and for the number of connections its offers in a small footprint which would not be possible through traditional connectors.

The other end of the ribbon that joins to the LCD is terminated on the glass on Indium tin oxide (ITO) which is one of the most widely used transparent conducting oxides.

If you want more information there are many different types of LCM assemby (LCD Display plus it driving chips) to look at but these are the main ones (increasing in density):

In manufacture of these modules a machine is used for assembly which would compress HSC to the LCD Or the PCB and then apply the correct amount of heat.

Attached is a picture of a screen from a Brookstone clock. I think it may be an LCD. The black pads show where a ribbon cable was connected and I see not transmission paths from the pads into the screen. How does this work? Is it really an LCD?

Are the paths in this ribbon cable covered on both sides as mine is and can you adhere the ribbon without removing any covering by applying heat? And what do I do on the LCD side where there appears to be no pads on the LCD but the ribbon cable was apparently applied in this manner?0

I have two items to add, kapton tape and sil-pads used to isolate heat-sinks from semiconductor devices. With kapton tape it brings the means to secure the ribbon to the board, place the tape over the whole connection area, and kapton resists heat very well, ( try and melt it with your soldering iron). This means an average soldering iron turned down will allow heat to be applied to each joint. With experience a rework can be done in a few minutes. The bond can also be renewed on the LCD glass as well, kapton also works here. Sil-pads allow heat to be passed to the joint with some pressure applied at the same time. The sil-pad can be dragged up and down all the ribbon connections allowing uniform heating. Once the bond is resurrected the sil-pad is discarded. http://goo.gl/mpZNkm0

It"s pretty cheap and easier to solder, then you just have to clamp the cable into the connector. Maybe you are interested in reworking that to get all lines back.

Sorry, the connector on the link doesn"t match the board design... you must search for FFC, FPC connectors with the number of vias of your cable and look for the real dimensions on the datasheet.

I just thought the same way, adding aLCD flat connector... then you can swap chinese or VDO oem screens. Seems the VDO LCD(as for Audi A3-Vw golf/jetta4) have 50 pins and the ribbons is 48mm width. Then you have to look to modify the metal bracket to avoid pressure on ribbon.

i would not rule out a connector fix totally but its nice if you can fix for zero cost if possible. Also you then have to manage the mechanical constraints as well as choosing a suitable connector. Usually only the semi flexi PCB circuits ribbons go into connectors not the carbon screen printed sort so may not be so desirable.0

i have an alarm clock which doesn"t have a ribbon, but instead some sort of rubbery contact strip against which the display should be pressed. You can find pics of it on google images for "lcd rubber contact strip", it seems to be called a zebra rubber. Any idea on how to glue/solder the display to that rubbery contact strip?More CommentsPost Comment

As long as the edges around the screen aren’t dented and there are no bends to the display, an LCD panel replacement is all that is needed for a cracked screen repair.

If you would like to have your computer repaired and are not sure about the costs involved or what service you need, please fill out this free quote form. I will reply to you within a few hours.

I understand how frustrating having a broken laptop can be, so I have created my nationwide repair service with your ease in mind. You will see it is an easy process indeed.

This step is optional, if you have already found the pricing for the repair you want on my website, you can skip this step. Otherwise, fill out my quick quote form and I’ll get back to you quickly! Note that my prices include the shipping to get the computer back to you after repair.

I’ll take care of your Mac and get it back up and running as quickly as possible. I’ll also keep you updated throughout the entire process with email updates. When the repair is complete, I will send you an invoice via email. I use Square for my invoices, so you can pay with any major credit card.

However your MacBook Air was damaged, if it has a cracked or broken LCD, let me help! As one of the few repair shops that provide component-level repair for MacBook Air displays, I have the services you need to get your Air fixed quickly and affordably. My screen repair offerings include MacBook Air LCD replacements for a fraction of the cost of replacing the entire display. By replacing just the broken component (the LCD panel), I can save you $100’s. If you want to see the process for these repairs, check out my MacBook Air screen repair guide.

I offer low-cost screen repair for almost every 13″ MacBook Air. My pricing is a flat fee based on the model computer you have. If you would like to learn more about the cost of replacing a MacBook Air screen, I have an entire page dedicated to the cost of MacBook Air screen repair.

My service includes replacing your cracked or broken LCD with a brand-new panel. You can click on the images below to see some examples of MacBook Airs that required LCD panel replacements. If your Mac looks anything like the ones below, you likely need a new LCD! If you are unsure what you need, feel free to chat with us at the bottom of this page, or contact us here. You can even submit a photo of the damage on your computer and we will get back to you with what you need.

While most screen repairs do not require any difference in service, there are a couple of scenarios that come up once in a while with LCD-only replacements on MacBook Airs.

When something hits the MacBook Air screen from the back or very hard, sometimes the backlight sheets get damaged as well as the LCD. The backlight LED’s shine up from the bottom of the laptop and reflect off a white sheet of paper-like substance. There are additional sheets after this white sheet that diffuse the backlight and spread it evenly through the LCD panel.

Normally, we can just replace the LCD and any backlight issues are purely cosmetic. As you can see in the picture below, a damaged backlight usually causes white spots on the LCD. Normally this white spot is only where the impact point is.

So if the computer got hit from the back or front hard enough to damage the backlight, we can either replace the entire screen assembly for a possible additional fee or just replace the LCD and ignore the cosmetic white spot. If you want to read more about this issue, here is a White Spot On Backlight post on our blog.

If you wish to have us replace the entire display, please let us know so we can look up the exact cost for repair and send you a quote for approval before we complete the work.

This MacBook Air came in from Texas with a vertical line right down the middle of the screen. What usually causes these vertical lines is an issue with the LCD panel and the wiring between the TCON board and the panel. In order to fix a line on the screen like this, you only have …

This 2019 MacBook Air with model number A1932 got a cracked screen. Immediately after the damage occurred the screen would no longer show any image, just a blank screen with some lines showing where the cracks were. The client sent it in for the screen repair utilizing my MacBook Air mail-in repair service. I had …

This Silver 2020 MacBook Air was being cleaned when the LCD panel cracked on the bottom right-hand corner. The cleaning solution also entered the display assembly itself during the cleaning process, causing some areas of cloudiness in the backlight. The client wanted to replace just the LCD panel if possible so as to not spend …

Having a MacBook closed on an object (think AirPods, charger cable, pencil, etc), is one of the most common causes of cracked screens I see. This M1 MacBook Air was closed on something that was laying on the keyboard, and that caused the LCD panel to crack as you see in the photos. I also …

11. You should see that the power supply board is now loose and can be wiggled free making sure you don"t damage the berg strip connector which attaches it to the other board. it usually comes out at a slight angle quite easily.

12. Once out flip it over and examine the tops of the brown capacitors you"ll see that two have vented, and gone pyramid shaped, they"ve blown.... In my experience and I"ve repaired hundreds of these monitors it is only ever these two that have gone, but if you find others that have vented replace those as well, making sure you observe polarity and type correctly with the replacement capacitors.

For more advanced fixers, this guide will help you replace only the iPhone 5c LCD and digitizer assembly (a.k.a. the bare “front panel”). This requires you to transfer several components from your original screen to the new one before installing it—including the front-facing camera, earpiece speaker, LCD shield plate, and home button assembly.

From their website - you can get the instructions for these connectors which includes contact extraction. They list tool number 457241-1 as the proper extraction tool. If you search for this on their website - it shows it as still active but the photo shown is wrong. Click on the Instruction Sheets for proper image and instructions.

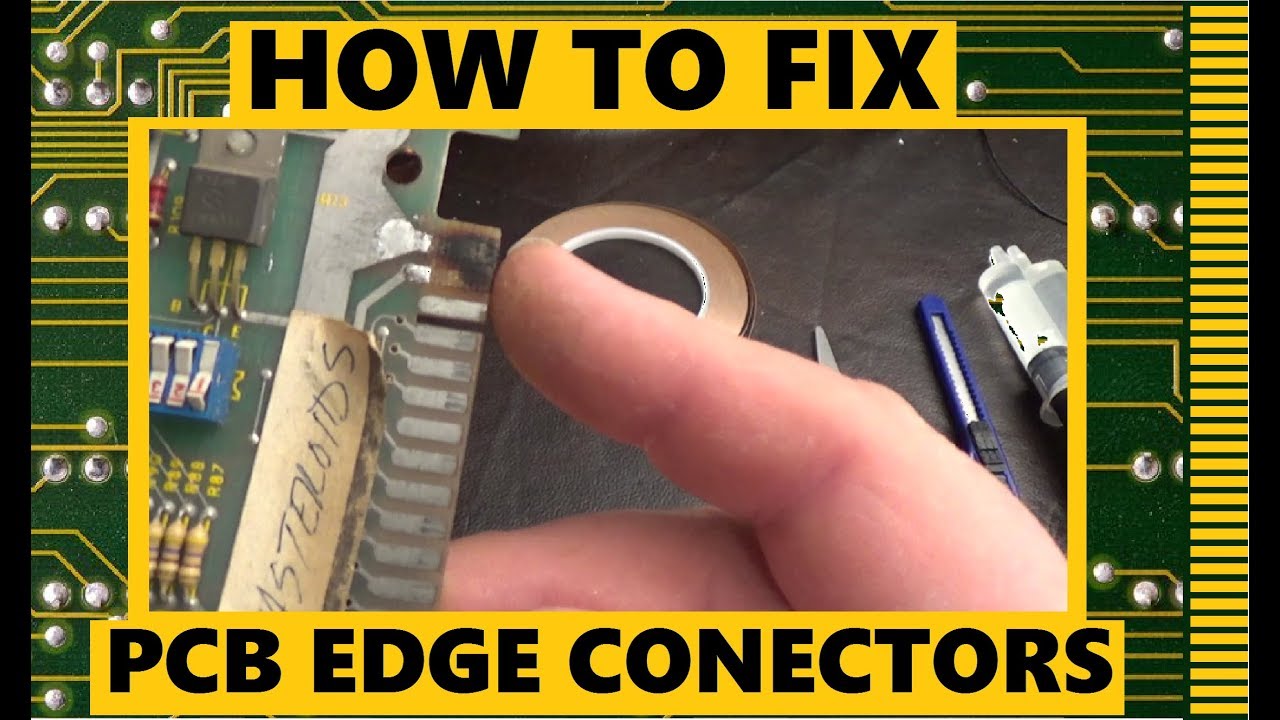

Luckily, it’s possible to repair or remanufacture boards to make them like new again. This does one of two things. Either the board in question can be returned to its original device, making it function again. Or, it can be used in a completely different device, as a form of recycling if you will.

Of course, before any board can be repaired or reconditioned, engineers need to discern and understand why it failed in the first place. You can’t very well fix a problem if you don’t know what went wrong, can you?

Boards are often produced in layers, which include various levels of conductive and non-conductive sheets. They can be one-sided with a single copper layer, two-sided with a double copper layer on both sides of a substrate layer, or multi-layer with differing layers of copper and substrate. It is worth mentioning that multi-layer boards provide a variety of benefits like an increased component density, however they are much harder to analyze, repair and modify.

It’s important to understand that circuit board repair parts and practices often consist of the same materials and components used to build the hardware in the first place. There are very few substitutes or alternatives, especially when talking about reliable and conductive materials. This highlights the need to find a proper, professional repair team with the right assets and connections.

As technology has advanced over the years, so has the design and development of circuit boards allowing for smaller, more complex components, and thinner, less bulky boards. This makes the circuit board repair process particularly tricky because there are so many different types of varying sizes and design. You can’t go to just anyone to have a printed circuit board repair, modified or re-manufactured. It is crucial that you go to an authorized party who has both the experience and necessary gear to make it happen.

So long as complete failure is not the scenario—the board fell upon the ground and shattered or broke completely—physical damage can be remedied through the remanufacturing process. Generally, this involves melting down the damage sections of the board or repairing through disassembly and reassembly. Due to the nature of most physical damage, it’s highly unlikely that this can be done as a DIY project by those without experience with printed circuit board repair. The repair of physical damage should only be done by a trained and experienced professional. In most cases, it calls for remodeling of the board, resoldering of components, and the reballing of conductive traces.

You may be asking, how to fix a printed circuit board when a component fails? Again, the repair and remanufacturing process for faulty components is best left to professionals. There are voltage tools and various devices that can be used to test the conductivity of a board’s circuit. They can also be used to discern if there’s electricity flowing to a component, or if an element of the board has failed entirely. A lot of times, by just opening up the device you can see components that have failed. Their outer shell may seem burnt, cracked or broken, or the component is completely detached from the board and loose.

To repair faulty or damage trace pathways, you simply need to resolder or reball the board with the necessary material. This reconnects the broken circuit and allows electricity to flow freely throughout the board.

You’ll know as soon as you have a faulty or poor circuit board because your device will continue to fail time and time again, even after a repair or service session. The best solution for a shoddy circuit board is to replace it completely, by visiting an official or licensed repair center.

The easiest way to identify a poorly designed board is the number of failures or problems after extended use. Barring significant physical or electrical damage to the device, if you take the board to be repaired or analyzed somewhere and there are a handful of issues, there’s likely something wrong with the way the board was constructed. In some cases, this simply means the original manufacturer used cheap or unreliable components, but the board itself is fine.

All professional repair teams have a power or voltage meter that can be used to identify electrical issues with a board and its components. Voltage tools are really the only way to diagnose a problem outside of visible damage to a component. As for repair, the process is best left to professionals but generally involves reseating or replacing components.

There are several ways in which a printed circuit board can be repaired or serviced, with varying degrees of skill required. For the most part, however, anything to do with the internals of an electronic or device calls for knowledge of engineering and mechanics, and basic electrical circuits. For some of the larger devices on the market, you could seriously injure or even fatally wound yourself if you don’t know what you’re doing.

For physical or visible damage to a board, base board repair is necessary. This may include melting down similar materials to reshape or modify the board, or can sometimes even call for complete disassembly.

For conductor and component repair, knowledge and skill of soldering, desoldering, BGA rework and pinpoint accuracy may all be necessary. If you’ve ever worked with or held a soldering iron before, it’s not so easy to retain a steady hand and spread the material evenly. You will want extensive experience with a soldering and desoldering iron, just to be sure the components and parts are seated properly to the board.

Of course, there are a variety of IPC and ICO standards necessary to follow for professionals, to ensure electronics and components are constructed and repaired using proper protocols. If you are not aware or don’t know enough about these standards, you may find yourself in hot water later.

An EMS, if you don’t know, is often a circuit board repair company that designs, manufactures, tests, distributes, and repairs electronic components and internal assemblies. They commonly service components and devices for OEMs or original equipment manufacturers. An OEM is the company that originally designed and owns the product in question.

As is to be expected, most repairs require the same materials—or improved materials—used in the official design of a board. It may call for copper or silver to be reseated to repair trace pathways. PCB substrates are often comprised of fiberglass or an epoxy resin with copper foil bonded to the conductive layer. They may also be comprised of reinforced phenolic resin, a more paper-like material that’s thinner than fiberglass.

The best service and repair teams can reassemble or fix a damaged board near enough to its original condition that there’s almost no difference in a previous version and the upgraded one. Certainly, this requires a great deal of finesse and experience that you won’t find outside of an experienced and professional setting.

An important part of researching and hiring a professional repair service is making sure they have the proper PCB repair materials and tools available to get the job done. Some service repair teams don’t have everything on property or on-site, which can balloon the time it takes to repair or reassemble parts. They have to wait to receive the requisite materials or tools.

It’s no secret that a lot of the materials used are not environmentally-friendly or conducive to safety. We’re a long ways off, but there are scientists and bleeding edge teams working on bio-degradeable PCBs that will break down naturally after being discarded.

For PCB repair and remanufacturing and industrial PCB repair service options you can’t do any better than EMSG Inc. (Electronic Manufacturing Services Group). We are well suited to handle board level and complete box build assemblies, including any custom packaging you may have created or utilized.

We have a highly advanced facilitywith the latest manufacturing and repair technologies, which allow us to be incredibly precise, yet efficient in our duties. This, coupled with our incredibly experienced personnel, modern equipment and great management team means we can be swift and reliable and get any repairs or development done within the schedule of your choosing.

We are highly confident that EMSG will play an integral role in the design and development of your product. The information presented here is merely scratching the surface of what’s necessary to conduct and perform a professional-grade repair and remanufacturing service. You can rest assured, we have the skills, experience and tools to get you to market as soon as possible.

If you’re interested in our manufacturing or repair services, please fill out this contact form and allow us to reach out to you. You can also give us a call, anytime, to speak to a company representative.

Accidental Damage is any damage due to an unintentional act that is not the direct result of a manufacturing defect or failure, and is therefore not covered under the standard warranty of the LCD-Monitor. Such damage is most often the result of a drop or an impact to the LCD screen or any other part of the product which may render the device.

A dying or cracked display doesn’t mean your laptop is a paperweight. For most laptops, a screen replacement takes $80 and an hour of your time at most. If you’re a DIYer, replacing a broken laptop screen yourself is a great way to save cash, as most computer repair shops will quote you $150 to $300 for the job.

Before you replace your laptop’s LCD, here are the caveats to the general steps that follow. This is not meant to be a guide for ultrabooks, two-in-ones, tablets, Macbooks, or other, more specialized notebooks, however. It’s more for average, run-of-the-mill laptops. But even then the general steps I discuss do not work for all such laptops. Some will require a different process and/or more work to replace the screen, such as accessing the motherboard by opening the main case of the laptop.

Because of that crucial caveat, before buying a new LCD, it may be a good idea to try to remove the damaged screen first, to ensure you can perform the replacement. If, after following the first few steps the process looks different for your laptop, I recommend scouring Google and YouTube or finding a repair professional for further help on your exact laptop brand and model.

Finding a replacement LCD is typically easy—and you don’t have to pay the crazy prices the manufacturer usually wants. Just search eBay, Amazon, or Google with your laptop model number and the words LCD screen. You’ll find most regular screens can be had for as low as $50 to $80. If you aren’t finding anything, try other identification numbers from the laptop label or documentation. Some vendors have one or two different sets of identification numbers that could serve as your model number.

When shopping for the LCD, most sellers will alert you to compare the specs and placement of the video cable on the back of their screen to your current screen. This is another reason to crack open the laptop bezel before ordering a replacement. However from my own experience, if the seller says the screen is compatible with your exact laptop model, it usually works.

Small-head magnetic philips screwdriver: Not small like a mini screwdriver from an eyeglass repair kit, but I’d say between that size and a mid-sized screwdriver would work. If you don’t have a magnetic-head screwdriver, try to find a magnet big enough to magnetize the driver head. This helps the screws stick to the head, making it much easier to remove and replace the screws without cursing as they fall all over the place.

Use a sharp, pointy object—like an opened safety pin or needle—to help remove the cover stickers without damaging them. Stick it between the edge of the cover and bezel, and then pry the sticker away. Once removed, place the covers in a safe spot, with the sticky side up to help ensure there’s enough stickiness when you place them back on.

Once the bezel is fully removed, you’ll find the LCD secured to a metal trim frame on the left and right sides. Remove the two screws (one on each side, on the top) holding the trim frame pieces to the back screen case. Now, you should be able to lift the LCD (with the trim frame pieces attached) slightly away from the back screen case.

On each of the trim frames’ sides, remove any screws that are securing it to the LCD. Most laptops have three screws on each side; however, the smaller laptop I photographed here doesn’t have these screws—the LCD is actually secured to the trim frame pieces by tape on each side.

Now you should be able to set the LCD face-down onto the keyboard. Be careful not to put excessive force on the video cable attached to the back of the LCD.

Disconnect the video cable from the back of the LCD. Though the laptop I photographed here has the connector on the very bottom, most laptops have the connector near the center. If so, keep in mind that the portion of the cable running down the screen is usually stuck on the back of the screen with some mild adhesive. Just gently pull the cables away from the screen. You usually must remove tape that’s securing the video connector to the back of the screen as well. When you get to the point of actually pulling the video cable out of the screen connector, it should unplug with little force.

Once you’ve fully removed the broken LCD, simply place the new one face-down like you did the old one. Reattach the video cable to the connector and place the cables and any tape just like they were for the old one.

When you get to the point of putting the bezel back on, just line it up and push/squeeze the bezel back into the snaps of the rear screen case. Before replacing the bezel screws, ensure the bezel is fully snapped in place and no crack exists around the edges of the screen case. Lastly, use that safely pin or needle to reattach the sticky screw covers.

You should also know that repairing your laptop screen isn’t always the easiest job, and there is a possibility you can make the problem worse while voiding the manufacturer warranty. It’s important to feel confident in your skills before you begin the process of replacing your screen, and to consider if you would be more comfortable taking it in to a qualified repair shop.

If you’re wondering about broken laptop screen repair costs, you’ll be happy to know it’s not as expensive as you may assume. Professional repair costs are usually around $300 or so [1]. If you are comfortable working on your laptop yourself, you can usually find replacement screens online for reasonable prices - sometimes as low as $50 to $100 - and it often only takes an hour or two to complete the replacement job.

If you’re willing to take the leap and do this yourself, then you can end up rescuing a computer you may have thought you needed to replace. Here are 5 steps you can take to successfully replace or repair your cracked computer screen.

Before you begin the process of changing your screen, it’s important to know exactly what’s wrong and what needs to be repaired. The type of device you have can influence how much you’ll have to pay for another screen, as will its age, which may make finding a replacement rather difficult. You should do some research online to find out if you even have the option to fix the screen yourself.

Also, if the frame of your laptop has suffered physical damage, then you may have some difficulty repairing your screen. Once you have looked over your device and determined whether you can fix it on your own, it’s time find the right screen for your computer.

Note: If you’re concerned about your laptop’s touch screen repair, it can be more complicated to fix this problem without professional help. These displays are designed with factors like sensitivity in mind, so it’s a good idea to have an expert take a look at it, even if it means spending a bit more than anticipated.

One of the main reasons you should know the model of your laptop is so you’re sure that you’re purchasing the correct replacement screen. While a number of companies offer laptop screen repair kits that can make the process easier, if you order the wrong screen you won’t be able to make any repairs. If you’re having difficulty figuring out your computer model, you can visit the “Settings” menu and find the serial number to assist you in your search.

Fortunately, finding the right screen for your device doesn’t have to be stressful. Often you can find what you are looking for simply by entering your laptop model number into the search bar of online retailers. You may also want to include the search term “LCD” in order to narrow down the accessories that are available for your computer. For the most part, screens should be priced fairly reasonably and you may even be able to buy some for around $50, although it depends on the type of computer you have.

Screen repair kits are also available for certain models, so it can be worth it to research your type of computer and see if they’re available. These kits provide you with everything you need ahead of time so you can get to work and not worry about missing an essential tool. Of course, items around your home can work just as well while saving you a bit of money.

Once you have assembled the tools you need to replace the screen, you can get to work repairing your device. Lay the closed laptop on the flat surface you have chosen and keep your tools nearby.

One of the trickier parts of replacing your laptop screen will be removing the LCD. First, make sure that the bezel is completely off so you can have unfettered access to the LCD screen. It will be secured onto the laptop’s metal frame, and you will have to take it off from the left and right sides.

There will be two more screws to loosen at the top corners before you can lift the screen slightly away from the metal frame. You’ll probably find a few more screws securing the LCD on the sides, and these will also need to be unscrewed. In some cases, heavy duty tape may have been used instead.

After you remove the attachments, your screen should now lie on your keyboard. It can be a bit of a challenge to make sure there is enough space between the LCD and the metal frame, but you should be gentle to avoid ruining the video cable that runs from the back of the screen to the body of the laptop. If this is damaged, you will need a professional’s help to repair it.

Now it’s time to disconnect the cable from the LCD. You can usually find the connectors in the center, though they may alternatively be located at the bottom of your screen. It’s likely that adhesive was used to connect the two, so you will need to gently pry one from the other. There may also be some tape that needs to be removed, but overall it should be pretty simple to disconnect your LCD from the video connector. Set it somewhere away from your tools.

As you remove the screen, you should be able to locate where your new one will go. Place it face down within the frame so it fits perfectly. After that, you can reattach the video connector so it is placed exactly where the previous LCD sat. Make sure that it is as aligned as possible then attach it with tape or adhesive.

Reinsert the remaining screws into the bezel after you’re certain everything is snapped correctly into place. You shouldn’t be able to see any cracks at all along the edges of the screen. Once the screws are inserted, reattach the screw covers using your pin or needle.

Repairing a broken laptop screen doesn’t have to be done by a professional. If you have the time and interest, then you can end up saving a lot of money by doing it yourself. By following these DIY steps, you can have your laptop display back up and running in an hour or two.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey