led over lcd displays factory

The customization process requires some time.This is why we offer standard or express deadlines. The customized design of our screens requires an advanced process of high-level engineering so that its development is complete and satisfactory. Below, we detail the subsequent steps generically, the typical manufacturing steps of a LED screen, and what happens once the buyer confirms the beginning of the project for his advertising screen.

An exclusive professional department with more than a decade of experience in advertising LED screen manufacturingwill thoroughly study your needs and technical concepts required to perform a new order.

The manufactured structure is assembled in such a way that there is no visual separation in the whole unit in general.All the inside pieces are placed according to a pattern and perfectly aligned by laser.

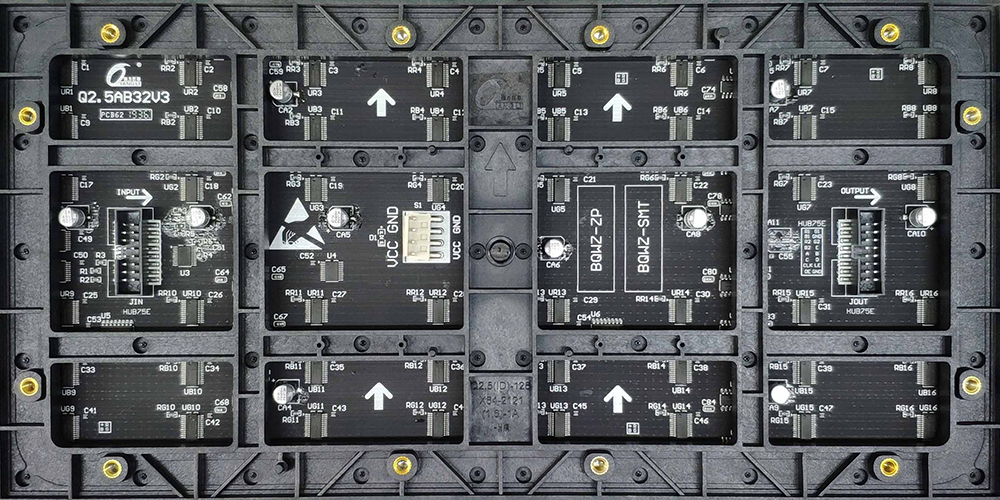

Assembling of electronic and LED equipment is programmed to assure that only the parts corresponding an order are used. This is one of the most complex and delicate tasks of the entire process. It is the most important phase of the LED advertising screen’s creating.

LED panels are adjusted to light and chromatic levels to assure that sharpness and color are the same in the entire LED advertising screen.To do this, photoelectric sensors measuring chromatic patterns adjusting and memorizing each LED component are used.

In Visual Led we maintain a screen stock in continuous renewal. In case we have the LED screen of your interest in any of our warehouses, it will be possible to streamline the entire delivery process in really short terms. If you have a project with great urgency, we recommend that you consult our sales representatives about screens in stock.

Visual Led’s LED screens are personalized for each client. The standard delivery time is applied by defect on all orders. As there are several phases, these are attended to in strict order of request.

In some cases, it is possible to make a priority order to significantly reduce the delivery time of an order. Priority delivery times are not available for all products and / or screen sizes and represent an extra cost in shipping and order management. Ask Visual Led’s commercial team about the possibility of making a priority order for your LED screen.

Priority orders are manufactured individually and with priority over the standard order manufacturing batches. Manufacturing processes follow the same quality standards as standard orders

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

Ultraviolet light (UV) is used to illuminate the surface of the photoresist through a pre-made electrode pattern mask, which causes the photoresist layer to react. The photoresist is selectively exposed under ultraviolet light by covering the photoresist on the glass coated with the photoresist.

Then etch off the ITO film without photoresist covering with appropriate acid etching solution, and only retain the ITO film under the photoresist. ITO glass is conductive glass (In2O3 and SnO2). The ITO film not covered by photoresist is easy to react with acid, while the ITO film covered by photoresist can be retained to obtain the corresponding wire electrode.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

However, no matter CCFL backlight or LED backlight is placed in various ways, the nature of the backlight source cannot be a surface light source, but a linear light source or point light source. Therefore, other components are needed to evenly distribute the light to the whole surface. This task is accomplished by the diffuser plate and diffuser plate.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

However, it is much simpler to use a side white LED as a backlight. The small circuit board on the far left of the figure above is the backlight of the LED.

This is the general structure of the backlight system. Since I have never seen the backlight mode of R.G.B LED, I cannot tell you what the backlight mode is like. I will share it with you when I see it in the future.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Colantonio, Andrea; Burdett, Richard; Rode, Philipp (2013-08-15). Transforming Urban Economies: Policy Lessons from European and Asian Cities. Routledge. ISBN 9781134622160. Archived from the original on 2019-01-01. Retrieved 2019-06-09.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

Unilumin Group Co., Ltd., a world-classLED display manufacturer in China, aims to be an advanced LED supplier with high quality LED display products for global customers. The LED display market share of Unilumin ranks among the top three in the world for consecutive years. Unilumin, as smart bases of Chinese LED manufacturer, now has the “iron triangle” structure based on Fuhai headquarters, Pingshan and Daya Bay, equipped with first-class R&D, production and experimental equipment. The level of modernization, scale and standardization are the leading LED industry in the world. At present, Unilumin is constructing the second phase of Daya Bay Industrial Park. After the completion of the construction, the total construction area of the entire industrial park will reach 400,000 square meters, which will become the largest intelligent LED screen and lights manufacturer base in the world.

Shenzhen Absen Optoelectronic Co., Ltd., an integrated LED supplier and Chinese LED manufacturer was founded in 2001 within the Optoelectronics industry, focusing on premium quality turnkey LED display solutions. Absen products reflect strict quality control guidelines and combine more than a decade of experience with meticulous craftsmanship and a passion for delivering the best quality possible to customers. At the same time, Absen is constantly developing and expanding international customer s service networks to ensure more and more services are available to local customers.

Leyard Group is a LED screen manufacturer in the world with visual effects technology products and its application platform. Founded in 1995, it adheres to the philosophy of “profit is lower than morality” and shares culture. It is a LED supplier based in China and focuses on the United States. After 24 years of development, the Group is 23 domestic holding companies, 8 foreign companies, more than 2,000 distribution partners, nine LED manufacturers bases and seven international marketing centers all over the world, with more than 4,600 employees, and orders over 10 billion last year.

Shenzhen Liantronics Co., Ltd, as a LED supplier, plays an important role in Chinese LED manufacturers industry, which provides system solutions with medium and high-end LED full-color display products. As a national high-tech enterprise with registered capital of nearly 97.8 million USD, Liantronics is specializing in LED application products from developing, manufacturing, sales to service.

Since its founding in 1993, SANSI has been dedicated to technological innovation in a wide range of Chinese LED manufacturers, from commercial displays to home lighting. Sansi fully integrated product design, production, sales, installation, and customer support in effort to be an affordable, state-of-the-art LED technology supplier. Having successfully launched dozens of cutting-edge projects, SANSI’s mission is to raise the bar for LED applications.

First, as a special economic zone, Shenzhen had first released domestic “LED Industry Development Special Planning” in China. With the support of the national policy, Shenzhen intended to be another “Chinese Silicon Valley” and vital LED industry R&D manufacturing base around the world, which would focus on developing high-tech industries. As a result, it had attracted hundreds of international and domestic manufacturers and companies to set up in Shenzhen, especially including some LED suppliers and LED video wall manufacturers, such as Unilumin, Absen and LianTronics.

Second, due to the rapid development and the open market, LED display market of Shenzhen, even the whole China dramatically has expanded as well as raising demand. Besides, thousands of migrant population and technical personnel had entered Shenzhen, these population had provided companies and plants with large labour. Further, the rent price of factories in

Shenzhen was favourable, since LED is the abbreviation of Light-Emitting Diode, and Diode is an electronic device, LED displays product is a standardized electronic product, there is no doubt that all the top-notch LED suppliers and LED display manufacturers are concentrate mainly on Shenzhen. Moreover, Unilumin was founded in 2004, as a National Hi-Tech Enterprise of LED display manufacturer in Shenzhen, China.

Unilumin Group Co., Ltd. is a professional LED application and LED supplier, which went to the public in 2011 with a stock code of 300232. Based on the corporate vision of “Together, for a brighter future”, Unilumin is dedicating to providing high-quality and high-performance LED full-color display and LED professional lighting and urban landscape lighting as well as solutions for global customers. Unilumin has been granted the title of “Manufacturing Individual Product Champion” in Chinese manufacturing industry by MIIT in 2018.

Product design plays a vital role in innovation. The modified concept of design will bring significant progress of products, which is not just about the preference of product, but also it is related to the performance. Currently, Chinese LED manufacturers are aiming to make more practical design , for example, the product Unano, premium 1mm rental & fine pitch LED display from Unilumin has just won the top design award "Red Dot Award 2019: best of the best". Further, Unilumin, as a Chinese LED supplier and manufacturers had obtained 1113 patents at home and abroad.

Since the performance of product is related to its life expectancy, product testing is also extremely important, which could guarantee the quality of products. In Shenzhen, the LED manufacturing base of Unilumin has a central laboratory, which has been recognized by CNAS (code L6507) and has become SGS, TUV-SUD, TUV Rheinland, UL-WTDP eyewitness laboratory. It is the co-construction unit of CSA state key laboratory of semiconductor lighting joint innovation.

The laboratory mainly provides the design, development and verification of new products with reliable testing data in the early stage, quality control in the later stage and pre-certification prediction test within the company, and also provides the same service for external customers, making it a testing platform shared by the industry. Therefore, the central laboratory of Unilumin is responsible for the product testing, which makes sure each LED product is in high quality.

Stable product performance is the guarantee for customers. It means the products supposed to perform well in a good and harsh environment, or passing the high standard of testing. Unilumin, Chinese LED manufacturers, have passed plenty of certificate, such as CE, ETL, CCC, UL, CUL, CB, FCC and RoHS certificate. These passed certifications had proven the product performance of Unilumin were excellent and stable.

Many companies had not pay more attention to after-sales service, while it might cause lose their customers. After-sales service is as important as sales, which may raise the credit of the company in the market and amongst the customers. Moreover, the sales and support networks of Unilumin had covered more than 160 countries, which had over 700 channels with subsidiaries in New York, Amsterdam, London, Moscow, Melbourne, Dubai, Stuttgart, Seoul, Tokyo, Singapore and so on, as well as having offices in Hong Kong, Italy, Canada, America and Mexico, etc. Thus, Unilumin could be the first to help customers from all around the world.

We don’t design our products to meet the standard; we design our products to exceed the standard. Covered by ISO9001 and ISO14001, Viewpointec"s engineers design LED displays to provide a consistent light output and light color for many years.

By collaborating with leading market suppliers for our components, and guaranteed by quality management, we can achieve our low defect percentage. Moreover, with continuous efforts to improve the efficiency of our products, we strive to deliver a meaningful contribution to a better environment.

LED displays have been installed in manufacturing environments for years. Now there is a new, revolutionary standard that will instantly provide all of your plant employees with real-time, critical information, saving time and money – daily!

Founded in 2009, Sansi North America (SNA Displays) has become a leading LED display manufacturer in the United States with offices across the country and LED displays in major cities from coast to coast. We are the only LED signage manufacturer headquartered in Times Square and boast a major percentage of the digital LED displays in the world’s most coveted advertising space right outside our doors. In recent years, we’ve provided more LED display technology to Times Square than any of our competitors. Likewise, SNA Displays leads the industry in providing LED screens to the Los Angeles area and other major markets in North America.

Whether from the BRILLIANT™, BOLD™, or EMPIRE™ product series, our LED screens come in a vast array of sizes and pixel pitches for numerous indoor and outdoor applications. Whether you need an LED display screen for a conference room or one big enough to cover a skyscraper, SNA Displays has the custom-engineering knowledge and experience to make your vision come to life. We also have all-in-one, out-of-the-box LED screens perfect for on-the-go messaging.

SNA Displays emphasizes maximum communication throughout all phases of each of our projects. When you choose LED display products from SNA Displays, you not only get top-tier technology but a dedicated point of contact who will work with you from start to finish. Every project manager at SNA Displays is a structural, electrical, or mechanical engineer, meaning that our SNAPros™ have the engineering chops to help you at every step along the way, from design to installation to commissioning.

iDisplay LED display manufacturer was founded in 2018 with a passion for the LED display industry. Headquartered in Shenzhen, China with a factory in Huizhou, China. We are dedicated to designing and manufacturing LED displays for XR stages, film studios, broadcasting, retail, religious sites, educational transportation, immersive experience rooms, conference rooms, and other commercial sectors. Also, we have extensive experience in ODM and OEM. We have completed many custom projects, such as diamond-shaped LED displays, spherical LED displays, irregular LED displays, and rotating LED displays.

iDisplay is a high-quality LED display solution provider, focusing on overseas markets in more than 30 countries. Traditional LED display products to include virtual product LED wall ImmerSiv Pro, outdoor vertical OOHposter, outdoor front service light screen OOHmedia, outdoor traffic sign VMS, indoor vertical poster iPoster, indoor fixed screen Gshelf, conference screen iConference, soft screen iFlex, etc.

iDisplay has 6000 square meters of factory area / 20000000000+ annual output / 30+ countries / 4 global service centers (Dubai, Saudi Arabia/Barcelona, Spain/Cape Town, South Africa/Miami, USA) / 10+ distributors / 20+ engineers / 20+ years of LED display experience / 10+ patents / 6+ software copyrights, with rich experience and professional team can provide you with flexible LED display solutions.

A light-emitting diode (LED) is a semiconductor light source that emits light when current flows through it. Electrons in the semiconductor recombine with electron holes, releasing energy in the form of photons.

This question is important. Outdoor panels are usually seen from further distance, thus resolution will be lower. Outdoor led panels will likely be brighter because they are used in sunlight. Also outdoor panels will be more durable as they need to withstand weather conditions, dust, moisture and dirt. Indoor panels offer superior color, smaller pixels and a more refined picture. For the same pitch, indoor screens are cheaper. For all these reasons, we recommend indoor panels, unless you actually need to use an outdoor screen.

With LED walls, each individual LED is a pixel. The pixel pitch number indicates the distance between LEDs on the wall in millimeters, as well as the minimum viewing distance in meters. The optimal viewing distance is typically 2-3 times the pixel pitch number in meters.

1) Ground Support Installation: This method system is a combination of a base-unit, connection bar and ladder truss that creates a very stable system to support your LED screens in various configurations and offers flexibility in height as well as width.

2) Flown Method (rigging): There are certain requirements that need to be in place in order to fly a screen. Most importantly, there needs to be ample structural support in the ceiling to hold the total weight of the screen. When someone says they want to “Fly” an LED screen, that means the screen will be rigged to either an overhead truss system, a ceiling grid, a crane, or some other support structure from above.

3) Wall Mounted: Some panels can be drilled and mounted into the wall. This is a great option if you’re looking for an aesthetically clean look with easy maintenance features, but it will add cost to the panels.

Most LED Panels are rated for 60,000 to 100,000 hours. You’ll have these panels for a long time and will get a lot of life out of them. In case something malfunctions, you can get in contact with us and we will give you all the information to properly service and maintain your panels.

2020 Working harder and forging forward. Feb, 2020 Implementing a value of 10 million RMB for led display screens April,2020 got the prize of “2018 LED video screen initiative Prize” June,2020 releasing K series outdoor SMD display solution.

2008 In 2008, the company achieved the second expansion, with a production area of 1,5000 m2 and sales of over 10 million, which successfully expanded into the international market. The company has a registered capital of 1 million.

2005 Htile LED Display Co., Ltd. was established. The company covers an area of 1000m2 and has sales of 3 million in the same year. It mainly sells outdoor full-color displays. Registered capital of 300,000.

The Leyard Group is a global leader in fine pitch LED and premier supplier of visual digital signage and displays,established in 1995,main products include pine pitch LED displays series, front access LED display series,outdoor fixed led display series, rental led display series,MicroLED series, interactive conference LED display series, wholesales series, custom led screens and so on.

Shenzhen Lianjian Optoelectronics Co., Ltd. was established in 2003 and successfully listed on the Shenzhen Stock Exchange Growth Enterprise Market in 2011 with stock code 300269. It is a leading LED screen display supplier in China, providing domestic and foreign customers with mid-to-high-end LED display equipment and display. Control system development, manufacturing, engineering installation and after-sales service and other overall solutions.LianTronics is dedicated to provide professional digital media and visualization solutions for industries such as retailing,government,military,utility,transportation,education and broadcasting.The successful cases such as sports event Olympic games,World Cup and NBA,important clients like Tencent,Huawei,Alibaba and so on.

Founded in 2012, as a LED display brand of Unilumin which is focusing on channel distributions.Lamp is the world’s leading provider of large-screen digital display systems and comprehensive solutions for big data information visualization.Focus on new display panels, big data information visualization, optical electronics, image processing, signal transmission, etc. In the field of technology, it is committed to improving the visual experience of human display technology.Products mainly in HD LED screens,fixed LED screens,rental LED screens and creative LED screens.

Shenzhen Unilumin Technology Co., Ltd. was established in 2004 and listed in 2011.Unilumin supplies world-class LED screens and solutions for control room,broadcast,commercial,retail,entertainment,sports,landscape lighting and many other applications.Products mainly in commercial LED signage, rental LED signage, sports LED signage and so on.

Flinky has been specialized in LED field since 2014,a world-class manufacturer in China,aims to be your reliable LED screen partner and manufacturer.The LED displays meet international standards such as CE,RoHs,CCC,FCC,TUV,Saber,BIS,UL and so on.Providing you with 3~5 years warranty.For more information about Flinky LED display, please follow us on Twitter,Linkedin,Facebook,Instagram,Pinterest,Tumblr and so on!

Absen Group (stock code: 300389), founded in 2001, is the world’s leading provider of true LED display applications and services. Products are exported to more than 130 countries and regions in America, Europe, Australia, Asia, Africa, etc. Excellent product cases include Presidential Press Conference, China International Import Expo, World Cup, NBA game, New York Times Square, etc. So far, more than 50,000 cases have been successfully implemented. An application example, widely used in advertising display (standard billboards, outdoor large screens, transportation hubs, street view advertising, digital signage, sports, etc.), stage display (corporate events, public events, performing arts activities, TV broadcasting, etc.), commercial display (brand chains, commercial complexes, theme parks, exhibitions, churches, cruise ships, casinos, etc.), data visualization (control rooms, radio and television studios, etc.), conference screens (government and enterprises, education, finance, hotels, etc.), The export value of display products has ranked first in the industry for 12 consecutive years

Shenzhen ROE Technology Co., Ltd.was established in 2006 with a registered capital of 215.5 million. It is a provider of comprehensive solutions for “LED vision system”; it is a provider of “LED creative” integrating research, production and sales. It is a high-tech enterprise with “type display solutions”; it is a benchmark enterprise in the “LED stage display rental industry”.ROE, dubbed the “Apple” of the display industry, is a company that shares the same philosophy with Disney. They attach great importance to quality and service, and have the most high-end products in the industry, including various international industrial design awards. ROE ranks first in the LED rental display industry in terms of scale, and ranks top 1 in North America and Europe in terms of export volume. It is the preferred partner of top international leasing companies. It has offices in many overseas places, provides global services, and has great international brand influence.

Shenzhen InfiLED Electronics Co., Ltd., headquartered in Shenzhen, China, is a national high-tech enterprise with a professional modern factory, using the most advanced production equipment and the most reliable components, and strictly implementing the ISO9001 quality management system, total quality Management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system, focusing on R&D and manufacturing of LED large video equipment.

The range of LED displays developed, designed and produced by InfiLED include fast and thin rental screens, smart high-definition fixed screens, multi-functional angle creative screens and high-brightness refresh stadium screens. The product application fields cover advertising, transportation, performing arts, sports, monitoring, Conducting, conference, cultural and creative industries, etc., have been exported to more than 85 countries and regions around the world. Passed CCC, CE, UL, ETL, FCC, RoHS, TUV and other certifications.

InfiLED has a global sales and service network, with service centers in Hong Kong and the United States, Spain, the Netherlands, the United States , Japan, Australia and Canada have branch offices, continue to provide customers with the best experience, the most environmentally friendly and energy-saving LED products and the best service.

Shenzhen Ledman Optoelectronics Technology Co., Ltd. (stock abbreviation: Ledman, stock code: 300162) was established in 2004. It is the world’s leading expert in LED ultra-high-definition display, the leader in 8K ultra-high-definition LED giant screen display, and the first company in China. LED display high-tech listed company, strategic partner of China’s aerospace industry, producer of ice and snow rings for the opening ceremony of the 2022 Beijing Winter Olympics. Ledman focuses on the 8K ultra-high-definition video industry, assists the development of 5G+8K, takes the 8K Micro LED ultra-high-definition display products based on advanced COB technology as the leader, and jointly creates a full range of LED products and solution ecosystems.

Focusing on high-tech LED products, Ledman has established LEDMAN Ledman ultra-high-definition display large screen based on advanced COB technology, LEDMAN Ledman smart conference interactive large screen, LEDMAN Ledman ultra-high-definition giant screen and LED intelligent lighting, LED creative display in The whole series of LED products in the ecosystem and solution system. Under the background of today’s 5G ultra-fast coverage, Ledman keeps up with the trend of the times, starting from 5G+8K+AI, and is committed to building platforms in the fields of smart cities and data center visualization solutions.

Shenzhen Chip Optoelectronics Co., Ltd. (stock code: 430561) was founded in 2001 and is headquartered at 5F, Building C, Baoshi Science and Technology Park, Baoshi Road, Shiyan Street, Baoan District, Shenzhen, China. The production base was built in Zhongnan Science and Technology Park, Huizhou City, Guangdong Province. It has subsidiaries in the United States and Europe, and offices in South America, Australia, the Middle East, Africa and other regions. The company has established a flexible and intelligent product manufacturing system, with a production and operation area of 20,000 square meters. Focusing on the development of LED outdoor sports, LED outdoor advertising media, LED outdoor transportation, LED outdoor signage, LED outdoor rental and other fields ), 12 utility model patents, 6 appearance patents, 6 software copyrights; products have successively passed 3C certification, US FCC, UL certification, TUV Rheinland, European CE and RoHS certification, ISO9001 quality management system certification, ISO14001 environmental management system certification Certification, ISO45001 Occupational Health and Safety Management System Certification, and won domestic and foreign industrial design awards such as the Beauty of Made in China and the German IF. The company strictly abides by the ISO9001:2015 quality management system, ISO14001:2015 environmental management system, ISO45001:2018 and GJB9001C-2017 quality management system regulations. Continuously improve product quality and insist on daily 7S management. The company’s LED outdoor advertising media products occupy a large market share and enjoy a good reputation in Japan, the United States and South America.

EagerLED provide unbeatable LED display solutions for your applicaitons and events. If you have any questions or query, you can always email us or talk with our online services. We are always ready to serve.

With an unparalleled depth of shades, fitting color saturation, sharp and clear picture, full digital processing mode and proven technology, LianTronics dedicated high-resolution broadcasting studio display solution for has become a contemporary TV studio"s favorite choice.

Conference display device is important for work efficiency as it collects over 60% perceived information. Based on the most advanced HD technology, LianTronics professional meeting room display solution has provided a smooth "transmission-execution-feedback" commanding process to facilitate a highly efficient meeting.

LianTronics digital signage display solution adopts affordably and finely crafted advertising LED displays to showcase your content to people passing by in both indoor and outdoor settings. With sharp and bright images, your content will be highlighted to its best advantage.

LianTronics provides a one-stop professional glasses-free 3D display solution including LED walls and 3D broadcasting content customization. With years of LED display experience, LianTronics has patented seamless curved surface display technology, which contributes to perfect carriers for 3D delivery without glasses, and meanwhile built up a professional team for 3D video customization. So far LianTronics has conducted glasses-free 3D projects in 20+ cities with a total area of 20000+sqm.

LED display being applied to create immersive and dynamic backgrounds, the LED virtual studio integrates high-configuration LED walls, camera tracking system and real-time rendering technology, and applies advanced technologies like motion capture, AR & VR, to complete virtual production without chroma keying and costly post-production.

The LED floor displays are equipped with thousands of interactive touch sensors, and when combined with an interactive media server, your steps will turn into magic.

With highly valued currencies of flexibility, speed, cost-effectiveness, and advanced technology at its disposal, Irregular creative LED display is being utilized as a palette upon which endless possibilities can be created

Now CBD buildings become an important part of the modern city, in the building on the installation of LED display, not only can play landscape images can also play advertising.

The outdoor Grille display The structure design idea of Louver for reference. The LED panel has The characteristics of high transparency, light and thin, easy to install and maintain. It is a good choice for a CBD Building Display Scheme.

DOOH advertising displays allow brands and stores to be seen and to enhance their reputation, generate traffic at points of sale and stand out from the competition. Brands communicate and relay key information or campaigns in real-time.

Product Display box with a translucent LCD display built in front of it. You put your product in the box, and load a video into the accessory, which connects to your computer, and then the display loops the video over your product. Primarily for business use, very futuristic

With highly valued currencies of flexibility, speed, cost-effectiveness, and advanced technology at its disposal, Irregular creative LED display is being utilized as a palette upon which endless possibilities can be created

With highly valued currencies of flexibility, speed, cost-effectiveness, and advanced technology at its disposal, Irregular creative LED display is being utilized as a palette upon which endless possibilities can be created

-INMO TECH provides global Advertisers / Event Planners with a comprehensive range of LED display-related services from project consultation & planning, raw material supply to technical & aftermarket services.

The LED display is mainly composed of an LED module, power supply, cabinet, and control system. We will introduce in this article, LED module, power supply, and case part. 1. LED Module It is one of the main components that make up the finished LED display. The main...

Large LED display, like traditional electronic products, not only need to pay attention to the use of the process but also need to maintain the screen, in order to make LED display life longer. Now let"s take a look at one of the following: 1. Switching screen...

Why LED display is not energy-saving? In fact, the LED display luminescent material itself is energy-saving, but sometimes the LED screen is usually used in larger areas and needs the big led screen for advertising, So the overall power consumption is still relatively...

Which type of LED display do you need?indoor fixed modeloutdoor fixed modelindoor rental modeloutdoor rental modelbehind windows(shopping centers, low light)behind windows(street front, high light)behind windows(street front, high light)others

The LED display is mainly composed of an LED module, power supply, cabinet, and control system. We will introduce in this article, LED module, power supply, and case part. 1. LED Module It is one of the main components that make up the finished LED display. The main...

Large LED display, like traditional electronic products, not only need to pay attention to the use of the process but also need to maintain the screen, in order to make LED display life longer. Now let"s take a look at one of the following: 1. Switching screen...

Why LED display is not energy-saving? In fact, the LED display luminescent material itself is energy-saving, but sometimes the LED screen is usually used in larger areas and needs the big led screen for advertising, So the overall power consumption is still relatively...

Bibi Led is a leading LED video wall supplier based in Shenzhen, China. To meet the high-quality demand of our customers over the world, we have established modern LED display manufacturing equipment in our LED display factory.

As a world-famous manufacturing area: LED screen China, we have the top quality LED screen chain and best machine made in Japan branding Yamaha in our LED wall factory.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

LED video wall solution with advanced video wall processing, off-board electronics, front serviceable cabinets and outstanding image quality available in 0.9mm pixel pitch

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey