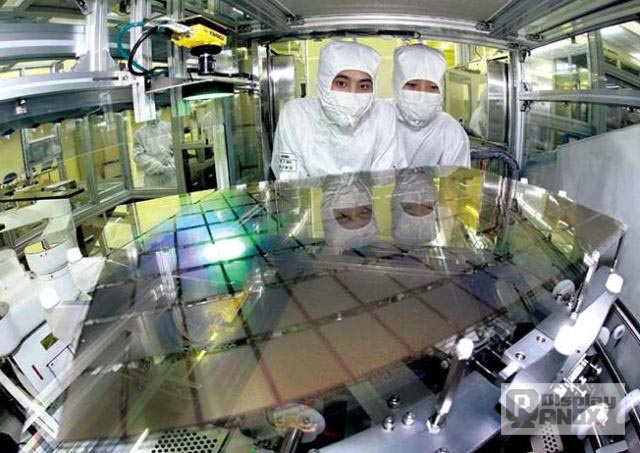

8k lcd panel factory

Before the internet boom, the only source of entertainment was the T.V. Due to its monopoly for years, there were no significant changes made in making it better. Yet with the onset of the internet, everything changed. The entertainment Industry was forced to adapt to the latest market trends. The visual appeal that was once the USP of many devices, was questioned leading to invention of 8K technology by the leading 8K technology manufacturers.

To get a better understanding of the 8K technology, we must first look at the forces such as YouTube and other OTT platforms that pushed the mainstream adoption of the 8K market. The Global 8K Technology Market’s demand rose only during the start of this decade. Prior to this, no major challenges were made to enhance the visual quality of the videos. Different market patterns and external factors helped in carving out an all new viewpoint towards the visual appeal of the videos. Moreover, with the inflow of capital to upgrade the existing technology has attracted new players into the 8K market to explore the arising opportunities.

Basically, the 8K Technology points out the resolution of the picture. Ultimately, the 8K is calculated in terms of the length*width design. The 8K UHD is the highest resolution currently available in the market and has the resolution equivalent to 7680*4320 pixels. It empowers the devices in furnishing the perception of the picture with a superior point and high clearness.

After the extensive research done by the market research experts of the Verified Market Research, it was found out that theGlobal 8K Technology Market was valued at USD 2,758.32 million in 2019. With the ongoing competition to offer the best visual technology and the never ending situation of new players entering into the market, it is expected to expand to USD 62,491.09 million by 2027 (growing at a CAGR of 52.39% from 2020 to 2027).

Subsidiaries: Beijing BOE Display Technology Co., Ltd.; Chongqing BOE Optoelectronics Technology Co., Ltd.; Mianyang Boe Optoelectronics Technology Co., Ltd.; CEC Panda Flat Panel Display Technology Co., Ltd., etc.

Sharp has been regularly making headlines due to its world class technology. The 8K technology is regularly updated and tested to give a refined product to the audience. Sharp is one of the leading names in the 8K display market due to the fact that it uses a unique and innovative approach (not an established method) to design its products.

As compared to the existing conventional players of the market, InnoLux offers products that are completely distinct. Innolux is the only manufacturer that solely focuses on empowering the customers with a complete solution package. This package covers the panel expertise, and vertical integration. Additionally, Innolux gears up the product with its advanced management skills so that the product can last long.

Inclination of the prospective audience towards the 8K innovation is ascending like never before. Due to the elliptical rise in its demand, the TV industry is going to transform itself yet again. Moreover, the buyer’s buying capacity has also improved at global level making the accessibility of 8K much easier.

The market for 8K TVs relies upon the demand of the market. With the reduced costs and better option availability in the market, the TV industry will see a sudden rise in the number of shipments internationally during the upcoming quarters. Huge screens and 8K resolution TVs offer better quality and practical pictures, just like a face to face encounter. This feature has single handedly motivated the people to move towards the 8K innovation market. If you wish to know more about the 8K market, you can also check out the in-house report –. You can get your sample report.

Compared to the number of pixels of 4K panel, 8K panel is 4 times the number of pixels, 10K panel is 5.4 times the number of pixels, so the corresponding number of driver chips are to be correspondingly multiplied. And the more the number of chips, the higher the cost, the control difficulty is also correspondingly increased.

According to the latest IHSLargeAreaDisplayMarketTracker large size shipment report, in July and August 2016, 4K LCD TV panel shipments all reached a single month of about 6 million pieces, accounting for 26% and 24% of LCD TV panel shipments in that month, respectively. And with the LCD TV market large size and 4K TV penetration of each other, the future of this proportion will be further enhanced.

For example, according to the latest IHS large size flat panel display product shipment forecast, in the fourth quarter of this year, this proportion is expected to exceed 30%, and by the second quarter of next year, is expected to further reach 35%. Therefore, following HD, FHD and other resolutions, 4K resolution has become a mainstream in the LCD TV panel market, is already an indisputable fact.

And with the evolution of the market, the flat panel display industry for higher specifications and higher resolution products in the pursuit of the footsteps of far from stop. In the recent various industry exhibitions such as the IFA exhibition in Germany, various manufacturers of 4K products, but more and more 8K products began to appear in various booths, began to enter everyone’s vision, and even some manufacturers such as the mainland panel factory exhibited 110-inch 10K panel products.

According to IHSLargeAreaDisplayProductRoadmapTracker shows that the current panel manufacturers in production or research and development of 8K panel products up to more than 40 models, size range from 65 inches to 110 inches, showing a very optimistic attitude towards the prospects of 8K panel products.

Compared to 4K, with a resolution of 3840×2160, the 8K panel has four times the number of pixels of the 4K panel, with a resolution of 7680×4320 and an image aspect ratio of 16:9, which is also the most mainstream aspect ratio in the current TV market.

The 10K panel exhibited by BOE has a resolution of 10240×4320 and an aspect ratio of 21:9, which is the same as the aspect ratio of the video signal of movie theaters, aiming to bring consumers a more vivid and realistic home theater experience.

Compared to 4K panel, because 8K TV panel pixel density (PPI) is higher, is the same size 4K panel 2 times, so in the production, the manufacturing process, fine processing ability requirements are more demanding, 10K panel is required to go further.

Therefore, and 4K panel just started to enter the market, the panel manufacturers are facing slow yield improvement and even occasionally process problems resulting in poor yields, 8K/10K panel production is also particularly difficult.

The 8K panel requires the source drive and door drive electrode must be copper, so the process is more difficult than the 4K panel general aluminum electrode. Currently only LGD in this area of technology is more mature, while Samsung is in 2016 began a comprehensive technical improvement, the copper electrode process into the whole line, other panel manufacturers are in the 8K panel copper electrode process are more or less encountered a small problem.

In addition, due to the 8K panel pixel amount, pixel density is high, so if you choose a smaller panel size, by too high pixel density will bring additional process difficulties. Therefore we can see that the current 8K panel minimum size that is 65 inches, pixel density of 136PPI; and the vast majority of 8K panel products are selected 75 inches, 85 inches or even like 98 inches / 110 inches and other large size panel.

And oversized panel manufacturing process itself is a complex process, the manufacturing capacity has high technical requirements. And large size, high pixel density, how to control the display image quality, such as brightness, contrast, consistency, etc., are on the production enterprises is a considerable challenge.

But therefore 8K/10K is the “ultimate technology” or “resolution peak” of the panel, seems a bit premature. Although the current flat panel display industry has been huge, but the pace of technological progress has never stopped, especially with domestic enterprises BOE as the representative of the panel manufacturers, has been in the pursuit of higher resolution products tirelessly. With the future domestic BOE and Huaxing photoelectric 10.5 generation / 11 generation production line mass production, in the larger size LCD TV panel production capacity, the pursuit of higher resolution products on the basis of the possibility is still very high.

However, although panel manufacturers and TV brand manufacturers are very active in 8K products, 8K products really enter the market mainstream still need a very long-term industrial development and accumulation. For example, although 4K products have become the mainstream of the market, the majority of TV broadcasting network systems cannot support the broadcasting of 4K content.

As for the production and trial broadcast of 8K content, only NHK in Japan has cooperated with BOE to make some active attempts in the Japanese market since 2015, and some trial recordings and broadcasts were made for the 2016 Summer Olympics in Rio.

Therefore, although we are still very optimistic about the prospects of 8K products, we expect that it will take at least 2~3 years before 8K products really start to take off in the market. In the current situation, 8K products are costly and priced at a premium, so we must wait for the technology to mature further and the products to be priced more affordably before they can take a place in the market.

Based on this and the fact that the sales volume of 8K products in 2016 was less than a thousand units, we expect that in 2018, 8K TV sales will reach more than 300,000 units and break through one million units in 2019, and thereafter enter a rapid growth channel.

![]()

Corning’s newest display glass innovation – Corning® Astra™ Glass – fills an important niche in the evolving world of high-performance displays. Manufacturers will use the glass as a substrate in panels for large-screen 8K technology TVs and other high-performance devices, meeting the demands of customers who want the most lifelike display imagery possible.

For many years, the preferred transistor material for the LCD industry has been amorphous silicon – called a-Si for short. A-Si transistors work beautifully in this application, even up to resolutions of 8K. Corning® EAGLE XG® Glass has led the industry as a substrate for a-Si panels since 2006. EAGLE XG Glass is expected to continue to support the evolution 8k displays over the coming years. However, in some areas the technology necessary to deliver 8K displays is evolving and this evolution is requiring some panel makers to use glass substrates with even-higher levels of thermal and dimensional stability.

A different material – low-temperature polysilicon, or LTPS – proved up to the task, but required glass substrates to endure temperatures of up to 600 degrees Celsius, much hotter than the a-Si panel. Corning Lotus™ NXT Glass, widely available since 2013, gives manufacturers the ideal option for these LTPS mobile electronics devices.

Oxide TFTs are now being adopted by a growing number of panel manufacturers for both organic light-emitting diode (OLED) displays and liquid crystal displays (LCD) with higher electron mobility than amorphous silicon. Oxide panels offer brighter, sharper resolution than a-Si panels and a lower production cost than LTPS, making them well-suited for enabling 8K televisions and other high-performance devices.

Astra Glass is also optimized to reduce sludge during the customer etching process – especially important in smartphone and tablet production. This helps lower both waste and customer costs, both factors that should help support the growing affordability of 8K technology.

As the TV industry evolves, Astra Glass will be a crucial component in both oxide LCD and OLED TVs, as well as in high-performance notebooks and tablets. As part of Corning’s display glass portfolio, it gives panel makers even more options, helping usher in a future of stronger, thinner, faster images with richer colors and an immersive experience across a wide array of devices.

You can get 8k lcd display with an operation range that suits your specific application, choosing from a wide selection of suppliers. Source wholesale 8k lcd display on Alibaba.com for your business and enjoy a wide variety and great deals.

8k lcd display (Liquid crystal display) are made of liquid crystals that form digital images made visible through ambient light or through LED backlight. LCDs are used in the place of other displays that are less efficient such as cathode ray tubes (CRTs) and have become the most popular display type on the market.

Explore the extensive selection of wholesale 8k lcd display LCD displays, TFT, and HMI that can be used across a range of industries, including domestic, medical, industrial, automotive, and many others. You can choose from a number of standard industry sizes and find the 8k Lcd display that are applicable to your required use. If you would like options that allow a smaller environmental footprint due to low power consumption, you can browse the Chip-on-Glass (COG) LCDs. COGs are designed without PCBs so have a slimmer profile.

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

LG Display was, until 2021, the No. 1 display panel manufacturer in the world. Owned by LG Group and headquartered in Seoul, South Korea, it has R&D, production, and trade institutions in China, Japan, South Korea, the United States, and Europe.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Since its establishment, Truly Semiconductors has focused on researching, developing, and manufacturing liquid crystal flat panel displays. Now, after twenty years of development, it is the biggest small- and medium-sized flat panel display manufacturer in China.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

Founded in June 1998, Hannstar specializes in producing thin-film transistor liquid crystal display panels, mainly for use in monitors, notebook displays and televisions. It was the first company in Taiwan to adopt the world’s top ultra-wide perspective technology (AS-IPS).

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

TCL CSOT – short for TCL China Star Optoelectronics Technology (TCL CSOT) – was founded in 2009 and is an innovative technology enterprise that focuses on the production of semiconductor displays. As one of the global leaders in semiconductor display market, it has bases in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou, and India, with nine panel production lines and five large modules bases.

TCL CSOT actively produces Mini LED, Micro LED, flexible OLED, printing OLED, and other new display technologies. Its product range is vast – including large, medium, and small panels and touch modules, electronic whiteboards, splicing walls, automotive displays, gaming monitors, and other high-end display application fields – which has enabled it to become a leading player in the global panel industry.

In the first quarter of 2022, TCL CSOT’s TV panels ranked second in the market, 55 inches, 65 " and 75 inches second, 8K, 120Hz first, the first, interactive whiteboard and digital sign plate; LTPS flat panel, the second, LTPS and flexible OLED fourth.

EDO (also known as EverDisplay Optonics) was founded in October 2012 and focuses on the production of small- and medium-sized high-resolution AMOLED semiconductor display panels.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Although Sony’s TVs use display panels from TCL CSOT (VA panel), Samsung. Sony still produces the world’s best micro-OLED display panels. Sony has many micro OLED model such as 0.23 inch, 0.39 inch, 0.5 inch, 0.64 inch, 0.68 inch, 0.71 inch. Panox Display used to test and sell many of them, compare to other micro OLED manufacuturers, Sony`s micro OLEDs are with the best image quality and highest brightness (3000 nits max).

Innolux Corp (群創) and AU Optronics Corp (AUO, 友達光電) are to ship the world’s first ultra-high-definition 8K LCD TV panels next quarter, one quarter ahead of their South Korean rivals, in an attempt to repeat the success in unveiling 4K panels, market researcher TrendForce Corp (集邦科技) said yesterday.

Innolux started shipping a small volume of 65-inch 8K TV panels for customers, while AUO is to ship 65-inch 8K TV panels for global TV vendors next quarter, according to WitsView, an LCD research team of TrendForce.

“The 8K TV panel is a business opportunity for Taiwanese LCD manufacturers as long as they do not engage in a capacity race with their rivals,” WitsView senior research director Eric Chiou (邱宇彬) said by telephone.

However, this time, local panel makers might not be able to benefit from selling 8K panels as much as they did in introducing 4K TV panels, Chiou said.

Only a few 8K LCD TVs will be available on the market this year, WitsView said, adding that these will be equipped with 4K chips, as 8K chips are under development.

On a recent visit to light field display developer Looking Glass Factory (LGF), we had a chance to see their new glasses-free 3D displays holographic monitors. This lineup includes the new 7.9” Portrait Display and Generation 2 versions of the 15.6” 4K model and the 32” 8K monitor. After a 2-year hiatus in showing their products, the company was pleased to start showing off these new displays.

These displays use a sophisticated light steering lens to blend dozens of views only in the horizontal direction. This lack of vertical parallax is perfectly adequate for a wide range of use cases and creates some compelling images. The lens array always reduces the native resolution of the underlying display panel. You can see some modest structure in the images presented on our visit – even on the 8K display holographic monitors. But this is negated by the fidelity of the overall 3D image.

Stepping up to 8K is a big jump in price – $20K but on sale now for $17.5K. But this size also makes a big difference in the impression it creates. Apparent resolution is probably on the order of 4K. This resolution has appeal in professional design applications and retail and signage applications.

This display is based on LCD technology and is a 10-bit panel, so it can potentially support HDR mage display, although LGF does not market it as having this capability. There may be a need for an HDR version in professional design markets, but its value at retail may be less.

Content creation is always a concern as well. CAD files and content created with tools like Maya and Blender can be imported into a Unity or Unreal game engine and formatted for display on the LGF monitors. Camera capture using volumetric rigs works very well, and LGF even has a rail-based system that snaps 70 images as the DSC moves along the rail. Capturing a 3D image of the author and display was possible with this approach on the 8K monitor, only seconds after capture. Pretty impressive.

We also asked about a larger 55” to 65” class 8K version. “This is probably the question our customers ask us the most about, noted Shawn Frayne, company CEO. “We are certainly considering this option, and you will be the first to know!” I doubt that but nice of him to say so. Check out the video below as well.

Electronics manufacturing giant Foxconn Technology Group has high hopes for its 8K display ecosystem, especially in the security, healthcare and manufacturing industries, according to a senior executive of the firm.

Foxconn launched 8K TVs last year, but its vice-president Jacob Chen said there is wider potential for application of the technology and the future market could be worth thousands of trillions of yuan.

The 8K TVs have a screen resolution ratio of 7,680 by 4,320 pixels - 4.3 times clearer than human eyesight and four times higher than the 4K ones, which are still hit products of most TV manufacturers in Chinese home appliance stores.

But the price of an 8K TV is more than four times higher than a 4K set. Chen told China Daily that Foxconn will release a new 8K TV this year at a price equivalent to 4K sets, or even cheaper.

Besides, Foxconn has also developed a 5 kg camera for 8K content and plans to set up several 8K content producing centers, and even open an 8K channel with a domestic TV station in the future.

However, it is more than just entertainment. Chen believes the large number of ultra high-definition video data it generates could improve work efficiency in the manufacturing industry. Foxconn already uses 8K technology in its own factory production lines.

Wang Cheng, senior vice-president of TCL Corp, agreed, saying the era of 8K is about to come, as chip, signal transmission and data storage technology have significantly improved nowadays.

"The establishment of more and more new generations of production lines will largely cut the cost of 8K displays," he said on Tuesday at the China Information Technology Expo in Shenzhen.

TCL"s Generation 11 display production line in Shenzhen is expected to come online next year, while Foxconn is building the world"s largest 8K-resolution panel factory in Guangzhou, the capital of Guangdong.

Qiao Yueshan, deputy director of the information technology department at the Ministry of Industry and Information Technology, on Sunday said at a meeting before the CITE that the total market size of ultra high-definition video technology, including 4K and 8K, is expected to reach $2.2 trillion in 2022.

ELEGOO, a company specializing in the research, development and production of 3D printers, has launched the Saturn 2 8K MSLA Printer, an 8K printer in its product portfolio, at US$500. It also unveiled a new series of 8K resins, its latest Mercury XS Bundle Washing and Curing machine, and the Neptune 3 FDM printer. The latest product lineup is available for purchase.

ELEGOO"s Saturn 2 8K is equipped with a 8K 10-in. mono LCD screen, which the company has jointly developed with Innolux, a subsidiary of the Foxconn Technology Group, a professional TFT-LCD panel manufacturer and a supplier of Apple.The Saturn 2 8K"s screen delivers more clarity and precision for 3D printing. Saturn 2 8K can reproduce the details needed for realistic 3D models.

Recognizing the delicate nature of an 8K screen, ELEGOO"s Saturn 2 8K has a replaceable 9H tempered film to guard against wear and tear. 9H tempered glass resists scratches from 9H pencils, the hardest standard grade of lead. As a result, the Saturn 2 8K is highly durable and has an extended screen life compared to other devices on the market.

Equipped with combination optical design of FCLS (Fresnel Collimating Light Source), a technology independently developed by the ELEGOO R&D team, the Saturn 2 8K overcomes the large-angle problem of typical COB light sources and the light spot problem of matrix light sources by adopting the Fresnel lens, an optical lens design technique that limits the light angle under 5 degrees. This results in more realistic printed models.

Working with ELEGOO"s new 8K standard and water washable resins, ELEGOO also introduced the new thermochromic resin, which changes from gray to purple at 50 degrees Celsius and returns to its original color when cooled.

ELEGOO also released new iterations of products in its portfolio. A step up from the popular Neptune 2, the Neptune 3 printer is priced at $209.99, with features of RSG (Resistance Strain Gauge) Auto Leveling System, Filament Runout/Clog Detector and taking less than 10 minutes to install. In tandem, ELEGOO has launched its new Mars 3 Pro LCD Printer and Mercury XS Bundle Clean and Cure machine, priced at $300 and $180 respectively.

TV Display BOE television displays cover 23.6-inch to 110-inch products, with maximum resolutions of 8K and 10K. They feature ultra HD, super narrow border, and high image quality. Products are extensively used in smart home appliance, entertainment, business, education, finance, and other fields.

One of the joys of 8K is that you can use huge displays yet still avoid that ‘dotty’ look or ‘pixelation’ where you can see the individual dots that make up the image. The author once was late into an early digital cinema demonstration and ended up in the front row. At that time, digital cinema projectors were just 1280 x 1024 resolution – probably lower resolution than your smartphone – and the dots were very obvious. It was not a great experience!

8K can enable displays right up to 100″ or more to look really, really good. However, although 55″ and 65″ sets are incredibly cheap these days, prices start to rise, and options tend to reduce at 75″ and above. We thought we’d look at what is happening in the market for 100″ class sets from 90″ to 110″ diagonal that could offer 8K.

The easiest way to get such a big display is to use a projector, but there are no native 8K consumer projectors on the market. However, JVC does offer a native LCOS-based 8K projector for a customer in the simulation market. Projectors use tiny imaging devices based on DLP, LCOS, or LCDs. These have challenges in getting down to the small pixel sizes needed for 8K, at least with the optical efficiency required to give the brightness that you would want to see. One solution to this challenge is using 4K or UltraHD imagers and shifting them rapidly to create more dots within a single frame. That’s the same technique used to create a lot of 4K projectors using FullHD imagers.

JVC also offers a pixel-shifting projector that touts 8K resolution. It uses a UHD-resolution set of images and shifts the image four times very rapidly to resent an 8K image on the screen (DLA-NZ9 / RS4100 & DLA-N8 / RS3100). The DLA-NZ7 / RS2100 projectors use two shifts to present a near-8K image. Digital Projection offers a 3-chip DLP projector with pixel shifting to offer 8K as well, primarily for commercial customers.

OLEDs are significantly more challenging to make than LCDs because the backplanes that control each pixel are considerably more complicated than those used by LCDs. That’s because of the way that OLEDs work, and you also have to use better quality silicon than LCDs – all the energy for the display has to go through the transistors. 8K is a challenge for OLED because there are, believe it or not, at least 300 million transistors on the back of an 8K OLED panel! That makes them very tricky to make. Furthermore, for 8K, you have to send the current to the pixels from the edge of the display twice as fast, so each line on the display is only addressed for half the time. That means that you need twice as much current for the same brightness, which again makes things very difficult.

Currently, the only OLED panels with 8K are available from LG Display. Samsung is still developing its 4K QD OLED panels and has not yet fully stabilized its production, so it is sticking to 4K for now. It may stick there for a while as it has limited capacity for the new technology in its new factory in Korea.

LG Display has only been making 8K panels in the 77″ and 88″ sizes up to now, so OLED is also out of the picture unless you extend the definition down a little. Still, those set costs from $13,000 to $30,000, so they are not exactly mainstream sets. There is a new 2022 UltraHD/4K 97″ set, a G2 model from LG Electronics that is expected to be available this year at $25,000. We have also seenrumors about a new 97″ 8K OLED TV panel from LG, but at the moment, there has been no confirmation.

LCD makers have been making 100″ class panels for quite a long time, partly to prove that they can (there was a ‘mine’s bigger than yours’ competition between Sharp and Samsung for some years!). LG Philips (the forerunner of LG Displays) reported making a 100″ panel in 2006.

The pixel size for an 8K is the same as a 50″ 4K panel or a 25″ FullHD monitor, so it’s not difficult at the pixel level for LCDs, although the faster drive time does present some challenges.

For OLEDs or LCDs, the key to getting an excellent and uniform image is to deliver the proper voltage for each pixel at the right time directly over the pixel through transparent or very, very fine metallic electrodes from the top edge of the display. It’s challenging to achieve that over a (relatively) long electrode from the top to the bottom of the display. Early 100″ class LCDs used drivers at both the top and the bottom to get around this, but that adds a lot of cost and complication. Still, makers have worked out how to do it now, and products are available.

However, they are not cheap. The main reason for this is the challenge of getting good yields for these panels. The same area of LCD glass with transistors can make 16 25″ monitor panels or 64 12.5” notebook panels. When you have a significant defect in the manufacturing process caused by a speck of dust or an impurity in some materials, if you are making notebook panels, you can throw away the defective one and sell the other 63. However, if you are making 100″ panels, you have to throw away the whole thing. That makes it tricky to get good production yields, so the cost goes up.

One way to get around this yield issue is to make modular displays and combine them, but nobody has successfully done that with LCDs, although several firms have tried. However, dvLED or direct view LED (to distinguish from LCDs with LED backlights) displays are made that way using either PCB modules or, in the future, using glass substrates, not very different from those used to make smartphone LCDs and about the same size. However, there are two challenges with this approach.

The first challenge is cost. Unfortunately, the cost of LED displays scales with the number of LEDs rather than the area. So an 8K 100″ microLED would cost up to four times as much as a 4K set – almost regardless of size. Now, given that the price of a current Samsung 110″ ‘The Wall’ 4K set is around $156,000, an 8K set could cost over half a million dollars!

Although microLED can be modular (so you can have a Sony MicroLED TV up to a 16K set with 63′ of diagonal or a more modest 8K at just 440″ diagonal (32′ x 18′), at the moment, Samsung’s LEDs between 89″ to 110″ are ‘monolithic’ and assembled before delivery.

A few years ago, Panasonic made and sold 100″ PDPs and even demonstrated a 150″ PDP set. They used much thicker glass than LCDs, so they were cumbersome, and the logistics of shipment from the factory in Japan added a massive cost to the 100″ sets. The 150″ was just a demonstrator, and shipping it between trade shows around the world cost hundreds of thousands of dollars!

Of course, LG has a very expensive ($100,000 for a 65″!!) rollable OLED TV that could be used to deliver a 100″ set. Still, all the issues of yield and difficulty of manufacture get worse with this technology, so a rollable 8K 100″ is likely to be some years away (although, in the long term, we wouldn’t bet against it appearing!)

For all these reasons, at the moment, LCD is the only game in town for native 8K displays, and buyers can exploit the remarkable developments in quantum dot color and backlight processing to get truly compelling displays.

Foxconn CEO Terry Gou was the first official to speak at the announcement, and his short talk focused on high-definition "8k" displays, which would have higher resolution than most current TV screens on the market, which are sold as "4K."

The planned Wisconsin factory will make flat-panel LCD screens for televisions and other electronics. Bloomberg previously reported that the screens could be used to make Sharp-branded televisions.

*Remember to check the Aqua-Gray 8K add-on box before adding your 8K printer to the cart!*For US customers, free shipping is available only for the 8K printer. The two free Aqua-Gray 8K’s shipping fees will be calculated at checkout.

With the highest resolution of 22 µm and 1152 ppi, Sonic Mini 8K surpasses all consumer electronics on the market. The 7.1” LCD screen & 18 cm Z-axis are perfect for printing all sorts of extremely intricate miniatures, bust sculpts, and more!

Both North American & European Adapters will be provided with the Sonic Mini 8K. If either adapter is not designated for use in your country or region, please feel free to purchase your own.

All products purchased from the official website of Phrozen are warranted under different terms. Phrozen offers a one-year warranty for all our products except consumables and components; this includes the LCD screen and the FEP film. All LCD screens for the Sonic Mini, Sonic Mini 4K, and Sonic 4K are covered under a 3-month warranty. For more details, please refer to our

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey