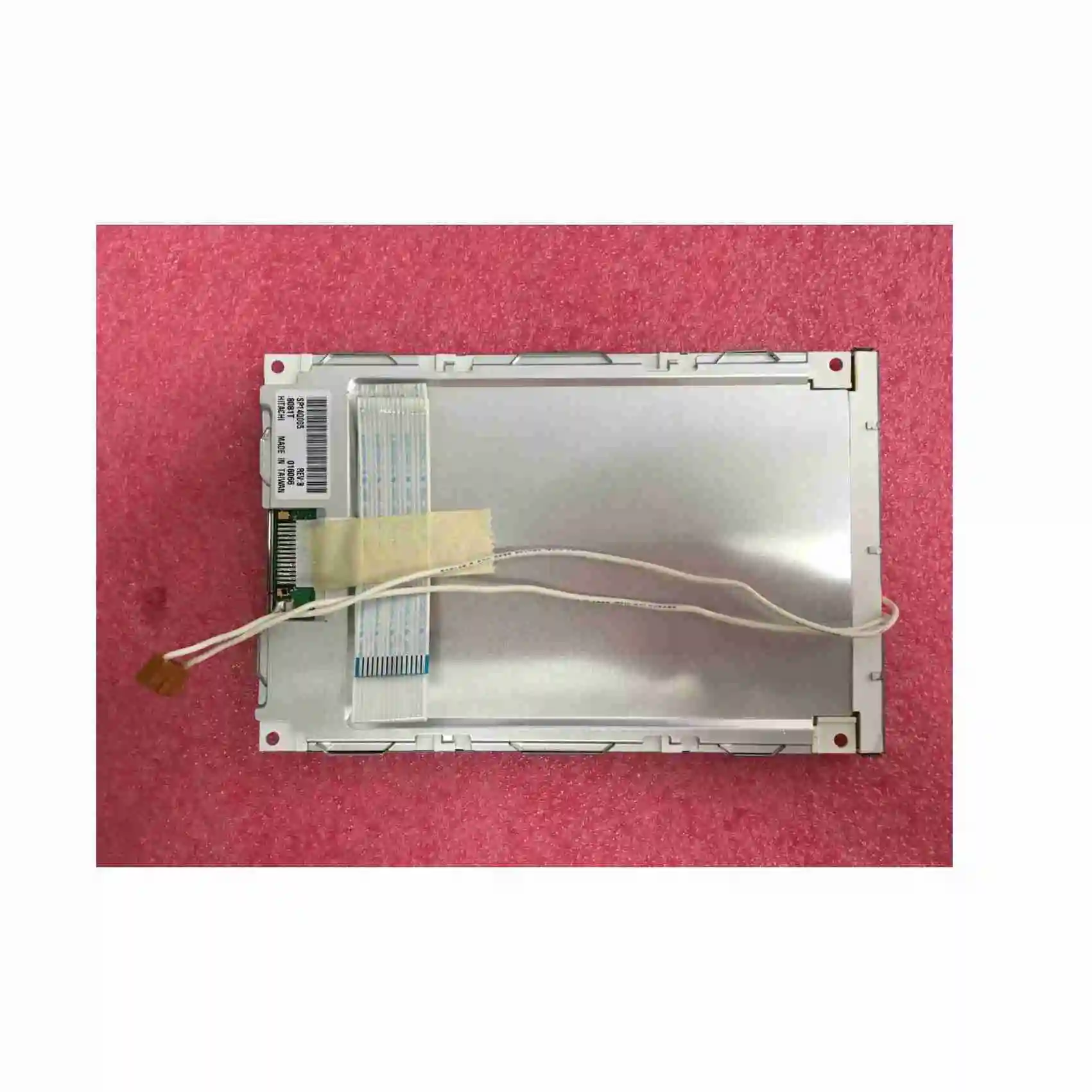

taiwan lcd panel in stock

Our products for sale include world-renowned LCD brands such as LG.PHILIPS, AUO, CMO, SHARP, NEC, SAMSUNG, CPT, MITSUBISHI, BOE.HYDIS, CHIMEI and HANNSTAR.

We emphasize product quality and reasonable prices for the products and work hard at establishing a product supply chain for all brands, so that non-bulk purchasers and research and development personnel can more easily acquire LCD panels.

1743 lcd panel taiwan products are offered for sale by suppliers on Alibaba.com, of which lcd modules accounts for 67%, mobile phone lcds accounts for 1%.

A wide variety of lcd panel taiwan options are available to you, such as original manufacturer, agency and retailer.You can also choose from tft, ips and standard lcd panel taiwan,

Innolux Corp. is engaged in the manufacture and sale of thin-film-transistor liquid-crystal display and touch panel modules. It offers television, desktop monitors and notebook computer, audio and video, and mobile panels. It also offers glass, film, and one glass capacitive touch panels. The company was founded on January 14, 2003 and is headquartered in Miaoli, Taiwan.

All firms with considerable business scales in Taiwan"s electronics industry are publicly traded. When they release their tentative annual financial indicators, we can already grasp the growth momentum of the industry, as well as the interactions between different industry sectors and the medium- and long-term outlook. DIGITIMES has again collected data on the ICT product manufacturing, semiconductors, optoelectronics, IC distribution and components sectors, providing readers with a comprehensive picture of the electronics industry and an outlook of the industry trends in 2023.

Samsung Display (SDC) and LG Display (LGD) will ramp up their OLED panel output in 2023 to fend off competition from Chinese rivals, according to sources at the TV supply chain makers.

LCD TV panel prices will likely remain stable in February, as panel makers" efforts to control capacity utilization rates have brought a healthier supply-demand balance for the display industry, according to industry sources.

Taiwan-based makers received export orders totaling US$52.17 billion in December 2022, down 23.2% on year, according to the Ministry of Economic Affairs (MOEA).

LG Display"s and Samsung Display"s globally leading TV OLED technology has been threatened by China-based makers of TV OLED panels, according to industry sources.

The Taiwanese government approved 2,566 investment projects proposed by foreign (excluding China-based) and overseas Chinese enterprises in 2022, with the total investment of US$13.303 billion hiking 77.94% on year, reaching a 15-year height, according to Taiwan"s Ministry of Economic Affairs (MOEA).

LG Electronics has sourced OLED panels from Samsung Display for its new Gram Style notebooks, marking the first time Samsung has supplied LG with OLED panels, according to Korean media reports.

Before microLED technology becomes mature for commercial use, miniLED-backlit LCD panels will compete with OLED panels for application to high-end automotive displays.

Display panel makers" production utilization rates are expected to remain at low levels while panel prices will stay stable in the first quarter of 2023, according to industry sources.

TFT-LCD panel maker Innolux has undertaken zero-waste and zero-pollution automation of its liquid crystal extraction process, according to the company.

Although LCD panel makers have recently seen a short-term surge of their capacity utilization rate to 60-70%, up from 60% in September 2022, most makers in the line believe demand for their products will remain weak in 2023.

As it will take time for the sagging global economy to recover, panel demand from the primary application sectors, such as LCD TVs, monitors, notebooks, tablets and smartphones, will likely continue declining instead of picking up in 2023, according to industry sources.

Samsung has struck LTAs for the supply of TV panels with AU Optronics (AUO), China Star Optoelectronics Technology (CSOT) and HKC, according to industry sources.

LG Display (LGD) may continue to scale down its LCD TV panel production, having closed its 7.5G fab in Paju, South Korea, at the end of 2022, according to industry sources.

Price for handset panels have dropped further in the first quarter of 2023, while quotes for TV and IT display products hold steady, according to industry sources.

Despiting the rising popularity of OLED panels among notebook brands, miniLED-based displays have also been expanding their presence in the notebook market.

While LCD panels have been dominantly used in automotive displays, demand for higher-quality in-vehicle displays will lead to competition between OLED and LCD panels, according to Taiwan-based LCD DDI (display driver IC) and TDDI (touch & display driver integrated IC) design houses.

More panel makers, including BOE Technology and Sharp, have begun churning out OLED displays for notebook applications as notebook brands have added more OLED-based models to their offerings.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Taiwanese manufacturers of the panels used to make flat-screen computer displays are set to grab an even larger slice next year of a global market they now control two-thirds of, analysts said yesterday.\nBy the end of next year, Taiwan is expected to control 73 percent of the thin-film transistor liquid-crystal display (TFT-LCD) panel market for computer monitors, up from 65 percent of this year, according to a report given yesterday by Li Hsiou-ling (勵秀玲) of the Market Intelligence Center (MIC) under the Institute for the Information Industry.\nFalling prices have encouraged more people to buy new computer systems with flat-screen computer monitors and replace the bulky cathode-ray tube (CRT) screens in existing systems.\nWorldwide LCD monitor sales are expected to jump almost 60 percent to around 51 million this year compared to last year, Li said, and will grow a further 35 percent next year to over 68.5 million.\n"Price is a major factor in the rise of LCD monitors," Li said. "But for the average consumer the current average selling price of between US$300 and US$330 still needs to come down."\nLocal manufacturers AU Optronics Corp (友達光電), Chi Mei Optoelectronics Corp (奇美電子), Quanta Display Inc (廣輝電子), HannStar Display Corp (瀚宇彩晶), and Chunghwa Picture Tubes Ltd (中華映管) have been increasing production to supply world brandnames like Dell Inc and Hewlett-Packard Co with TFT-LCD panels.\nDell outsources 55 percent of its production to Taiwanese manufacturers, MIC said yesterday, while HP places 90 percent of its LCD monitor orders here.\n"I think it is possible for Taiwan"s flat-panel makers to break the 70-percent barrier in the computer monitor market next year," said Martha Chen (陳紅), an LCD panel industry analyst with Primasia Securities Co in Taipei.\n"They are increasing their production based in China which will probably win them more orders, and they have a ready supply of downstream suppliers," she said.\nIn a recent report, US-based researcher DisplaySearch already predicted that Taiwan"s share of the global flat-panel monitor market would increase to 69 percent in the third quarter from 63 percent in the second.\nBut when panels for notebook computers, color-screen mobile phones, flat-screen televisions and other consumer products are taken into consideration, Taiwan falls into second place behind rivals in South Korea with 39 percent of the world"s total TFT-LCD panel market, compared to South Korea"s 43 percent, Japan"s 14 percent and China"s 3 percent, according to figures released yesterday by MIC.\nTaiwan is not expected to overtake South Korea in the next twelve months as manufacturers here were slow in opening more efficient and advanced fifth-generation (5G) facilities which produce bigger panels, or more panels from an original piece of glass.\n"The [South] Koreans are well ahead of Taiwanese companies," Chen said. "The Taiwanese are trying to close the gap."\nWith more than a year"s head start on the Taiwanese, the South Koreans have fine-tuned production at their 5G plants so that the number of defective panels has been reduced drastically.\n"South Korea"s 5G production already has a yield of more than 80 percent," MIC"s Ann Hsu (徐美雯) said. "The Taiwanese are facing a shortage of color filters [panel components] and their 5G yield rates are very low."

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey