photocentric lcd panel quotation

Photocentric has been working with Ukrainian aligner experts, Usmih, to help them develop an innovative aligner manufacturing process that pushes the boundaries of what 3D can offer the dental industry in both throughput and cost.

Bridge are one of the first Dental customers to switch to our new high-performance resin for the printing of clear aligners. Photocentric’s rigid 3D printing resin has 50% plant-based raw materials offering a reduction in carbon emissions in comparison with conventional resins.

SouSmile is Brazil’s largest direct to consumer invisible aligner company with a presence in 30 cities, they invested in a trio of Photocentric Liquid Crystal Magna 3D printers to produce their dental aligners in scale.

The 3D Printing Store (3DPS) has used Photocentric’s LC Magna to manufacture a custom drill collet, making windshield repair easier and more efficient than ever before. Photocentric partner 3DPS was approached by Tim Evans and his company Crack Eraser.

As an homage to this classic game, 3D w praktyce were tasked with creating a short stop-frame animation. For this animation, a 3D print-ready file of the character Rockford was created using Photocentric Studio which was then printed on the LC Magna.

Discover how military collectable manufacturer Staples & Vine overcame production challenges with the adoption of Photocentric’s 3D printing processes.

The powerful alliance of Xkelet and Photocentric has created a new solution to traditional orthotics; a digital 3D printed splint that provides significant benefits over traditional methods and is revolutionising the treatment of damaged bones.

Photocentric supplied millions of printed face shields to the NHS at a time of national need. We did it in weeks by making a purpose-built factory housing 45 Magna printers, operating 24/7. We made 50,000 parts every day.

We invented 3D LCD printing and the Liquid Crystal Magna represents the pinnacle of our product development. Our largest printer, with 1,000’s successfully deployed around the world. See how Magna can transform your business.

By working together with Photocentric and their LC Magna 3D printer we want to continue to push the boundaries in investment casting to make the impossible, possible for our customers, and their customers’.

We now have a solid and reliable way of turning our products into reality thanks to our collaboration with Photocentric and their unique LC Magna 3D printer technology.

We have recently tested 3D prints produced by the Photocentric Magna and were thoroughly impressed with their accuracy and quality, when measured against our standard calibration models.

Photocentric have spent 1000’s of hours developing proprietary technologies that enable consistent, high-quality prints to be produced at scale. Blow-Peel is a patented technology that features in our LC Magna.

Jointly developed by Photocentric and CoreTechnologie, the innovative Photocentric Additive software suite has been designed for Liquid Crystal Magna.

Enabling custom mass manufacture and large component printing. From Dentistry to product design and manufacture, the LC Magna’s 23.8” LCD screen and 510 x 280 x 350mm build volume manages larger projects with speed and accuracy delivering print results and geometry previously impossible using traditional manufacturing techniques.

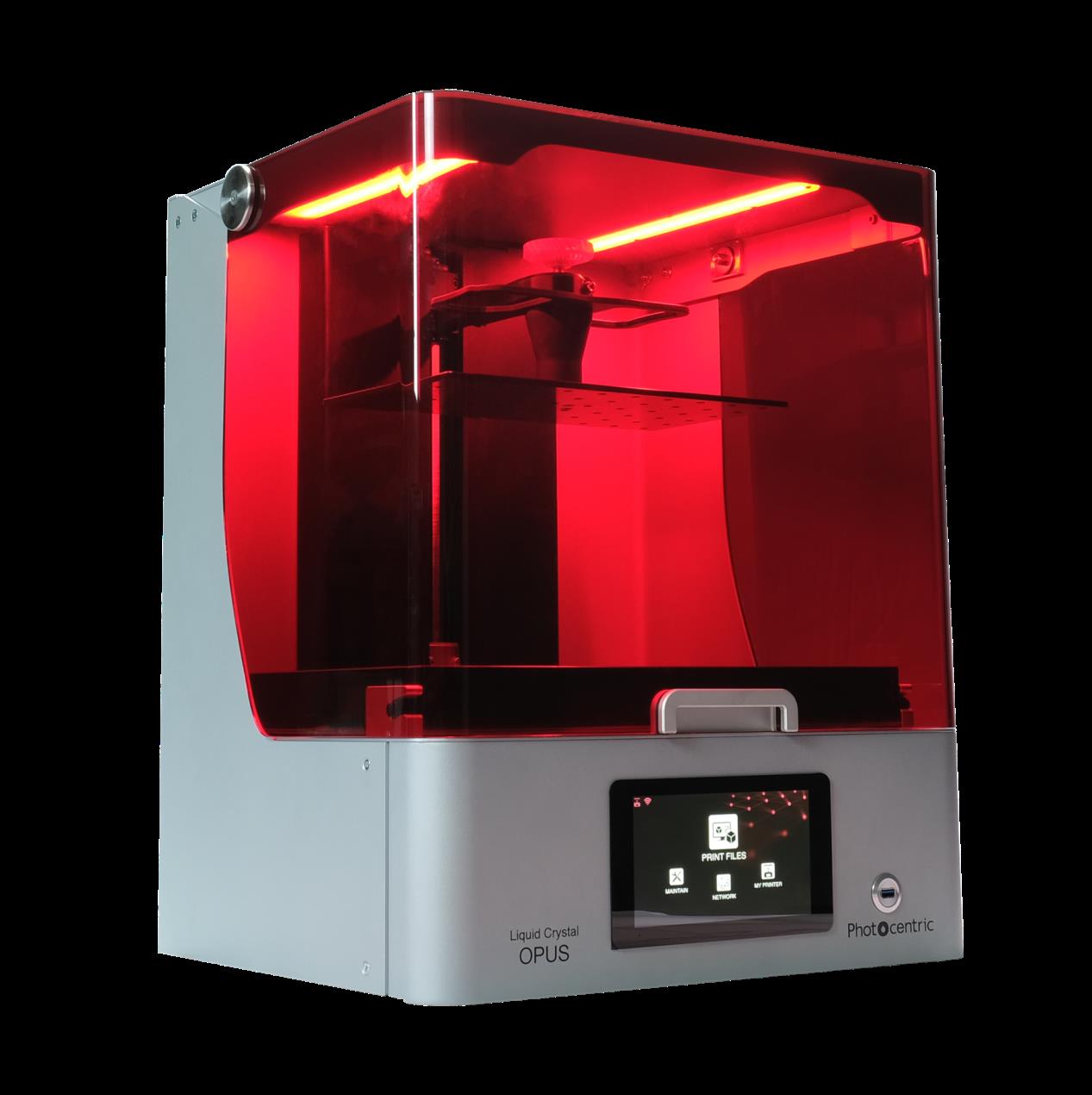

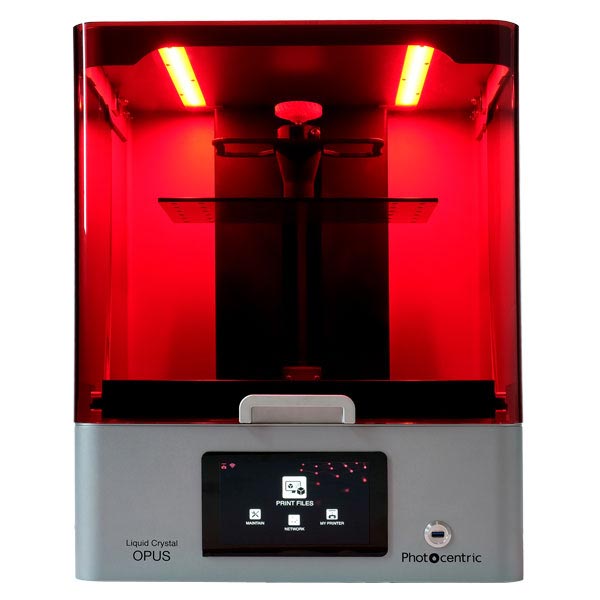

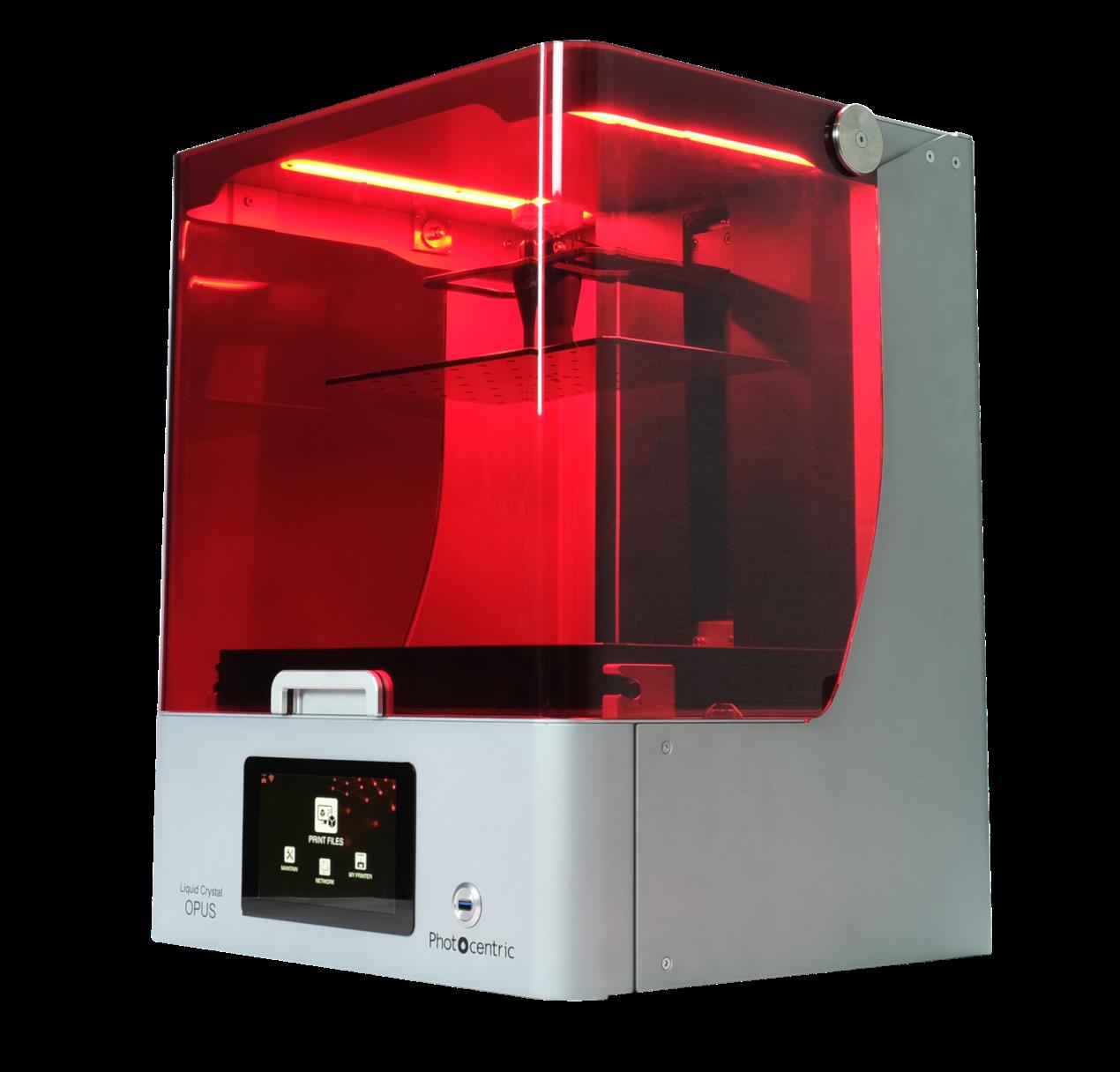

The Photocentric LC Opus utilizes an interesting workaround to break the suction formed between a freshly cured layer of resin, the vat film, and the LCD below: "Vat-Lift." By using a second stepper motor at the rear of the LC Opus, the vat is gently lifted and lowered with each layer, relieving tension in the system, allowing air to flow between the various layers, and for the vat film to act as a flexible membrane.

The biggest hurdle for any new 3D printer is getting it tuned and set up for reliable 3D printing. Fortunately, Photocentric calibrates every LC Opus before it leaves their production line and heads to your workshop.

With LCD 3D printing, print times are dictated by the tallest model in the batch; one instance or one hundred will have exactly the same print times. In tandem with the Vat-Lift mechanism, you can trust that a build plate full of 3D prints will finish successfully and packing it full to the edge is an efficient use of your print jobs.

From the feet to the frame, every part of the Photocentric LC Opus has been thoughtfully considered and intentionally designed. Trust that this machine has what it takes to be a 3D printing powerhouse for your productions.

Photocentric has developed a pair of 3D printers to fully equip your workshop, whether you need something large or something massive. Here are some Photocentric 3D printer features at a glance:

The LC Magna has the largest build volume an LCD 3D printer has to offer. Create full-sized one-piece prototypes or huge batches of products in one print job.

The Photocentric LC Magna breathes with every layer, blowing air under the vat to relieve pressure and allow the 3D print to gently separate. Air is then drawn out of the pocket between the vat film and the screen, suctioning it down to the LCD, ready for the next layer.

The biggest hurdle for any new 3D printer is getting it tuned and set up for reliable 3D printing. Fortunately, Photocentric calibrates every LC Magna before it leaves their production line and heads to your workshop.

With LCD 3D printing, print times are dictated by the tallest model in the batch; one instance or one hundred will have exactly the same print times. In tandem with the Blow-Peel mechanism, you can trust that a build plate full of 3D prints will finish successfully and packing it full to the edge is an efficient use of your print jobs

From the feet to the frame, every part of the Photocentric LC Magna has been thoughtfully considered and intentionally designed. Trust that this machine has what it takes to be a 3D printing powerhouse for your productions.

Photocentric has developed a pair of 3D printers to fully equip your workshop, whether you need something large or something massive. Here are some Photocentric 3D printer features at a glance:

Central to the Liquid Crystal is the patent pending Daylight Polymer Printing Technology. By combining a high resolution LCD screen and our specially formulated polymer, designers, engineers and artists can now produce large objects in high resolution.

Integral to the printer is the unmodified, Ultra High Definition LCD panel used to cure the resin. The 23.8” display offers 3840 x 2160 resolution with an XY pixel size of 137 microns, giving accuracy and fine detail. High brightness and high contrast ratio also contribute to building faithful representations of your 3D models.

Central to the Liquid Crystal is the patent pending Daylight Polymer Printing Technology. By combining a high resolution LCD screen and our specially formulated polymer, designers, engineers and artists can now produce large volumes at a fraction of the cost of other 3D printers

Integral to the printer is the unmodified LCD panel used to create parts. The 10” display offers a XY pixel size of 220 microns, giving good accuracy and detail.

Featuring a 700 x 395 x 1200 mm build volume and an 8K 7660 x 4320 pixel display, the LC Titan is the largest, most powerful Photocentric unit to date. These beefed-up specifications enable the firm’s latest system to 3D print polymer parts at a speed of up to 16 mm per hour, with automotive, transport, creative arts and merchandising applications.

Established in 2002, Photocentric has spent the last two decades progressively developing and wielding its photopolymer expertise to advance the manufacture of plastic parts. The firm’s 3D printer R&D really took off in 2014, when it received Innovate UK funding to develop a new LCD system. Since then, Photocentric has patented its technology and moved into a new 35,000 sq. ft facility.

In 2015, the company went on to launch its debut system, the Liquid Crystal, before introducing the larger-format LC Maximus. Up until the release of the LC Titan, the latter, which shipped with a 40” 4K LCD screen and enabled the mass-production of parts, was Photocentric’s largest machine to date. That said, the photopolymer specialist’s offering hasn’t always prioritized capacity.

The LC Opus, for instance, has a print speed of 18 mm per hour, meaning that despite its smaller 310 x 174 x 220 mm build volume, it remains Photocentric’s fastest machine. As such, the system is said to be ideal for those operating in dental labs or engineering workshops seeking a rapid, reliable and compact production tool.

Debuted in prototype form at this year’s Formnext, the LC Titan represents a significant upgrade on Photocentric’s recently-upgraded LC Magna system. Although the machines feature the same light output of 2MW per cm2 at 460nm and resulting print speed, the LC Titan packs a larger build volume and more powerful LCD display.

While other details about Photocentric’s latest offering remain thin on the ground, the firm has revealed that it is set to ship with a high-performance integrated control software. The system also comes fitted with a resin autofill system, designed to help users automate and accelerate their 3D printing workflow, and a peel release technology that makes it easier for users to remove parts once processed.

Alongside the LC Titan, Photocentric showcased a range of exhibits 3D printed at its purpose-built print farm in Peterborough. These included parts manufactured from alumina, a versatile ceramic with the ductility, as well as the chemical and thermal properties, needed to lend it aerospace, medical, automotive, chemical and electronics applications.

Working with the Centre of AM Excellence or ‘AM-COE,’ the firm has also started offering to mass produce 3D printed silica cores with improved performance compared to their injection molded counterparts, for high-value customers. Turbine blades produced through this partnership were displayed at Photocentric’s booth, as were aligners 3D printed by S4S Dental and casts created by Xkelet.

“We are thrilled to be back at Formnext bringing our latest advancements on materials, hardware and control software to scale up additive manufacturing processes through automation and enable customers to run production parts in our 66,000 sqft digital factory,” Photocentric CEO Paul Holt said ahead of the show. “On display there will be an array of parts with textures and finishes that we manufacture using [our] combined technologies.”

Below are the technical specifications for Photocentric’s new LC Titan 3D printer, which will be available for purchase from 2023. Prospective customers can request a quote from Photocentric directly.

The advanced technology of LC Dental’s screen and light engine enables you to use whatever resin you like; either Photocentric catalogue of materials or LCD, DLP and Laser materials available.

The Photocentric Cure M is specifically designed to provide a reliable and professional post-solution. User-friendly and its intuitive software allows you to control every aspect of the drying process.

The Photocentric Wash 15 is a state-of-the-art ultrasonic technology to remove any excess resin materials from the 3D printed objects. It is capable of cleaning parts regardless of the complexity of the geometry.

Photocentric Durable range is the most versatile material of the Photocentric functional materials, resisting impact, compression, bending, and stress fatigue without breaking or deforming. Photocentric Durable UV80 works with…

Ultracur3D EPD 1006 powered by Photocentric is the first in a new portfolio of 3D printing resins developed in partnership with BASF. This durable resin is perfect for creating…

Ultracur3D® EPD 4006 Powered by Photocentric is ideally suited for making large-scale objects where a hard finish is essential. This Daylight resin designed for use on Liquid Crystal Magna…

Ultracur3D® EPD 2006 Powered by Photocentric is ideal for making large-scale objects displaying extreme hardness when pressure is applied. This Daylight resin designed for use on Liquid Crystal Magna…

Ultracur3D® EPD 3500 Powered by Photocentric is a strong translucent daylight resin with superior strength and stiffness. This Daylight resin designed for use on Liquid Crystal Magna.

HighTemp DL400 is the first Photocentric temperature resistant resin possessing superior properties of both strength and stiffness. It can handle impact, compression, fatigue, high temperatures and moisture without bending…

Founded in Peterborough in 2002, Photocentric has grown far beyond its humble beginnings in a small room. The company essentially invented liquid crystal display, or LCD, 3D printing, which is a low-energy, scalable, visible light alternative to UV-based 3D printers, and now also has a US location in Arizona, as well as its original home in Cambridgeshire, UK. The award-winning company not only develops specialist resins but also manufactures LCD 3D printers, and has just introduced its most recent LCD system, the rugged LC Opus. The new 3D printer, which Photocentric calls its quickest LCD system to date, will have its official global launch at the International Dental Show in Cologne later this month.

“We wanted to build a versatile printer that was easy to use and delivered great performance and I believe that we have achieved this. It provides customers with a speedy, simple and versatile solution that is equally at home in a dental laboratory as it is in an engineering workshop,” Sally Tipping, Sales Director for Photocentric, stated in a press release. “Its intuitive and simple operation makes LC Opus perfect for both beginners and experienced users alike across a broad range of applications. With its fast cure speed, low running costs and impressive build volume, LC Opus is an excellent all-rounder.”

Photopolymerization specialist Photocentric holds patents in visible light curing AM technologies, and its newest LCD 3D printer works through a simple workflow, starting with loading CAD files into Photocentric STUDIO and preparing them for printing, which takes place on the LC Opus. The printed parts are then washed to remove any excess resin, before they’re finally cured in the last step before use.

The company says that its LC Opus is fast, reliable, and accurate, able to achieve a repeatable performance and featuring a unique design with a custom monochrome 4k LCD screen. Thanks to even light distribution, the printer offers a uniform cure, and its patented Vat-Lift peel release technology means that large surface area printing can be more reliable. The LC Opus can run for longer periods of time at high temperatures, thanks to its efficient and super-quiet PWM fans, and quiet, smooth operation is also helped along by the printer’s Trinamic motor drivers. Made out of aluminum and solvent-resistant paint, the LCD system should be ready to print right out of the box, as it comes pre-calibrated.

With a build volume of 310 x 174 x 220 mm, the 38 kg LC Opus could be used as either a desktop or workbench printer, and Photocentric also says that its new system is extremely durable, thanks to a newly developed double-sealed, long-life vat with handles and tough annealed plastic hood, which is resistant to cracking from chemical exposure. In addition, depending on the resin you use, the LC Opus can supposedly reach fast cure speeds of up to two seconds per layer at 50µm layer thickness.

While the LC Opus, which replaces Photocentric’s LC Dental, is obviously a great fit for the dental industry, it could also be used for many other applications in various environments. The new 3D printer has begun production at the company’s Peterborough headquarters, and has broken all pre-order records for the other eight Photocentric 3D printer models manufactured in the UK. Printer models will be shipped in Q3, starting in September 2021. You can see the new LC Opus 3D printer for yourself at IDS 2021, Hall 3.1, Stand M011, from September 22-25.

The company itself knows all about resin 3D printing, being one of the few companies that manufactures liquid photo-polymer resins. Founded thirteen years ago, Photocentric produces about 500 tons of the material every year, much of which is sold to 3D printer manufacturers. They already have offices in the UK and Phoenix, Arizona, and employ about 75 people. Perhaps in a bid to increase resin sales, they took a bold step in 2013, when they began development on their very own 3D printing system with help from a UK Govt. Innovate grant.

As the company explained, they decided to opt for a remarkable concept that harnesses the power of mass-produced LCD screens, which are widely used in smartphones and other hand-held devices to ensure the highest resolution. As that technology is already well-established and affordable, it is a perfect light source for affordable 3D printing. “The concept is simple - use the daylight emitted from an LCD screen to polymerize resin that is tailored to that wavelength and intensity. All other 3D printers that polymerize resin use a combination of both daylight and UV light at considerably higher intensities,” they say.

When combined with a custom resin that is extremely sensitive to daylight, a very low-cost platform is created. “Photocentric has been able to make this work by developing the world’s most sensitive daylight resins. The power of this idea is profound. What might seem to be disadvantages- that it works solely in daylight and it works with orders of magnitude lower intensities of light are actually its greatest strengths,” they say. Photocentric calls the technique “Daylight Polymer Printing”, or “DPP” (patent pending).

Practically, it works by placing an LCD panel (which are mass-produced) under a resin tank. This shines pixels of plain light (not UV) into the resin. Using very little energy, the resin is solidified – which also solves the problem of parts sticking to the bottom of the tank. As the company explains, that is caused by using too much UV energy, causing unwanted solidification. “The very low intensity luminance from these screens, an order of magnitude lower than produced by digital light projectors and lasers, means there is no scattered light to create unwanted overcure - light used to harden a layer is simply absorbed at that depth and not passed on,” they say. Incidentally, the low-energy approach also increases production speeds, while the light is not harmful to human eyes.

Photocentric’s potent Daylight Polymer Printing solution is getting quite a lot of attention, and has already won the Europe 2016 award for innovation in 3D printing at the

Thanks to these price tags, both are doubtlessly attractive options for home users and should be very useful for producing small prototypes for jewelry, for instance. But Photocentric has said that this is only the beginning. “The opportunities are limitless; higher and higher resolution screens becoming available in all formats from mobiles to large format televisions provide the lowest cost imaging systems ever imagined,” they say, adding that larger 3D printers employing DPP 3D printing technology is forthcoming. A

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey