lcd screen backlight voltage supplier

LCD Panel are used for TV,Personal Computer, Mobile Phone, Degital Camera etc widely. LCD Panel can not emit light by itself. To emit light, it need the backlight(light source) on the back of LCD Panel. Minebea develops and manufactures the parts used for backlight and backlight using LED light source,for Mobile phone, PC application.

As below picture,Backligt are made with some optical parts.Key parts of Backligtht Unit are light guide plate and housing frame. Minebea"s principal competitive advantages are its ultraprecision machining and mass production technologies. Injection mold die need sub-micron ultraprecision machining and stable injection mold technologies.Minebea has amassed precision ball bearing"s technologies enables it to achieve levels of precision unmatched by its competitors. Minebea also uses these technologies for in-house parts, modl die,tooling and product of Backlight Unit.The function of light guide plate are transforming positional light source to surface light on display uniformly and efficiently.It realize optical design by own optical simulation and independently developed design program. Minebea assembles Backlight Unit by the technologies it put parts into limited space, greatly contributing to the precision and reliability. Minebea put into force exhaustive environmental control at Thai and China factories and enable manufacturing the bulk of Backlight with high quality and stable supply.

It is possible to buy LCD displays where the LEDs are in parallel and these can be powered from 5V. However series connection is more common since there are plenty of low cost boost ICs you can get to drive them, and these will allow operation from a wide range of supply voltages and incorporate PWM and current regulation brightness control (not always easy to get right, especially if you are worried about colour balance).

Monochrome character, graphic and static displays require different input voltages. All the different LCD voltage symbols can be confusing, but believe it or not, there is a system to the madness.

The voltages VCC, VDD, VSS and VEE are used in describing voltages at various common power supply terminals. The differences between these voltages stem from their origins in the transistor circuits they were originally used for.

This LCD voltage terminology originated from the terminals of each type of transistor and their common connections in logic circuits. In other words, VCC is often applied to BJT (Bipolar Junction Transistor) collectors, VEE to BJT emitters, VDD to FET (Field-Effect Transistor) drains and VSS to FET sources. Most CMOS (Complementary metal–oxide–semiconductor) IC data sheets now use VCC and GND to designate the positive and negative supply pins.

In the Pleistocene era (1960’s or earlier), logic was implemented with bipolar transistors. NPN (Negative-Positive-Negative) were used because they were faster. It made sense to call positive supply voltage VCC where the “C” stands for collector. The negative supply was called VEE where “E” stands for emitter.

When FET transistor logic came around a similar naming convention was used, but now positive supply was VDD where “D” stands for drain. The negative supply was called VSS where “S” stands for source. Now that CMOS is the most common logic this makes no sense. The “C” in CMOS is for “complementary” but the naming convention still persists. In practice today VCC/VDD means positive power supply voltage and VEE/VSS is for negative supply or ground.

The convention of VAB means the voltage potential between VA and VB. The convention of using 3 letters was used to show power supply and ground reference voltages as well. In some cases a processor may have both an analog and digital power supply. In this case VCCA/VCCD and VSSA/VSSD are used. Another reason for the 3 letters is in an NPN circuit with a load resister between the collector and VCC. VC would be the collector voltage. In this case VCC is the positive power supply voltage and would be higher than VC.

Pin three (3) is Vo and is the difference in voltage between VDD and VSS. This LCD voltage is adjusted to provide the sharpest contrast. The adjustment can be accomplished through a fixed resistor or a variable potentiometer. Many products have firmware that monitor the temperature and automatically adjust the contrast voltage.

In a Liquid Crystal Display (LCD), V0 is used to vary the screen brightness or contrast. Contrast, simply put is the ratio of the light areas to the dark areas in a LCD. This is usually done in a production setting with values which are optimized for most users. Temperature can have an undesirable effect on the display brightness and for this reason a varying resister or potentiometer is used to accommodate the desires of the user.

Below is a data sheet of a 16x2 Character LCD module that shows various recommended driving voltages. The LCD voltage can range from MIN (minimum) to TYP (Typical) to Max (maximum).

If the supplied LCD voltage drops too low, the display is ‘under-driven’ and will produce segments that are ‘grey’. The lower the LCD voltage falls below the acceptable threshold, the lower the contrast will be.

If the LCD is over-driven, you may see ghosting. This is where segments that should not be ‘on’ are gray. They are not as dark as the segments that should be on, but they can be seen and may cause confusion for the end user.

There are times when a customer needs to replace a display that has been discontinued or EOL (End-Of -Life) by their previous LCD supplier. The previous LCD’s pin-outs may be different than Focus’ standard, off-the-shelf display. This is not a large problem to overcome.

LED backlights are DC (Direct Current) driven and can be supplied from any one of three locations. The most popular is from pins 15 and 16. The second most popular option is to draw power from the ‘A’ and ‘K’ connections on the right side of the PCB.

The third option is to pull power from pins one and two. This is the same location from which the LCD is pulling its power. Focus does not recommend this option and can modify the PCB for the customer to connect the backlight from a different location.

Many LCD Modules will require more than one internal voltage/current. This may make it necessary for the customer to supply the needed inputs. They may need to supply 3V, 5V, 9V, -12V etc.

The solution for this is to integrate a charge pump (or booster circuit) into the LCD circuitry. This solution works in most applications, but if the product will be operating in an intrinsic environment, care must be taken with layout of the circuit board.

Intrinsically-safe LCDs are Liquid Crystal Displays that are designed to operate in conditions where an arc or spark can cause an explosion. In these cases, charge pumps cannot be employed. In fact, the total capacitive value of the display needs to be kept to a minimum.

Focus Display Solutions does not build a display that is labeled ‘Intrinsically safe’ but we do design the LCD to meet the requirements of the engineer. In meeting the design engineer’s requirements, the display may need to contain two or three independent inputs. Focus can redesign the PCB and lay out the traces to allow for these additional inputs.

I saw your post about the way you hooked up the Optrex DMC20261 display. I have one of these and cannot make it work like all of my other displays. Could you post on how you hooked it up, what library you use, and what voltage level it needs? I can only get a backlit screen. No characters show up no matter where I turn the 1K pot. I am using the standard LiquidCrystal arduino library. I don"t have this problem with my 16x2 or my 20x4 displays. I"m stumped.

Use this circuit, then set the PWM pin to analogWrite(pin, 127) to generate a 50% duty cycle square wave to drive the inverter. If the LCD display ends up too dark (i.e. too much contrast), you can decrease the negative voltage by using a smaller value on the PWM pin (i.e. analogWrite(pin, 64)). Use any value between 0 and 127 to get the contrast you want. Going above 127 is pointless since 128 to 255 is equivalent to 127...0.

NHD-12232WG-EYYH-V#A | Monochrome Graphic Module | 122x32 Pixels | Transflective LCD | Yellow/Green Backlight | STN (+) Positive Yellow/Green Display | Built-in DC-DC Voltage Converter | Non-Stocked

Newhaven 122x32 graphic Liquid Crystal Display module shows dark pixels on a bright yellow/green background. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-12232WG-EYYH-V#A display includes a built-in DC-DC voltage convertor. It has an optimal view of 6:00, operates at 3V supply voltage and is RoHS compliant.

NHD-320240WG-BoTFH-VZ# | Monochrome Graphic Module | 320x240 Pixels | Transflective LCD | White Backlight | FSTN (+) Positive Display | Built-in Negative Voltage

This 320x240 graphic Liquid Crystal Display module shows dark pixels on a white background. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-320240WG-BoTFH-VZ# display includes built-in negative voltage and has a built-in RA8835 controller. It has an optimal view of 6:00, operates at 5.0V supply voltage and is RoHS compliant.

Most iPad/iPhone hardware operates at voltages between 1.8 V - 5.2 V. However, the backlight circuit operates at about 15 - 20 V. At this higher voltage, the backlight components are more prone to damage when a short circuit occurs. The high voltage backlight circuit is also prone to corrosion from water damage.

The backlight diode - Like the backlight filters, the backlight diode is a fragile component. In cases where a backlight filter is particularly burned up, you’ll often find that the diode has failed as well. Diode failure in the absence of filter damage is rare, but it can happen.

The most common cause of a self-induced short occurs from working on the device with the battery still connected. Even when the screen is dark, there is voltage in the backlight circuit. A slipped pair of tweezers or misalignment of the LCD connector can short the backlight circuit to ground. (The iPad mini is particularly prone to this fault, as simply removing or inserting the flex cable into its connector at a slight angle is enough to bridge the backlight’s high voltage pin to the adjacent ground pin.) Avoid self-induced shorts by always disconnecting the battery before working on a device.

Another cause of backlight shorts is faulty assembly procedures. iPhone screens have a soldered joint on the LCD flex cable connecting the thinner backlight flex cable that powers the LED light strip. During device fabrication, these solder joints are protected by piece of black tape—however, during the screen refurbishing process some manufacturers neglect to replace the tape, apply it misaligned, or fail to apply it securely. As a result, the screen initially works during testing—but once the metal LCD shield is installed, the exposed solder joints touch the grounded frame, shorting the backlight circuit.

Backlight shorts can occur when the latch for the ZIF connector securing the LCD flex is missing. The LCD flex slides out an angle and the high voltage backlight pin contacts the ground pin, causing a short circuit.

Water damage is a frequent source of backlight problems. Water will corrode the LCD connector pin/pad junction, which breaks the electrical path to the connector and can damage the filter.

Backlight circuit failure can also occur from damage to the electrical traces on the circuit board. If the electrical traces buried in the board are inadvertently severed—for example, from trying to fasten the board with too large a screw—the backlight circuit will not conduct power to the backlight LEDs.

To diagnose whether your device is “dead” or just has a malfunctioning screen, try connecting it to your computer. If the computer recognizes the device, then the problem probably resides with the LCD screen or backlight circuit. Additionally, iPhones will notify the user of a backlight problem by repeatedly playing a chime sound and vibrating.

The good news is that nearly all backlight failures are repairable. Once the damaged component is identified it can simply be replaced. If this isn’t something that you can do yourself, call a knowledgeable microsolder shop and send it out for a quick repair.

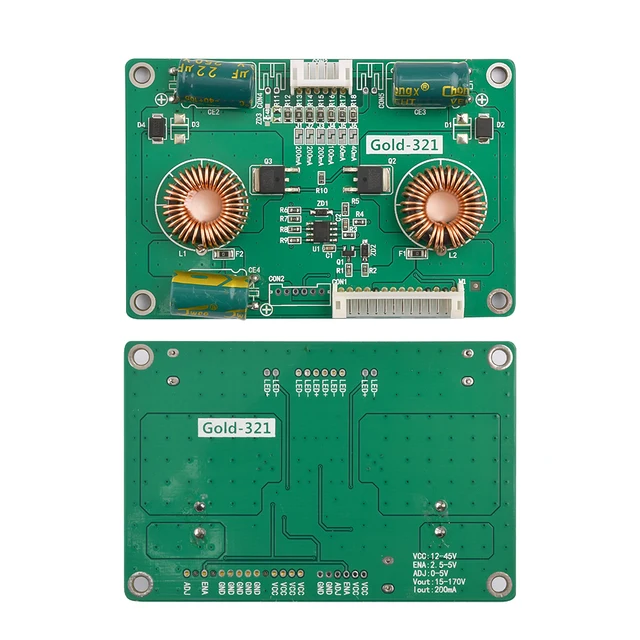

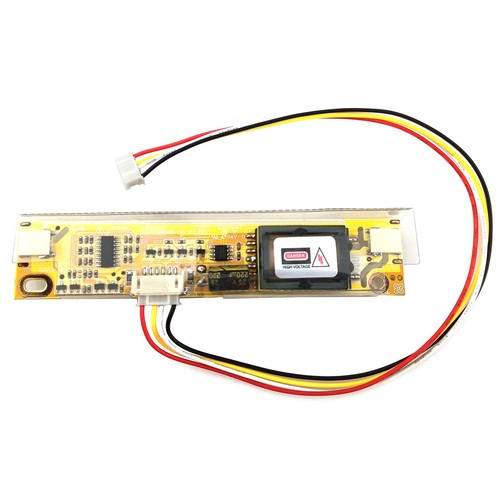

As on charts, LED driving Voltage is always higher than controller"s supply voltage (usually 12V) , that way we need driver/inverter, whatever we call step-up converter, it make from regular Vcc (12V) voltage, voltage able to supply and light up LED strings.

Most problem become, because for newer bigger screens are not available any datasheets, so many times I have to test LED backlight parameter by myself.

That is the reason, we must tread LED backlit screens very carefully, normally we must to test each particular screen separately and be sure to NOT overCurrent or overVoltage LED strings, as LEDs will simply burn off.

Some of those universal drivers have on-board places(pads) for I-Sense resistors mount/remove, and/or short-pads to regulate Current for particular LED backlight, this made possible to match LED driver"s Current parameter with particular screen. However such work need some experience and knowledge about DC/DC step-up converters, to avoid any LED burning disaster.

In practice, is not so difficult, because in monitor"s screens are usually 2 - 6 strings, in fact all strings practically have almost equal Vf , so in all those "universal" drivers, Cathodes of strings are connected together.

So there is only one I-Sense Resistor for total current, so if we know the driver"s chip reference voltage and proper Current value for particular screen backlight, we can count Sense Resistor for particular current, as from Ohm"s law R=U/I , but we have to know exactly the Current of particular LCD display we use, and reference (feedback threshold) voltage of IC used in driver (usually 150mV to 500mV depend on IC type and manufacturer) .

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey