lcd screen backlight voltage in stock

It is possible to buy LCD displays where the LEDs are in parallel and these can be powered from 5V. However series connection is more common since there are plenty of low cost boost ICs you can get to drive them, and these will allow operation from a wide range of supply voltages and incorporate PWM and current regulation brightness control (not always easy to get right, especially if you are worried about colour balance).

Most hardware operates at voltages between 1.8 V - 5.2 V. However, the backlight circuit operates at about 15 - 20 V. At this higher voltage, the backlight components are more prone to damage when a short circuit occurs. The high voltage backlight circuit is also prone to corrosion from water damage.

The backlight diode - Like the backlight filters, the backlight diode is a fragile component. In cases where a backlight filter is particularly burned up, you’ll often find that the diode has failed as well. Diode failure in the absence of filter damage is rare, but it can happen.

The most common cause of a self-induced short occurs from working on the device with the battery still connected. Even when the screen is dark, there is voltage in the backlight circuit. A slipped pair of tweezers or misalignment of the LCD connector can short the backlight circuit to ground. Avoid self-induced shorts by always disconnecting the battery before working on a device.

Another cause of backlight shorts is faulty assembly procedures. During device fabrication, these solder joints are protected by piece of black tape—however, during the screen refurbishing process some manufacturers neglect to replace the tape, apply it misaligned, or fail to apply it securely. As a result, the screen initially works during testing—but once the metal LCD shield is installed, the exposed solder joints touch the grounded frame, shorting the backlight circuit.

Backlight shorts can occur when the latch for the ZIF connector securing the LCD flex is missing. The LCD flex slides out an angle and the high voltage backlight pin contacts the ground pin, causing a short circuit.

Water damage is a frequent source of backlight problems. Water will corrode the LCD connector pin/pad junction, which breaks the electrical path to the connector and can damage the filter.

Backlight circuit failure can also occur from damage to the electrical traces on the circuit board. If the electrical traces buried in the board are inadvertently severed—for example, from trying to fasten the board with too large a screw—the backlight circuit will not conduct power to the backlight LEDs.

To diagnose whether your device is “dead” or just has a malfunctioning screen, try connecting it to your computer. If the computer recognizes the device, then the problem probably resides with the LCD screen or backlight circuit.

The good news is that nearly all backlight failures are repairable. Once the damaged component is identified it can simply be replaced. Follow this Samsung Television Backlight Replacement guide for more details.

This content is almost entirely sourced from Reed Danis and his iPhone/iPad Backlight Troubleshooting page. Users were finding this content when searching for TV related backlight issues so we repurposed it for TV.

There are a wide variety of LCD technologies including TFT, character, segment, graphic and OLEDs; but they all share the same characteristics and follow the same rules of electronics.

Alternating Current (AC) is not polarized. This means that AC does not have a positive and negative side like a battery. AC voltage is measured in Cycles per second or Hertz (HZ). For example, 60 cycle or 60 hz. AC power alternates (changes) from a positive voltage to a negative voltage 60 times a second ( see Figure 1). Most of the outlets in your house are rated at 120VAC.

Every time AC voltage switches from positive to negative an electrical field is generated in the atmosphere around the wire or component. When the electrical field comes into contact with metal, or wire, a current is generated in the metal or wire. If this effect is not desired the result is interference (called EMI or noise), the same effect is used to couple signals, drive electrical motors and transmit radio signals. This electrical field sustains the voltage over long distances. That is why power lines carry AC.

EL backlights use Alternating Current. The advantage to this is that they cannot be connected wrong. There are no black or red wires. It does not matter which wire is connected it will still work.

Direct Current is always measured with respect to ground. (Ground is zero volts, so voltage is measured by starting at zero) DC has a distinct polarity, either Positive or Negative. A positive voltage is considered to be more positive than ground. A negative voltage is considered to be more negative than ground. While current always flows from positive to negative, we characterize the flow from the source and always assume that current flows towards ground. A negative voltage is considered to flow from the source towards ground ( Figure 3). DC voltage is used in applications where stability in the supply voltage is needed or where the supply is from a battery. DC voltage has to travel from the source to the termination. The ground is considered to be the termination or ending point. All current flows towards the ground plane, the ground plane is what is used to complete the circuit.

Over long distances Direct Current is absorbed by the transmitting medium, and as a result less current finds it way to the termination resulting in a reduction of power. DC voltage does not create electrical interference. The farther DC travels the less electricity arrives on the other end. Think of this as a sprinkler hose with hundreds of little holes in it that allow water to spray out. One end of the hose is connected to the water source, and on the other end of the hose very little water spills out. This is how it is with Direct Current that is carried a long distance. When the electricity reaches the house, it is converted from Alternating Current to Direct Current.

A flashlight has two wires. The wires are connected to a DC battery on one end and a light bulb on the other end. As in Figure 4, one wire is always positive and one is always negative. This is the type of current that is used by LED backlights, which we will discuss in the LCD Manual.

Engineers will design their product around the dimensions of the LCD display. For this reason, it is critical to make sure there is a reference system in place. In the construction industry, dimensions are referenced as: length, width and height.

One critical component is the dimensions between the mounting holes of the display. This is the first item we look at when helping a customer locate a replacement LCD.

The number of times per second a signal, or voltage, completes a full cycle from zero volts to maximum positive voltage through zero to maximum negative voltage and back to zero again. Frequency is measured in Hertz and/or cycles per second. ( Figure 5)

The frequency in your house is 60Hz. This means the voltages switches between positive voltage and negative voltage 60 times a second. So the voltage is +120V then –120V then back to +120V. This happens 60 times a second.

EL andCCFL backlights are just like fluorescent lights. They use AC current and operate at a high frequency (Hertz). This means the current switches back and forth between positive and negative many times a second.

In the data sheet below ( Figure 6) the LED backlight voltage (V) and current (I) is in DC. The EL backlight power is 110V ACand it shows the frequency to be 400Hz. That means that the voltage on this EL backlight switches between positive and negative 400 times a second.

The disadvantage to AC current is that it generates what is known as ‘noise’. Noise is radiated out from the light and can interfere with the LCD electronics that are nearby. This noise is also called EMIbut most people just call it noise.

Many customers must use a LED backlight because it does not create any noise. They would like to use the EL but it will cause their circuit not to work correctly.

In the world of LCD displays, there are two standards: the US and the rest of the world. The US still prefers inches, feet etc. over meters. Although the majority of engineers in the US prefer metric over the US’s SAE system.

Metrics is one word that most American’s do not understand or use in daily life. But in order to work with LCD’s, or any weights and measures used outside of the United States (such as tools, cars, money, travel, water, etc.) one must have an understanding of metrics. The United States and parts of Canada are the only places in the world not to use metrics.

Meters come in different sizes. Common examples are: centimeter (c), a millimeter (m), even a picometer (p). The only one we normally use in working with LCD’s is the millimeter.

With regard to LCD’s, a multiplier is a letter that goes in front of another word, or follows a number, to express its increased or diminished size. There are three main letters we will use.

LCD’s use very small amounts of current, and are not referred to whole amps of current, but rather milliamps, or mAmps. If an amp is cut into one thousand equal pieces, a mAmp would be only one of those pieces. And 20 mAmps would be 20 of those pieces, or 20/1,000 of an amp.

As stated above, volts come as either positive or negative. Sometimes a LCD will need both a positive and a negative voltage to work. If a data or spec sheet calls out a voltage of 5V, it is assumed to be a plus 5 volts (+5 volts). The data sheet will put a negative (–) sign in front of the voltage amount if it is negative.

To help us gain an understanding of voltage and current, we will introduce the concepts with an illustration using water as the example. For the basic concept, think of voltage as how much water volume we have in gallons, and current as how fast the water moves in gallons per minute.

Using our water analogy again, we can say that voltage (volts) is how much water is needed to make a plant grow, and current (amps) is how fast the water is moving along the irrigation line.

As a general rule, voltage is not the driving force in electronics. It is the current. 120V(volts) at 1mA (read 1 milliamp or 1/1000 of a amp) is barely enough to turn on a small light bulb. On the other hand 120V(volts) at 13 Amps is enough to run a TV or microwave.

LCD’s use small amounts of volts and amps. Think of a LCD as the cactus from our illustration, the LCD’s usually run on 5 volts or less, and the current is around 50mA at the most.

Focus Displays is able to supply you both standard, in stock, LCD displays such as TFTs, OLED, characters, segments, and graphics. We also offer an in-house, US-based, LCD engineering department to help you with your LCD design.

If you find that one of our standard LCDs will not work for your design or you need a replacement LCD, then we are able to design and supply a custom LCD to fit your design requirements.

Call a human today at FocusLCDs.com at 480-503-4295 or use our online quick LCD elector tool to choose a LCD that is in stock and can ship the same day.

The LCD screen on your phone, with all of its rich colors and detail is just a dim slab of nothing without the backlight. Looking at a replacement screen, you"ll see the wide digitizer cable, and the smaller LCD cable carrying the data to color the pixels of the screen. Looking even closer you can see a thin little third flex soldered to the assembly. This the backlight flex. Through this flex flow the electrons that light a tiny strip of LED lights---the backlight. The light is diffused and spread around nicely by several backlight sheets. The whole thing is married to the back of the LCD. As long as the electrons march through the flex, the strip of LEDs light, and the backlight comes on.

The brains of the display is the Power Management ic chip. This guy generates a voltage that is passed to the coil. Remember a voltage is a hill for the river of current to flow down.

The magical power of the coil is to boost power. The coil, or inductor, can transform the relatively small incoming voltage from the Power chip into the big 15-20 V required to light the energy sucking display. The flow of current through the coil does some magiccalled electromagnetic induction that can be at once incredible and overwhelming. But really, it is just mechanics. When electrons go for a swirly ride through a coil, they generate a big voltage. A big voltage that can push electrons all the way to through to the flex and light the LEDs. All we need to know is "The coil. Big Slinky. Sturdy. Boost voltage" In order for the coil to stop working, you"d have to come by and snip off the wire as it connects the coiled spiral of wire inside to the pad below the component. Practically, this can only happen in very specific cases of water damage, where water essentially eats the base wire of the coil. Since the days of the iPhone 3Gs, modern coils are surrounded by waterproofing. Hence--they never fail.

The diode is a cop, a bouncer, an organizer--it will only let electrons file across its sensitive middle if they move along single file from one side to the other. It is constructed from delicate materials--chocolate on one side, vanilla on the other. Red light. Green light. And that kind of makes it prissy. It is not a simple semiconductor--not like a wire or a rod. No. Inside it has two different materials seamed together. This is what makes it directional, it stands on two simple pads, and you must install it only one way. Guess what happens to the poor little guy if an excessive unregulated voltage were to hit it? Like, say, someone pokes a screwdriver snagging a component to the frame, shorting the circuit? The diode will wilt like the delicate flower it is, and let out its magic black smoke. We all know that once any component lets out it magic black smoke, it is curtains.

Wait, backlight diode? What? You may be skeptical. You may not have heard about the backlight diode before. However, I"ve bet you"re heard of "the backlight ic." News flash. In modern phones and iPads, they are the same. Identical. An ic, or integrated circuit, is an overstretched promotion for the simple diode. This misuse of terminology was intentional. When folks started hiring other people to fix their iphone backlight circuits, the implication that what was being done was the installation of some sort of ic chip perpetuated a sense of difficulty of the operation. While some phones do have a small ic providing some logic for the backlight, nearly all iPhones and iPads today just have a simple diode. The terminology "backlight ic" remains because--- "Install an ic, means hire a professional" "Install a diode, means give it a shot myself"

The intact filter is required to complete the path from the diode to the LCD connector. The problem is that they tend to be very susceptible to 1.) water damage and 2.) current spikes. In practice, the filter is the first component to go when the circuit is in trouble. As such, they act as a fuse. Intentional or not, I don"t know. However, when a sudden drop in voltage from pulling the LCD connector in the iPad mini while the battery is still connected causes a transient spike in amperage, like a dutiful Romeo, the backlight filter will sacrifice itself, breaking continuity. Some backlight circuits have one filter, some have two or three. All of them are required for the intact delivery of the voltage necessary to light the LCD.

The last guy in the line is the LCD connector. Most of the pins of the connector are receiving data to build the image on the LCD. Only a few pins are required to deliver the voltage to the backlight LEDs. Can you guess which ones they are? Take a look at the LCD connector of any water damaged phone. Look for a pin that is the blackest with the most chewed up pad--that"s the one meant to carry the big voltage for the LCD display.

Normally, a failure in any component of the backlight circuit will cause a dark display when the device is on. However, in later model full sized iPads--the iPad 3, 4 and Air things are a wee bit more complex. The backlight circuit is split into two. There are two coils, two diodes, two filters that come together to feed one LCD connector. This strange situation can result in this common problem:

Give yourself a star if you chose B. No backlight is a CLASSIC and COMMON problem in all mobile devices. It is almost always repairable, you just have to know where to look.

Once done, hunt for the backlight filters. They may be near or far from the LCD connector. You are looking for ceramic components with a black center. Think ferrite bead = iron= black and find them. (I can"t believe that this little relationship just occurred to me for the very first time right now.) If they are damaged, they will not have continuity from one side to the other. Get out your multimeter. Set it to continuity testing. If you don"t hear a beep on the backlight filter, that"s the problem. Many times, if the backlight filter is severely burned, it has become welded inseparably from the underlying pad. In these cases, it is not possible to replace the component. But it is still possible to save the device---build a custom microjumper to restore continuity in the line. If you do find a backlight filter that looks severely burned, then

Check out the diode. If you find the filter you can find the diode using your multimeter even if you"ve never seen the device before. Put one probe on the end of the filter. Stab around with the other probe until you find a diode-looking component that has continuity with the filter. That"s the backlight diode! Test the diode. Set your multimeter for diode testing. Measure black probe to one side red to the other. Reverse probes. You should get a "1" = infinite resistance in one direction, but not the other. If you get a "1" in both directions, replace the diode. Remember that the new diode should go in the same direction as the original diode! After you have done this, and your device will still not show a backlight with a known good display, THEN and ONLY THEN should you consider the coil. But honestly,

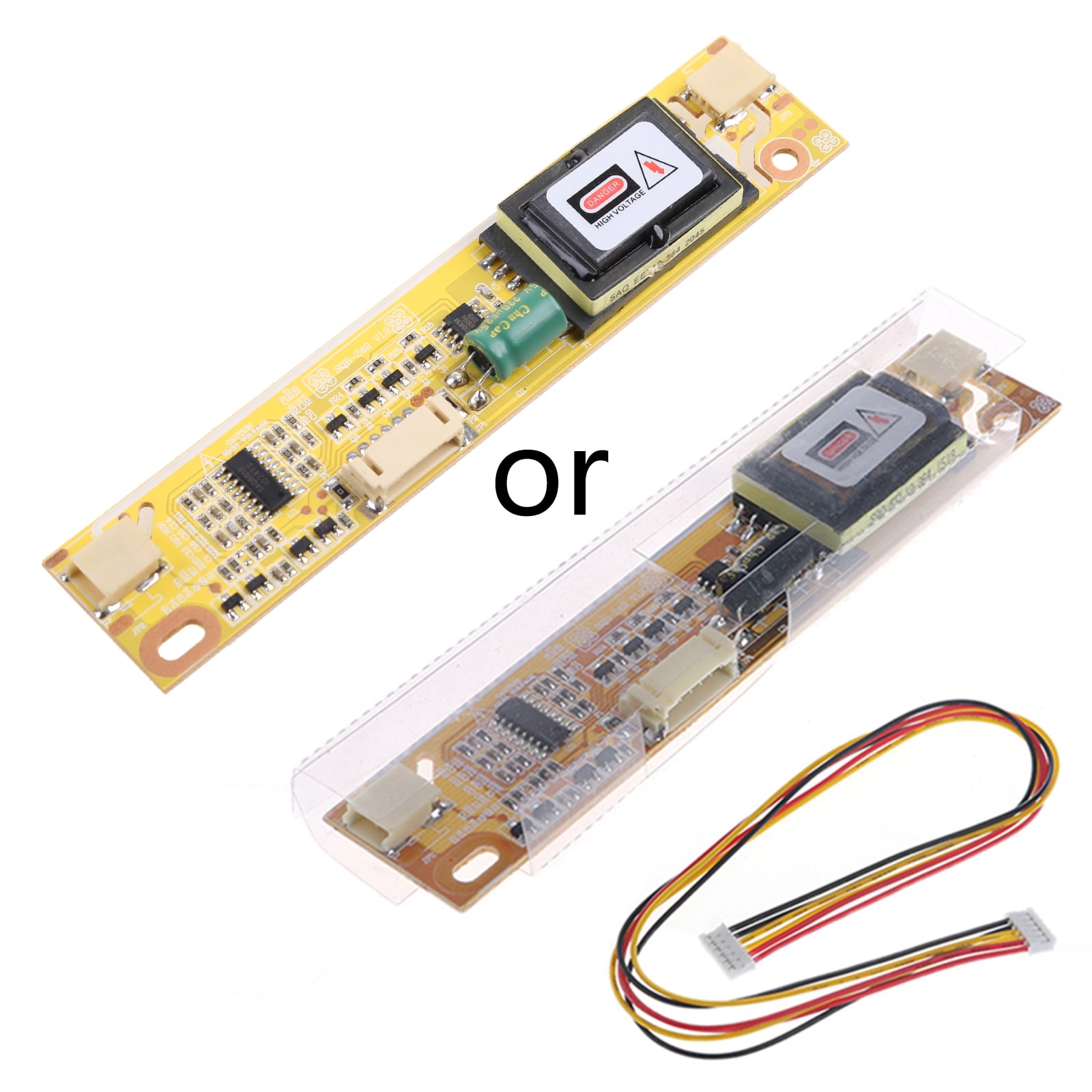

This DC-AC Inverter was developed for 1CCFL lamps of LCD back lighting system.High performance low consumption special operating temperature,Open lamp protection,Lamp Current Balance Control .The DC to AC back-light inverter is special designed on any type LCD display in implement (Is suitable in 17 -22 inches the liquid crystal display runs).

This DC-AC Inverter was developed for 1CCFL lamps of LCD back lighting system.High performance low consumption special operating temperature,Open lamp protection,Lamp Current Balance Control .The DC to AC back-light inverter is special designed on any type LCD display in implement (Is suitable in 17 -22 inches the liquid crystal display runs).

Plazmo is the largest supplier of CCFL backlights (Cold Cathode Fluorescent Lamp) in North America. We currently have more 1 million CCFL backlights in stock and ready to ship.

The CCFL products we carry consist of hundreds of different sizes of raw Cold Cathode Fluorescent Lamps (CCFLs) available in diameters from 1.8mm - 6.0mm, and lengths from 40mm all the way up to 1,400mm. We also have more than 200,000 complete LCD backlight assemblies in stock in addition to the millions of CCFL backlights Plazmo has in stock.

We specialize in precision color-matching technology and use the latest in testing equipment that allows us to both analyze and produce any color CCFL backlight you want. This includes the full spectrum of white lamps commonly used in various LCD screens as well as specialty color, UV, and infrared lamps that are used in a wide range of applications.

In addition to our standard CCFL backlight offerings, we have complete engineering and manufacturing capabilities for custom designs. We can make any type of CCFL backlight you might need. If you have an old, obsolete LCD or even a new, yet uncommon, LCD requiring a specific or custom-made backlight, we can help. We make new, specialty backlight lamps for any and all LCD applications, including straight and shaped lamps. Some of the CCFL backlight shapes Plazmo offers are: C, U, L, and M shape lamps. In short, if you don"t find the perfect solution for your LCD backlighting needs on our website,CCFLWarehouse.comorPlazmo.com, just give us a call or send us an email with your specific needs.

To go with the vast array of CCFL backlights we have in stock, we also offer the most common CCFLwire harnessesused in LCD backlighting. We stock UL-rated wire harnesses which include connector types from brands like JST, JAE, Molex, Honda, and many more. We also stock all of the components you would need to make your own, custom harnesses. Those components include High Voltage CCFL lamp wire, terminals, connectors and shrink tube, to name a few. If you need a CCFL wire harness that isn’t found atPlazmo.com, give our experts a call or send us an email. We can custom design and make practically any CCFL wire harnesses you might need. Whether you are a small LCD repair facility or a large OEM, we are CCFL backlight and LED backlight experts, and we are here to help.

Silicone end caps for CCFL backlights are a necessary component in making LCD backlight repairs. That’s why Plazmo carries hundreds of different models of silicone end caps. These include a variety of single, dual and triple LCD backlight lamp assembly varieties. However, not all of the end cap possibilities out there are available directly from our website, but we are able to help you find one that would be compatible with your needs. Send our experts an email or give us a call and we will help you find the right end cap, or, in the rare occurrence that we can not find the right end cap, we can custom manufacture the ones you need. For more information on custom CCFL silicone end caps, our contact information is below; we are here to help.

CCFLs have been used for years as a backlight source. These backlights usually have a hollow glass cylinder - 2 to 10 mm in diameter, that’s internally coated with a phosphorescent material and filled with a noble gas (most commonly argon). The tube is then sealed at both ends with an iron-nickel electrode located at each end of the tube.

CCFLs operate on high-voltage alternating current (AC). When the high voltage is applied the resulting arc ionizes the internal noble gas which produces ultraviolet energy. The ultraviolet energy excites the phosphorescent lining which then produces light in the visible range (400 to 700 nm). The phosphorus make-up determines the color temperature of the visible light output. Typically, the resulting temperature color is in the 2800 - 3200K range, which looks like a warm to standard white light.

Most systems that have LCD panels run on direct current (DC), the DC has to be converted to AC in order power the lamp. An inverter is typically used to create the high-voltage AC. In addition, CCFL backlights require constant current, not constant voltage. Also, the strike voltage or the voltage required to start the light of the CCFL is different than the sustaining voltage. The inverter that’s designed to power an LCD CCFL will typically run at about 50 kHz. The inverter has to be matched to the specifications of the CCFL, particularly the current, strike voltage, and operating voltage.

When power is applied to the inverter, it starts by ramping up the output voltage until the CCFL turns on (an arc strikes). The strike voltage may be several hundred volts higher than the sustaining voltage, just to get the CCFL to light up. After the tube strikes which is identified by current flowing, the inverter then drops the voltage until the rated current is flowing which is typically around 5 to 7 mA. For example, a CCFL may have a strike voltage of approximately 1200 V, an operating voltage of approximately 800 V, and an operating current of 6 mA. Using this example, the power draw would then be 4.8 watts. The inverter switch has built-in protection so that if the tube does not strike after it’s gotten a few hundred volts more than the normal strike voltage, the tube is considered dead.

The life expectancy of CCFLs used as backlights is now around 50,000 - 60,000 hours. CCFLs rarely exhibit catastrophic failure unlike incandescent bulbs. Rather, the tube slowly dims over time due to phosphor erosion. The useful life for all backlights is defined by when the light output from the tube reaches half of its initial brightness. Increasing the current will decrease the life expectancy, but will increase the brightness. The color temperature of the tube doesn’t usually change as the bulb gets older.

In many LCD panels, the CCFLs may be replaced when they reach the end of their useful life. CCFLs typically have low heat generation, about 6 - 8 watts per tube. The heat is spread over the surface area of the tube easing heat dissipation. Most LCDs in the embedded market use 4 tubes or less. However, when many CCFLs, more than 4, are used together in an enclosed panel, overall heat dissipation should be taken into account. The optimum ambient temperature range for the highest efficiency and brightness is 77 to 104°F (25 to 40°C). Depending on the design of the tube, it may operate at temperatures from -22 to +185°F (-30 to +85°C); however, performance may be affected at either end of the spectrum, especially the lower end. At low temperatures the brightness decreases and the strike voltage increases. The typical efficiency of CCFLs is in the range of 70 to 90 lumens-per-watt, although with the competition of LED backlights, new advances are being made to boost efficiency.

Ever had your TV showing nothing but a black screen even if the audio was working? Unfortunately, that’s a common issue with low/middle-end LCD/LED TVs these days… Even more frustrating, this issue often comes from a rather tiny and cheap component that can be easily replaced. Most common issues are:

The first step into repair is to find the root cause of the issue. As backlight failure is a very common issue, this is the first thing to test. To do so, the easiest way is to power on your screen, put a flashlight very close to it and check if you can see the image through. The image would be very dark, like turning the brightness of the screen very very low.

That implies disassembling the TV to access the backlight which is between the LCD screen in the front and the boards in the rear. In my case, with a Samsung F5000, I had to process as follows:

First we have to remove the back housing to reveal the boards (from left to right: main board, T-CON, power supply) and disconnect the LCD panel from the T-CON board.

Note: Older TVs have neon tubes for backlight, which is thicker and less exposed to this kind of failure. LED backlight is the most common thing these days, but do not mistake an LED TV with an OLED TV. The first one is a classic LCD panel with a LED backlight, whereas the second is an OLED panel that doesn’t need any backlight as it is integrated in each pixels (making the spare parts much more expensive by the way).

As we can see, the backlight system is made of 5 LED strips. First thing to do is look for burnt LEDs. Most LED backlight systems have strips set in series, meaning that if one of the them fails, all the system goes dark…

One LED like those ones typically needs between 2.5-3.6v input voltage to light up. By looking up this model online, I found out that the ones used on those strips need 3.6v; so as there are 9 LEDs per strip: 3.6 x 9 = 32.4v input voltage required to light a single strip. That’s the maximum voltage we do NOT want to exceed, otherwise LEDs could be damaged during testing.

After repeating this operation on all strips, I found only 1 defective LED, the same we thought looked burnt when we first had a look at the backlight (3rd strip from the top, 6th LED from the left). For a better understanding at what a burnt LED looks like here are 2 pictures of a burnt one and an OK one. Mind the roasted color compared to the regular one.

Once we have by-passed the LED, we can power the TV on. Careful! High voltage (200-300v) runs through the TV when plug, so be very careful how you handle it so you don’t electrify yourself!

There might be a lot of other root causes for similar symptoms, a black screen often looks like something very serious and therefore expensive to repair, but this case is the perfect example that taking some time to look for the root cause can sometime lead to a good surprise: here a 1$ fix!

You should have basic electrical test equipment such as a Digital Multimeter and a basic working knowledge of electronics. Soldering is a must if you plan on doing more than testing a screen.

We will be gaining access under the dreaded “DO NOT TOUCH” plastic tape. What they really mean to say is.. “Do not touch the multiple ribbons along the top or bottom edge of the board.” These ribbons interface with the LCD screen and pass information to the pixel matrix. They are fragile!

This guide applies to Laptop LCD panels more so than your desktop"s 24" LCD screen. Some LED backlights are fed with up to 96 volts, but not usually… and not on laptops.

Finally, if you break something.. it"s on you! There is a lot of variance between LCD manufacturers.. they are all different! Hold only yourself responsible if something goes wrong... that"s an order, not a suggestion

It appears that the LED has a forward voltage, \( V_f \) of 4.1 V at 100 mA but that there is no current limiting built in. If connected directly to a 5 V supply then excessive current would flow (as predicted by the IV curves), the backlight would be destroyed and the display ruined.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey