lcd screen backlight voltage quotation

LED backlighting is the most commonly used backlight for small, LCD panels. Light-emitting diodes, or LEDs, are practical components for a light source because of their small size. LED backlighting is popular due to its overall low cost, long life, variety of colors and high brightness.

LED backlights are housed in a light box that has a diffuser to evenly distribute the LED light. The light box is then mounted behind the LCD’s viewing area. The LED backlight comes in two configurations: array and edge lit. The array configuration has the LEDs mounted in a uniform, grid layout within the light box. This configuration gives off a very bright, even light. The disadvantage of an array configuration is that it requires a thick light box design to accommodate the number of LEDs required. The high number of LEDs in this configuration also means it consumes more power.

The other configuration for LED backlights is edge lit. An edge lit configuration is the most commonly used construction for LED backlights. This configuration mounts the LEDs along one edge of the light box. The layout results in a thin design. Edge lit also uses less LEDs overall and therefore consumes less power than an array configuration.

Another type of backlight options is the use of fiber optic technology. Fiber optic backlights use sheets of fiber optic woven cloth and are bundled by a ferrule (metal cap) to an LED or halogen light source. Advantages for the fiber optic technology includes low voltage, low power, and a very uniform brightness. This type of backlighting is ideal for custom display shapes or sizes however it is priced at a higher cost compared to other technologies available.

A third type of backlight option available uses an electroluminescent (EL) panel. The EL backlight is constructed of a series of different material layers that work together to create the light. The EL panel generates light when an electric current (AC power) is applied to its conductive surfaces. The advantage with EL backlighting is its low power consumption, no heat emission, and overall thin composition. EL backlighting is limiting in that it requires an invertor to generate the VAC needed to emit the light.

The last common backlight option available are cold cathode fluorescent lamps (CCFLs). CCFL backlights are a cost effective option typically found in graphic displays. The CCFL backlight for LCDs is usually configured with the lamp on the edge of a diffuser to distribute the light. An inverter is required to supply the voltage required by the fluorescent lamp. CCFLs offer a bright white light with low power consumption. This backlight option is not ideal for cold-temperature applications (less than 15°C) as the light output decreases with decreased ambient temperature.

There are many different backlight options available for your LCD. The most common types are LED, fiber optic, EL, and CCFL backlights. Cost and application of your product will have the highest influences on which backlight technology is best for your LCD.

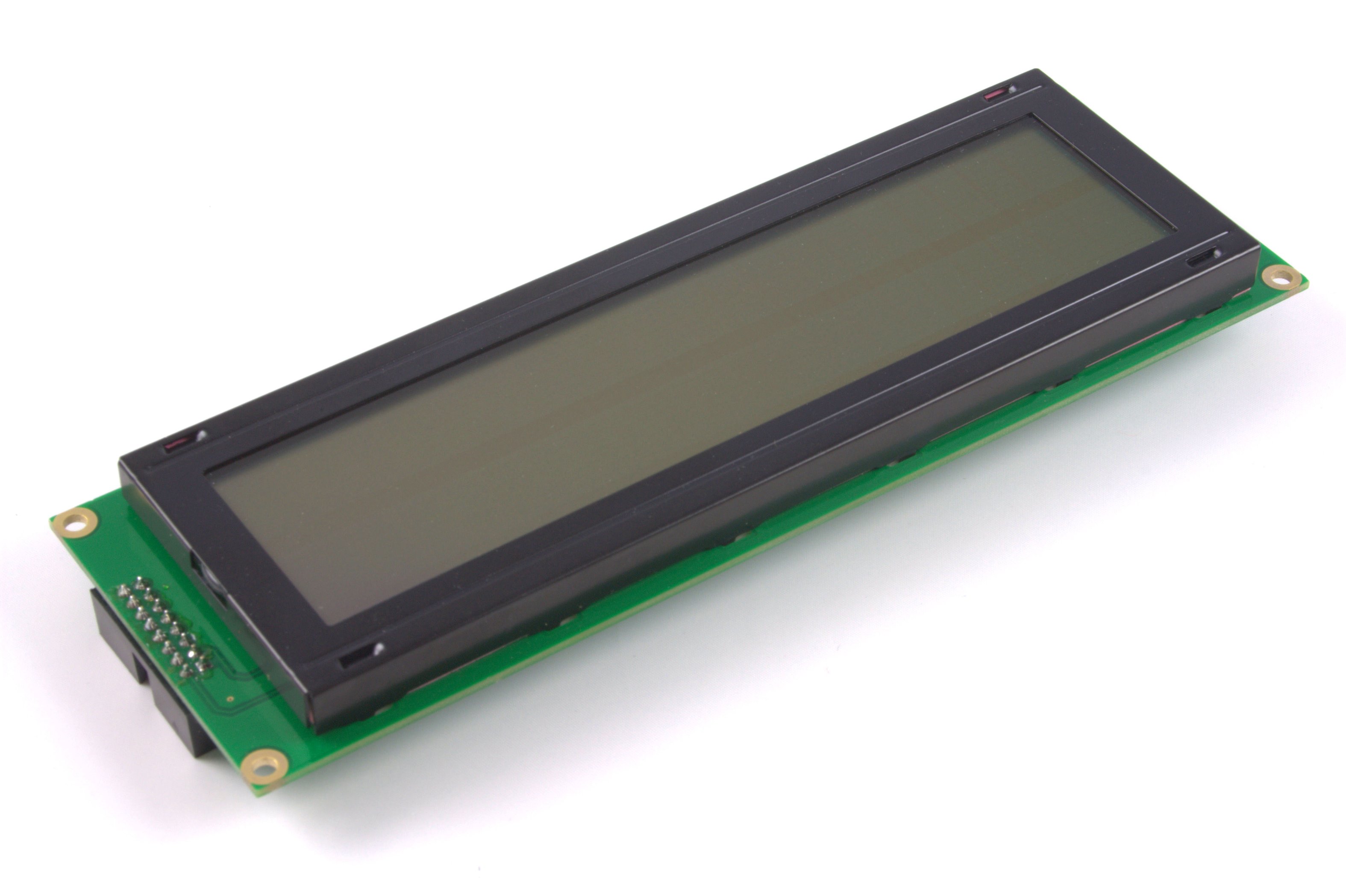

NHD-320240WG-BoTFH-VZ# | Monochrome Graphic Module | 320x240 Pixels | Transflective LCD | White Backlight | FSTN (+) Positive Display | Built-in Negative Voltage

This 320x240 graphic Liquid Crystal Display module shows dark pixels on a white background. This transflective LCD Display is visible with ambient light or a backlight while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-320240WG-BoTFH-VZ# display includes built-in negative voltage and has a built-in RA8835 controller. It has an optimal view of 6:00, operates at 5.0V supply voltage and is RoHS compliant.

NHD-12864WG-BTMI-V#N | Monochrome Graphic Module | 128x64 Pixels | Transmissive LCD | White Backlight | STN (-) Negative Blue Display | Built-in Negative Voltage

Newhaven 128x64 graphic Liquid Crystal Display module shows white pixels on a dark blue background. This transmissive LCD Display requires a backlight for visibility and offers a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-12864WG-BTMI-V#N display includes built-in negative voltage. It has an optimal view of 6:00, operates at 5V supply voltage and is RoHS compliant.

It is clearly seen from (13) that the switching frequency must be varied to regulate the output voltage. The highest switching frequency appears at the highest input voltage and the lightest load. On the other hand, the lowest switching frequency happens at the lowest input voltage and the heaviest load. For the SRC to operate in the zero-voltage-switching (ZVS) region, the lowest switching frequency must be higher than the resonant frequency as expressed in (5). Moreover, due to the switching speed limitations of the power devices, the highest switching frequency is below a specified value. In other words, the variations of the input DC voltage and the load variations must be confined to a small range. Usually a power factor corrector (PFC) is added in front of the DC-DC converter to raise the input power factor and reduce the input current harmonics. A phase-shift pulse width modulation (PSPWM) dimming control can effectively confine the load variation of the DC-DC SRC. Consequently, the output voltage variation of the PFC can be limited to a smaller extent. This results in a better operating condition for the SRC. For the PSPWM dimming strategy, the working durations of the shunt LED arrays are properly phase-shifted to confine the variation of the output current of the SRC. Figure 6 illustrates the circuit arrangement for N shunt single-colored LED arrays with PSPWM dimming method. It is almost the same as the conventional one, except that the dimming signals are applied with a specified phase difference. With the PSPWM dimming, there are always overlaps between the LED driving currents. The maximum duty cycle, or the overlap, is 100 %, corresponding to the highest brightness. To prevent the DC-DC SRC from operating at no load, the minimum duty cycle of the PSPWM dimming signal is 1/N, where N is the number of the shunt LED arrays. Under this circumstance, the overlap is zero, corresponding to the lowest brightness. Compared with the conventional dimming scheme, it is apparently recognized that the load variation of the SRC is less with the proposed PSPWM dimming function. To further investigate the operating principle of the PSPWM dimming, a more general case with N shunt LED arrays is discussed as follows. Figure 7 shows the waveforms of the N driving currents and the output current of the SRC. As stated earlier, the duty cycle range of the dimming signal is from 1/N to 100 %. In terms of the phase angle, if a complete period is 360º, the duty cycle range is from 360º/N to 360º. Assuming that the dimming signal for the LED array 1 starts at 0º, then the dimming signal for the k-th LED array would start at

This article is about backlights in liquid crystal displays. For the rear window of an automobile, see Car glass. For the lighting design practice, see Backlighting (lighting design). For other uses, see Backlight (disambiguation).

A backlight is a form of illumination used in liquid crystal displays (LCDs). As LCDs do not produce light by themselves—unlike, for example, cathode ray tube (CRT), plasma (PDP) or OLED displays—they need illumination (ambient light or a special light source) to produce a visible image. Backlights illuminate the LCD from the side or back of the display panel, unlike frontlights, which are placed in front of the LCD. Backlights are used in small displays to increase readability in low light conditions such as in wristwatches,smart phones, computer displays and LCD televisions to produce light in a manner similar to a CRT display. A review of some early backlighting schemes for LCDs is given in a report Engineering and Technology History by Peter J. Wild.

Simple types of LCDs such as in pocket calculators are built without an internal light source, requiring external light sources to convey the display image to the user. Most LCD screens, however, are built with an internal light source. Such screens consist of several layers. The backlight is usually the first layer from the back. Light valves then vary the amount of light reaching the eye, by blocking its passage in some way. Most use a fixed polarizing filter and a switching one, to block the undesired light.

An ELP gives off uniform light over its entire surface, but other backlights frequently employ a diffuser to provide even lighting from an uneven source.

Backlights come in many colors. Monochrome LCDs typically have yellow, green, blue, or white backlights, while color displays use white backlights that cover most of the color spectrum.

Colored LED backlighting is most commonly used in small, inexpensive LCD panels. White LED backlighting is becoming dominant. ELP backlighting is often used for larger displays or when even backlighting is important; it can also be either colored or white. An ELP must be driven by relatively highAC power, which is provided by an inverter circuit. CCFL backlights are used on larger displays such as computer monitors, and are typically white in color; these also require the use of an inverter and diffuser. Incandescent backlighting was used by early LCD panels to achieve high brightness, but the limited life and excess heat produced by incandescent bulbs were severe limitations. The heat generated by incandescent bulbs typically requires the bulbs to be mounted away from the display to prevent damage.

For several years (until about 2010), the preferred backlight for matrix-addressed large LCD panels such as in monitors and TVs was based on a cold-cathode fluorescent lamp (CCFL) by using two CCFLs at opposite edges of the LCD or by an array of CCFLs behind the LCD (see picture of an array with 18 CCFLs for a 40-inch LCD TV). Due to the disadvantages in comparison with LED illumination (higher voltage and power needed, thicker panel design, no high-speed switching, faster aging), LED backlighting is becoming more popular.

LED backlighting in color screens comes in two varieties: white LED backlights and RGB LED backlights.blue LED with broad spectrum yellow phosphor to result in the emission of white light. However, because the spectral curve peaks at yellow, it is a poor match to the transmission peaks of the red and green color filters of the LCD. This causes the red and green primaries to shift toward yellow, reducing the color gamut of the display.a red, a blue, and a green LED and can be controlled to produce different color temperatures of white. RGB LEDs for backlighting are found in high end color proofing displays such as the HP DreamColor LP2480zx monitor or selected HP EliteBook notebooks, as well as more recent consumer-grade displays such as Dell"s Studio series laptops which have an optional RGB LED display.

RGB LEDs can deliver an enormous color gamut to screens.additive color) the backlight can produce a color spectrum that closely matches the color filters in the LCD pixels themselves. In this way, the filter passband can be narrowed so that each color component lets only a very narrow band of spectrum through the LCD. This improves the efficiency of the display since less light is blocked when white is displayed. Also, the actual red, green, and blue points can be moved farther out so that the display is capable of reproducing more vivid colors.

A newNanosys, claims that the color output of the dots can be tuned precisely by controlling the size of the nanocrystals. Other companies pursuing this method are Nanoco Group PLC (UK), QD Vision, 3M a licensee of Nanosys and Avantama of Switzerland.Sony has adapted Quantum Dot technology from the US company QD Visionedge-lit LED backlight marketed under the term Triluminos in 2013. With a blue LED and optimized nanocrystals for green and red colors in front of it, the resulting combined white light allows for an equivalent or better color gamut than that emitted by a more expensive set of three RGB LEDs. At the Consumer Electronics Show 2015, Samsung Electronics, LG Electronics, the Chinese TCL Corporation and Sony showed QD-enhanced LED-backlighting of LCD TVs.

CCFL backlighting has also improved in this respect. Many LCD models, from cheap TN-displays to color proofing S-IPS or S-PVA panels, have wide gamut CCFLs representing more than 95% of the NTSC color specification.

There are several challenges with LED backlights. Uniformity is hard to achieve, especially as the LEDs age, with each LED aging at a different rate. Also, the use of three separate light sources for red, green, and blue means that the white point of the display can move as the LEDs age at different rates; white LEDs are also affected by this phenomenon, with changes of several hundred kelvins being recorded. White LEDs also suffer from blue shifts at higher temperatures varying from 3141K to 3222K for 10 °C to 80 °C respectively.Benq G2420HDB consumer display has a 49W consumption compared to the 24W of the LED version of the same display (G2420HDBL).

To overcome the aforementioned challenges with RGB and white LED backlights an "advanced remote phosphor" cockpit displays,Air Traffic Control displays and medical displays. This technology uses blue pump LEDs in combination with a sheet on which phosphorous luminescent materials are printed for colour conversion. The principle is similar to Quantum Dots, but the phosphors applied are much more robust than the quantum dot nano-particles for applications that require long lifetime in more demanding operational conditions. Because the phosphor sheet is placed at a distance (remote) of the LED it experiences much less temperature stress than phosphors in white LEDs. As a result, the white point is less dependent on individual LEDs, and degrading of individual LEDs over lifetime, leading to a more homogenous backlight with improved colour consistency and lower lumen depreciation.

The use of LED backlights in notebook computers has been growing. Sony has used LED backlights in some of its higher-end slim VAIO notebooks since 2005, and Fujitsu introduced notebooks with LED backlights in 2006. In 2007, Asus, Dell, and Apple introduced LED backlights into some of their notebook models. As of 2008Lenovo has also announced LED-backlit notebooks. In October 2008, Apple announced that it would be using LED backlights for all of its notebooks and new 24-inch Apple Cinema Display, and one year later it introduced a new LED iMac, meaning all of Apple"s new computer screens are now LED. Almost every laptop with a 16:9 display introduced since September 2009 uses LED-backlit panels. This is also the case for most LCD television sets, which are marketed in some countries under the misleading name LED TV, although the image is still generated by an LCD panel.

Most LED backlights for LCDs are edge-lit, i.e. several LEDs are placed at the edges of a lightguide (Light guide plate, LGP), which distributes the light behind the LC panel. Advantages of this technique are the very thin flat-panel construction and low cost. A more expensive version is called full-array or direct LED and consists of many LEDs placed behind the LC panel (an array of LEDs), such that large panels can be evenly illuminated. This arrangement allows for local dimming to obtain darker black pixels depending on the image displayed.

For a non-ELP backlight to produce even lighting, which is critical for displays, the light is first passed through a lightguide (Light guide plate, LGP) - a specially designed layer of plastic that diffuses the light through a series of unevenly spaced bumps. The density of bumps increases further away from the light source according to a diffusion equation. The diffused light then travels to either side of the diffuser; the front faces the actual LCD panel, the back has a reflector to guide otherwise wasted light back toward the LCD panel. The reflector is sometimes made of aluminum foil or a simple white-pigmented surface.

The LCD backlight systems are made highly efficient by applying optical films such as prismatic structure to gain the light into the desired viewer directions and reflective polarizing films that recycle the polarized light that was formerly absorbed by the first polarizer of the LCD (invented by Philips researchers Adrianus de Vaan and Paulus Schaareman),

The evolution of energy standards and the increasing public expectations regarding power consumption have made it necessary for backlight systems to manage their power. As for other consumer electronics products (e.g., fridges or light bulbs), energy consumption categories are enforced for television sets.

Dimming options for LCD brightness; J. Moronski; Electronicproducts.com; 3 Januari 2004; "Dimming options for LCD brightness control". March 2004. Archived from the original on 2017-07-28. Retrieved 2017-11-20.

Energy Efficiency Success Story: TV Energy Consumption Shrinks as Screen Size and Performance Grow, Finds New CTA Study; Consumer Technology Association; press release 12 July 2017;

LCD Television Power Draw Trends from 2003 to 2015; B. Urban and K. Roth; Fraunhofer USA Center for Sustainable Energy Systems; Final Report to the Consumer Technology Association; May 2017; "Archived copy" (PDF). Archived from the original (PDF) on 2017-08-01. Retrieved 2017-11-20.link)

Controlling Power Consumption for Displays With Backlight Dimming; Claire Mantel et al; Journal of Display Technology; Volume: 9, Issue: 12, Dec. 2013; Mantel, Claire; Burini, Nino; Nadernejad, Ehsan; Korhonen, Jari; Forchhammer, Soren; Pedersen, Jesper Meldgaard (2013). "Controlling Power Consumption for Displays with Backlight Dimming". Journal of Display Technology. 9 (12): 933–941. Bibcode:2013JDisT...9..933M. doi:10.1109/JDT.2013.2260131. S2CID 24082090.

Ever had your TV showing nothing but a black screen even if the audio was working? Unfortunately, that’s a common issue with low/middle-end LCD/LED TVs these days… Even more frustrating, this issue often comes from a rather tiny and cheap component that can be easily replaced. Most common issues are:

The first step into repair is to find the root cause of the issue. As backlight failure is a very common issue, this is the first thing to test. To do so, the easiest way is to power on your screen, put a flashlight very close to it and check if you can see the image through. The image would be very dark, like turning the brightness of the screen very very low.

That implies disassembling the TV to access the backlight which is between the LCD screen in the front and the boards in the rear. In my case, with a Samsung F5000, I had to process as follows:

First we have to remove the back housing to reveal the boards (from left to right: main board, T-CON, power supply) and disconnect the LCD panel from the T-CON board.

Note: Older TVs have neon tubes for backlight, which is thicker and less exposed to this kind of failure. LED backlight is the most common thing these days, but do not mistake an LED TV with an OLED TV. The first one is a classic LCD panel with a LED backlight, whereas the second is an OLED panel that doesn’t need any backlight as it is integrated in each pixels (making the spare parts much more expensive by the way).

As we can see, the backlight system is made of 5 LED strips. First thing to do is look for burnt LEDs. Most LED backlight systems have strips set in series, meaning that if one of the them fails, all the system goes dark…

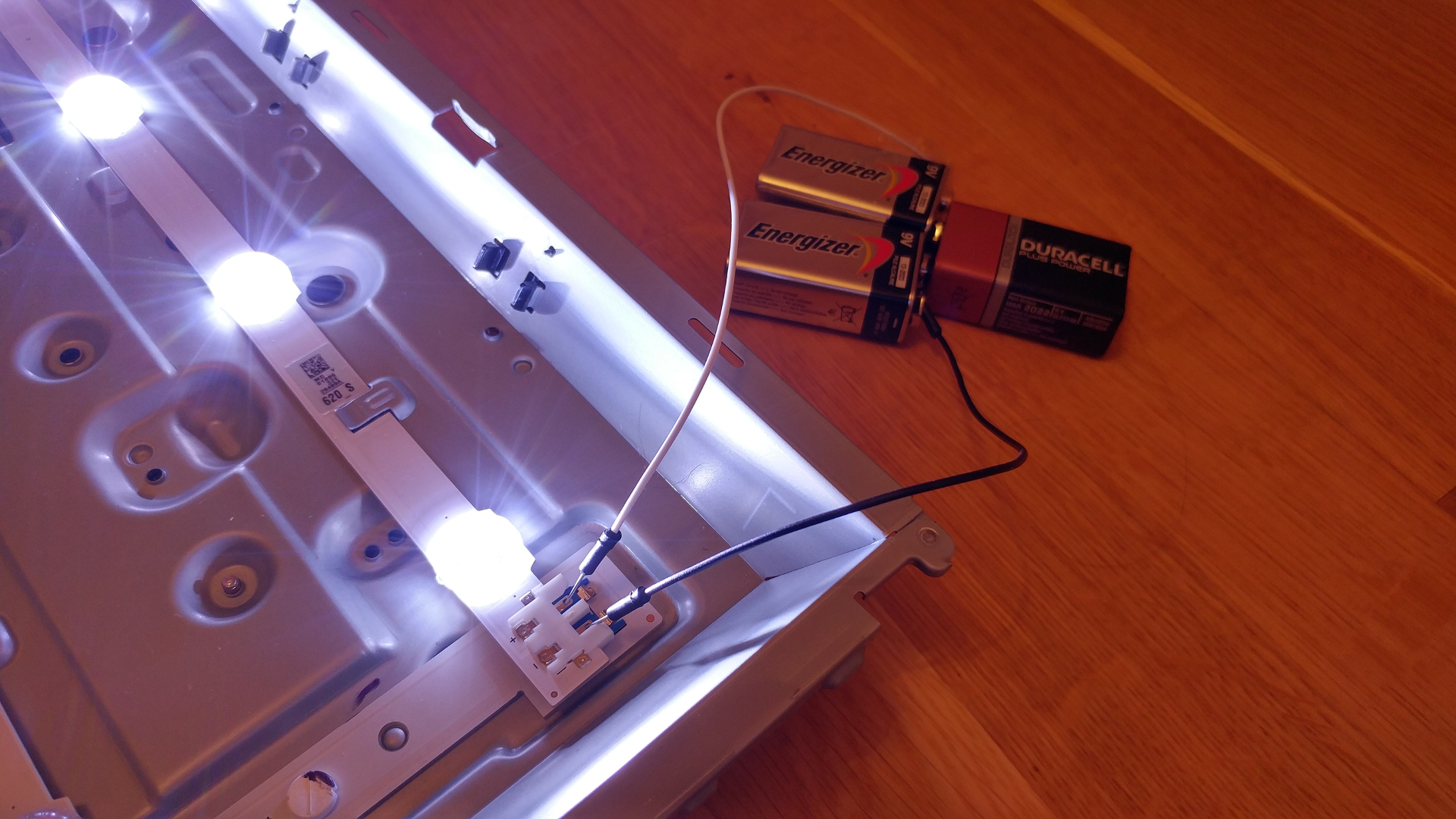

One LED like those ones typically needs between 2.5-3.6v input voltage to light up. By looking up this model online, I found out that the ones used on those strips need 3.6v; so as there are 9 LEDs per strip: 3.6 x 9 = 32.4v input voltage required to light a single strip. That’s the maximum voltage we do NOT want to exceed, otherwise LEDs could be damaged during testing.

After repeating this operation on all strips, I found only 1 defective LED, the same we thought looked burnt when we first had a look at the backlight (3rd strip from the top, 6th LED from the left). For a better understanding at what a burnt LED looks like here are 2 pictures of a burnt one and an OK one. Mind the roasted color compared to the regular one.

Once we have by-passed the LED, we can power the TV on. Careful! High voltage (200-300v) runs through the TV when plug, so be very careful how you handle it so you don’t electrify yourself!

There might be a lot of other root causes for similar symptoms, a black screen often looks like something very serious and therefore expensive to repair, but this case is the perfect example that taking some time to look for the root cause can sometime lead to a good surprise: here a 1$ fix!

EL backlight is obsolete technology, it is disappearing. CCFL backlight is disappearing, too. They are both being replaced by LED Backlight. I have never heard anyone ask for a quote about CCFL backlight. But every now and then, I can hear my customers ask about EL backlight, so let us dig in and find out “What is EL backlight?” and “Why EL backlight still has market demand?”

EL is an abbreviation for ELECTRO LUMINESCENT which is a type of flat cold light. The luminous principle of EL Backlight is that two pieces of paper plates that sandwich the phosphor are driven by the high voltage and the phosphor is emitting light because of the high voltage. The brightness depends on the magnitude of the voltage and the frequency of the alternating current. Within the range of 30V ~ 250V, the higher the voltage, the brighter the EL backlight. However, although the higher voltage can make the EL backlight brighter, the excessive voltage will directly and seriously affect the using time of EL backlight and we strongly suggest that the voltage should not exceed 140v under normal circumstances. Within the range of 50Hz ~ 2000Hz, the brightness will increase with the increase of frequency of the alternating current. Certainly, the frequency is another important factor in determining the using time of EL backlight. It is considered that in general the frequency should not exceed 2000Hz. By the way, the using time of EL backlight is that the time span from the initial luminance to the half luminance. If it is calculated by hours, the using time of EL backlight is more than 10,000 hours theoretically. Working temperature is the most important factor affecting the using time. It can make the brightness rapidly decrease until the complete loss of light. Therefore, a good environment and working condition is the premise of the long-term use of EL backlight.

I think I have already given you the answer. We can see that among all the light sources of backlight, EL backlight is the thinnest one. I am sure that the trend of LED backlight is becoming super thin and lightweight. I have made the thinnest LED backlight for one of my clients. The light guide plate is as thin as 0.6 mm, but it is the best we can do. The total thickness of LED backlight is 0.9 mm. You may not know that it caused lots of trouble for us. 0.6 mm is too thin to install SMD LED into PCB in the traditional way. The minimum thickness of PCB to install SMD is 1.0 mm, so we have to make a dedicated FPC for it.

EL backlight can be made as thin as 0.12 mm. No wonder why it is popular in a world where people pursue super thin and regard the thinner the better as an aesthetical standard.

Then the brightness will be double or triple. Please see the picture above. I admit that is insane. It is too expensive. Usually, edge LED backlight with two edges that are installed with SMD LEDs is more than enough in the brightness.

This is crazy. It will be incredibly expensive. We have never made the pitch 5.0 mm bottom LED backlight for any of my customers before. I just want to tell you it is possible that we can increase the brightness of LED backlight.

◆ Color. EL backlight usually only has one color which is white. And LED backlight is much better in color saturation and color variousness. Seethe advantages of LED backlight.

Theoretically, the using time of LED backlight is 100,000 hours and the using time of EL backlight is 10,000 hours. But practically, the using time of LED backlight is 20,000~30,000 hours and the using time of EL backlight is 2000~3000 hours. The practically using time is determined by so many factors and there is a huge difference in each individual.

3 LED lamps and 1 electronic resistor are serially connected as one group. The driving voltage is 12V. I am not here to talk aboutthe benefit of LED Serial and Parallel Hybrid Connection.

Meanwhile, the driving voltage of EL backlight is from 30V ~ 250V. By the way, the direct current of portable batteries can drive EL backlight too. But it usually needs an exterior battery voltage booster. Please see the picture below.

We cannot set the chip both in constant voltage control and constant current control. For LCD application, I think if current through LCD is 180mA, the voltage will be 9.3V which don"t need to be controlled. So I think constant current control is suitable for LCD.

I am a hobbyist in electronics, my neighbour has an LCD monitor of make ZENITH (Indian Company) bought back in 2008, the problem with the LCD is the display goes dimmer & dimmer until he cannot see anything on the screen this has been happening for last 2 weeks now, he turned off the computer and after some time when he turned it on the LCD used to work, Now there is no picture on the screen but the power led is glowing. I connected my LCD screen to his computer to see if the fault is with the monitor or the CPU and my monitor is working giving clear display. So the faulty is with his LCD monitor

Then I connected it to the mains AC and checked the output voltages in circle marked 1 it gave 12v & 5v DC for the main board then I checked the voltage in circle marked 2 it gave me 14v AC for the LCD backlight,

then the backlight was glowing and giving me display, so i thought it was a loose connection so I turned off the monitor and after 15 mins I turned it back on (my PC was on) now it was not giving any display and the backlight was not glowing then I checked output voltage at circle marked 2 now it was not giving any voltage. then I disconnected the main board, backlight from the power supply and checked the voltages it was giving output of 12v & 5v DC but was not giving any voltage for the backlight of the LCD (Circle no 2).

Then I googled and found some articles online for inverter board testing, most of them suggested to check the inverter transformer (circle No. 4) and transistors near the transformer, to check the feedback circuit, so I removed the Schottky barrier diodes (2 Nos) circle no. 3, part no - SBLF10100CT (attached datasheet as this is the only website providing me the information as google suggested me equivalent MBR10100CT with same as SBLF10100CT). They are Common-Cathode High Voltage Schottky Rectifier Diodes, I checked with my DMM - diode function they tested out fine.

Medical diagnostic devices have become powerful state-of-the-art instruments for instantaneous display of vital patient information. Key to their effectiveness are monitors to display the critical information they provide. Devices such as defibrillators, cardiac monitors, vital signs monitors, and full-clinical-parameter bedside and portable monitors demand that the information displayed be clear, crisp, and easily readable. Most medical diagnostic devices utilize LCDs in the size range of 6.4˝ to 12.1˝. These displays are typically backlit and have traditionally used cold cathode fluorescent lamps (CCFL) for this function. The CCFL backlight units (BLUs) are powered by DC to AC inverters, which turn direct voltage and current into alternating voltage and current.

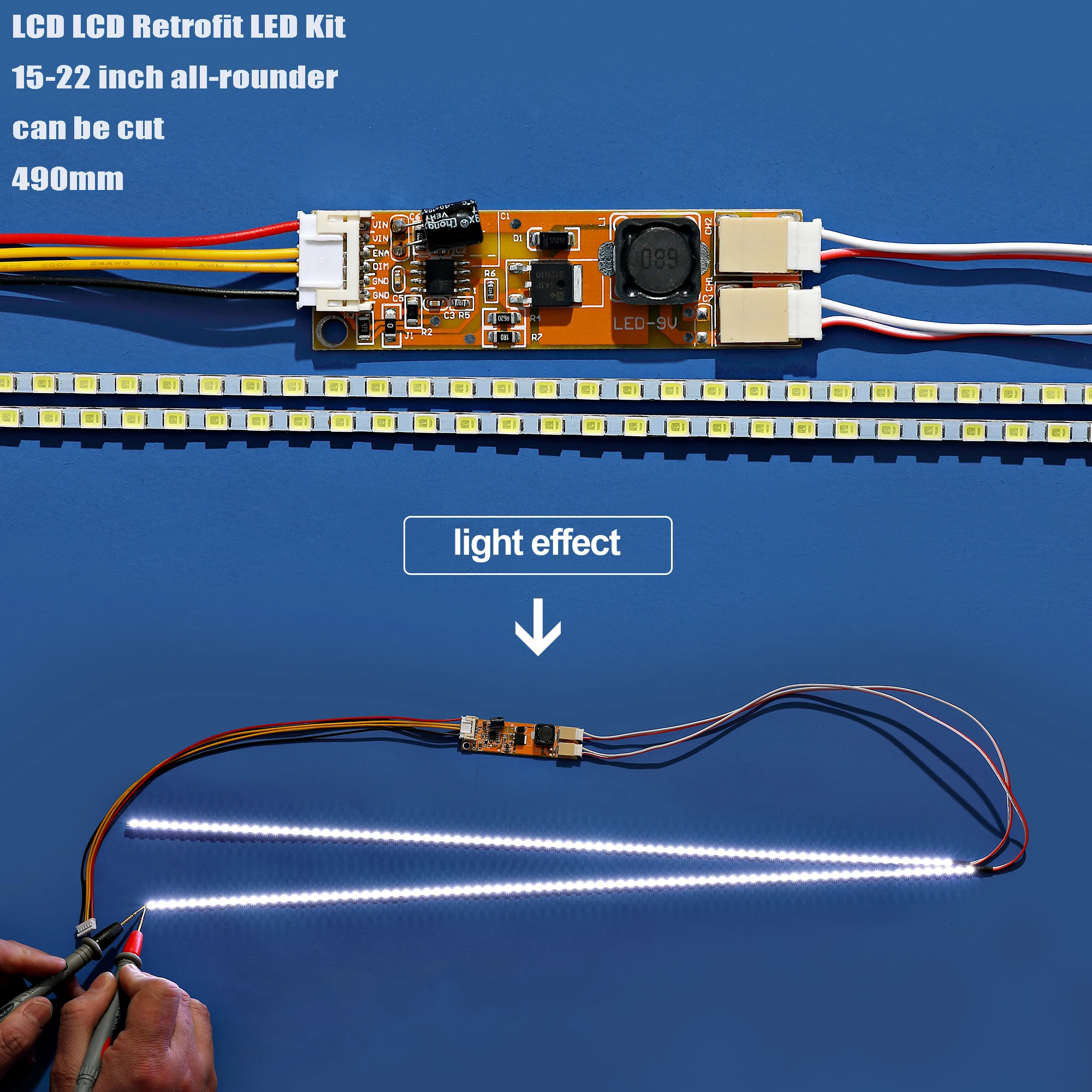

Figure 1: CCFLs have been the dominant backlighting technology for medical displays, but challenges from LED backlights (such as the LED rail shown here) are on the horizon.

Medical devices present a special set of requirements for the LCD BLU and the backlight inverter. The LCD needs to provide high contrast, high resolution images, and data, as well as a resistance to glare. Portable medical devices must provide a bright, long lasting image when powered by batteries. Displays incorporated into devices used in emergency vehicles must withstand extreme temperatures and conditions, including shock, vibration, and even harsh environments, such as being sprayed with a fire hose.

A typical medical device display uses one or two CCFLs in the BLU. These small lamps are able to provide an extremely bright white light source to properly backlight the LCD. CCFL temperatures do not rise far above the ambient temperature, making them thermally good for LCD panels since the light source may be close to other components that could be affected by excessive heat.

Depending on the application, the DC to AC inverter that powers the CCFL backlight can have an input voltage ranging from 5 to 48 VDC. The inverter provides the high AC voltages required to light the CCFL and maintains the constant AC current required to control the CCFL brightness.

The quality of the displayed image depends heavily on the inverter. The LCD manufacturer or distributor supplies the LCD panel to the medical device manufacturer with a CCFL BLU that meets the application requirements. The medical device manufacturer must choose an inverter that will provide acceptable brightness, lamp life, dimming features, and dependable performance. The device manufacturer may contact the LCD manufacturer for an inverter recommendation or may talk to a field application engineer (FAE) at the LCD distributor. Another, and perhaps better option is to contact an engineer at the inverter manufacturer. Inverter manufacturers are familiar with all of the panels from the major LCD manufacturers and can offer expertise in recommending the optimum inverter.

While CCFLs continue to be the dominant technology used to backlight medical device displays, BLUs utilizing LED (light emitting diode) light sources are being considered as an alternative and, in some cases, the design of preference. LEDs are already used to backlight a wide range of smaller displays (e.g., cell phones and MP3 players). Because of their higher power consumption and, in some cases, their mercury content, CCFL BLUs are beginning to be replaced by LED BLUs for mid-size and even larger displays.

An LED BLU is generally driven by a constant current and does not require an alternating current at high voltage, therefore an inverter is not required. This does not mean that LED BLUs do not require appropriately designed drivers to maintain constant brightness and to provide dimming. An LED’s efficiency depends on the amount of current flowing through it and, therefore, for quality performance in a BLU application, a constant current driver is required to maintain constant brightness. To compensate for changes in the voltage of an LED string, which may occur with changing temperature, or may vary with tolerances across a large number of LED backlights, drivers must be designed with the ability to adapt to changes in LED voltage.

LEDs can provide higher brightness than CCFLs. Lower efficiency (lumens/watt) LEDs may provide 20% more brightness than CCFLs. A typical increase in brightness might be 420 cd/m2 or “nits” for an LED BLU compared to 350 cd/m2 for the CCFL BLU version of the same LCD utilizing the same amount of power. High brightness, higher efficiency LEDs may provide 200% more brightness than conventional CCFL BLUs. Also, LED backlights are typically more reliable and more durable over the lifetime of the display. LEDs are less fragile than CCFLs, and won’t degrade if operated for long periods of time at cold temperatures (down to -30°C).

Other advantages include higher light output per electrical power input efficiencies and the ability to optimize color gamut. Also, since LEDs contain no mercury, they provide a “green” backlight. Finally, the wide range dimming capability of LEDs can be a valuable advantage up to 20,000:1. At present, the biggest obstacle to more widespread adoption of LED backlights is that LED backlights cost more than CCFL backlights.

A new series of “intelligent” DC to AC inverters named “Smart Force” has been designed for display applications like medical monitors that require high efficiency, wide range dimming, and lamp current stability over a wide range of input voltages and operating temperatures, and with either non-RoHS or full RoHS compliance. The Smart Force inverter series offers a low profile (‹6.0 mm high), wide input voltage range, and wide range PWM (pulse width modulation) dimming. Available in single and dual-lamp versions, they feature a ruggedized transformer that has helped them test successfully at extremely wide temperature ranges.

A dual-lamp Smart Force inverter (Figure 2) has recently been selected by the manufacturer of a widely used portable defibrillator (similar to the device shown in Figure 3). The application required an inverter with a minimum five year life, a wide input voltage operating range, closed loop lamp current regulation, and a wide operating temperature range. The selected Smart Force closed-loop CCFL inverter provides constant voltage and current output over a range of input voltages so that constant brightness is maintained on the LCD screen. The brightness does not change as the input voltage changes—a key performance feature for this battery-powered application. This inverter also provides higher efficiency and, consequently, less heat, than alternative inverter designs.

Figure 2: Smart Force inverters have been designed for display applications like portable defibrillators (Figure 3) that require high efficiency, wide range dimming, and lamp current stability over a wide input voltage range.

A wide variety of LED driver ICs are becoming available for use in LED driver circuits. Most of these driver ICs employ switching and/or linear circuits to control the LED current. Depending on the configuration and number of strings, there is generally an optimum topology choice for a given display backlight. Many times, the voltage available is not usable to drive the wide array of string voltages that are required from display to display; therefore, it is not possible to use the standard +5 or +12 V available with a driver IC chip to drive the backlight. Many LED drivers employ boost or buck circuits to either increase or decrease the supply voltage, and they also employ a secondary circuit that will directly drive the LEDs to a constant current. High power backlights are often driven by a different topology than a lower power backlight, as one topology may be more optimized than another for a given power level. Along with making the correct topology choice, those developing a backlight driver need to be well versed in power supply layout for switching and linear circuits. The designer will also face EMI and thermal issues if the proper components are not chosen and the layout is not optimized.

LED drivers are now available as standard products for a broad range of LCDs, including the 6.4˝ to 12.1˝ sizes commonly used in medical device displays (Figure 4.) These drivers provide full function in a compact size, with wide range dimming, wide input voltages, and full brightness and enable controls. Available in a range of sizes, input voltages, and dimming ratios, they are compatible with most OEM LED-backlit panels or can also be used with the Smart Force LED rails shown in Figure 1 and Figure 4.

One OEM’s patient monitors utilize CCFL-backlit LCDs, but the company is considering replacement of the CCFLs with LED backlighting and driver boards rather than keeping the CCFL backlight and replacing the inverters.

One option is to use an LED-backlit LCD from an LCD manufacturer. These LCDs provide slightly higher brightness than the CCFL equivalents or lower input power at the same brightness as the CCFL equivalents. The LED drivers previously described will provide the control needed to optimize display operation.

Another option is to retrofit the CCFL BLU to an LED BLU. This can provide a solution for LCDs already in the field. The LED BLU rail shown in Figure 1 is designed as a drop-in replacement for CCFL BLU rails. When used with compatible LED drivers, the LED rails provide the often simpler CCFL to LED retrofit option. replacement for CCFL BLU rails. When used with compatible LED drivers, the LED rails provide the often simpler CCFL to LED retrofit option.

A major manufacturer of patient monitoring solutions was looking for drop-in replacement inverters for their high-performance transportable patient monitors, which are backlit with a CCFL BLU. When presented with the option of an LED rail/driver retrofit solution that could be installed in the field by their service personnel, they decided to consider the performance advantages of LED backlights now instead of in the future, regardless of the higher cost of the LED BLU.

CCFL BLUs powered by DC-AC inverters are the dominant backlighting technology for medical device displays. As LED costs decline and efficiencies increase, LED BLUs will become more popular. So, while CCFLs driven by DC-AC inverters remain the leading backlighting technology for the present, LEDs are likely to be the future backlight technology of choice.

You should have basic electrical test equipment such as a Digital Multimeter and a basic working knowledge of electronics. Soldering is a must if you plan on doing more than testing a screen.

We will be gaining access under the dreaded “DO NOT TOUCH” plastic tape. What they really mean to say is.. “Do not touch the multiple ribbons along the top or bottom edge of the board.” These ribbons interface with the LCD screen and pass information to the pixel matrix. They are fragile!

This guide applies to Laptop LCD panels more so than your desktop"s 24" LCD screen. Some LED backlights are fed with up to 96 volts, but not usually… and not on laptops.

Finally, if you break something.. it"s on you! There is a lot of variance between LCD manufacturers.. they are all different! Hold only yourself responsible if something goes wrong... that"s an order, not a suggestion

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey