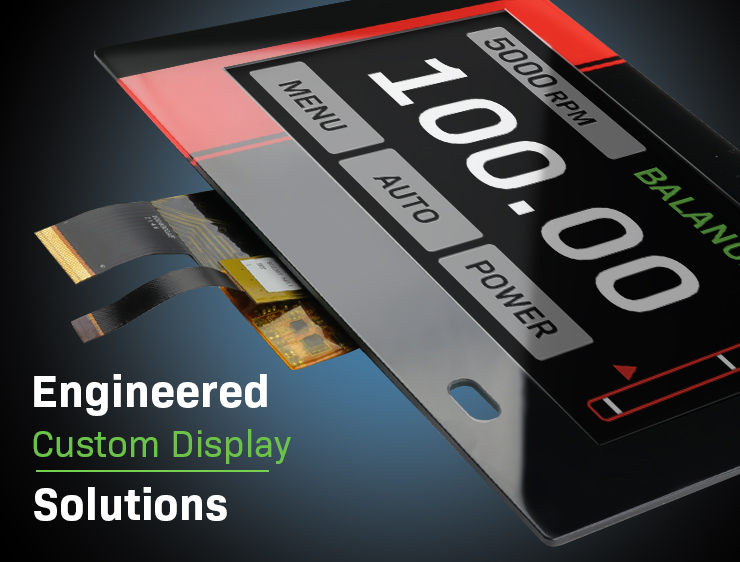

tft lcd screen future manufacturer

Our new line of 10.1” TFT displays with IPS technology are now available! These 10.1” IPS displays offer three interface options to choose from including RGB, LVDS, and HDMI interface, each with two touchscreen options as capacitive or without a touchscreen.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

A thin-film-transistor liquid-crystal display (TFT-LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT-LCD is an active-matrix LCD, in contrast to passive-matrix LCDs or simple, direct-driven LCDs with a few segments.

TFT LCDs are used in appliances including televisions, desktop monitors, notebook PC, tablet PC, mobile phones, handheld video game systems, personal digital assistants, navigation systems and projectors.

TFT LCDs are also used in car instrument clusters because they allow the driver to customize the cluster, as well as being able to provide an analogue-like display with digital elements.

In terms of product, Large TFT-LCD is the largest segment, with a share over 95Percentage. And in terms of application, the largest application is LCD TV, followed by Notebook PC, LCD Monitor, etc.

In 2020, the global TFT-LCD market size was USD 107140 million and it is expected to reach USD 92120 million by the end of 2027, with a CAGR of -2.1Percentage during 2021-2027.

The report makes an excellent effort to reveal key opportunities that are available in the global TFT-LCD market to assist players in achieving a strong market position with analysis that complies with industry standards and high data integrity. The report provides access to verified and trustworthy market forecasts, such as those for the global revenue size of the Personalized In-Vehicle market.

On the basis on the end users/applications, this report focuses on the status and outlook for major applications/end users, sales volume, market share and growth rate of TFT-LCD Market applications, includes:

Overall, the report proves to be a useful tool for players looking to gain an advantage over their rivals and ensure long-term success in the global market for TFT-LCD. With the assistance of reliable sources, the report"s findings, data, and information are all validated and revalidated. Analysts employing a novel and best research and analysis strategy carried out an in-depth examination of the global Personalized In-Vehicle market.

Following Key Questions Covered in the TFT-LCD Market Report Are: ● Comprehensive Evaluation of TFT-LCD market carries customers and associations make out systems?

● What is the size of TFT-LCD industry of dynamic countries like Asia-Pacific, Latin America, Europe, North America, The Middle East and Africa and so on?

Research Report on Global TFT-LCD Market considerably focuses on growth prospects compiling a holistic mix of crucial determinants such as Product Portfolio, Application, Industry Size, Share, description as well as technological advancement. The report also examines the subjective effects of market factors on key segments and major Key Players.

Global “TFT-LCD Market” Research Report 2022 is a historical overview and in-depth study of the current and future market of the TFT-LCD industry. The report represents a basic overview of the TFT-LCD market share, and competitor segment with a basic introduction of key players, top regions with major country’s data, product types, and end industries. This report provides a current overview of the TFT-LCD market trends, growth, revenue generated, gross margins, ex-factory price, capacity, cost structure, and key driver’s analysis. The report further investigates and assesses the current landscape of the ever-evolving business sector and the present and future effects of COVID-19 on the TFT-LCD market.

About TFT-LCD Market Report:A thin-film-transistor liquid-crystal display (TFT-LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT-LCD is an active-matrix LCD, in contrast to passive-matrix LCDs or simple, direct-driven LCDs with a few segments.

TFT LCDs are used in appliances including televisions, desktop monitors, notebook PC, tablet PC, mobile phones, handheld video game systems, personal digital assistants, navigation systems and projectors.

TFT LCDs are also used in car instrument clusters because they allow the driver to customize the cluster, as well as being able to provide an analogue-like display with digital elements.

The TFT-LCD industry touched the bottom in 2011, then has warmed up slowly since 2012 and is expected to reach its peak in early 2015, but it will fall into another lengthy decline stage by 2016. After the TFT-LCD industry slumped, TFT-LCD vendors in different countries chose varying countermeasures. South Korean vendors represented by Samsung strived to explore the OLED field. In Japan, Sharp transferred to be a small and medium-sized panel vendor, produced mobile phone panels with 8.5-generation lines and vigorously developed IGZO technology. Hitachi, Sony and Toshiba set up a joint venture Japan Display (referred to as JDI) to develop LTPS technology. Taiwanese vendors developed 4K HD technology. Chinese mainland vendors promoted the construction of new production lines at low costs aggressively. As a result, Chinese mainland vendors are the most notable winners, followed by Taiwanese and Japanese counterparts.

Although TFT-LCD market is going to step into another lengthy decline stage, it is full of opportunities if investors have wonderful countermeasures to cut the raw material cost of TFT-LCD and ensure that the production line is efficient enough, since there is still huge demand of TFT-LCD in some regions like China.

The TFT-LCD market was valued at million USD in 2018 and is projected to reach million USD by 2025, at a CAGR during the forecast period. In this study, 2018 has been considered as the base year and 2019 to 2025 as the forecast period to estimate the market size for TFT-LCD.

This report presents the worldwide TFT-LCD market size (value, production and consumption), splits the breakdown (data status 2014-2019 and forecast to 2025), by manufacturers, region, type and application.

This study also analyzes the market status, market share, growth rate, future trends, market drivers, opportunities and challenges, risks and entry barriers, sales channels, distributors and Porter’s Five Forces Analysis.

Market Segment Analysis:The research report includes specific segments by Type and by Application. Besides, the report also covers segment data, including type segment, industry segment, channel segment, etc. It covers different segment market sizes, both volume, and value. Also cover different industries client’s information, which is very important for the manufacturers. it provides insights into market threats or barriers and the impact of the regulatory framework to give an executive-level blueprint of the TFT-LCD market

With tables and figures helping analyze worldwide Global TFT-LCD market trends, this research provides key statistics on the state of the industry and is a valuable source of guidance and direction for companies and individuals interested in the market.

Due to its high performance ratio and low cost, TFT liquid crystal displays are used more and more in automotive configurations, and have become the mainstream of automotive audio and video systems and automotive navigation system displays. With the development of artificial intelligence, the content of vehicle display will continue to be enriched, and the specifications of vehicle LCD panels will also increase day by day. High-definition display quality, high brightness, large size, wide viewing angle, thinning, light weight, high reliability, low power consumption, etc. will become the future development trend of on-board displays.

The central control area of some cars is still dominated by traditional structural solid buttons, and the high-end version of some cars uses a touch screen. The design concept of physical buttons greatly limits the interior design, and the space utilization rate is low, which hinders the passenger space in the front row. At the same time, the central control needs to set up corresponding functional areas, such as the central control screen, air conditioning area, vehicle control area, etc., which will complicate the central control area and is not conducive to user operations. Users must find the corresponding button operation among the numerous buttons, and must also adapt to the arrangement of the central control buttons of different models. Compared with the touch screen used in the consumer electronics field, the touch screen used in the automotive field should have the following characteristics:

Among them, large-scale and multi-touch are mainly to meet the user"s experience, which is the same as the trend of electronic consumer goods. At the same time, the automotive field has put forward higher requirements for touch screens, which require high reliability and high durability. These characteristics embody the specific requirements of the automotive field for the central control touch screen of the TFT liquid crystal display.

With the development of intelligence, the touch screen in the car has also become the mainstream. In response to this trend, panel manufacturers have developed new technologies in the field of in-vehicle displays to occupy a favorable market position. Large-size, high-definition multi-function integrated vehicle touch panels will become a standard configuration. At the same time, the vehicle panel needs to be able to be affected by the driving environment, outdoor strong light and high temperature, and the vehicle navigator with resistive or capacitive touch screen has strong anti-interference ability.

TFT is an LCD Technology which adds a thin-film transistor at each pixel to supply common voltages to all elements. This voltage improves video content frame rates. Displays are predominantly utilizing color filter layers and white LED backlighting.

IPS TFT is a deviation of a traditional TN TFT Display. The most fundamental difference is that light is not rotated in plane and passing through polarizer films, but instead perpendicular to shutter the light. This approach to the technology improves contrast and enables symmetrical viewing angles from all directions.

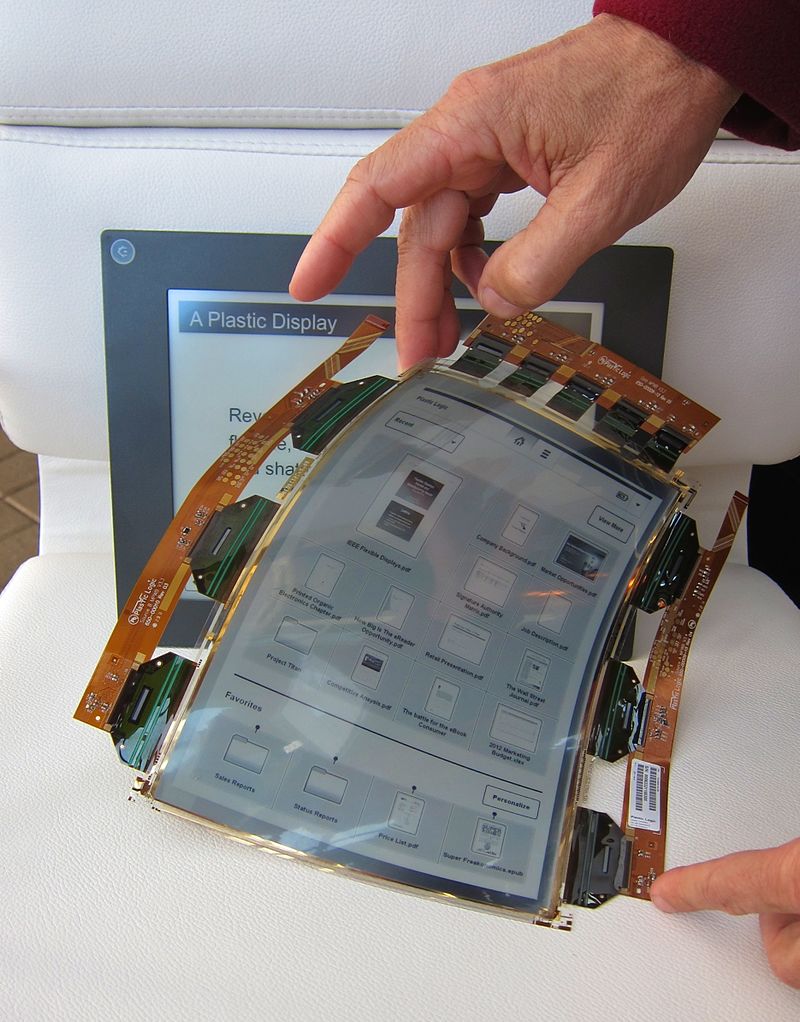

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Welcome to our comprehensive guide on the latest developments in gaming LCD display modules and monitors. As technology continues to advance, so do the capabilities of gaming displays, which are becoming more advanced and feature-rich with each passing day. In this article, we will explore some of the latest developments in gaming LCD display modules and monitors, and how they are revolutionizing the gaming experience.

.jpg)

Exyte offers advanced FPD manufacturing capabilities built for the future of the flat panel display market. We offer a unique combination of in-house expertise covering FPD processing technology, cleanroom contamination control and factory integration of the processing tools alongside equally large automation systems required to ensure high-productivity manufacturing. The process technologies utilized by our clients include thin film transistor (TFT) LCDs, organic light-emitting diodes (OLED), active-matrix organic light-emitting diode displays (AMOLED), as well as state-of-the-art touch screen panels.

We have been proud from the higher consumer gratification and wide acceptance due to our persistent pursuit of high quality both on product or service and service for Industrial Tft-Lcd Panel, Lcd Monitor, Medical Tft-Lcd Panel, Face Recognition Tft-Lcd Panel,Touch Displays/Screen. As an experienced group we also accept customized orders. The main goal of our company is to build up a satisfying memory for all customers, and establish a long-term win-win business relationship. The product will supply to all over the world, such as Europe, America, Australia,Russia, Holland,Boston, Qatar.Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don"t hesitate to contact us. We will do our best to meet your needs.

With reliable good quality system, great standing and perfect consumer support, the series of products and solutions produced by our organization are exported to quite a few countries and regions for 10 Inch Tft Lcd Monitor, Sunlight Readable Monitor, Widescreen Flat Panel Monitor, Flexible Tft Display,Tn Lcd Module. We have four leading products. Our products are best sold not only in the Chinese market, but also welcomed in the international market. The product will supply to all over the world, such as Europe, America, Australia,Lithuania, Azerbaijan,Russia, French.we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

According to a recently released report by SEMI, thin-film transitor-LCD manufacturing capacity in China is expected to show 35 percent growth in 2007 and 50 percent growth in 2008, as new fab capacity begins to come online.

At present, China has two fifth generation (G5) TFT-LCD fabs in production, one coming online, one existing G5 fab expansion, one G1 plant and three Chinese-owned G2-G3 lines in Korea.

“To date, there has been very little production of TFT-LCD materials or components in China,” said Mark Ding, president of SEMI China. “However, the influx of both Chinese and foreign-owned companies that are beginning to establish these local facilities is helping to significantly grow this market, and will ultimately help establish China as a global panel making market center of TFT-LCD materials and components.”

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

If you are in the market of color TFT LCD displays and you haven’t already been affected by the recent changes in the global market, then it’s just a matter of time. If you have recently asked, ‘What is going on with TFT-LCD panel prices lately?’, you are not alone. Here at Phoenix Display we have had a lot of questions regarding the TFT-LCD panel price increase that the market is seeing. We want to help explain what is happening, why it’s happening, and what to expect in the near future so that you can be aware of the effects and adjust accordingly.

In recent months there has developed a fair amount of uncertainty in regards to manufacturing conditions for TFT panels at the TFT glass fab level. This has caused a lot of fluctuation and volatility in both the supply and price of TFT panels. We are seeing that the price of TFTs has increased from 25% to 70% on average, and have seen some instances of a 2.5 times increase for the less common configurations. Combined with the fact that lead time is now only confirmed upon placing an actual order with payment in advance, in makes planning and producing around your color display product even more challenging.

One of the important things to realize with regards to TFT market conditions is that flat TFT panels in almost every size are currently in short supply. This is the first time this has happened in almost 20 years.

Some of the larger panel manufactures are exiting TN TFT manufacturing to focus on newer, more profitable technologies. The market has seen a trend towards low-temperature polysilicon (LTPS) TFT LCD panels, which provide customers lower power consumption along with higher resolution, along with a big shift into OLED to support wearables, the latest smart phone designs, and even the flat panel Television market as well.

In 2016 there has been a rise in the proportion of LTPS/Oxide TFT smartphone panel shipment production, rising to 34.6% market share compared to 29.8% in 2015. In the coming year we expect to see a variety of panel makers including CSOT, Taiwanese AUO, Chinese Tianma, and Japanese JDI, roll out new LTPS capacities eclipsing and impacting conventional TFT manufacturing. In May the industry had a shortage of television panels which was followed by a similar supply-demand dynamic for notebook and smartphone small panels. This was largely due to JDI, LG Display Co. and Samsung Display Inc., shutting down their production lines in these verticals.

In the last 5 months the TFT cell glass cost has been rapidly increasing, largely due to the influence of upstream LCD panel maker’s supply. As a result of these market fluctuations almost all TFT mother glass suppliers have increased their pricing across the board. Due to these new market impacts, we highly doubt that any of the major TFT mother glass manufacturers will reopen lines that have previously been closed. In fact, current trends lend us to believe that if these lines were ever reopened, they would be used for OLED production rather than TFT. We believe that the capacities problems the market is seeing is not a short-term problem, and will likely not ease until the second quarter of 2017, at the earliest. This leaves the current state of the market in a fair amount of turmoil as the suppliers battle the glass shortage and while offloading the increased cost to manufacturers.

While there is a trend at the manufacturing level to diversify away from traditional color TN TFT LCD display, the positive is there is still be a strong market for this product for years to come due to TN TFTs lower cost advantage and availability. In short, we don’t see TFT displays going away any time soon, but we will be impacted by higher costs and longer lead times for the near future.

You’ve already taken the first step by educating yourself on the issue. By preparing your business and supply chain for the increase in price and decrease in supply which lead to longer lead-times, you can mitigate potential delays and issues in your production. If you have any additional questions about TFT panels or any other standard or custom display needs, please

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

The amount of pollutants produced during manufacturing processes of TFT-LCD (thin-film transistor liquid crystal display) substantially increases due to an increasing production of the opto-electronic industry in Taiwan. The total amount of wastewater from TFT-LCD manufacturing plants is expected to exceed 200,000 CMD in the near future. Typically, organic solvents used in TFT-LCD manufacturing processes account for more than 33% of the total TFT-LCD wastewater. The main components of these organic solvents are composed of the stripper (dimethyl sulphoxide (DMSO) and monoethanolamine (MEA)), developer (tetra-methyl ammonium hydroxide (TMAH)) and chelating agents. These compounds are recognized as non-or slow-biodegradable organic compounds and little information is available regarding their biological treatability. In this study, the performance of an A/O SBR (anoxic/oxic sequencing batch reactor) treating synthetic TFT-LCD wastewater was evaluated. The long-term experimental results indicated that the A/O SBR was able to achieve stable and satisfactory removal performance for DMSO, MEA and TMAH at influent concentrations of 430, 800, and 190 mg/L, respectively. The removal efficiencies for all three compounds examined were more than 99%. In addition, batch tests were conducted to study the degradation kinetics of DMSO, MEA, and TMAH under aerobic, anoxic, and anaerobic conditions, respectively. The organic substrate of batch tests conducted included 400 mg/L of DMSO, 250 mg/L of MEA, and 120 mg/L of TMAH. For DMSO, specific DMSO degradation rates under aerobic and anoxic conditions were both lower than 4 mg DMSO/g VSS-hr. Under anaerobic conditions, the specific DMSO degradation rate was estimated to be 14 mg DMSO/g VSS-hr, which was much higher than those obtained under aerobic and anoxic conditions. The optimum specific MEA and TMAH degradation rates were obtained under aerobic conditions with values of 26.5 mg MEA/g VSS-hr and 17.3 mg TMAH/g VSS-hr, respectively. Compared to aerobic conditions, anaerobic biodegradation of MEA and TMAH was much less significant with values of 5.6 mg MEA/g VSS-hr and 0 mg TMAH/g VSS-hr, respectively. In summary, biological treatment of TFT-LCD wastewater containing DMSO, MEA, and TMAH is feasible, but appropriate conditions for optimum biodegradation of DMSO, MEA, and TMAH are crucial and require carefully operational consideration.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey