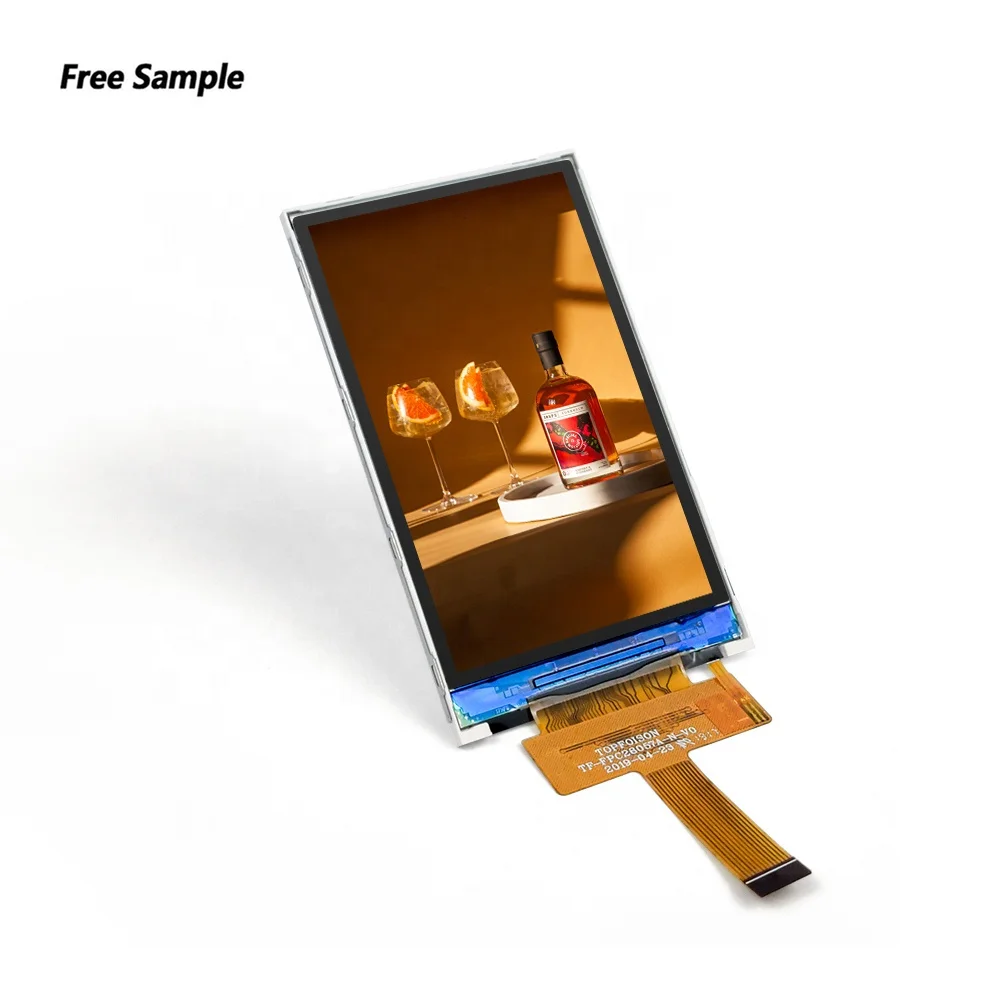

tft lcd screen future free sample

Focus Displays offers a wide range of standard full color TFT displays. 64 million unique colors, high brightness, sharp contrast, -30C operating temperature, and fast response time are all good descriptions of a TFT display. This is why TFT technology is one of the most popular choices for a new product.

Thin Film Transistor (TFT) display technology can be seen in products such as laptop computers, cell phones, tablets, digital cameras, and many other products that require color. TFT’s are active matrix displays which offers exceptional viewing experiences especially when compared to other passive matrix technologies. The clarity on TFT displays is outstanding; and they possess a longer half-life than some types of OLEDs and range in sizes from less than an inch to over 15 inches.

CCFL’s are still available, but are becoming a legacy (obsolete) component. TFT displays equipped with a CCFL require higher MOQs (Minimum Order Quantities) than displays with LED backlights.

The majority of TFT displays contain a touch panel, or touch screen. The touch panel is a touch-sensitive transparent overlay mounted on the front of the display glass. Allowing for interaction between the user and the LCD display.

Some touch panels require an independent driver IC; which can be included in the TFT display module or placed on the customer’s Printed Circuit Board (PCB). Touch screens make use of coordinate systems to locate where the user touched the screen.

Resistive touch panels are the lowest cost option and are standard equipment on many TFT modules. They are more common on smaller TFT displays, but can still be incorporated on larger modules.

Resistive touch panels are constructed using flexible materials with an air gap between and are coated with a resistive layer. When an object applies pressure to the top layer, it makes contact with microdots located on the bottom layer. This allows the touch screen to find the location of the touch using X and Y coordinates.

Custom resistive touch screens are an option if the customer requires a seal or gasket to be in contact with the glass and not in contact with the touch panel.

Resistive touch panels allow a single touch, although advances in new resistive technology will allow multi-touch operation in the near future. One main advantage of a resistive touch screen is the ability to be activated by the touch of any material. This includes a range of items from a bare finger, to a pencil, to even the edge of a credit card; regardless of its composition.

Current capacitive touch technology is limited to a conductive stylus such as a finger. The touch screen operates on capacitive sensing, based on capacitive coupling. A capacitive touch screen detects any material that is conductive or has a different dielectric then the air around it.

Contrast ratio, or static contrast ratio, is one way to measure the sharpness of the TFT LCD display. This ratio is the difference between the darkest black and the brightest white the display is able to produce. The higher the number on the left, the sharper the image. A typical contrast ratio for TFT may be 300:1. This number ratio means that the white is 300 times brighter than the black.

TFT LCD displays are measured in inches; this is the measurement of the diagonal distance across the glass. Common TFT sizes include: 1.77”, 2.4”, 2.8”, 3”, 4.3”, 5”, 5.7”, 5.8”, 7”, 10.2”, 12.1 and 15”.

TFT resolution is the number of dots or pixels the display contains. It is measured by the number of dots along the horizontal (X axis) and the dots along the vertical (Y axis).

Certain combinations of width and height are standardized and typically given a name and a letter representation that is descriptive of its dimensions. Popular names given to the TFT LCD displays resolution include:

Transmissive displays must have the backlight on at all times to read the display, but are not the best option in direct sunlight unless the backlight is 750 Nits or higher. A majority of TFT displays are Transmissive, but they will require more power to operate with a brighter backlight.

A primary job of the driver is to refresh each pixel. In passive TFT displays, the pixel is refreshed and then allowed to slowly fade (aka decay) until refreshed again. The higher the refresh frequency, the sharper the displays contrast.

The TFT display (minus touch screen/backlight) alone will contain one controller/driver combination. These are built into the display so the design engineer does not need to locate the correct hardware.

If you do not see a Thin Film Transistor (TFT) Display module that meets your specifications, or you need a replacement TFT, we can build a custom TFT displays to meet your requirements. Custom TFTs require a one-time tooling fee and may require higher MOQs.

Ready to order samples for your TFT design? Contact one of our US-based technical support people today concerning your design requirements. Note: We can provide smaller quantities for samples and prototyping.

Reflective displays really are a unique thing. You don’t have to hide them from the sun. You don’t have to shield your screen with your hand in order to eliminate glare. You don’t have to tilt it at funny angles that cause your neck to throb in pain, just so that you can read what’s on the screen. Funny, because those are our natural reactions whenever LCD and sunlight combine. Not with a reflective display though.

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The third example is a game. Actually it’s a replica of the popular Flappy Bird game for smartphones. We can play the game using the push button or even using the touch screen itself.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Now we need to make the buttons functional so that when we press them they would send us to the appropriate example. In the setup section we set the character ‘0’ to the currentPage variable, which will indicate that we are at the home screen. So if that’s true, and if we press on the screen this if statement would become true and using these lines here we will get the X and Y coordinates where the screen has been pressed. If that’s the area that covers the first button we will call the drawDistanceSensor() custom function which will activate the distance sensor example. Also we will set the character ‘1’ to the variable currentPage which will indicate that we are at the first example. The drawFrame() custom function is used for highlighting the button when it’s pressed. The same procedure goes for the two other buttons.

So the drawDistanceSensor() custom function needs to be called only once when the button is pressed in order to draw all the graphics of this example in similar way as we described for the home screen. However, the getDistance() custom function needs to be called repeatedly in order to print the latest results of the distance measured by the sensor.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

Adding a display to your Arduino can serve many purposes. Since a common use for microcontrollers is reading data from sensors, a display allows you to see this data in real-time without needing to use the serial monitor within the Arduino IDE. It also allows you to give your projects a personal touch with text, images, or even interactivity through a touch screen.

Transparent Organic Light Emitting Diode (TOLED) is a type of LED that, as you can guess, has a transparent screen. It builds on the now common OLED screens found in smartphones and TVs, but with a transparent display, offers up some new possibilities for Arduino screens.

Take for example this brilliant project that makes use of TOLED displays. By stacking 10 transparent OLED screens in parallel, creator Sean Hodgins has converted a handful of 2D screens into a solid-state volumetric display. This kind of display creates an image that has 3-dimensional depth, taking us one step closer to the neon, holographic screens we imagine in the future.

Crystalfontz has a tiny monochrome (light blue) 1.51" TOLED that has 128x56 pixels. As the technology is more recent than the following displays in this list, the cost is higher too. One of these screens can be purchased for around $26, but for certain applications, it might just be worth it.

The liquid crystal display (LCD) is the most common display to find in DIY projects and home appliances alike. This is no surprise as they are simple to operate, low-powered, and incredibly cheap.

This type of display can vary in design. Some are larger, with more character spaces and rows; some come with a backlight. Most attach directly to the board through 8 or 12 connections to the Arduino pins, making them incompatible with boards with fewer pins available. In this instance, buy a screen with an I2C adapter, allowing control using only four pins.

The screens are capable of a large variety of preset characters which cover most use cases in a variety of languages. You can control your LCD using the Liquid Crystal Library provided by Arduino. The display() and noDisplay() methods write to the LCD, as shown in the official tutorial on the Arduino website.

These tiny LCD screens are monochrome and have a screen size of 84 x 48 pixels, but don"t let that fool you. Coming in at around $2 on AliExpress, these displays are incredibly cheap and usually come with a backlight as standard.

Depending on which library you use, the screen can display multiple lines of text in various fonts. It"s also capable of displaying images, and there is free software designed to help get your creations on screen. While the refresh rate is too slow for detailed animations, these screens are hardy enough to be included in long-term, always-on projects.

For a step up in resolution and functionality, an OLED display might be what you are looking for. At first glance, these screens look similar to the 5110 screens, but they are a significant upgrade. The standard 0.96" screens are 128 x 64 monochrome, and come with a backlight as standard.

They connect to your Arduino using I2C, meaning that alongside the V+ and GND pins, only two further pins are required to communicate with the screen. With various sizes and full color options available, these displays are incredibly versatile.

These displays can be used in the same way as the others we have mentioned so far, but their refresh rate allows for much more ambitious projects. The basic monochrome screen is available on Amazon.

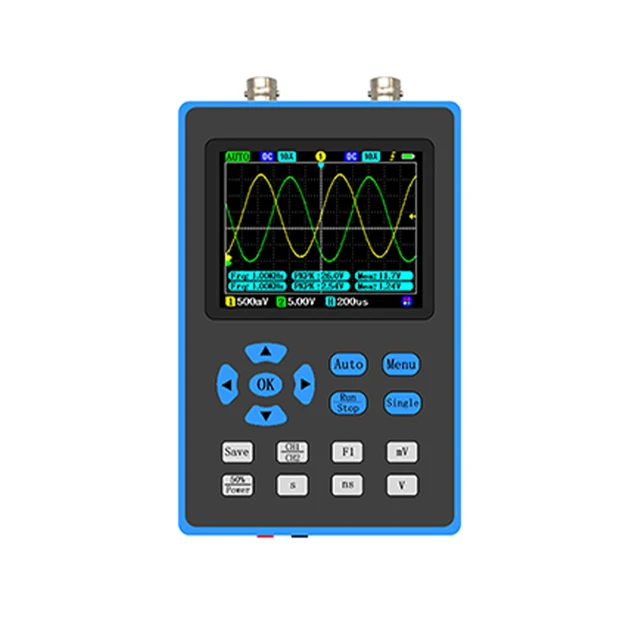

Thin-film-transistor liquid-crystal displays (TFT LCDs) are in many ways another step up in quality when it comes to options for adding a screen to your Arduino. Available with or without touchscreen functionality, they also add the ability to load bitmap files from an on-board microSD card slot.

Arduino have an official guide for setting up their non-touchscreen TFT LCD screen. For a video tutorial teaching you the basics of setting up the touchscreen version, YouTuber educ8s.tv has you covered:

With the touchscreen editions of these screens costing less than $10 on AliExpress, these displays are another great choice for when you need a nice-looking display for your project.

Looking for something a little different? An E-paper (or E-ink depending on who you ask) display might be right for you. These screens differ from the others giving a much more natural reading experience, it is no surprise that this technology is the cornerstone of almost every e-reader available.

Now that you have an idea of what is out there, why not incorporate a screen into your DIY smart home setup? If retro gaming is more your thing, why not create some retro games on Arduino?

Amulet’s capacitive 7” GEMmodule (AM070RVS01) is a fully customizable, high-performance, touch screen display module with a 7” WVGA LCD and robust capacitive touch panel. This feature rich solution, including thick protective cover glass and water resistant and glove-enabled touch panel, provides the ideal attributes required in the embedded industrial and medical equipment markets.

Amulet’s resistive 7” GEMstarter-kit (STK-070R) provides everything needed to create and drive a Graphical User Interface, including a 800 x 480 TFT LCD, an integrated touch panel and controller board, stylus, power supply, and USB PC interface cable. The GEMstarter-kit also comes with a free 30-Day Trial of GEMstudio Pro.

Amulet’s resistive 7” GEMstarter-kit (STK-070R) provides everything needed to create and drive a Graphical User Interface, including a 800 x 480 TFT LCD, an integrated touch panel and controller board, stylus, power supply, and USB PC interface cable. The GEMstarter-kit also comes with a free 30-Day Trial of GEMstudio Pro.

Amulet’s capacitive 4.3” GEMstarter-kit (STK-CY-043) provides everything needed to create and drive a Graphical User Interface, including a 480 x 272 TFT LCD, a capacitive touch sensor, removable stands, and USB PC interface cable.The GEMstarter-kit also comes with a free 30-Day Trial of GEMstudio Pro.

Amulet’s capacitive 4.3” GEMstarter-kit (STK-CY-043) provides everything needed to create and drive a Graphical User Interface, including a 480 x 272 TFT LCD, a capacitive touch sensor, removable stands, and USB PC interface cable.The GEMstarter-kit also comes with a free 30-Day Trial of GEMstudio Pro.

Amulet’s resistive 4.3” GEMstarter-kit (STK-043R) provides everything needed to create and drive a Graphical User Interface, including a 480 x 272 TFT LCD, an integrated touch panel and controller board, stylus, and USB PC interface cable.The GEMstarter-kit also comes with a free 30-Day Trial of GEMstudio Pro.

Amulet’s resistive 4.3” GEMstarter-kit (STK-043R) provides everything needed to create and drive a Graphical User Interface, including a 480 x 272 TFT LCD, an integrated touch panel and controller board, stylus, and USB PC interface cable.The GEMstarter-kit also comes with a free 30-Day Trial of GEMstudio Pro.

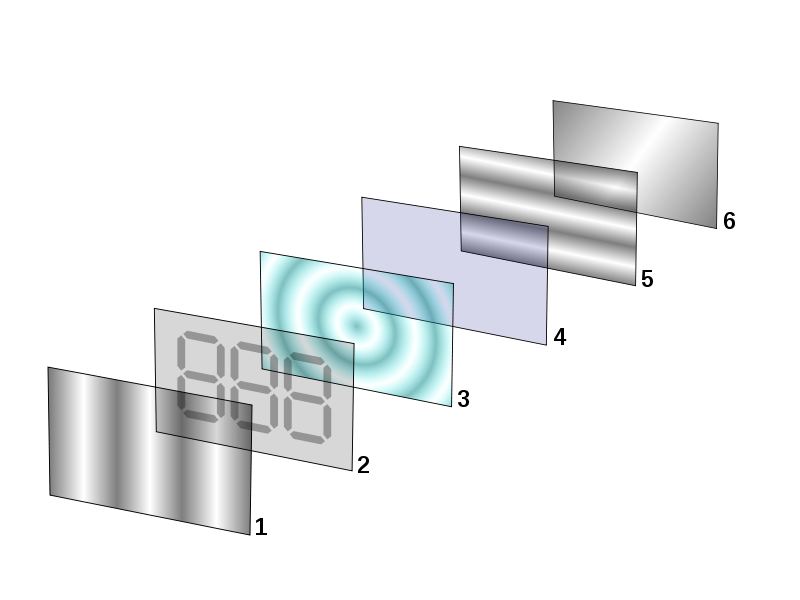

Dr Pan: Hello, Greg. TFT LCD module is one of the best LCD technology. We can simply consider it as TFT+LCD+LED backlight, and monochrome LCD module consists of LCD+LED backlight. An image on an LCD we can see is composed of pixels. TFT is the abbreviation for thin film transistor and it controls the R, G, B colors of each pixel respectively on the surface of LCD.

TFT LCD is a high standard product and it is not well customized as monochrome LCD. But still, it has a variety of options to meet the customers’ requirements.The sizes range from 1.44 inch to 130.0 inch;

The worldwide Automotive TFT-LCD Display Market is expected to grow at a booming CAGR of 2023-2030, rising from USD billion in 2023 to USD billion in 2030. It also shows the importance of the Automotive TFT-LCD Display Market main players in the sector, including their business overviews, financial summaries, and SWOT assessments.

Automotive TFT-LCD Display Market is split by Type and by Application. For the period 2017-2030, the growth among segments provide accurate calculations and forecasts for revenue by Type and by Application. This analysis can help you expand your business by targeting qualified niche markets.

The study examines the Automotive TFT-LCD Display Market"s competitive landscape and includes data on important suppliers, including LG Display, Innolux, AUO, Sharp, BOE, JDI& Others.

The Automotive TFT-LCD Display Market report covers the following countries: the United States, Canada, Mexico, Brazil, Argentina, Peru, the rest of South America, Germany, France, the United Kingdom, the Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Hungary, Lithuania, Austria, Ireland, Norway, Poland, the rest of Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, the Philippines, and Vietnam.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

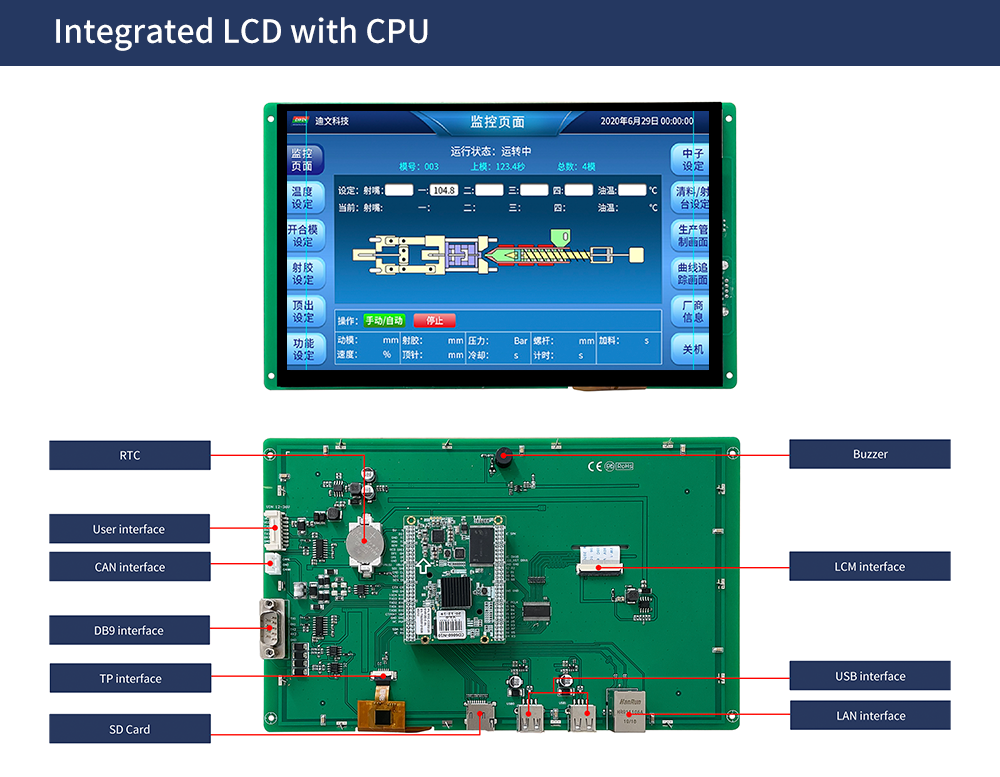

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

In recent years, China and other countries have invested heavily in the research and manufacturing capacity of display technology. Meanwhile, different display technology scenarios, ranging from traditional LCD (liquid crystal display) to rapidly expanding OLED (organic light-emitting diode) and emerging QLED (quantum-dot light-emitting diode), are competing for market dominance. Amidst the trivium strife, OLED, backed by technology leader Apple"s decision to use OLED for its iPhone X, seems to have a better position, yet QLED, despite still having technological obstacles to overcome, has displayed potential advantage in color quality, lower production costs and longer life.

Zhao: We all know display technologies are very important. Currently, there are OLED, QLED and traditional LCD technologies competing with each other. What are their differences and specific advantages? Shall we start from OLED?

Huang: OLED has developed very quickly in recent years. It is better to compare it with traditional LCD if we want to have a clear understanding of its characteristics. In terms of structure, LCD largely consists of three parts: backlight, TFT backplane and cell, or liquid section for display. Different from LCD, OLED lights directly with electricity. Thus, it does not need backlight, but it still needs the TFT backplane to control where to light. Because it is free from backlight, OLED has a thinner body, higher response time, higher color contrast and lower power consumption. Potentially, it may even have a cost advantage over LCD. The biggest breakthrough is its flexible display, which seems very hard to achieve for LCD.

Liao: Actually, there were/are many different types of display technologies, such as CRT (cathode ray tube), PDP (plasma display panel), LCD, LCOS (liquid crystals on silicon), laser display, LED (light-emitting diodes), SED (surface-conduction electron-emitter display), FED (filed emission display), OLED, QLED and Micro LED. From display technology lifespan point of view, Micro LED and QLED may be considered as in the introduction phase, OLED is in the growth phase, LCD for both computer and TV is in the maturity phase, but LCD for cellphone is in the decline phase, PDP and CRT are in the elimination phase. Now, LCD products are still dominating the display market while OLED is penetrating the market. As just mentioned by Dr Huang, OLED indeed has some advantages over LCD.

Huang: Despite the apparent technological advantages of OLED over LCD, it is not straightforward for OLED to replace LCD. For example, although both OLED and LCD use the TFT backplane, the OLED’s TFT is much more difficult to be made than that of the voltage-driven LCD because OLED is current-driven. Generally speaking, problems for mass production of display technology can be divided into three categories, namely scientific problems, engineering problems and production problems. The ways and cycles to solve these three kinds of problems are different.

At present, LCD has been relatively mature, while OLED is still in the early stage of industrial explosion. For OLED, there are still many urgent problems to be solved, especially production problems that need to be solved step by step in the process of mass production line. In addition, the capital threshold for both LCD and OLED are very high. Compared with the early development of LCD many years ago, the advancing pace of OLED has been quicker.While in the short term, OLED can hardly compete with LCD in large size screen, how about that people may change their use habit to give up large screen?

Liao: I want to supplement some data. According to the consulting firm HIS Markit, in 2018, the global market value for OLED products will be US$38.5 billion. But in 2020, it will reach US$67 billion, with an average compound annual growth rate of 46%. Another prediction estimates that OLED accounts for 33% of the display market sales, with the remaining 67% by LCD in 2018. But OLED’s market share could reach to 54% in 2020.

Huang: While different sources may have different prediction, the advantage of OLED over LCD in small and medium-sized display screen is clear. In small-sized screen, such as smart watch and smart phone, the penetration rate of OLED is roughly 20% to 30%, which represents certain competitiveness. For large size screen, such as TV, the advancement of OLED [against LCD] may need more time.

Xu: LCD was first proposed in 1968. During its development process, the technology has gradually overcome its own shortcomings and defeated other technologies. What are its remaining flaws? It is widely recognized that LCD is very hard to be made flexible. In addition, LCD does not emit light, so a back light is needed. The trend for display technologies is of course towards lighter and thinner (screen).

But currently, LCD is very mature and economic. It far surpasses OLED, and its picture quality and display contrast do not lag behind. Currently, LCD technology"s main target is head-mounted display (HMD), which means we must work on display resolution. In addition, OLED currently is only appropriate for medium and small-sized screens, but large screen has to rely on LCD. This is why the industry remains investing in the 10.5th generation production line (of LCD).

Xu: While deeply impacted by OLED’s super thin and flexible display, we also need to analyse the insufficiency of OLED. With lighting material being organic, its display life might be shorter. LCD can easily be used for 100 000 hours. The other defense effort by LCD is to develop flexible screen to counterattack the flexible display of OLED. But it is true that big worries exist in LCD industry.

LCD industry can also try other (counterattacking) strategies. We are advantageous in large-sized screen, but how about six or seven years later? While in the short term, OLED can hardly compete with LCD in large size screen, how about that people may change their use habit to give up large screen? People may not watch TV and only takes portable screens.

Some experts working at a market survey institute CCID (China Center for Information Industry Development) predicted that in five to six years, OLED will be very influential in small and medium-sized screen. Similarly, a top executive of BOE Technology said that after five to six years, OLED will counterweigh or even surpass LCD in smaller sizes, but to catch up with LCD, it may need 10 to 15 years.

Xu: Besides LCD, Micro LED (Micro Light-Emitting Diode Display) has evolved for many years, though people"s real attention to the display option was not aroused until May 2014 when Apple acquired US-based Micro LED developer LuxVue Technology. It is expected that Micro LED will be used on wearable digital devices to improve battery"s life and screen brightness.

Micro LED, also called mLED or μLED, is a new display technology. Using a so-called mass transfer technology, Micro LED displays consist of arrays of microscopic LEDs forming the individual pixel elements. It can offer better contrast, response times, very high resolution and energy efficiency. Compared with OLED, it has higher lightening efficiency and longer life span, but its flexible display is inferior to OLED. Compared with LCD, Micro LED has better contrast, response times and energy efficiency. It is widely considered appropriate for wearables, AR/VR, auto display and mini-projector.

However, Micro LED still has some technological bottlenecks in epitaxy, mass transfer, driving circuit, full colorization, and monitoring and repairing. It also has a very high manufacturing cost. In short term, it cannot compete traditional LCD. But as a new generation of display technology after LCD and OLED, Micro LED has received wide attentions and it should enjoy fast commercialization in the coming three to five years.

Interestingly, quantum dots as light-emitting materials are related to both OLED and LCD. The so-called QLED TVs on market are actually quantum-dot enhanced LCD TVs, which use quantum dots to replace the green and red phosphors in LCD’s backlight unit. By doing so, LCD displays greatly improve their color purity, picture quality and potentially energy consumption. The working mechanisms of quantum dots in these enhanced LCD displays is their photoluminescence.

For its relationship with OLED, quantum-dot light-emitting diode (QLED) can in certain sense be considered as electroluminescence devices by replacing the organic light-emitting materials in OLED. Though QLED and OLED have nearly identical structure, they also have noticeable differences. Similar to LCD with quantum-dot backlighting unit, color gamut of QLED is much wider than that of OLED and it is more stable than OLED.

Another big difference between OLED and QLED is their production technology. OLED relies on a high-precision technique called vacuum evaporation with high-resolution mask. QLED cannot be produced in this way because quantum dots as inorganic nanocrystals are very difficult to be vaporized. If QLED is commercially produced, it has to be printed and processed with solution-based technology. You can consider this as a weakness, since the printing electronics at present is far less precision than the vacuum-based technology. However, solution-based processing can also be considered as an advantage, because if the production problem is overcome, it costs much less than the vacuum-based technology applied for OLED. Without considering TFT, investment into an OLED production line often costs tens of billions of yuan but investment for QLED could be just 90–95% less.

Peng: Good questions. Ligand chemistry of quantum dots has developed quickly in the past two to three years. Colloidal stability of inorganic nanocrystals should be said of being solved. We reported in 2016 that one gram of quantum dots can be stably dispersed in one milliliter of organic solution, which is certainly sufficient for printing technology. For the second question, several companies have been able to mass produce quantum dots. At present, all these production volume is built for fabrication of the backlighting units for LCD. It is believed that all high-end TVs from Samsung in 2017 are all LCD TVs with quantum-dot backlighting units. In addition, Nanosys in the United States is also producing quantum dots for LCD TVs. NajingTech at Hangzhou, China demonstrate production capacity to support the Chinese TV makers. To my knowledge, NajingTech is establishing a production line for 10 million sets of color TVs with quantum-dot backlighting units annually.China"s current demands cannot be fully satisfied from the foreign companies. It is also necessary to fulfill the demands of domestic market. That is why China must develop its OLED production capability.

Huang: The importance of China"s LCD manufacturing is now globally high. Compared with the early stage of LCD development, China"s status in OLED has been dramatically improved. When developing LCD, China has adopted the pattern of introduction-absorption-renovation. Now for OLED, we have a much higher percentage of independent innovation.

units for LCD and electroluminescence in QLED. For the photoluminescence applications, the key is quantum-dot materials. China has noticeable advantages in quantum-dot materials.

For electroluminescence, it is very likely to co-exist with OLED for a long period of time. This is so because, in small screen, QLED’s resolution is limited by printing technology.

Peng: If electroluminescence can be successfully achieved with printing, it will be much cheaper, with only about 1/10th cost of OLED. Manufacturers like NajingTech and BOE in China have demonstrated printing displays with quantum dots. At present, QLED does not compete with OLED directly, given its market in small-sized screen. A while ago, Dr. Huang mentioned three stages of technological development, from science issue to engineering and finally to mass production. For QLED, the three stages have been mingled together at the same time. If one wants to win the competition, it is necessary to invest on all three dimensions.

Huang: When OLED was compared with LCD in the past, lots of advantages of OLED were highlighted, such as high color gamut, high contrast and high response speed and so on. But above advantages would be difficult to be the overwhelming superiority to make the consumers to choose replacement.

It seems to be possible that the flexible display will eventually lead a killer advantage. I think QLED will also face similar situation. What is its real advantage if it is compared with OLED or LCD? For QLED, it seems to have been difficult to find the advantage in small screen. Dr. Peng has suggested its advantage lies in medium-sized screen, but what is its uniqueness?

Peng: The two types of key advantages of QLED are discussed above. One, QLED is based on solution-based printing technology, which is low cost and high yield. Two, quantum-dot emitters vender QLED with a large color gamut, high picture quality and superior device lifetime. Medium-sized screen is easiest for the coming QLED technologies but QLED for large screen is probably a reasonable extension afterwards.

Huang: But customers may not accept only better wider color range if they need to pay more money for this. I would suggest QLED consider the changes in color standards, such as the newly released BT2020 (defining high-definition 4 K TV), and new unique applications which cannot be satisfied by other technologies. The future of QLED seems also relying on the maturity of printing technology.

Peng: New standard (BT2020) certainly helps QLED, given BT2020 meaning a broad color gamut. Among the technologies discussed today, quantum-dot displays in either form are the only ones that can satisfy BT2020 without any optical compensation. In addition, studies found that the picture quality of display is highly associated with color gamut. It is correct that the maturity of printing technology plays an important role in the development of QLED. The current printing technology is ready for medium-sized screen and should be able to be extended to large-sized screen without much trouble.

Peng: Domestic industry sector has begun to invest in these future technologies. For example, NajingTech has invested about 400 million yuan ($65 million) in QLED, primarily in electroluminescence. There are some leading domestic players having invested into the field. Yes, this is far from enough. For example, there are few domestic companies investing R&D of printing technologies. Our printing equipment is primarily made by the US, European and Japan players. I think this is also a chance for China (to develop the printing technologies).

Liao: Due to their lack of kernel technologies, Chinese OLED panel manufacturers heavily rely on investments to improve their market competitiveness. But this may cause the overheated investment in the OLED industry. In recent years, China has already imported quite a few new OLED production lines with the total cost of about 450 billion yuan (US$71.5 billion).Lots of advantages of OLED over LCD were highlighted, such as high color gamut, high contrast and high response speed and so on …. It seems to be possible that the flexible display will eventually lead a killer advantage.

Zhao: Today there are really good observations, discussions and suggestions. The industry-academics-research collaboration is crucial to the future of China"s display technologies. We all should work hard on this.

Global Thin Film Transistor (TFT) Display Market, By Technology (Plasma Display (PDP), Organic Light Emitting Diode (OLED), Other), Type (Twisted Nematic, In-Plane Switching, Advanced Fringe Field Switching, Multi-Domain Vertical Alignment, Advanced Super View, Cell Technology), Panel Type (A_MVA, ASV, MVA, S_PVA, P-IPS), End Use (Domestic Use, Industrial Use) – Industry Trends and Forecast to 2029

Global Thin Film Transistor (TFT) Display Market was valued at USD 270.26 million in 2021 and is expected to reach USD 968.64 million by 2029, registering a CAGR of 17.30% during the forecast period of 2022-2029. Twisted Nematic accounts for the largest type segment in the respective market owing to its low cost. The market report curated by the Data Bridge Market Research team includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and pestle analysis.

A thin-film-transistor display refers to a form of LCD that uses TFT technology for enhancing image quality including addressability and contrast. These displays are commonly utilized in mobile phones, handheld video game systems, projectors, computer monitors, television screens, navigation systems and personal digital assistants.

The increase in the smartphone and tablet proliferation acts as one of the major factors driving the growth of thin film transistor (TFT) display market. Technological advancements are leading a radical shift from traditional slow, bulky and imprecise resistive mono touch to highly sensitive multi-touch capacitive screen have a positive impact on the industry.

The increase in application areas of large e thin film transistor (TFT) display due to the advantages offered by these paper displays in terms of user experience, manufacturing cost, readability, and energy consumption further influence the market.

Additionally, rapid urbanization, change in lifestyle, surge in investments and increased consumer spending positively impact the thin film transistor (TFT) display market.

On the other hand, high cost associated with the manufacturing is expected to obstruct market growth. Also, lack of awareness and low refresh rate are projected to challenge the thin film transistor (TFT) display market in the forecast period of 2022-2029.

This thin film transistor (TFT) display market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on thin film transistor (TFT) display market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

The COVID-19 has impacted thin film transistor (TFT) display market. The limited investment costs and lack of employees hampered sales and production of electronic paper (e-paper) display technology. However, government and market key players adopted new safety measures for developing the practices. The advancements in the technology escalated the sales rate of the thin film transistor (TFT) display as it targeted the right audience. The increase in sales of devices such as smart phones and tablets across the globe is expected to further drive the market growth in the post-pandemic scenario.

The thin film transistor (TFT) display market is segmented on the basis of technology, type, panel type and end-use. The growth amongst these segments will help you analyze meager growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

The thin film transistor (TFT) display market is analysed and market size insights and trends are provided by country, technology, type, panel type and end-use as referenced above.

The countries covered in the thin film transistor (TFT) display market report are U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA).

North America dominates the thin film transistor (TFT) display market because of the introduction of advanced technology along with rising disposable income of the people within the region.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points like down-stream and upstream value chain analysis, technical trends and porter"s five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

The thin film transistor (TFT) display market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies" focus related to thin film transistor (TFT) display market.

From the MOSFET, the TFT was born. The TFT varies from standard MOSFETs, or bulk MOSFETs, because, as the name implies, it uses thin films. The TFT began a new era of electronics. In 1968, just six years after the first TFT development, Bernard J. Lechner of RCA shared his idea of the TFT Liquid Crystal Display (LCD), something that would boom in popularity in our modern times. The TFT LCD was then first created in 1973 at the Westinghouse Research Laboratories. These LCDs were composed of pixels controlled by transistors. In FETs, substrates were just the semiconductor material, but in manufacturing TFT LCDs, glass substrates were used so that the pixels could be displayed.

But that was not the end of TFT developments. Soon after, in 1974, T. Peter Brody, one of the developers of the TFT LCD, and Fang-Chen Luo created the first active-matrix LCD (AM LCD). An active matrix controls each pixel individually, meaning that each pixel’s respective TFT had its signal actively preserved. This opened doors to better performance and speed as displays became more complex.

Though TFTs can use a variety of materials for their semiconductor layers, silicon has become the most popular, creating the silicon-based TFT, abbreviated as Si TFT. As a semiconductor device, the TFT, as well as all FETs, use solid-state electronics, meaning that electricity flows through the structure of the semiconductor layer rather than vacuum tubes.

Due to the variety in silicon’s possible structures, the Si TFT’s characteristics can vary as well. The most common form is amorphous silicon (A-Si), which is deposited during the first step of the semiconductor fabrication process onto the substrate in low temperatures. It is most usable when hydrogenated into the form A-Si:H. This then significantly alters the properties of A-Si; without the hydrogen, the material struggles with doping (the introduction of impurities to increase mobility of charges); in the form A-Si:H, however, the semiconductor layer becomes much more photoconductive and dopable. The A-Si:H TFT was first developed in 1979 which is stable at room temperature and became the best option for AM LCDs which consequently began rising in popularity after this breakthrough.

The biggest difference between these forms, notably A-Si and poly-Si, is that charge carriers are much more mobile and the material is much more stable when it comes to using poly-Si over A-Si. When creating complicated and high-speed TFT-based displays, poly-Si’s characteristics allow for this. Yet, A-Si is still very important due to its low-leakage nature, meaning that leakage current is not lost as heavily when a dielectric insulator is not totally non-conductive.

As TFTs began to increase their presence in display technology, transparent semiconductors and electrodes became more appealing to the manufacturers. Indium tin oxide (ITO) is an example of a popular transparent oxide used for its appearance, good conductivity, and ease of deposition.

Research of the TFT with different materials has led to the application of threshold voltage, or how much voltage is needed to turn on the device. This value is greatly dependent on thickness and choice of the oxide. When it comes to the oxide, this relates back to the idea of leakage current. With thinner layers and certain types of oxide, the leakage current may be greater, but this in turn could lower threshold voltage, as leakage into the device will also increase. In order to tap into the TFT’s potential for low power consumption, the lower the threshold voltage, the better the device’s appeal.

Another branch of development that stemmed from the TFT is that of organic TFTs (OTFT). First created in 1986, OTFTs usually use solution-casting of polymers, or macromolecules. This device made people hesitant, as it tended to have a slow carrier mobility, meaning slow response times. However, researchers have carried out experimentation with the OTFT because it has potential to be applied to displays different from those that traditional TFTs are used for, such as flexible, plastic displays. This research still continues today. With its simpler processing than traditional silicon technology, the OTFT holds much potential for modern day and future technologies.

With the increasing popularity of smartphones and tablet computers, touch has become one of the most common user interfaces encountered today. For our final project design we have converted a number of open-source C++ libraries to C in order to interface with an LCD and touch screen via the Atmel ATmega644 microcontroller. In addition to these new libraries we included three pieces of software: a free drawing mode, a game called Yellow which pays homage to the arcade game Pac-Man© developed by Namco in 1980, and the classic pencil and paper game Tic-Tac-Toe. Each piece of software serves to demonstrate some of the many capabilities of the LCD and touch screen combination.

Our goal for the final project was to provide the ECE 4760 course with an easy to setup and cheap touch screen interface to be used with the Atmel ATmega644 microcontroller. While researching ways to implement this, we found the tutorial for an Arduino-based touch screen provided by LadyAda. The resulting C libraries that we created for our device are based upon the open-source C++ libraries provided in the tutorial.

We opted to display images with an LCD screen rather than using a CRT monitor due to the onboard memory of LCD screens. This means that the entire screen does not need to be refreshed when displaying a new image. This severely reduces the amount of overhead required by the CPU to update the screen.

The touch screen used in our project uses resistance rather than capacitance to sense touch. Resistive touch screens consist of two plastic sheets covered with a resistive coating separated by a very thin gap of air. Each sheet contains vertical and horizontal lines that allow for precise location measurement when they come in contact with the lines of the opposite sheet. Resistive touch screens have a number of advantages and disadvantages when compared to capacitive screens. The major benefit for us, due to the limited budget of the project, is the reduced cost. Resistive screens are also highly resilient to liquid damage, and so are widely used in restaurants and hospitals where liquid hazards are more common. The major disadvantage is the need for pressure in order to sense touch. This means that the screen can be easily scratched if the user is using a sharp object as a stylus. For this reason, we recommend using a plastic protective cover to mitigate damage to the screen.

Many of the touch screen design patents that were filed during the 1970s and 1980s have since expired. Therefore, use of touch screens and different designs are no longer hindered by potential patent infringements. Software patents for touch screens such as multiple input sensing and page scrolling do exist, but our project does not implement any of these methods and so is not in violation of the owners" intellectual property.

The only hardware used for this project is the protoboard with an ATmega644 and a TFT LCD with resistive touch screen purchased from Adafruit. The LCD is a 2.8" 320x240 pixel resolution screen with an attached resistive touch screen. A built in linear regulator allows the screen to be used with either 5V or 3.3V logic. The wiring was done using a tutorial from LadyAda. The LCD screen has four control lines, eight data lines, a reset pin, a backlight pin, four pins for the touch screen, VCC and ground. VCC is connected to 5V from the MCU and ground is connected to MCU ground. The backlight should always be on, so it is simply connected to VCC. It is possible to use a PWM signal to dim the backlight, but that was not necessary for this project.

The four control signals are chip select, command/data, write, and read. They are connected to pin C0, pin C1, pin C2, and pin C3, respectively. The chip select pin is held low for the duration of register reads and writes and when a command or data is being written. Immediately following the read or write the pin is set back to high. The command/data pin is set low while writing a command or writing a register. It is kept high while writing data or reading data from the LCD. Once the command or register is finished being written, the command/data pin is set high again. When writing a register or data to the LCD, the data is written eight bits at a time. First, the eight data lines are set to their appropriate values using the write8 function. The write pin is set low and then immediately set high. If 16 bits of data need to be written, the write8 function is called again for the second 8 bits. The write pin is then toggled again to write the data. When reading data from the LCD, the read pin is toggled low and the data is read using the function read8. Once the bits are read, the read pin is set high again. If more bits need to be read, the read pin is set low and the next eight bits are read. Once finished, the read pin is set high again.

The reset pin is active high. It is connected to pin C4. It is left high for the duration of the operation of the LCD screen and is only set low when the program first starts in order to reset the LCD controller chip.

The four pins for the resistive touch screen are Y+, Y-, X+, and X-. Y+ is connected to pin A0, X- is connected to A1, X+ is connected to A2, and Y- is connected to A3. The X position on the touch is determined by setting Y+, Y-, and X- to ground and X+ to high. The voltage on Y+ is then read. To get the most accurate position, the 10-bit ADC result from the microcontroller is used. This requires reading the low bits first and then reading the high bits and concatenating the results. The final raw x position returned is the 10-bit ADC result subtracted from 1023. The Y position is determined in a similar way. This time the X+, X-, and Y- pins are grounded and the Y+ pin is set high. The voltage on the X- pin is then read.

As this is a resistive touch screen, the pressure must be measured to determine if someone is actually pressing on the screen. This is accomplished by setting X+, X-, and Y+ to ground and Y- high. First the voltage across X- is read, then the voltage across Y+. The pressure is determined using the following equation:

The software for this project is based off of the open-source libraries released by Adafruit. There are three libraries: TFTLCD, TouchScreen, and Adafruit_GFX. These libraries are written for Arduino microcontrollers and are in C++. Converting the libraries to C involved removing the classes and converting all of the functions to static functions. The libraries also contained a large number of Arduino specific functions. These functions were manually replaced with code that performs the same functionality, but that works on the ATmega644. The touch screen libraries were initially using PORTC as inputs to the ADC. However, since the input to the ADC on the ATmega644 is PORTA, this had to be changed. To see the mapping of all of the pins, refer to the hardware section. To make it easier for future students to use, the converted libraries are located in separate C files from the programs we wrote. The TFT LCD and Adafruit_GFX libraries have been combined into a single C file. A few additional functions were added to the libraries. These include the map function which is included in the Arduino software package. This function remaps a number from one range to another. Additional drawing functions added include the ability to draw half a circle and the ability to draw strings instead of individual characters. Comments were also added to the header files to allow the user to quickly understand what a function does and what the appropriate inputs are.

To showcase the capabilities of the touch screen and LCD, three simple programs were written. The first is a simple drawing program based off an example provided with the TFT LCD library. The second is a Tic-Tac-Toe game which allows the player to draw X"s on their turn. The final program is Yellow. Yellow is a simple demonstration that draws its inspiration from the popular arcade game Pac-Man©, created by Namco in 1980.

The menu was created by first filling the entire screen black using the fillScreen function. Then three grey boxes are drawn in the middle of the screen to make the "buttons" using the fillRect function. Next, the text is drawn using the drawString function. Once the menu is drawn, the program waits in an infinite while loop for user input. On each iteration of the loop the program gets the x and y position from the touch screen as well as the pressure.

Since we are using a resistive touch screen, a threshold pressure must be used in order to determine if the user is actually touching the screen or if it is just noise. The pressure values we considered were between 250 and 750. When a valid pressure is detected, the program then determines where the user is touching. The x and y values read from the touch screen must first be mapped to the resolution of the LCD to give a useful x-y position. This is done using the map function which is provided by Arduino. The program checks the x and y position against the boundaries of each "button." If the user touches within a "button," then the program calls the function to launch the appropriate program. As indicated by the message at the bottom of the menu, the user can return to the main menu from any program by simply touching the very top of the LCD screen. When the user touches the top of the LCD screen, the running program will detect this touch, return to main and the main menu will be redrawn. The positioning of the text and "buttons" on the menu was determined by estimating the appropriate position given the resolution of the screen and then doing a bit of guess and check positioning.

When the user clicks on the Free Draw button, the free_draw function is called. The program first clears the screen using the fillScreen function. The program then draws 6 colored squares across the top of the screen using the fillRect function. A second row of white squares are drawn under the color buttons also using the fillRect function. The white squares are then filled in with different icons to represent their function.

There are twenty-four different colors the user can choose from. These colors are split into four groups of six colors. When the free draw program starts, the first set of co

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey