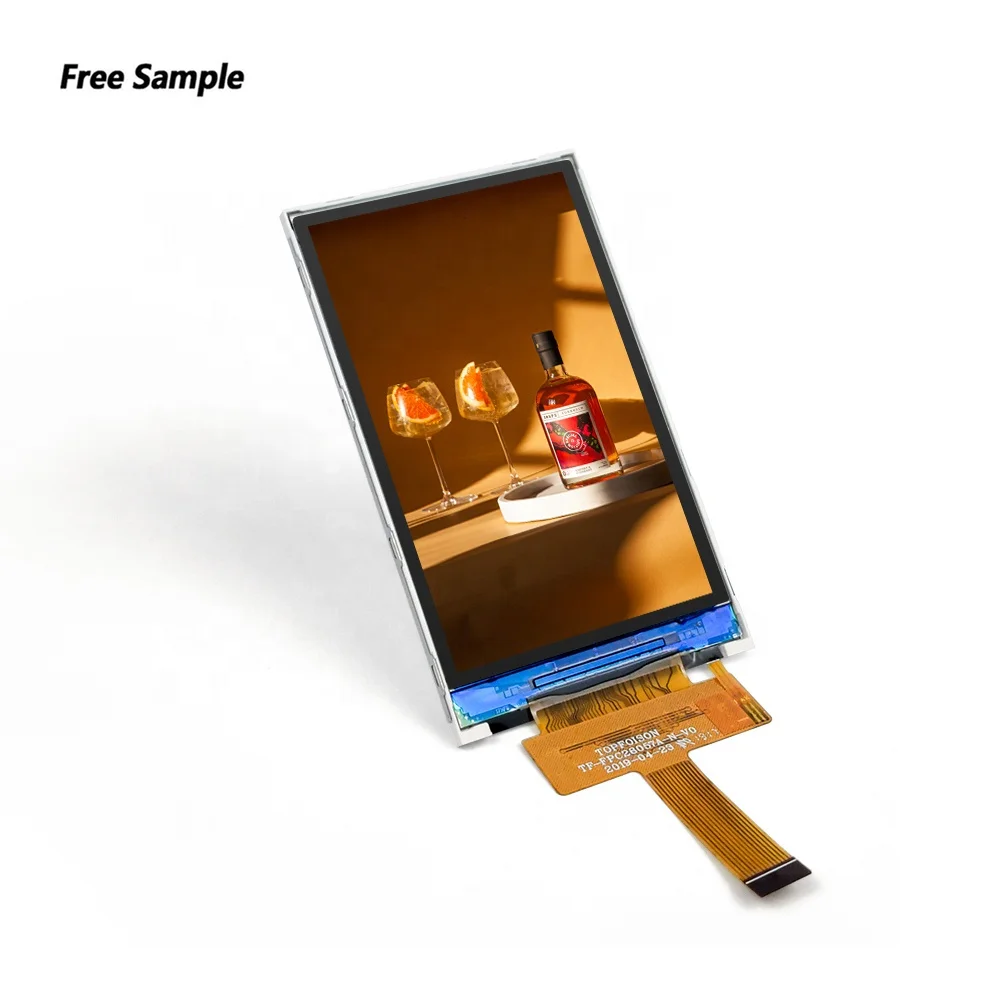

2.8 tft display with resistive touchscreen free sample

This LCD is a 240x320 resolution IPS TFT display. The IPS technology delivers exceptional image quality with superior color representation and contrast ratio at any angle. This 8-bit/16-bit parallel interface Liquid Crystal Display is RoHS compliant and has a 4-wire resistive touchscreen.

Enhance your user experience with capacitive or resistive touch screen technology. We’ll adjust the glass thickness or shape of the touch panel so it’s a perfect fit for your design.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Equip your display with a custom cut cover glass to improve durability. Choose from a variety of cover glass thicknesses and get optical bonding to protect against moisture and debris.

Touchscreen displays are everywhere! Phones, tablets, self-serve kiosks, bank machines and thousands of other devices we interact with make use of touchscreen displays to provide an intuitive user interface.

Today we will learn how touchscreens work, and how to use a common inexpensive resistive touchscreen shield for the Arduino. Future videos and articles will cover capacitive touchscreens, as well as a touchscreen HAT for the Raspberry Pi.

Although touchscreens seem to be everywhere these days we tend to forget that just a few decades ago these devices were just science fiction for most of us. For many people, the touchscreen concept was introduced 30 years ago in the television seriesStar Trek: The Next Generation.

Eric A Johnson, a researcher at the Royal Radar Establishment in Malvern UK is credited for describing and then prototyping the first practical touchscreen. HIs device was a capacitive touchscreen, and it’s first commercial use was on air traffic control screens. However, the touchscreens used then were not transparent, instead, they were mounted on the frame of the CRT display.

In 1972, a group at the University of Illinois filed for a patent on an optical touchscreen. This device used a 16×16 array of LEDs and phototransistors, mounted on a frame around a CRT display. Placing your finger, or another solid object, on the screen would break two of the light beams, this was used to determine the position and respond accordingly.

The first transparent touchscreen was developed atCERNin 1973. CERN is also home to the Large Hadron Collider, and this is where Tim Berners-Lee invented the World Wide Web.

The first resistive touchscreen was developed by American inventor George Samuel Hurst in 1975, although the first practical version was not produced until 1982.

In 1982 theUniversity of Toronto’sInput Research Group developed the first multi-touch touchscreen, a screen that could interpret more than one touch at the same time. The original device used a video camera behind a frosted piece of glass. Three years later the same group developed a multi-touch tablet that used a capacitive touchscreen instead.

The first commercial product to use a touchscreen was a point-of-sale terminal developed by Atari and displayed at the 1986 COMDEX expo in Las Vegas. The next year Casio launched theCasio PB-1000 pocket computerwith a touchscreen consisting of a simple 4×4 matrix.

LG created the world’s first capacitive touchscreen phone, theLG Pradaused a capacitive touchscreen and was released in early 2007. A few weeks later Apple released its first iPhone.

Most early touchscreen devices were resistive, as this technology is generally less expensive than capacitive screens. However, nowadays capacitive screens are more common, being used in the majority of smartphones and tablets.

Although they were invented after capacitive touchscreens, resistive touchscreens are probably the most common type used by hobbyists. The reason for that is the price and performance, resistive touchscreens are cheaper than capacitive ones and they are generally more accurate.

A resistive touchscreen consists of two thin layers of material, separated by a tiny gap. Spacers are used to maintain the gap and keep the two sheets apart.

In a 4-Wire Analog touchscreen, there are two electrodes or “busbars” on each of the conductive layers. On one layer these electrodes are mounted on the two X-axis sides, the other layer has them on the two y-axes.

This is the most inexpensive method of designing a resistive touchscreen. The touchscreen display that we will be working with today uses this arrangement.

In a 5-Wire Analog touchscreen, there are four wires, one connected to a circular electrode on each corner of the bottom layer. A fifth wire is connected to a “sensing wire”, which is embedded in the top layer.

This 8-Wire Analog touchscreen uses an arrangement of electrodes identical to the 4-Wire variety. The difference is that there are two wires connected to each electrode, one to each end.

Capacitive touchscreens are actually older technology than resistive displays. They are commonly used in phones and tablets, so you’re probably familiar with them.

The capacitive touchscreen makes use of the conductivity of the human body. The touchscreen itself consists of a glass plate that has been treated with a conductive material.

The surface capacitive touchscreen is the most inexpensive design, so it is widely used. It consists of four electrodes placed at each corner of the touchscreen, which maintain a level voltage over the entire conductive layer.

When your finger comes in contact with any part of the screen, current flows between those electrodes and your finger. Sensors positioned under the screen sense the change in voltage and the location of that change.

This is a more advanced touchscreen technique. In a projected capacitive touchscreen transparent electrodes are placed along the protective glass coating and are arranged in a matrix.

The module we will be experimenting with today is a very common Arduino Shield, which is rebranded by many manufacturers. You can easily find these on Amazon, eBay or at your local electronics shop.

You can also just use the shield as an LCD display and ignore the two other components, however, if you intend on doing that it would be cheaper just to buy an LCD display without any touchscreen features.

This is a TFT orThin Film Transistordevice that uses liquid crystals to produce a display. These displays can produce a large number of colors with a pretty decent resolution.

You do need to be looking directly at the display for best color accuracy, as most of these inexpensive LCD displays suffer from distortion and “parallax error” when viewed from the side. But as the most common application for a device like this is as a User Interface (UI) this shouldn’t be a problem.

This shield uses a 4-wire analog resistive touchscreen, as described earlier. Two of the wires (one X and one Y) are connected to a couple of the analog inputs on the Arduino. The analog inputs are required as the voltage levels need to be measured to determine the position of the object touching the screen.

The microSD card socket is a convenience, it’s normally used for holding images for the display but it can also be used for program storage. This can be handy for holding things like calibration settings and favorite selections.

You should note that the microSD card uses the SPI interface and is wired for the Arduino Uno. While the rest of the shield will function with an Arduino Mega 2560, the SPI connections on the Mega are different, so the microSD card will not work.

The last paragraph regarding the microSD card may make you think that an Arduino Uno is the best choice for the Touchscreen Display Shield. And it you require the microSD card then it probably is a good choice.

But using an Arduino Uno with this shield does have one big disadvantage – a limited number of free I/O pins. In fact there are only three pins left over once the card has been plugged in:

If your product is self-contained and doesn’t need many (or any) I/O pins then you’ll be fine. But if you need more pins to interface with then an Arduino Mega 2560 is a much better choice. It has a lot of additional analog and digital pins.

As there are three devices on the shield you will need libraries for each of the ones you want to use. TheSD Libraryis already installed in your Arduino IDE, so you will just need libraries for the display and touchscreen.

For the LCD you will have a lot of choices in libraries. Most of these shields come with a CD ROM with some sketches and libraries, so you can use the LCD libraries there. Bear in mind however that code on these CD ROMs tends to be a little dated, you may have better lick on the vendors website.

This useful resource contains code, libraries and datasheets for a wealth of LCD displays, both touchscreen and non-touchscreen. You’ll also find code for some common OLED displays as well.

I ran my touchscreen through all of the code samples I obtained from the LCD Wiki. It’s an interesting exercise, and by examining the sketch for each demo you can learn a lot about programming the display.

This test does not make use of any of the extra libraries, it drives the LCD directly. It is only a test of the LCD display, it does not make use of the touchscreen membrane.

This example does use the custom libraries, and is a very good way to learn how to use them. You’ll note that theLCDWIKI_GUI.hlibrary is loaded, which is the graphics library for the LCD display.

A look at the loop will show how this is done. TheLCDWIKI_GUI.hlibrary has a “Fill_Screen” method that fills the screen with an RGB color. You can specify the color in both hexadecimal or decimal format, the example illustrates both ways.

This sketch uses a number of functions from theLCDWIKI_GUI.hlibrary, along with some custom functions to draw geometric shapes. It then displays a cycle of graphs, shapes, and patterns on the LCD display.

One way in which this sketch differs is that most of the graphics routines are executed in the Setup function, so they only run once. The loop then displays some text with a selection of colors and fonts. The orientation is changed as it cycles through the loop.

This example makes use of a second file that contains fonts. The Display Scroll sketch illustrates a number of different methods of scrolling characters, in different fonts, colors and even languages.

One interesting thing about this test is that it illustrates how to display text in different “aspects”, Portrait and Landscape, Right side up and Reversed.

Unlike the previous examples that put the text in with a number of graphics, this example is a pretty simple one with just a block of text in different sizes and colors. This makes it very simple to understand how the text is positioned on the display.

The result of running the sketch is the display screen fills with rows of hexadecimal values while the background alternates between blue and black and the orientation (or “aspect”) changes. If you stand back to see the “big picture” you’ll note that the color values form “number patterns”.

The Display Phone Call sketch draws a mockup telephone keypad. Pressing one of the keys will display the result on a line of text at the top. There is also a key to delete your entries, as well as ones to send and disconnect the call – the latter two are “dummy” functions of course as it’s only a demo.

In addition to the graphics and “helper” libraries that have been used in the previous examples this sketch also uses theTouchScreenlibrary to read screen interaction. This was one of the libraries included in the original ZIP file.

As its name would imply, this sketch displays a bitmap image on the display. The images need to be placed onto the root of a microSD card, which in turn is plugged into the socket on the display shield.

The images will show off the display resolution, which is reasonably impressive. You’ll also note that to see them at their best, you need to be directly in front of the display, viewing the display at an angle causes the display to distort colors.

Another thing you will notice is the speed at which the images draw, which is not particularly impressive. The clock speed of the Arduino has a lot to do with this, as does the method used to extract each individual pixel from the image.

This example draws some small “switches” on the display. The switches are active and respond to touch. There are slide switches, a push button, some radio buttons and some text-based expandable menus to test with.

The Calibration utility lets you calibrate the resistive touchscreen. It achieves this by placing a number of crosses on the screen. You can calibrate the screen by using the stylus to touch the center of one of the crosses as accurately as you can.

After calibration, the sketch will display a number of calibration values for the resistive touchscreen. These values can be used in your future sketches to make the touchscreen more accurate.

The examples are a great way to demonstrate the capabilities of your touchscreen. But to really put your interface to work you’ll need to write your own interface code.

Writing a touchscreen interface can be challenging. I would suggest that you start by modifying one of the example codes, one that is closest to your desired interface.

The digital I/O connector at the back of the Mega is still accessible even when the touchscreen display shield is installed, so I used three of those connections for the LEDs. I hooked up each LED anode through a 220-ohm dropping resistor and connected them as follows:

The sketch is based upon the telephone keypad sketch. I modified it to eliminate the other functions and just display three buttons. Then I added code to toggle the LEDs.

TheAdafruit GFX Libraryis a comprehensive graphics library that can be used in a variety of display applications. It is a “core library”, meaning that it is called by other Adafruit libraries.

TheAdafruit TFTLCD Libraryis used. It uses the previous library to provide an easy method of drawing on the LCD display. It works with LCD displays that use driver chips like the ILI9325 and ILI9328.

TheTouchScreenlibrary comes in the code that you downloaded from the LCD Wiki or from the CD ROM included with your touchscreen shield. As its name implies it is used to interface with the touchscreen.

TheMCUFRIEND_kbvlibrary is also included in the software you obtained for your display shield. It takes care of supplying the correct hardware information for your display shield to the other libraries.

We also define some “human-readable” colors to use within our code, it’s a lot simpler and more intuitive than providing RGB values. I’ve includes all of the colors from the phone sketch I used as the basis for this code, so if you want to change button or background color you can easily do it.

Next, we define some touchscreen parameters. You can ‘fine-tune” your code here by using parameters from your own display, which you can obtain from the Calibration Sketch we ran from the sample code. Otherwise, just use the values here and you should be fine.

Now onto the button definitions. These are set up using arrays, which is a great technique to use for multiple buttons with similar dimensions and properties. If you want to change the button colors or text this is the place to make your changes.

Next, we reset the display and try to identify it. This will run through a list of display chip drivers in the MCUFRIEND_kbv library and will attempt to select the correct one.

Now, still in the Setup, we set up the LCD display rotation and fill the background in black. Next step is to draw our buttons. Once we are done that the Setup is finished, and our screen should be displaying the three buttons on a black background.

We start by triggering the touchscreen, which is done by toggling pin 13 on the Arduino high. If something is touching the screen we read it and assign it to a TSPoint object named “p”.

We then need to reset the pin modes for two of the touchscreen pins back to outputs. This is done as these pins get shared with other LCD display functions and get set as inputs temporarily.

Now we check to see if the pressure on the screen was within the minimum and maximum pressure thresholds we defined earlier. If it makes the grade then we determine where exactly the screen was pressed.

Now that we know where the screen was pressed we need to see if the pressure point corresponds to one of our buttons. So we cycle through the button array and check to see if the pressure point was within 10 pixels of our button location.

Load the code into your Arduino IDE and upload it to your Arduino Mega 2560. Make sure you have the correct processor-type set in your Arduino IDE, especially if you are used to working with the Uno!

This is a pretty simple demo but it does illustrate how to create a simple IDE. You can expand upon it to add more buttons, or to change the button colors or shapes. And, of course, you don’t have to light LEDs with your buttons, they can control anything that you can connect to your Arduino.

Touchscreen interfaces are used in a number of products, and now you can design your own devices using them. They can really make for an intuitive and advanced display and will give your project a very professional “look and feel” if done correctly.

This is not the only time we will look at touchscreen displays. Next time we’ll examine a capacitive touchscreen and we’ll explore the Adafruit Graphics libraries further to create some very fancy displays with controls and indicators.

Let"s learn how to use a touchscreen with the Arduino. We will examine the different types of touchscreens and will then create a simple interface using an inexpensive Arduino touchscreen shield.

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

As the code is a bit longer and for better understanding I will post the source code of the program in sections with description for each section. And at the end of this article I will post the complete source code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Next is the distance sensor button. First we need to set the color and then using the fillRoundRect() function we will draw the rounded rectangle. Then we will set the color back to white and using the drawRoundRect() function we will draw another rounded rectangle on top of the previous one, but this one will be without a fill so the overall appearance of the button looks like it has a frame. On top of the button we will print the text using the big font and the same background color as the fill of the button. The same procedure goes for the two other buttons.

Here’s that function which uses the ultrasonic sensor to calculate the distance and print the values with SevenSegNum font in green color, either in centimeters or inches. If you need more details how the ultrasonic sensor works you can check my particular tutorialfor that. Back in the loop section we can see what happens when we press the select unit buttons as well as the back button.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

ER-TFT028-4 is 240x320 dots 2.8" color tft lcd module display with ILI9341 controller and optional capacitive touch panel and 4-wire resistive touch panel,superior display quality,super wide viewing angle and easily controlled by MCU such as 8051, PIC, AVR, ARDUINO ARM and Raspberry PI.It can be used in any embedded systems,industrial device,security and hand-held equipment which requires display in high quality and colorful image.It supports 8080 8-bit,9-bit,16-bit,18-bit parallel,3-wire,4-wire serial spi interface. FPC with zif connector is easily to assemble or remove.Lanscape mode is also available.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!".Here is the link for 2.8"TFT Touch Shield with Libraries, Examples.Schematic Diagram for Arduino Due,Mega 2560 and Uno . For 8051 microcontroller user,we prepared the detailed tutorial such as interfacing, demo code and development kit at the bottom of this page.

ER-TFT028A3-4 is 240x320 dots 2.8" color tft lcd module display with ST7789V controller and optional capacitive touch panel and 4-wire resistive touch panel,superior display quality,super wide viewing angle and easily controlled by MCU such as 8051, PIC, AVR, ARDUINO ARM and Raspberry PI.It can be used in any embedded systems,industrial device,security and hand-held equipment which requires display in high quality and colorful image.It supports 8080 8-bit,9-bit,16-bit,18-bit parallel,3-wire,4-wire serial spi interface. FPC with zif connector is easily to assemble or remove.Lanscape mode is also available.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!".Here is the link for 2.8"TFT Touch Shield with Libraries, Examples.Schematic Diagram for Arduino Due,Mega 2560 and Uno . For 8051 microcontroller user,we prepared the detailed tutorial such as interfacing, demo code and development kit at the bottom of this page.

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big (2.8" diagonal) bright (4 white-LED backlight) and colorful (18-bit 262,000 different shades)! 240x320 pixels with individual pixel control. It has way more resolution than a black and white 128x64 display. As a bonus, this display has a resistive touchscreen attached to it already, so you can detect finger presses anywhere on the screen. (We also have a capacitive-touch version of this shield here)

We"ve updated our original v1 shield to an SPI display - its a tiny bit slower but uses a lot less pins and is now much easier to use with Mega & Leonardo. We also include an SPI touchscreen controller so you only need one additional pin to add a high quality touchscreen controller. Even with all the extras, the price is lower thanks to our parts sourcing & engineering skillz!

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (UNO/Duemilanove/Diecimila). Solder three jumpers and you can use it at full speed on a Leonardo or Mega as well.

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. This shield needs fewer pins than our v1 shield, so you can connect more sensors, buttons and LEDs: 5 SPI pins for the display, another pin for the SPI touchscreen controller and another pin for uSD card if you want to read images off of it.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x, y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

The display uses digital pins 13-9. Touchscreen controller requires digital pin 8. microSD pin requires digital #4. That means you can use digital pins 2, 3, 5, 6, 7 and analog 0-5. Pin 4 is available if not using the microSD

2.8" TFT Touch Shield is an Arduino / Arduino Mega compatible multicolored TFT display with a 4-wire resistive touch screen. It includes an Arduino shield compatible footprint for attachment. The TFT driver is based on professional Driver IC and with 8 bit data and 4 bit control interface.

The TFT library provides the following Application Programming Interfaces(API). The library makes use of direct access to PORT registers instead of Arduino APIs. This is to increase the speed of communication between MCU and TFT. At present, the library supports Arduino, Arduino Mega (1280 or 2560) and Seeeduino ADK Main Board compatible boards. In Mega the 8bit data port of TFT is distributed to different pins belonging to different ports. This decreases the speed of graphics drawing when compared to Arduino. The choice of port pins are purely based on Arduino / Mega port pin arrangement.

TFT Touch Shield uses the Adafruit Touch Screen Library. To understand the principle behind resistive touch screen refer External Links. In short, a 4-wire resistive touch screen provides two voltage divider each for X and Y axis. By applying proper voltages for each axis and scanning the ADC values the position of the touch can be detected. These values are always prone to noise. Hence a digital filter is used.

The Raw ADC value has to be converted to Pixel Co-ordinates. This is done with map function. This mapping changes for v0.9 and v1.0. The demo applications already takes care of this mapping.

Orient Display offers many types of standard resistive touch panels. All of them are low cost 4 wire types. We can also custom made 5 wires or 8 wires resistive touch panels. The connection of resistive touch panels are mostly FPC. Orient Display can provide resistive touch panels separately or integrated with LCD displays. The standard resistive touch panels include, 1.44”, 1.77”, 2.0”, 2.2” , 2.4”, 2.8”, 3.0”, 3.5”, 4.3”,5.0”, 7.0”, 8.0”, 10.1”, 12.0”, 14” , 15.6” etc. with different aspect ratio. Please contact: Sales Inquiries, Customer Service or Technical Support for more details and availability.

The history of resistive touch panels starts in the 1970s. For years, that was the most common touch input technology. But it has been quickly replaced by CTP (capacitive touch panels) especially the emerge and development of iPhone starting 2007.

The resistive touchscreen consists of a glass layer with a conductive coating on top and a polyester top sheet with a conductive coating on the bottom. The conductive surfaces are held apart by “spacer dots”, usually glass beads that are silk-screened onto the coated glass. On a 5-wire resistive design (the most commonly used kind of resistive screen in large format POS applications), a voltage is applied to the 4 corners of the glass layer. When a person presses on the top sheet, its conductive side comes in contact with the conductive side of the glass, effectively closing a circuit (this is called pressure sensing). The voltage at the point of contact is read from a wire connected to the top sheet.

If you have any questions about Orient Display resistive touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

This TFT display is big (2.8" diagonal) bright (4 white-LED backlight) and colorful (18-bit 262,000 different shades)! 240x320 pixels with individual pixel control. It has way more resolution than a black and white 128x64 display. As a bonus, this display has a resistive touchscreen attached to it already, so you can detect finger presses anywhere on the screen. (We also have a capacitive-touch version of this shield here)

Adafruit have updated their original v1 shield to an SPI display - its a tiny bit slower but uses a lot less pins and is now much easier to use with Mega & Leonardo. They also include an SPI touchscreen controller so you only need one additional pin to add a high quality touchscreen controller. Even with all the extras, the price is lower thanks to our parts sourcing & engineering skillz!

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up the library - you"ll have it running in under 10 minutes!Works best with any classic Arduino (UNO/Duemilanove/Diecimila). Solder three jumpers and you can use it at full speed on a Leonardo or Mega as well.

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. This shield needs fewer pins than their v1 shield, so you can connect more sensors, buttons and LEDs: 5 SPI pins for the display, another pin for the SPI touchscreen controller and another pin for uSD card if you want to read images off of it.

The display uses digital pins 13-9. Touchscreen controller requires digital pin 8. microSD pin requires digital #4. That means you can use digital pins 2, 3, 5, 6, 7 and analog 0-5. Pin 4 is available if not using the microSD

I am using the example file that came on a CD with my display called "Example07-ShowBMP" (as mentioned above), so I copied and pasted the pertinent lines from the "SoftwareSpi.ino" file into the "Example07-ShowBMP" and tried to run it.

I still had issues after fixing this issue with this example file. It seems the bmpReadheader(File f) function has issues with the SDFat library. If I comment out the call to that function, the bitmaps are displayed, but they are shifted to the right by about 10 pixels.

I compared the serial values that are printed between the previously mentioned NANO connected to this display with hardware SPI and default SD library compared to the exact same display and SD card connected to a MEGA and using the SDFat.h file. I am including that serial output here:

I hope to add some serial print lines and try different things and look into the SDFat library and see if I can figure out what is going on. I am also convinced the example program I am using is not very well written, as I tried to change the size of the display and found that while they made height and width variables at the top of the program, they did not use those variables inside the function to allow the different sized displays to be easily used. I"m sure the SDFat library is fine, but it is not a plug and play with this particular display"s example programs. Once I get it resolved, I intend to post better example software on the Amazon page where I bought the display. I like the display, but I must think this would annoy many customers.

HY-TFT280 is a 2.8 inch TFT LCD Screen module, 320*240 (resolution), 65K color, 40pins interface , not just a LCD breakout, but include the Touch screen, SD card. So it’s a powerful extension module for your project.

This Screen includes a controller ILI9331, it’s 16bit data interface, easy to drive by many MCU like STM32 ,AVR and 8051.HY-TFT280 is designed with a touch controller in it . The touch IC is XPT2046 , and touch interface is included in the 40 pins breakout. Another useful extension in this module is the SD Card socket . It use the SPI mode to operate the SD card, the SPI interface include in the 40pins breakout.

The TFT library is required to be installed to get this screen model display. This library is especially designed for TFT LCD screen using 16 bit mode. The library require the following connections.

Note: The TFT controller model needs to be declared in the initializing statement. ITDB02 myGLCD(38,39,40,41) needs to be modified as myGLCD(GEEE28,38,39,40,41) when using Arduino Mega2560.ITDB02 myGLCD(GEEE28,19,18,17,16) needs to be commented when using Aduino UNO. Otherwise it just show a blank screen. In practice, RS, WR, CS, RSET can be connected to any free pin. But the pin number must be in accord with myGLCD(RS,WR,CS,RST).

The LCD has a 2.8" 4-wire resistive touch screen lying over it. The Touch library needs to be installed to get it works. This library is designed for 2.4’’ TFT, 2.8” TFT LCD screen module.

Note:TCLK, TCS, TDIN, TDOUT, IRQ also can be connected to any free pin. But the pin number must be in accord with the touch screen initializing statement myTouch(DCLK,CS,IN,OUT,IRQ).

The default setting is accurate for 2.4” TFT module, but you need to calibrate when using 2.8” TFT module. A program to calibrate the touch screen is included in the example. If you touch screen is inaccurate, you need to run touch_calibration. Follow the on-screen instruction to calibrate the touch screen. Better not use your finger to calibrate it, use your accessory touch pen to pressure the frontsight with stength. Then record the calibration parameters and apply them in ITDB02_Touch.cpp in your touch screen library.

There is built-in SD card slot in the shield, so we can use it to upload images. But the images need to be converted RAW format first. SD libraries tinyFAT and tinyFAT_16 need to be preinstalled for displaying the image.

Note: The library only supports FAT16 fomatted SD card up to 2GB, so you need to fomat your SD card to FAT16. 4GB FAT16 fomatted SD card is tested not working. Long file names are not supported. Keep your file names compliant with 8.3 standard.

This article is part of our series on the different types of displaysthat you can use with Arduino, so if you’re weighing up the options, then do check out our guide to the best displays to use with Arduino.

The TFT displays come in two variants: With touch and without touch. The modules with touch come with an additional layer of transparent touch screen.

The pinouts for the display and the SD card remain the same. Only pinouts related to the touch sensor will change depending on whether the module has a resistive or capacitive type touch sensor.

Here is the link to the simulation – where you can actively change the code and see the results in action. You can save the project and share the links with others too.

Some dedicated controllers can help Arduino detect the screen’s finger touch easily. One example is an FT6206 which can support small to medium-sized screens with up to 28 sensors.

I am confident that the article was easy to follow. I have used TFT display with touch for an HMI project which controls the thermostat in my hobby projects to learn more about the OT system (open Therm)

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey