non blue screen custom tft lcd quotation

Orient Display is a company that specializes in manufacturing LCD displays, touch panels, OLED displays with competitive prices. The company was founded in 1996 by specializing in fields of production, R&D, quality controls. Thanks for the management and employee’s continuous hardworking and enormous effort and shareholder continuous investment over years, Orient Display factory is now the world’s leading custom LCD manufacturer in flat panel industry and is listed as a public company in China stock market. Now, Orient Display factory has 2 production lines that can produce PMOLED and AMOLED custom display modules. Factories have complete quality and environment management system, ISO9001, ISO/IATF16949, ISO14001, IECQ QC080000. Orient Display takes around 18% market share in global automotive market and is No.1 in automotive capacitive touch screen.

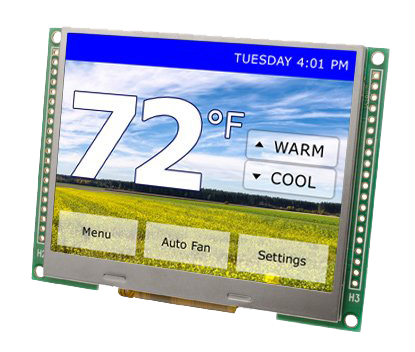

Orient Display has supported customers with custom LCD displays for tens of thousands of types and models for automotive, appliances, medical, smart homes, point of sales, industrial advices, etc. Whether your design requires a small custom LCD display glass, or a fully customized LCD module, or custom monitors and displays equipped with complicated embedded control board with touch panels, our experienced engineers in North America, Europe or in China factory will assist you in designing your customized displays.

Orient Display customer service sends quotation to you (might come with technical suggestions according to your targeted applications). The time will depend on the complexity of the project and the time to source components, normally, it takes 1-3 days for custom LCD glass panels, 2-5 days for custom LCD display modules or touch panels.

Orient Display engineers provide custom LCD display counter-drawings for you to approve with your signature on the drawing. The drawings might be modified several times until the designs are fully achieved your technical requirements. There can be a lot of technical discussions at this stage. The time our engineers take to arrange drawings also depend on the complexity of the project. Normally, it takes 1-3 days for custom LCD glass panels, 2-5 days for custom LCD display modules or touch panels.

After your drawing approval, Orient Display will start to make samples or prototypes for you to test. The lead time also varies depending on the production complexity and component/material sourcing. Normally, it takes 4-6 weeks for custom LCD glass panels, 8-10 weeks for custom LCD display modules or touch panels.

After your sample / prototype approval, Orient Display is ready for production. Orient Display welcomes trial production between the prototypes to large scale production so that you have the opportunity to fully test the custom LCD display or touch panel to run well in your designed products.

Congratulations! You have accomplished the journey of the idea, design, prototype and production in the market. The journey can take from 3 months to 3 years. Whatever the voyage, Orient Display’s engineers, customer services are proud to be part of your design. Our happiness is based on your success.

Dimensions (Specification / Drawing / Sketch of the LCD, if available). If it is a drop-in replacement, it is great to provide files in dwg. or dxf. format.

LCD Mode Preference if you have an idea or let us to decide (TN Positive/Negative, STN Positive YG, STN Negative Blue, STN Positive Gray, FSTN Positive, FSTN Negative, FFSTN Negative);

Dimensions (Specification / Drawing / Sketch of the LCD module, if available). If it is a drop-in replacement, it is great to provide files in dwg. or dxf. format.

LCD Mode Preference if you have an idea or let us to decide (TN Positive/Negative, STN Positive YG, STN Negative Blue, STN Positive Gray, FSTN Positive, FSTN Negative, FFSTN Negative);

Fully custom made TFT LCD display module can be very expensive, the NRE ranges from $80,000 to $1M depending on the size and the resolution of the LCD display and the generation of the production line the LCD display to be produced. For over 99% of our projects, we are talking about the modifications of the standard TFT LCD display. There are a lot of standard color TFT displays available in the market. You are highly likely to find one matching your requirement. If you can’t find a suitable one on our website, please check with our engineers, we have a database in factory with much more types.

Dimensions (Specification / Drawing / Sketch of the LCD module, if available). If it is a drop replacement, it is great to provide files in dwg. or dxf. format.

The above information can be overwhelming. Actually, we design a lot of touch panel and LCD custom display projects without being provided detailed information. Our engineers and customer service can quickly decide the parameters based on the customer’s application. Please feel free to contact our engineers for details.

Newhaven 16x1 character Liquid Crystal Display shows characters with white pixels on a blue background when powered on. This transmissive LCD Display requires a backlight for visibility while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-0116DZ-NSW-BBW display has an optimal view of 6:00. This display operates at 5V supply voltage and is RoHS compliant.

Newhaven 12x2 character Liquid Crystal Display shows characters with white pixels on a blue background when powered on. This transmissive LCD Display requires a backlight for visibility and offers a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-0212WH-ATMI-JT# display has an optimal view of 6:00 and comes with English and Japanese standard font. This display operates at 5V supply voltage and is RoHS compliant.

Dr Pan: Hello, Greg. STN is the abbreviation for Super Twisted Nematic. The main difference between TN, HTN, STN and FSTN LCD is the view angle. From the definition, the maximum view angle of STN LCD is 210~255 degree. Take this STN positive LCD for example. The view angle is 12 o’clock direction and it can be seen very clearly in the full view angle: 12 o’clock direction, 3 o’clock direction, 6 o’clock direction, 9 o’clock direction and the front side.

When it is a positive and reflective display, it can display without LED backlight; when it is a positive and transmissive/ transflective display, it can’t display without LED backlight, we have two options for the background color: grey background and blue letters, yellow-green background and black/blue letters.

When it is a negative and transmissive/ transflective display, it can’t display without LED backlight, the background is blue and the color of the letters is the color of LED backlight.

The Displaytech 162J series is a lineup of 16x2 character LCD modules. These modules have an 80x36 mm outer dimension with 66x16 mm viewing area on the display. The 162J 16x2 LCD displays are available in STN or FSTN LCD modes with or without an LED backlight. The backlight color options include yellow green, white, blue, pure green, or amber color. Get a free quote direct from Displaytech for a 16x2 character LCD display from the 162J series.

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

The third example is a game. Actually it’s a replica of the popular Flappy Bird game for smartphones. We can play the game using the push button or even using the touch screen itself.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Now we need to make the buttons functional so that when we press them they would send us to the appropriate example. In the setup section we set the character ‘0’ to the currentPage variable, which will indicate that we are at the home screen. So if that’s true, and if we press on the screen this if statement would become true and using these lines here we will get the X and Y coordinates where the screen has been pressed. If that’s the area that covers the first button we will call the drawDistanceSensor() custom function which will activate the distance sensor example. Also we will set the character ‘1’ to the variable currentPage which will indicate that we are at the first example. The drawFrame() custom function is used for highlighting the button when it’s pressed. The same procedure goes for the two other buttons.

So the drawDistanceSensor() custom function needs to be called only once when the button is pressed in order to draw all the graphics of this example in similar way as we described for the home screen. However, the getDistance() custom function needs to be called repeatedly in order to print the latest results of the distance measured by the sensor.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

TFT displays are now used in a wide range of products, including TVs, computers, appliances, medical equipment, instruments, mobile, and other gadgets. The utilization of LCDs in all market segments was significantly enhanced by incorporating thin film transistors into LCD architecture.

The liquid crystal display (LCD) uses TFT (thin-film transistor) technology and contains a transistor for each pixel (that is, for each of the tiny elements that control the illumination of your display). Since each pixel has a transistor, the current that initiates pixel lighting may be reduced and turned on and off more quickly. The active matrix display technology is another name for TFT (and contrasts with the "passive matrix," which does not have a transistor at each pixel).

The materials required to make a TFT display include ITO glass, liquid crystal, polarizer, sealing glue, and intermediate powder. These components themselves are simple enough, but the manufacturing process can often involve heavy investment in tooling, sourcing, and research. Each step of the process requires a unique line and space in the factory, along with dedicated design, engineering, and manufacturing staffing.

A custom sized TFT display will likely need to be designed such that each component fits into an appropriately sized housing that the project will require; this will often require experimentation and creative resources.

Regarding engineering support, the bespoke panels will need to be designed to function reliably and with the performance required for the use. This process will also require sourcing the tooling or suppliers for individual parts in order to manufacture the custom display. Finally, manufacturing the custom display will require a dedicated assembly line with the training to create the bespoke display configuration. Depending on the use case, this may require custom or unique processes that will require an investment in training and quality assurance. The quality assurance process for devices that are not mass-produced can be difficult and time-consuming. Because there are usually tight deadlines to follow and a limited number of samples, it can be difficult to reliably assess samples and understand the breadth of limitations surrounding a design.

Finally, economies of scale play a massive role in cost and pricing. Economies of scale relate to the cost-benefit a company has when it raises its output level for a specific screen size—the benefit results from the inverse connection between the amount produced and the fixed cost per unit. The fixed cost per unit decreases as production volume increases.

Therefore, it may not make sense for a small project scope if you need a small number of TFTs with custom sizes. While the overall cost may be lower due to unit price reductions as the number of displays purchased leads to a decreased cost per unit, this price reduction will not be feasible with a smaller purchase size of custom-size displays. Additionally, when considering the tooling cost, this is not able to be spread over a smaller number of custom displays purchased, leading to limited cost savings on small purchase orders. Custom can be cheaper if your project falls within mid-range volumes, but this is not the case for small projects.

Consequently, due to design, sourcing of materials, manufacturing considerations, and cost and time of quality assessment, it can be impractical to order a custom TFT configuration for smaller projects. Fortunately, FocusLCDs offers a wide variety of mass-produced screen sizes that allows you to benefit from economies of scale and may even be a perfect fit for your specific project.

Displaying a custom image or graphic on a LCD display is a very useful task as displays are now a premium way of providing feedback to users on any project. With this functionality, we can build projects that display our own logo, or display images that help users better understand a particular task the project is performing, providing an all-round improved User Experience (UX) for your Arduino or ESP8266 based project. Today’s tutorial will focus on how you can display graphics on most Arduino compatible displays.

The procedure described in this tutorial works with all color displays supported by Adafruit’s GFX library and also works for displays supported by the TFTLCD library from Adafruit with little modification. Some of the displays on which this procedure works include:

For this tutorial, we will use the 2.8″ ILI9325 TFT Display which offers a resolution of 320 x 340 pixels and we will display a bitmap image of a car.

To demonstrate how things work, we will use the 2.8″ TFT Display. The 2.8″ TFT display comes as a shield which plugs directly into the Arduino UNO as shown in the image below.

Before an image is displayed on any of the Arduino screens, it needs to be converted to a C compatible hex file and that can only happen when the image is in bitmap form. Thus, our first task is to create a bitmap version of the graphics to be displayed or convert the existing image to a bitmap file. There are several tools that can be used for creation/conversion of bitmap images including, Corel Draw and Paint.net, but for this tutorial, we will use the Paint.net.

Image2Code is an easy-to-use, small Java utility to convert images into a byte array that can be used as a bitmap on displays that are compatible with the Adafruit-GFX or Adafruit TFTLCD (with little modification) library.

To reduce the amount of code, and stress involved in displaying the graphics, we will use two wonderful libraries; The GFX library and the TFTLCD library from Adafruit.

The first two are thex and y coordinates of a point on the screen where we want the image to be displayed. The next argument is the array in which the bitmap is loaded in our code, in this case, it will be the name of the car and the text array located in the graphics.c file. The next two arguments are the width and height of the bitmap in pixels, in other words, the resolution of the image. The last argument is the color of the bitmap, we can use any color we like. The bitmap data must be located in program memory since Arduino has a limited amount of RAM memory available.

As usual, we start writing the sketch by including the libraries required. For this procedure, we will use the TFTLCD library alone, since we are assuming you are using a display that is not supported by the GFX library.

The last section of the code is the drawBitmap function itself, as earlier mentioned, to use the drawbitmap() function with the Adafruit TFTLCD library, we need to copy the function’s code and paste into the Arduino sketch.

Plug in your screen as shown above. If you are using any other display, connect it as shown in the corresponding linked tutorial. With the schematics in place, connect the Arduino board to your PC and upload the code. Don’t forget the graphics file needs to be in the same folder as the Arduino sketch.

According to Wikipedia, "an interface is a shared boundary across which two separate components of a computer system exchange information. The exchange can be between software, computer hardware, peripheral devices, humans, and combinations of these. Some computer hardware devices such as a touchscreen can both send and receive data through the interface, while others such as a mouse or microphone may only provide an interface to send data to a given system.” In other words, an interface is something that facilitates communication between two objects. Although display interfaces serve a similar purpose, how that communication occurs varies widely.

Serial Peripheral Interface (SPI) is a synchronous serial communication interface best-suited for short distances. It was developed by Motorola for components to share data such as flash memory, sensors, Real-Time Clocks, analog-to-digital converters, and more. Because there is no protocol overhead, the transmission runs at relatively high speeds. SPI runs on one master (the side that generates the clock) with one or more slaves, usually the devices outside the central processor. One drawback of SPI is the number of pins required between devices. Each slave added to the master/slave system needs an additional chip select I/O pin on the master. SPI is a great option for small, low-resolution displays including PMOLEDs and smaller LCDs.

Philips Semiconductors invented I2C (Inter-integrated Circuit) or I-squared-C in 1982. It utilizes a multi-master, multi-slave, single-ended, serial computer bus system. Engineers developed I2C for simple peripherals on PCs, like keyboards and mice to then later apply it to displays. Like SPI, it only works for short distances within a device and uses an asynchronous serial port. What sets I2C apart from SPI is that it can support up to 1008 slaves and only requires two wires, serial clock (SCL), and serial data (SDA). Like SPI, I2C also works well with PMOLEDs and smaller LCDs. Many display systems transfer the touch sensor data through I2C.

RGB is used to interface with large color displays. It sends 8 bits of data for each of the three colors, Red Green, and Blue every clock cycle. Since there are 24 bits of data transmitted every clock cycle, at clock rates up to 50 MHz, this interface can drive much larger displays at video frame rates of 60Hz and up.

Low-Voltage Differential Signaling (LVDS) was developed in 1994 and is a popular choice for large LCDs and peripherals in need of high bandwidth, like high-definition graphics and fast frame rates. It is a great solution because of its high speed of data transmission while using low voltage. Two wires carry the signal, with one wire carrying the exact inverse of its companion. The electric field generated by one wire is neatly concealed by the other, creating much less interference to nearby wireless systems. At the receiver end, a circuit reads the difference (hence the "differential" in the name) in voltage between the wires. As a result, this scheme doesn’t generate noise or gets its signals scrambled by external noise. The interface consists of four, six, or eight pairs of wires, plus a pair carrying the clock and some ground wires. 24-bit color information at the transmitter end is converted to serial information, transmitted quickly over these pairs of cables, then converted back to 24-bit parallel in the receiver, resulting in an interface that is very fast to handle large displays and is very immune to interference.

Is LCD or AMOLED better for eyes?The full English name of LCD is Liquid Crystal Display, which is a general term. According to its driving method, it can be divided into various specifications. Most monitors and laptops on the market today are thin-film transistors. Because TFT has better color saturation and viewing angles than other technologies, it is also the mainstream specification on the market today. The models on the market are mainly based on TFT, and LCD has now become synonymous with the term TFT display. Next, I will tell you in detail which LCD screen or OLED screen is better for the eyes.

Both OLED and LCD can cause damage to the eyes, because both OLED and LCD emit blue light, which is unavoidable. However, users can turn on the eye protection mode of the mobile phone to reduce the damage of blue light to the eyes. In addition, OLED"s dimming technology and LCD"s blue backlight are also one of the reasons for the "eye-hurt". OLED adopts PWM low-frequency dimming technology, which is a technology that adjusts the brightness through the rapid flickering of the light-emitting unit, so looking at the screen for a long time will cause eye fatigue. The blue backlight of an LCD monitor emits high-energy short-wave blue light.

In terms of manufacturing process, OLED adopts self-luminous technology and has no backlight layer, so this screen can be made very thin. In addition, each light-emitting unit of OLED can emit light independently when it emits light, and has the function of color screen display. LCD is composed of backlight layer, liquid crystal layer, color filter and other components, and the screen is made of inorganic materials, so the service life of this screen is relatively long.

Is LCD or AMOLED better for eyes?The above is the difference between lcd and oled. Users should try to avoid staring at the phone screen for a long time. Reduce LCD and AMOLED viewing time in dark environments. If you have the habit of reading late at night, you also need to turn on a light to neutralize the strobe light. Moisten your eyes with eye drops when your eyes are dry.

Digimax distribetes a wide range of professional LCD monitors and large format displays for digital signage applications manufactured by Philips: one of the world"s largest manufacturers of TFT monitors, recognized for quality products and cutting-edge solutions.

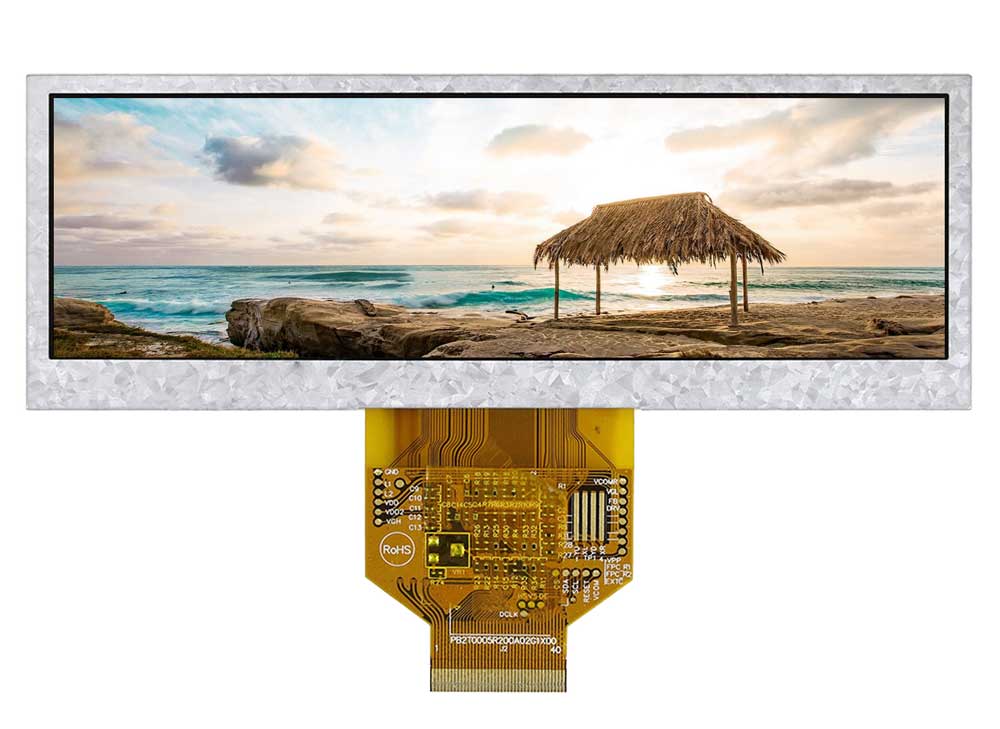

Digimax is able to customize the various components to adapt them to the specific needs of each industrial sector and renew them according to the latest technological innovations, such as bar type 16:4 displays that allow a very special view of the image, appreciated in advertising.

Distributor of component LCDs for equipment which provide high-contrast ratio, color saturation, luminance and performance enhancements such as advanced wide viewing (AWV) for true color fidelity, super-high brightness (SHB) and wide temperature range. Focus on industrial, instrumentation, hand-helds, medical and other low-to-medium volume markets. High-bright LED backlights for outdoor use. LVDS interfaces decrease EMI. Factory installed touch screen solutions. 3.5" to 12.1" QVGA, HVGA, VGA, WVGA, SVGA, XGA, WXGA. Also distributes other related products including LED drivers, lamps, indicators, LED assemblies, segment displays, LED mounts, LEDs, and light pipes. Distributor of electronic components, hardware and fasteners and provides design/value engineering support, fulfillment strategies, procurement services and transactional models to meet specific needs and priorities.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey