tinkercad lcd display made in china

I"m using LCD for the first time and I"m unable to make it work. It lights the background but it does not show any text. I tried three times from the beginning, each time with a different tutorial, and none of the solutions worked. Is there any mistake in my wiring that I do not see?

None of these instructions will produce a change on the screen without a display.display(); method. If your script does not appear to be working check you have included this line at the bottom of your screen changing code.

Tinkercad Circuits is a popular digital and analog electronics simulator for hobbyists, students, and makers. A previous article explored Tinkercad as well as a few other alternative simulators worth trying. This article explains how you can get started using Tinkercad circuits in your projects or a STEM class.

Visit the Tinkercad website to create a new Autodesk account or log in to an existing account if you have previously created one. Note that the Tinkercad website combines a few products helpful in all sorts of hobbyist projects. One example is the original Tinkercad CAD program. However, this article focuses on Tinkercad circuits. Therefore, make sure to select the circuits option in the left toolbar and then click the green button to create a new circuit design:

The website displays your existing projects below the green button. You can manage, edit, and share previously created projects by clicking on one of the images. Once you click the green button, the program takes you to your new circuit design:

The UI might look a bit complicated at first, but it’s simple to use once you get the hang of it. The app displays all the components you can place in your design in the panel on the right side of the UI. Drag and drop a part to the center area of the UI to add it to your design. You can rotate components using the app’s main menu bar or pressing the r-button on your keyboard. The main menu bar also lets you delete parts, undo and redo actions, add notes to your design, and change wire colors and connector types.

Then, close the code panel. If you leave it open, Tinkercad Circuits runs the simulation in debugging mode, which I found was slower than regular execution. Once you’re ready, click the run simulation button next to the code button. The simulation should start, and you should be able to click the buttons and hear a sound coming from the piezo speaker on the virtual breadboard.

Next to the start simulation button, you can find another button to export and share your design. Tinkercad circuits can export your design as a PNG file or an EAGLE/Fusion360 board design file. With this board design file, you can take your experiment and turn it into a PCB design. Then, you can order a few PCBs online and build a professional-grade physical version of your virtual design.

Once you get the hang of it, Tinkercad Circuits is an intuitive and fast tool for simulating all sorts of circuits, including Arduino-based designs. You’ll have to sign up for a free Autodesk account to use the app. Once logged in, start a new project from the app’s dashboard page or load an existing one.

Once you finish your electronic design, you can use the built-in code editor to define the behavior of certain programmable parts. For Arduino boards, you can use a blocks editor or a more traditional source code editor. Next, you can simulate your circuit within Tinkercad Circuits.

What does that actually mean? Let’s look at an example. Now some people have different interpretations of what the famous “Hello World” circuit is. Some say it’s your first project where you create a simple blinking LED circuit; others claim it’s when you have an LCD display that says “Hello world!”

Next we’ll use the free online Arduino simulator software at TinkerCAD. In about 2 minutes we’ve created exactly the same circuit, we’ve used the same exact code, and after hitting the “start simulation button”, we have a virtual version of exactly the same circuit. That is some serious efficiency!

Next we’ll show you exactly how to build the blinking LED circuit from previously. First go toTinkerCAD and setup an account if you don’t already have one. After that you’ll find yourself in the dashboard, this is where we can view previous designs or choose to create a new one.

So that’s how you build a very basic blinking LED circuit in TinkerCAD. There are lots of other really cool things about Tinkercad which we’ll explore now.

Go to your main dashboard by clicking the TinkerCAD logo at the top left of the screen, then click the “Learn” tab at the top right of the screen. Next click the drop down button (which defaults to 3D) and select “Circuits”. Here you can select various start guides and lessons.

You can see how there’s tons of really useful stuff on Tinkercad. It’s not only a great place to design circuits, but also a great place to learn from the community and get inspiration.

The serial monitor and the output of the LCD screen are showing the slide switch to always be on the right side (not creating an open circuit when the switch is on the left side).

As seen in the picture, the switch is on the left. And the code, I think, is correct. So it should display, "Switch on left." This is because pin8 is low (not connected to 3.3V).

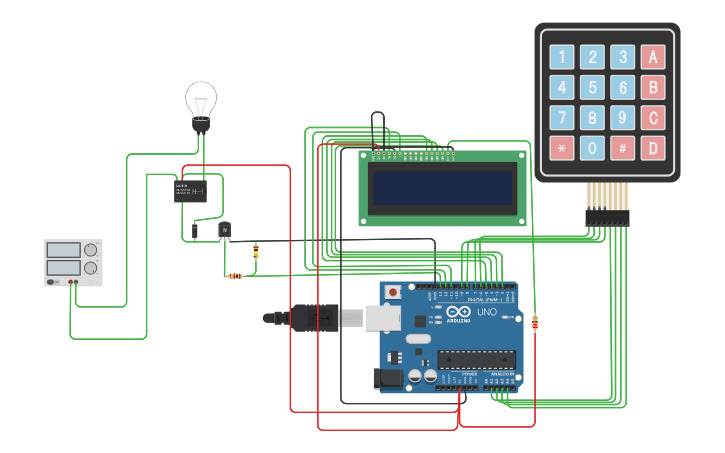

In this project, we will create a smoke detector setup using Arduino in the Tinkercad platform. The setup is simple and can be made by anyone. Also, the components we use are cheap and the hardware setup can be used in our homes, workplaces, etc. So let’s get started with the project and see its simulation.

You can visit the Tinkercad platform by clicking here. If you’re unfamiliar with the Tinkercad platform and want to know more about it, you can click here.

Subsequently, let’s start connecting the components one by one. So, let’s start by looking into the gas sensor connections. The gas sensor provided in Tinkercad has 6 terminals, namely A1, H1, A2, B1, H2, and B2.Connect the terminals A1, H1, and A2 to the power supply. After that, connect terminal B1 to the power supply and the terminals H2 and B2 to the ground. In order to increase the accuracy and sensitivity of the gas sensor, we connect a 22kΩ load resistor between the terminal B2 and the ground.

Here, we can see that when the gas sensor readings are below the threshold value, the LED remains GREEN and the piezo sensor doesn’t make any buzzing noise. The serial monitor continuously displays the gas sensor readings on a real-time basis.

This stems from the fact that the LCD controller itself does not inherently support the function and in fact treats the ASCII codes for and as displayable characters instead of control codes.

The fact that the LiquidCrystal library inherits from Print class and thus permits the use of println() essentially makes things worse. Instead of barfing and spitting out an error message it just happily displays two unrelated characters on the screen and the uninitiated have no idea of the cause.

In my opinion the basic LiquidCrystal library should concentrate on implementing all of the capabilities of the LCD controller and no more. If people want a library that more closely emulates a CRT (or LCD) terminal that is fine, but I think it should be done in a different library.

Case for WaveShare"s 5inch LCD touch screen for the raspberry pi Instructions The mount can also used to put the case upright on a flat surface. Does not have screw holes, but should be easy enough to drill some. I do not recommend gluing only the...

Raspberry Pi touchscreen case to protect the LCD panel electronics. Made to fit this screen http://bit.ly/RPItouchTindie Two sets of files; one set for large print area printer and one set for smaller print beds. There are holes for zip ties in the...

Post a make! I had to flip my screen as it was up-side down: In Terminal: sudo nano /boot/config.txt Add line: lcd_rotate=2 To exit: Ctrl + X Y Enter sudo reboot Links: Raspberry Pi 7" Touch Screen Display on Amazon GeeekPi 4010 Blue LED fan on...

In this article, I’ll explain how thermistors work, then I’ll show you how to set up a basic thermistor circuit with an Arduino that will output temperature readings to the serial monitor or to an LCD.

To output the temperature readings to a 16X2 LCD, follow our tutorial, How to Set Up an LCD Display on an Arduino, then upload this code to the board:

You will have to design the object of your dreams on Tinkercad’s easy to use software. Make sure to design your creation using Tinkercad and upload directly to MyMiniFactory using the built-in “Upload to MyMiniFactory button”. Don’t forget to tag your creation in the description or title using #TinkercadEaster.

Once your design has been uploaded and approved on MyMiniFactory, make sure you share it on Twitter with the hashtag #TinkercadEaster @MyMiniFactory @Tinkercad.

A panel of judges from MyMiniFactory and Tinkercad will decide on their favourite designs based on your originality, printability and element of surprise!

A few postsago we indeed presented a system that complements the 3Drag controller and allows it to print G-Code files directly from the SD card thanks to an LCD display and a rotating encoder. The board was made created with the idea to enclose it in a container in mind, but, apparently, any commercial container exists that can accommodate it without having to tweak it with a series of holes and a good amount of mechanical machining. This problem is a very common one in DIY electronics history and, until accessible 3D printing debuted on the market, hobbyists used to start from the few standard case models available since the very beginning of the layout design. Not choosing a standard case, was really laborious, sometimes more than the electronic part itself.

After trying several solutions, we understood that – even with limitations and flaws – Tinkercadweb is the best solution for beginners of three-dimensional modeling.

Being a web app, it works in a basically every browser with no downloads required. Models are stored directly on Tinkercad storage. Once you created your account, you will then always have both your works and the program available, regardless of the computer you will use, provided it is connected to the Internet and is also equipped with a compatible browser.

First of all we can say that the entire case (with the brackets to be fastened to 3Drag, the knob and the reset button) has been fully realized with Tinkercad, no tricks and no shortcuts. By the way, for the sake of readability, we will only focus on the implementation of part of the case – as a Tinkercad tutorial – since also the STL files are available for download and then you can download and make your case for the stand-alone printing interface for 3Drag or any RepRap printer with Sanguinololu controller.

Click on New Design from your personal page, and you’ll see your empty workspace. This container should have 2 millimeters of room on the sides and the walls should be as well 2mm thick. The calculation lead us then to 168mm in width, 69mm in depth, 36mm in height and allow us to have the LCD screen approximately 1 mm back from the surface. Click on the cube in the side palette and, by holding left mouse button, drag it to the center of the work area, then pull the centered handles (the blacks squares) on the two sides of the base and bring it to measure, the square centered at the top should be used instead to change the height of our cuboid up to 36mm. By positioning on one of the handles that are white inside, on the base corners, you should read the correct measurements.

To create room inside the box use another cuboid whose measures are calculated by subtracting the thickness of the side walls, or 2 +2 mm per side. Therefore, its expected size is 164x65mm. The height of the cuboid is not however a problem, provided that it is at least equal to or greater than 36mm. Note that Tinkercad provides a 3D printer work bench and therefore we are limited to 20 x 20 centimeters. Move the two boxes to fit them on the work surface and check once again that the measurements are the exact ones for the base. Do not worry about too much about alignments at this stage.

To accommodate the boxes in the correct way we use the alignment tool. First you select the smallercuboid and choose Hole in the Inspector (it becomes semi-transparent). Select both objects, and then choose Adjust -> Align to display the handles of alignment. You then choose the ones for centering – in gray in the screen – only for x and y axes. The thickness of the front of the container is managed by raising the smaller cuboid by 1.6 mm relatively to the plane. To do this you first need to select 0.1 in the bottom right of the Snap grid drop-down menu, then after selecting the internal cuboid, use the cone shaped handle that is approximately in the center of the upper face. Drag the mouse until 1.6mm value appears. Bring the Snap grid to 1.0mm, and select both objects – now lined up as required – then click Group.

Move the top created in the previous step at the top of the working area and proceed to the creation of the “negative” box with which we will produce the LCD screen hole. The screen size is 42 x 86mm: if we create a 45 x 90mm window and we place it properly, we will be able to see the screen without having the physical contact between cover and LCD. The few millimeters left will then become a nice frame around the screen. The procedure the same: drag the cube on the floor, then tweak the size via the handles, and finally make it solid (to be subtracted) by assigning the “Hole” attribute in the Inspector. In this case the height does not matter that much (in a case of a merger with a solid, the overlapping – both full and empty part – is eliminated, while the empty excess simply disappears.

In this step, we learnt how to use the dimensioning system and movement blocker. The goal is to accurately position the hole above the display. The measures taken earlier tell us that the hole is vertically centered, while it is about 12 mm from the edge of the board. From the base outside of the container there are 3.5 mm and thus by positioning our frame 14mm from the outside of the container we will leave a couple of millimeters of room, with about half a millimeter tolerance. To place the hole properly, use the align tool and center the hole and cover on the the y axis, than use the handle that right-aligns both solids. You will then have the hole centered vertically and everything right. Now pick it and move it to the left, then press the shift key to constrain movement to one axis and stop when you read a -14mm displacement. Select the two solids and click Group.

The hole of the encoder knob also needs to be carefully positioned, even if the knob covers the hole underneath hiding small misalignments. Again we took the measures and we know that the encoder pin is vertically centered and about 26mm from the edge of the print. Let’s add 2mm for the border, 2mm wall thickness and subtract 7.5 mm to base the procedure on the edge of the cylinder and not on its center. We get 22.5 mm (round up to 23mm), this is the distance which the edge of the cylinder must have from the left wall. As we did for the LCD screen hole, we start by selecting the cover and cylinder, then we align it left and vertically and at the center. Select the cylinder only and using the shift, block Y axis (it’s only movable on X): drag it to the right until you read 23mm: now you can assign the Hole material to the cylinder and, if you will, Group it with the cover.

Positioning the cylinder that houses the reset button piston requires a little attention, but it allows us to experience how Tinkercad makes even precision operations easy. The system is based on simple principles: alignment and shift offsets relative to a starting point. If, while moving, you leave the mouse button, the starting point becomes the one where you inadvertently dropped the object, and then you must start over. The Undo button, in this case, it is more useful than ever. In the screen on the right you see how the hollow cylinder should be positioned: 42mm from the left edge and 3mm from the bottom. Just 1mm space between the wall and the cylinder should be left. To be noted that we left the hole in its previous position. The procedure is the same just used: Align command is used to bring the cylinder to the bottom left of the cover and then move it up to the right heights.

To place the two holes in their right places, we once again use the relative offsets from the edges of the print. The cable is almost aligned with the left side of the LCD screen, while the slot for the SD memory card is positioned at its center. Transforming this into offsets, the 30mm hole should be 65mm away from the left side while the one for the memory card must be 94mm away, always from the edge. Alignment to the left and to the top so that the holes create a slit up to the top edge, interrupting it. Alignment and the y-axis size of these two cuboids is not important since they will be subtracted from the walls.

Now the work is really done: the creation stays on the floor with the front of the cover, and this allows a very simple print that with no particular inclinations or undercuts. The only difficulty may be the fairly extensive surface and therefore potentially subject to detachment from the plate. Click on Design and choose Download for 3D print to display the window that shows you the various formats. Select STL and then prepare the printer for this new job. Download the other elements of our stand-alone printing container from our website or from Tinkercad. For trouble-free printing, we suggest you to print two or three reset buttons: The terminal 4mm part is too small to be printed by itself without deformation, while if the printing is done with two or three buttons, the plastic is able to cool off and keep the shape.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey