sharp lcd screen factory

![]()

The most advanced facility for the integrated production of LCD TVs from the manufacturing of LCD panels to assembly of final products was completed in Kameyama, Mie Perfecture, Japan, and started operation. The plant also provides rationalization in the process of production, inspection and delivery, as well as technology development, resulting in high production efficiency and high value-added performance.

With the expansion of the supply of large LCD panels from the Kameyama factories, Sharp is greatly advancing LCD TV production to meet increasing market needs.

Production of Sharp’s AQUOS LCD color TVs passed the five-million mark*1 on December 28, 2004. Sharp has also been providing larger screen LCD TVs and higher performance models with a variety of lineup as well as delivering new viewing styles for LCD TVs.

This figure represents the total number of units produced at five of Sharp’s manufacturing sites: Yaita Plant (Tochigi Prefecture) and Kameyama Plant (Mie Prefecture) in Japan, and SEES (Sharp Electronica Espana S.A., Spain), SEMEX (Sharp Electronica Mexico S.A. de C.V., Mexico) and NSEC (Nanjing Sharp Electronic Co., Ltd., China) subsidiaries.

Sharp was the first to bring electronic calculators incorporating ICs or LSIs to the market but further miniaturization would only be possible if the display could be made smaller. The fluorescent elements, or LEDs (light emitting diodes), used in displays up to that time consumed a lot of electricity, so calculators had to be equipped with bulky batteries. Sharp set out to find a new display that would use less energy and take up less space. After examining the problem from every angle, it was finally decided to begin research into LCD (liquid crystal display) technology in 1970.

Though the superior characteristics of LCDs had already been recognized by researchers throughout the world, the technology was generally dismissed as impractical for commercial use due to the difficulty of selecting and combining the necessary materials. But through the unrelenting efforts of Sharp"s engineers, the company succeeded in 1973 in introducing a calculator with the world"s first practical LCD unit. This second electronic calculator was truly a breakthrough and became a big hit. Compared to the first calculator, it was only 1/12 the depth, 1/125 the weight, consumed only 1/9000 the power, and could be used 100 hours on one D3 battery.

One Sharp success in optoelectronics was the development in 1988 of the world"s first 14-inch color TFT LCD. A mere 2.7 cm thick, it boasted a sharp, bright picture. This development showed that the long-awaited, wall-mount LCD TV and truly portable data communications terminals were on the horizon.

In October 1992, the debut of the LCD ViewCam introduced a whole new concept in video cameras. Its ease of use gave Sharp an immediate share increase in the video camera market. The ViewCam was chosen as one of just 16 products from among approximately 13,000 nominated for Nikkei Product and Service Excellence Awards. It was also chosen for the Nikkan Kogyo Shimbun"s (Japan"s leading industrial daily) 10 Best New Products Awards. The LCD ViewCam became the flagship product that showed the world that "LCD is Sharp" and contributed to boosting the company image.

Sharp created a buzz with the announcement of a 28-inch TFT LCD using next-generation LCD technology. The announcement boosted demand enthusiasm for LCDs for computers and large-screen wall-mount TVs in a new age of multimedia.

Using the new CG-Silicon (continuous grain silicon) technology jointly developed with Semiconductor Energy Laboratory Co., Ltd. (Atsugi, Kanagawa Prefecture), Sharp made a splash with its prototype ultra high-definition 60-inch rear projector that uses three 2.6-inch CG-Silicon LCD panels.

The technology gained much attention for its ability to produce breathtaking ultra high-definition large-screen images and was regarded as pioneering a new age of digital audio-visual enjoyment.

Sharp went on to offer consumers more ways to enhance their lifestyles with more AQUOS product introductions: a PC card slot-equipped AQUOS (LC-20B1/15B1/13B1), a wide 30-inch digital HDTV model (LC-30BV3) that can be a family"s main TV, and the AQUOS Theater, a stylish entertainment system that"s a combination of AQUOS and a DVD 1-bit digital theater system.

The most advanced facility for the integrated production of LCD TVs from the manufacturing of LCD panels to assembly of final products is completed in Kameyama, Mie Perfecture, Japan, and started operation. The plant also provides the rationalization of the process of production, inspection and delivery, as well as technology development, resulting in high production efficiency and high value-added performance.

According to a Reuters report, Apple’s largest contract manufacturer Foxconn is planning to build an $8.8 billion factory in collaboration with Sharp in China, that will produce advanced liquid-crystal displays (LCDs). The project is aimed at increasing production to meet rising demand for large-screen LCD TVs and monitors in Asia.

The $8.8 billion investment to build the flat-panel factory will be made by Sakai Display Products Corp., which is mostly owned by Foxconn Group’s founder Terry Gou. The new plant in Guangzhou, which will have annual production capacity equating to $13.25 billion, will be a so-called Gen-10.5 facility specializing in large-screen LCDs and will be operational by 2019, according to Foxconn.

Global LCD output was hit this year by the closure of a Samsung factory that accounted for 3 percent of the market, as well as factory stoppages in Taiwan after an earthquake in March. China’s largest LCD panel maker, BOE Technology Group, began construction on its own Gen-10.5 plant in Hefei in December last year, with production scheduled to begin in 2018.

LCD displays are still going to be around for a long time, at least for smart TVs such as the ones that use Android TV and other operating systems. Today, the massive electronic manufacturing company Hon Hai Technology Group (Foxconn) announced a new partnership with Sharp to build and operate a new TV LCD flat-panel factory in China, which will cost $8.8 billion.AMOLED displays set to close in on LCD this year

Reuters reports that the new factory will help with the expected demand of new flat-screen TVs in Asia. Hon Hai Technology Group (Foxconn) said that the LCD factory will make 10.5-generation 8K displays, along with screens for smart TVs and electronic whiteboards. Production is expected to begin in 2019.

This news comes even as other companies are embracing OLED displays for both TV as well as smartphones. However, there’s still some life in the LCD market. Panasonic recently announced an LCD IPS display with a 1,000,000:1 contrast ratio. It is supposed to have 600 times more contrast compared to normal LCD panels, and those levels are close to those found in OLED displays.

The Nihon Keizai Shimbun newspaper reported in its Tuesday morning edition that Sharp plans to spend ¥5 billion (US$42 million) to build the factory, which will start operating in the latter half of this year and triple Sharp"s Mexican production capacity. The newspaper, which did not name its source, also said the new factory would be located near an existing facility in the Mexican state of Baja California.

Sharp is one of the world"s leading makers of LCD (liquid crystal display) televisions and said Monday that sales of its sets are strong during the current season in the U.S., Europe and Japan.

Sharp produces the LCD display panels for the sets in Japan and then sends them to several factories overseas where they are combined with other components to result in a finished television set. At present its factory in Kameyama can handle up to 15,000 sheets of LCD mother glass per month. Each sheet can be used to make eight 46-inch panels or six 52-inch panels. On Monday it said it will double capacity at the plant from January, which is two months earlier than originally planned, thanks to strong demand.

The current factory in Mexico produces both CRT (cathode ray tube) and LCD TVs, said Miyuki Nakayama, a spokeswoman for Sharp in Tokyo. Sharp also assembles LCD TVs at sites in Japan, China, Malaysia and Spain. Sharp currently assembles LCD TVs for the U.S. market in Mexico, China and Japan.

Sharp already makes smaller glass panels at a nearby plant, producing 60,000 panels a month there, for TVs with a diagonal measure around 30 inches, or 76 centimeters. It has sped up the start of the new plant to meet growing demand for larger 40-inch and 50- inch TVs, a company spokeswoman, Miyuki Nakayama, said.

The new plant will produce 15,000 panels a month, enough for 120,000 40- inch TVs. Production will be raised to 30,000 panels a month by March, Sharp said.

Last week, Sharp said its profit in the first fiscal quarter jumped 23 percent to ¥23.9 billion on growing sales of flat panel TVs and mobile phones. Quarterly sales totaled ¥693.7 billion, up 12.6 percent from the same period a year earlier.

Japanese display maker Sharp may build a $7.1bn plant to make LCD screens in the US in the first half of 2017, taking the lead on a project initially proposed by its Taiwanese parent Foxconn, Reuters reported yesterday.

A spokesperson for Sharp told Reuters that no decision on building a plant had been made, however one of the company’s executives told the Nikkei Asian Review yesterday that the project would go ahead, with Sharp in the lead.

The executive also suggested that Sharp may ask companies outside the Foxconn group, which owns a 66% stake in the Japanese company, to invest in the new plant.

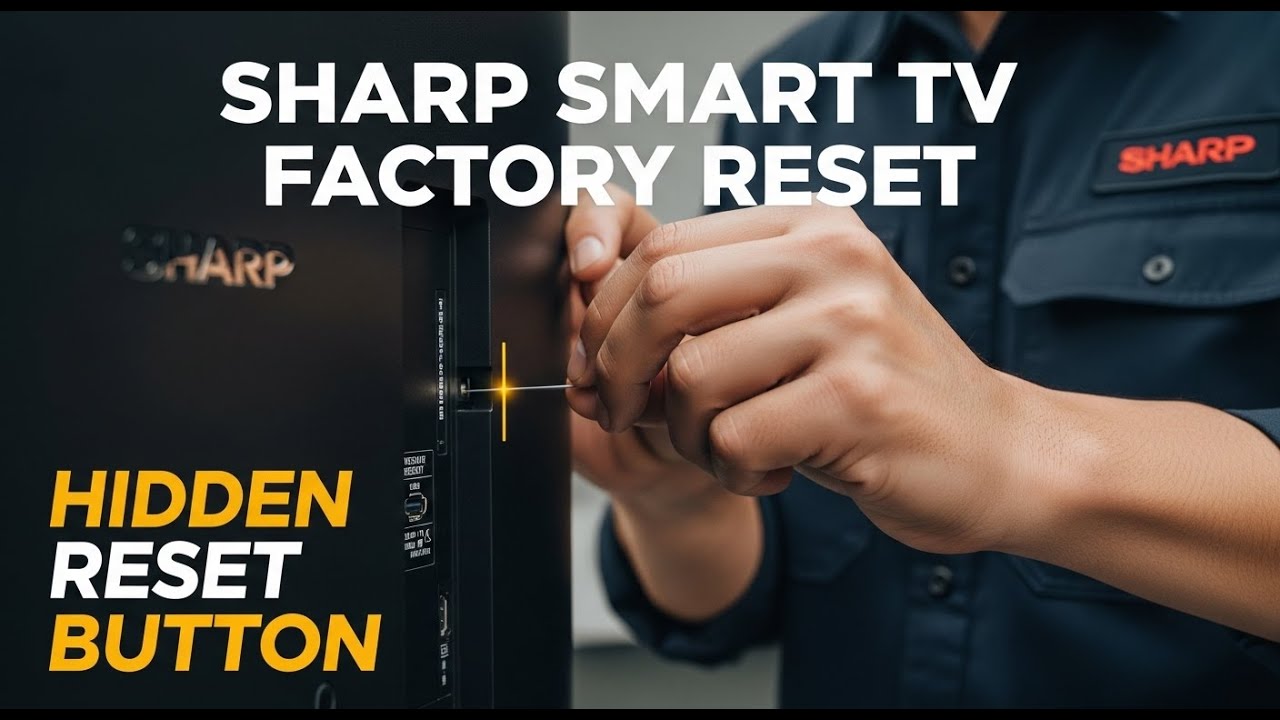

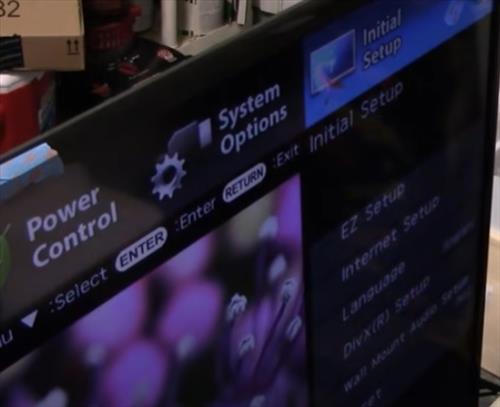

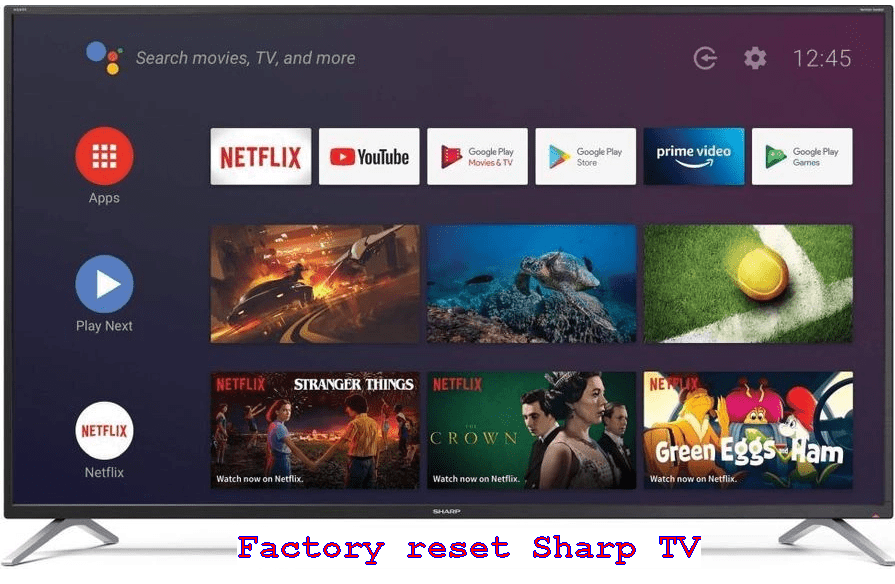

Be sure to always follow the manual that came with the TV. The below steps are general information for most Sharp TVs, but steps may differ between models.

OSAKA -- Sharp has turned LCD factory operator Sakai Display Products into a wholly owned subsidiary for an estimated 40 billion yen ($296 million), Sharp announced Monday.

Sharp previously held a 20% stake in SDP, which produces large display panels for televisions in the city of Sakai, near Osaka. It acquired the rest from a Samoa-based investment company by handing over 11.45 Sharp shares for each SDP share it received.

Sharp Corporation(シャープ株式会社, is a Japanese multinational corporation that designs and manufactures electronic products, headquartered in Sakai-ku, Sakai, Osaka Prefecture. Since 2016 it has been majority owned by the Taiwan-based Foxconn Group.mechanical pencil, which was invented by company founder Tokuji Hayakawa in 1915.

In 1912, Tokuji Hayakawa founded a metal workshop in Tokyo. The first of his many inventions was a snap buckle named "Tokubijo". Another of his inventions was the Ever-Ready Sharp mechanical pencil in 1915. The product became one of the first internationally available mechanical pencils (while concurrent US design replaced it soon and became a modern type), and due to this big success the Sharp Corporation derived its name from it.1923 Great Kantō earthquake, the company relocated to Osaka and began designing the first generation of Japanese radio sets. These went on sale in 1925.

In 1964, the company developed the world"s first transistor calculator (the Sharp CS-10A), which was priced at JP¥535,000 (US$1,400). It took Sharp several years to develop the product as they had no experience in making computing devices at the time. Two years later, in 1966, Sharp introduced its first IC calculator using 145 Mitsubishi Electric-made bipolar ICs, priced at JP¥350,000 (about US$1000). Its first LSI calculator was introduced in 1969. This was the first pocketable calculator priced at less than JP¥100,000 (less than US$300), and turned out to be a popular item.

Sharp produced the first LCD calculator in 1973. Sharp had a working relationship with Nintendo during the 1980s, and was granted licensing rights for the manufacture and development of the C1 NES TV (1983, later released in North America as the Sharp Nintendo Television), the Twin Famicom (1986), the Sharp Famicom Titler (1989), and the SF-1 SNES TV (1990). All of these units are considered collectors items on the secondary market. One of the company"s main inventors of LCD calculators was Tadashi Sasaki.

Sharp introduced low-cost microwave ovens affordable for residential use in the late 1970s. Sharp ventured into the high end stereo market in 1976 with the introduction of high end receivers, amplifiers, speakers, turntables and cassette players. The Optonica line as it was called, consisted of high quality and technically advanced components, that was expanded in 1979, to cover a broader selection of high end equipment. During this run, Sharp introduced digital technology to some of the Optonica products, along with the traditional analogue products, and offered a complete selection of models ranging from low power high end receivers to very powerful models. The line was again changed, in 1981, and moved mainly into digital high end, complete stereo systems with advanced technological features setting the trend towards the digital age. The line was discontinued after 1981, but the Optonica line was again re-introduced in the late 1980s for a high end line of television receivers and higher quality mass market audio products such as VCR"s, surround sound receivers, CD cassette boom boxes, and portable cassette players.

Since 2000, Sharp heavily invested in LCD panel manufacturing plants: Kameyama in 2004, Sakai in 2009. The Sakai plant is still the only 10th generation LCD manufacturing plant on the globe and its best fit for production of 60-inch or larger panels. However, the 2008 financial crisis and strong Yen (especially against Won) significantly lowered world demand for Japanese LCD panels. Furthermore, the switch to digital TV broadcasting was virtually completed in Japan by the middle of 2011. Via Japanese government issued coupons for digital TV sets, consumers were encouraged to purchase digital TV sets until March 2011. This hit the Japanese LCD TV market, reducing it almost by half from 2010. All of those events strongly hit Sharp"s LCD business. As the result, the Sakai LCD plant suffered a reduced operating rate until Q3 2012.

From 2005 to 2010 Sharp was the biggest mobile phone brand in Japan. Since then it has been constantly switching places through financial quarters against rivals Fujitsu, Apple and Sony.

On 25 June 2009, Sharp and Pioneer agreed to form a joint venture comprising their optical businesses, called "Pioneer Digital Design and Manufacturing Corporation".

In 2012 Sharp unveiled the largest production TV at the time, with a screen size of 80 inches. It is part of the Aquos range and went on sale in Japan at around JP¥950,000.

2012 was the 100th anniversary for Sharp but it announced the worst financial record in its history, with a loss of JP¥376 billion (US$4.7 billion) in April 2012. In September, Sharp announced job cuts.

In March 2012 the Taiwan-based electronics company Hon Hai, trading as Foxconn, agreed to acquire a 10% stake in Sharp Corporation for US$806 million, and to purchase up to 50 percent of the LCD displays produced at Sharp"s plant in Sakai, Japan.

After years of huge losses in its overseas TV business, Sharp sold its Mexico TV factory to Chinese electronics manufacturer Hisense for $23.7 million in July 2015. The sale includes rights to use the Sharp brand name and all its channel resources in North and South America, except Brazil. This meant that Sharp has exited the TV market in the Americas (except Brazil).LCD TVs a decade earlier.

Sharp began selling the world"s first commercially available TV with a 8K resolution in October 2015.NHK will have test broadcasts at 8K starting 2016, with regular services expected by the time of the Tokyo 2020 Olympics.

On 25 February 2016, Foxconn announced its intent to acquire a 66% controlling stake in Sharp for 700 billion yen (US$6.24 billion).contract manufacturer.

In September 2016 Sharp unveiled the Sharp INTELLOS Automated Unmanned Ground Vehicle (A-UGV) at the ASIS International 62nd Annual Seminar and Exhibits (ASIS 2016) in Orlando, Florida.

In June 2017, Sharp sued its Chinese licensee Hisense for damaging the reputation of its brand, seeking an exit from its licensing agreement. Sharp accused the company of producing "shoddily manufactured" televisions under the Sharp name, including products they believed were in violation of U.S. safety standards for electromagnetic radiation, and the subject of deceptive advertising over their quality. Hisense denied that it engaged in these practices, and stated that it planned to defend itself in court and "will continue to manufacture and sell quality televisions under the Sharp licensed brands."

In March 2020, in response to the coronavirus pandemic, Sharp announced it would use a TV factory with high-end clean rooms to manufacture surgical masks.

Sharp acquired the remaining shares of Dynabook from Toshiba in August 2020, making Dynabook a wholly owned subsidiary of Sharp. Sharp had first purchased Dynabook from Toshiba in 2018.

The first commercial camera phone was also made by Sharp for the Japanese market in November 2000. Recent products include the ViewCam, the Ultra-Lite notebook PC, the Zaurus personal digital assistant, Sidekick 3, and the AQUOS flat-screen television.

Sharp manufactures consumer electronic products, including LCD televisions, sold under the Aquos brand, mobile phones, microwave ovens, Home cinema and audio systems, air purification systems, fax machines and calculators.

For the business market, Sharp also produces projectors and monitors and a variety of photocopiers and Laser Printers, in addition to electronic cash registers and Point of sale technologies.

For the private security industry, Sharp produces an Automated Unmanned Ground Vehicle (A-UGV) named INTELLOS, which utilizes a navigation surveillance platform also developed by Sharp. The system combines automation, mobility, and a variety of monitoring and detection capabilities to extend the impact of a traditional security force.

For the corporate meeting room market, Sharp was the first company to bring the Windows collaboration display to market, which is a 70inch interactive display with built-in unified communication equipment and an IoT sensor hub for measuring environmental room conditions. The Windows collaboration display is conceived to be seamlessly compatible with Microsoft"s Office productivity products, as well as make use of the Microsoft Azure cloud services with the IoT sensor hub generated data.

It operates from 64 bases in 30 countries and its products are distributed in 164 countries worldwide. Many of its regional subsidiaries trade under the name Sharp Electronics.

Sharp"s headquarters are at 1 Takumi-chō, Sakai-ku, Sakai, Japan. Until the relocation to Sakai in 2016, the headquarters were in Abeno-ku, Osaka where Hayakawa restarted the business in the 1920s.

In September 2014, Sharp announced that Slovakian electronics company UMC (Universal Media Corporation /Slovakia/ s.r.o.) was acquiring an exclusive brand licence from Sharp and its European television and audio business UMC will also acquire Sharp"s Polish factory. As part of the deal, Sharp will support the design and development of televisions sold by UMC under the Sharp brand.

The same month, Sharp also announced a tie-up with Vestel in Europe for white goods. Vestel will sell Sharp-branded white goods (except air conditioners), such as refrigerators and microwave ovens manufactured by Sharp in Thailand and China. Sharp will also license its brand name to Vestel for volume home appliances such as refrigerators, washing machines and ovens. Sharp"s remaining European business will then focus on the business-to-business sector including multi-function printers and energy solutions.

Malaysia : Sharp has an export-only Television factory at the HICOM Industrial Park in Shah Alam, Selangor.Batu Pahat plant in Johor that manufactures audio-visual Equipment like television sets and Blu-Ray players, and the Sungai Petani plant in Kedah that manufactures radios as well as kitchen appliances like blenders and rice cookers.Petaling Jaya that manufactured television sets, VCRs, microwave ovens, washing machines and refrigerators, this plant was hit badly by the 1997 Asian financial crisis and shut down as Sharp moved the productions of the appliances to either Batu Pahat (TVs and VCRs) or Sungai Petani (microwave ovens), or out of the country altogether (refrigerators and washing machines) in a bid to reduce operating costs.

(former) Mexico : LCD plant (Sharp Electrónica Mexico S.A. de C.V. SEMEX) – established as a color CRT TV plant in 1997; began LCD production in 2003; a second LCD plant on site was opened in 2007.Hisense in 2015.

On November 8, 2008, the United States Department of Justice announced that Sharp had agreed to pay $120 million (United States Dollar) as a criminal fine. According to the announcement, Sharp participated in conspiracies to fix the price of TFT LCD panel for Dell"s computer monitors and laptops (2001–2005), Motorola"s Razr phones (2005–2006) and Apple"s iPod (2005–2006).

On December 18, 2008, Japan Fair Trade Commission ordered Sharp to pay JP¥261 million (US$3 million) as criminal fine. According to the order, Sharp and Hitachi Display participated in the conspiracies to keep the price for TFT LCD panels for Nintendo DS and DS-Lite. The fine for Hitachi Displays was waived by JFTC leniency program.

However, Sharp disagreed with the JFTC order and announced it would begin an appeals procedure against it on 2 February 2009.JFTC dismissed Sharp"s appeal.

In November 2011 Sharp was ranked in 11th place by Greenpeace"s re-launched Guide to Greener Electronics that ranks 15 electronics manufacturers according to their policies and practices to reduce their impact on the climate, produce greener products, and make their operations more sustainable. Greenpeace summarizes the corporation"s environmental record thus: "Sharp supports a new renewable energy law in Japan but scores poor on all sustainable operations criteria".

Sharp scored 3/10 and received most of its points on the Products criteria where the company was praised for the energy efficiency of its products with all of its TVs meeting the latest Energy Star standard. It also gained some points for having a relative long term target to reduce CO2 emissions by two percent (per production unit) compared to the previous year, yet sets out no clear target for absolute reductions. The company was also praised for its public support for a clean energy policy, after advocating the Japanese Government to increase the use of renewable energy.

Sharp scored the fewest points in the guide in the Sustainable Operations category, scoring no points for chemical management due to not communicating commitments made on phasing out hazardous substances in its supply chain. The guide also notes that Sharp had lacked any initiative to address the issue of conflict minerals and the exclusion of paper sourced from suppliers involved in illegal logging or deforestation.

In 2020, the Australian Strategic Policy Institute accused at least 82 major brands, including Sharp Corporation, of being connected to forced Uyghur labor in Xinjiang.

Sharp was the principal sponsor of Manchester United Football Club from 1983 until 2000, in one of the lengthiest and most lucrative sponsorship deals in English football.logo was on the front of United"s shirts over these 17 years, during which the team won seven Premier League titles, five FA Cups, one Football League Cup, one UEFA Cup Winners" Cup, and one UEFA Champions League title.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Back in 2014-2015, Japan Display (JDI) was considered to be Apple"s major smartphone display supplier. At that time, the iPhone 6 and the iPhone 6 Plus were bringing larger-sized LCD screens to iPhone users. The original 3.5-inch display found on the first iPhone models rose to 4-inches with the iPhone 5 and to 4.7-inches on the iPhone 6. The iPhone 6 Plus carries a screen size of 5.5-inches and those sizes remained the same until 2017"s iPhone X weighed in with a 5.8-inch OLED screen.

Apple to build a new LCD plant. With smartphone manufacturers-including Apple-turning away from LCD, JDI"s new factory was running at only 50% of capacity. According to the Nikkei Asian Review, on Friday Japan Display announced that it will sell a smartphone display factory and the land it sits on to Sharp for 41.2 billion yen (the equivalent of $386 million). The Hakusan LCD factory along with equipment that will be sold to a customer believed to be Apple, will bring Japan Display $668 million while at the same time cutting excess capacity that has negatively impacted its earnings. This specific factory has been idle since 2019.

Sharp, which is owned by iPhone assembler Foxconn, will rent the necessary equipment from Apple that will allow it to produce LCD displays for older iPhone models. Sharp also expects to use the facility for developing and producing the next generation of displays including microLED screens which use millions of tiny light-emitting-diodes to produce a sharp display (no pun intended). Sharp does plan to spin-off its LCD panel business in October.

A robotic forklift picks up a sheet of glass thinner than a credit card and as big as two table-tennis tables, and effortlessly swings it 90 degrees before gently placing it into an oven where it will bake at 200 degrees Celsius. It’s a graceful and finely engineered process and one of several that takes place minute after minute, hour after hour, day after day in Sharp’s LCD factory in Sakai, western Japan.

The factory, built at a cost of ¥430 billion (US$5 billion), is the most advanced display factory in the world and on Monday Sharp opened it to reporters for the first time.

Operations at Sakai began in October, just in time for the competitive year-end sales period, and the factory is already a key supplier of panels for big-screen TVs and one of the reasons why LCD TV prices continue to fall.

At the center of the plant’s claim of world-class status is the size of glass sheets processed. Typically several LCD panels are made on a single sheet of glass to benefit from economies of scale before the glass is cut to produce individual screens. The Sakai plant handles sheets measuring 2.88 meters by 3.13 meters — almost double the size of those at Sharp’s other factory — so LCD panels can be made more efficiently and prices lowered.

The glass panels are made by Corning at a plant next to Sharp’s LCD factory and transported on a conveyer that connects the two. Across the street Dai Nippon Printing and Toppan have factories that produce color filters for the LCD panels. In total 19 companies contribute to a sprawling facility at the center of which sits the LCD factory. Sharp also has a solar cell factory on the land, and there is unoccupied space for expansion.

Looking down from fifth-floor observation windows into one of the clean-room production areas, the sheer scale of the operation was obvious. Photo etching machines, each about 3 meters high and about the size of a tennis court, are lined up one after another for about 200 meters. Inside each sits a 200-ton camera, the largest in the world, according to Sharp.

Sharp says its Sakai operations have a comparatively lower impact on the environment than other plants. The larger glass sheets mean more efficient production and a central energy control center collectively manages the energy needs of all the factories on the site. Solar panels on the factory roofs supply 9 megawatts of power and there are plans to double this, while Sharp has also had a hand in constructing a nearby solar farm for Kansai Electric Power.

Sakai can currently handle up to 36,000 sheets of glass per month. Each sheet has enough space for 18 screens in the 40-inch size or 8 screens in the 60-inch size, and two sheets are sandwiched together in each finished screen. The plant is capable of making around 324,000 finished LCD panels per month for 40-inch LCD-TVs or 144,000 panels for 60-inch LCD-TV sets.

It’s a vital part of Sharp’s TV business and soon will play a similar role for Sony. On Dec. 29 Sony will invest ¥10 billion for a 7 percent stake in Sharp Display Products, the company that runs the factory, and gradually build its shareholding to 34 percent by the end of April 2011.

The investment will give Sony guaranteed access to a portion of the screens coming off the Sakai production line and follows an earlier joint venture deal with Samsung Electronics for previous-generation technology.

With extensive experience in liquid crystal display technologies and considerable manufacturing capacity, Sharp supplies reliable, high-quality LCD modules for a vast range of applications.

Pioneering research in the field of LCDs has led to the development of a number of breakthrough Sharp technologies such as our ultra-low power Memory in Pixel displays and more.

Sharp LCD technologies ensure the highest optical performance and resolutions. Browse our wide selection of standard LCD displays for use in consumer electronics, automotive, industrial automation, medical, home appliances, multimedia, and digital signage applications.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey