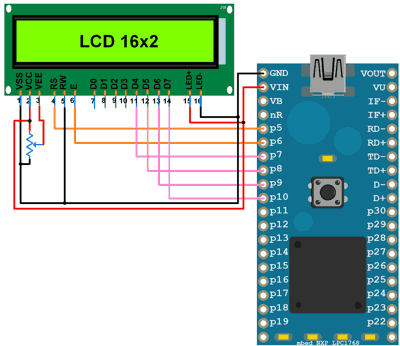

mbed lcd display manufacturer

E Ink is the originator, pioneer and commercial leader in ePaper technology. The company delivers its advanced display products to the world"s most influential brands and manufacturers, enabling them to install extremely durable, low power displays in previously impossible or unimaginable applications and environments.

E Ink encompasses the combined E Ink Corporation, which was spun out of the MIT Media Lab in 1997 to commercialize electronic ink and EPD technology, and Prime View International, which was established in 1992 as the first TFT LCD company in Taiwan, focusing on high quality small-to-medium-sized TFT LCDs. In 2009, Prime View acquired E Ink Corporation to further integrate and expand the EPD supply chain and the new combined companies were branded as E Ink.

The contrast VO pin seems to have different behaviour on different displays, so you may need to experiment for your display to see anything. I think I"ve seen some work tied to 0V, some to 3.3V, or with a different resistor.

Some displays need a negative voltage at VO. One side of the trimpot is connected to the negative voltage instead of GND in that case. F.i. a Maxim MAX1044 can be used to generate the negative voltage.

The underlying HD44780 chip is a driver used in many LCD character displays. It might sometimes be referred to as Hitachi HD44780U. There are also several compatible clones of this chip in use (eg Samsung KS0066).

Fourth test the test will work ok for a 20*2 lcd, for example if the text start as column 16 when it reach the end at 20 it will go fine to next line and continue the text

The C027 will now dial up to the internet. You will see the status “updated” in the LCD display. If the device cannot connect to the internet, it will display an error message. If there is an error message “Wrong APN setting” or “Unknown APN setting”, follow the instructions below in the section Troubleshooting.

, it will show its current status in the LCD display. The first line always displays the tenant name (until there is a message received from the platform, see the section To interact with control operations). The second line shows the signal quality in units of dBm. The third line displays information about which sensor data the u-blox is sending and their corresponding values. In the case of repeatedly sending similar data, the third line remains empty.

Switch to the Cockpit application using the application switcher and then navigate to Groups >

In the “Message sending” widget, enter a message in the text field, and then click Send. After several seconds, the first line of the LCD display should display the message you sent. This message will be displayed in the first line until you send another message or restart the device.

In the Configuration tab of the device, the supported configuration parameters are shown with their current values. Currently for the mbed u-blox, the only parameter is “interval” with the default value of 20 minutes, which determines the time period at which Cloud of Things

For temperature sensor: Place one finger atop the temperature sensor, which is located in the top middle of the u-blox device, above the text “Temperature LM7580”. You should immediately see its effect on the LCD display updating its status to send a temperature reading.

For acceleration sensor: Simply turn aside or rotate the device. You should immediately see the device sending an acceleration reading on its LCD display.

For analog sensor: Turn right or left the two blue knobs below the LCD display. You should immediately see the device sending analog readings on its LCD display.

Prior to 2.1, after the LCD display shows “Join Network” and the device is correctly joined to the network, you should see “Reset Success” shown on the LCD display, which indicates a successful factory reset. Starting from version 2.1, a factory reset is much faster, simply wait for “Factory resetting” to appear on the screen, and you can release your finger. After about 2 seconds, you should see “Reset Success” on the display.

The device failed to join a network and displays “Wrong APN setting” or “Unknown APN setting”: Review the source code file C027_Support/MDMAPN.h and add an entry with the Mobile Country Code (MCC), Mobile Network Code (MNC) and your APN setting. The current MMC and MNC code should be shown on the LCD display below the error message “Wrong APN setting” or “Unknown APN setting”.

The device does not appear as CONNECTED in the device registration process: Review the application output using a serial console. See https://os.mbed.com/handbook/SerialPC for details. Also make sure you flashed the device with the correct firmware version, that is, the one that performs the bootstrap against the correct server.

The device does not appear in the devices list in the UI: Review the application output using a serial console. See https://os.mbed.com/handbook/SerialPC for details.

Upon boot-up, the device displays “Connect to Cloud” right after “Agent Run”, instead of showing “Bootstrapping” and IMEI: The device is already registered with Cloud of Things

» Makerfabs is Open Hardware, Arduino, Raspberry Pi, mbed, BeagleBone, IoT, Smart Home, etc, Related Products& Services Vendor for Makers and new Startups.

Embedded and Internet of Things (IoT) development teams are under pressure to finish and ship their design as quickly as possible. To move fast, they need to use proven components and software frameworks that have a strong ecosystem around them. They also need to look at how their systems will be maintained and scaled in the future, which means that solutions also need to be portable and able to work across multiple hardware platforms if need be.

Considering these requirements, this article will introduce the Arm Mbed platform and operating system. It will show how developers can leverage the Mbed ecosystem to accelerate their embedded product development and use it to scale beyond the microcontroller vendor’s ecosystem.

Mbed is an online collaboration headed by Arm for developers interested in building IoT devices1. Mbed provides developers with a wide selection of resources designed to accelerate development, ranging from the Mbed OS and Mbed TLS all the way through development boards and individual hardware components that are supported by the Mbed libraries.

The premise behind Mbed is to enable developers to leverage a large ecosystem supported by 200,000 developers in online communities along with major microcontroller vendors such as Cypress Semiconductor, NXP Semiconductors, and STMicroelectronics to accelerate their development by using existing components, development tools, and libraries. There are many advantages to using the Mbed ecosystem:

Access to the Mbed online and offline compiler along with the Mbed command line interface (CLI), which makes developing software tests easy (and is even included in many examples and libraries).

The general architectural model for Mbed makes it extremely flexible and scalable for embedded developers. For example, the architectural model is generally broken up into three separate layers (Figure 1):

While Mbed provides a great software foundation, it offers more than just the software and the tools needed to develop that software. The quickest way that a team can develop a product is to also leverage the Mbed hardware ecosystem, which comprises three distinct areas:

Mbed boards are essentially development boards for different microcontroller families that are all supported by Mbed. Each development board has unique features and capabilities that are provided by the microcontroller vendor. For example, a developer interested in working with a board that supports Bluetooth Low Energy (BLE) might be interested in Cypress Semiconductor’s CY8CKIT-062-BLE (Figure 3).

The CY8CKIT is unique in that it features a multi-core PSoC 62 secure microcontroller. One core is an Arm® Cortex®-M4 processor while the second core is a low-power Arm Cortex-M0+. This allows developers to either partition their application code, such as having one processor handle the BLE communication, or lock down the application by using the Cortex-M0+ core as a security processor. All the I/O expansion available on the boards makes it a lot easier for developers to prototype their system by connecting Mbed components to them.

An Mbed component is a hardware component that has Mbed supported libraries and middleware associated with it that act as building blocks for creating a product. For example, a developer working on an IoT project may decide that they want to include a temperature sensor. A developer can search Mbed components for supported temperature sensors and they would come across, for example, Maxim Integrated’s MAX31723PMB1, which comes in a peripheral module that can be used for rapid prototyping (Figure 4).

What’s great about such Mbed components is that they nearly always come as a development board with schematics available. This allows a developer to not only see the hardware configuration required to make the sensor work, but have the software library available to get the sensor up and running.

Simple sensors like those measuring temperature and humidity aren’t the only types of sensors that are available through Mbed. For example, developers working on a medical device will find that the Maxim Integrated MAXREFDES220# module provides them with a reference design for a finger-based heart rate and SpO2 blood oxygen sensor (Figure 5).

Once a developer has selected their development board and components, they can start developing with Mbed by creating a “Hello World” LEDBlinky application to test that they can program their board successfully and blink an LED.

There are several different ways to develop an Mbed application: through the online compiler; the offline compiler; or by using the command line interface (CLI) tool. Personal experience suggests using the CLI because it provides more control over the development process and makes it easier to integrate into development processes, such as test harnesses and continuous integration servers.

The CLI provides command line interface capabilities so a developer working on Windows can use the command prompt to compile their code. The first step in creating the LEDBlinky application is to use the pre-made example provided with Mbed. This can be done by entering the following command into the command prompt:

It will take a few minutes to download the example as this also brings in supporting Mbed OS and other components that may be used in the application. Once the download is complete, a developer can navigate to the mbed-os-example-blinky folder where they will find a main.cpp file. This module can be opened in a developer’s favorite editor and will look something like the following:

Compiling the project for the first time can take several minutes since the toolchain will have to build all the associated files that automatically come into an Mbed application. Once the compilation cycle is completed, the result should look something like Figure 7 below.

Getting started with Mbed is straight forward, but there can be challenges for developers. Below are a few “tips and tricks” for starting to develop a product using Mbed:

Avoid using the online compiler. This is fine for hobbyists, but for professionals, having source code on someone else’s servers can be a problem. Also, the back and forth to the cloud can slow down debugging. A local compiler such as the Mbed IDE or the Mbed CLI are better options.

Embedded and IoT developers need a well-supported ecosystem that provides them with modern tools, processes, and software to help them accelerate their development efforts and minimize development costs. As shown, the Mbed platform and OS is one potential option that developers can leverage.

Mbed provides a scalable and flexible software architecture with many components that have already been integrated and tested together. The large support for various hardware modules, boards, and components makes it easy for developers to create a product prototype that can then be scaled into a production solution.

MBED SILICON ON-BOARD ZERO USB-BLASTER FEATURES80MHZ LCD ATION GRAPHIC ..SOFTWARE 구매, MBED SILICON ON-BOARD ZERO USB-BLASTER FEATURES80MHZ LCD ATION GRAPHIC ..SOFTWARE 가격비교

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey