tft display parallel interface manufacturer

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

If none of these part numbers meet your requirements in terms of brightness, interface, or connection method, please email us at info@orientdisplay.com.

Orient Display sunlight readable TFT displays can be categorized into high brightness TFT displays, high contrast IPS displays, transflective TFT displays, Blanview TFT displays etc.

The brightness of our standard high brightness TFT displays can be from 700 to 1000 nits. With proper adding brightness enhancement film (BEF) and double brightness enhancement film (DBEF) and adjustment of the LED chips, Orient Display high brightness TFT products can achieve 1,500 to 2,000 nits or even higher luminance. Orient Display have special thermal management design to reduce the heat release and largely extend LED life time and reduce energy consumption.

Our high contrast and wide viewing angle IPS displays can achieve contrast ratio higher than 1000:1 which can make readability under strong sunlight with lower backlight luminance. High brightness IPS displays have been widely accepted by our customers with its superb display quality and it has become one of the best sellers in all our display category.Transflective display is an old monochrome display technology but it has been utilized in our color TFT line for sunlight readable application. Orient Display has 2.4” and 3.5” to choose from.

Blanview TFT displays are the new technology developed by Ortustech in Japan. It can provide around 40% of energy consumption for TFT panels which can use smaller rechargeable or disposable batteries and generate less heat. The price is also lower than traditional transflective TFT displays. Orient Display is partnering with the technology inventor to provide 4.3” and 5.0”.

Orient Display can also provide full customized or part customized solutions for our customers to enhance the viewing experience. Orient Display can provide all the different kinds of surface treatments, such as AR (Anti-reflection); AG (Anti-glare), AF (Anti-finger print or Anti-smudge); AS (Anti-smashing); AM (Anti-microbial) etc. Orient Display can also provide both dry bonding (OCA, Optical Clear Adhesive), or wet bonding (OCR, Optical Clear Resin and OCG, Optical Clear Glue) to get rid of light reflective in air bonding products to make the products much more readable under sunlight and be more robust.

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch.

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

Engineers are always looking for lower cost, faster, more convenient interfaces to transmit signals and to accept data and commands. The numbers of available interfaces available in the market can be dazzling. Orient Display follows market trends to produce various kind of interfaces for our customers to choose.

Genetic Interfaces: Those are the interfaces which display or touch controller manufacturers provide, including parallel, MCU, SPI(,Serial Peripheral Interface), I2C, RGB (Red Green Blue), MIPI (Mobile Industry Processor Interface), LVDS (Low-Voltage Differential Signaling), eDP ( Embedded DisplayPort) etc. Orient Display has technologies to make the above interface exchangeable.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

A TFT LCD display module consists of a TFT LCD panel, one or more COG (chip-on-glass) or COB (chip-on-board) driver ICs, a backlight, and an interface. Several TFT display interface technologies exist today. Picking the right interface depends on specific end-product concerns. There are several types of TFT display interfaces which have been designed in the last number of years for various screen sizes, including LVDS, (Low-Voltage Differential Signaling) parallel, SPI (Serial Peripheral Interface) RGB and so on. Here is an overview of these display interfaces to give you a better idea of the variety of TFT LCD displays that are taking center stage.

SPI LCD Interface: Serial Peripheral Interface allows serial (one bit at a time) exchange of data between two devices. It has an advantage over parallel ones, that of simpler wiring. SPI also can have longer cables, since there is much less interaction or crosstalk in the cable. The downside of SPI is that you can"t read from the TFT LCD display, you can only write on it and it is slow. That"s why you normally see smaller TFT LCD screens use SPI.

MCU Parallel Interface: Many modern MCUs have built-in LCD controller function. There are two types that are commonly used, 6800 and 8080. Generally, MCU/Parallel interface consist of data signal(4/8/9/16 bits) and control signal. MCU interface is simple, but requires display RAM.

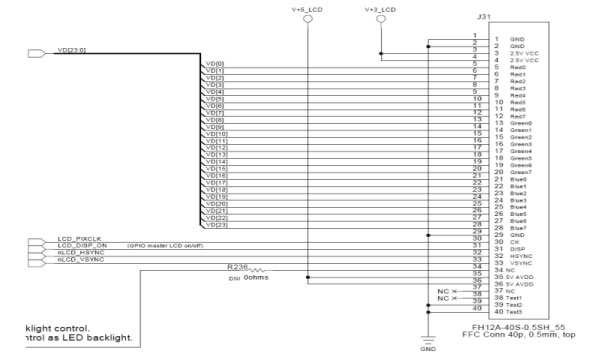

RGB Interface: RGB interface is a special kind of parallel interface. It requires no display RAM. MCU directly updates the TFT screen, sending Red Green & Blue sub-pixel data (16/18/24 bits) and timing signals. RGB interface provides high speed communication to TFT LCD, but it needs more data wires and controlling is more complex.

LVDS Interface: Low-voltage differential signaling is an electrical digital signaling standard. Devices with LVDS interface can communicate at very high speeds over inexpensive twisted-pair copper cables. It is much less susceptible to EMI and crosstalk issues, allowing the transmitting device to be located farther from TFT LCD display.

UART/RS232/RS485: These serial interfaces are used in Topway"s Smart TFT LCD display module. Universal Asynchronous Receiver/Transmitter (UART) is a block of circuitry responsible for implementing serial communication. Essentially, the UART acts as an intermediary between parallel and serial interfaces. On one end of UART is a bus of eight-or-so data lines (plus some control pins), on the other is the two serial wires – RX and TX.

HDMI Interface: High Definition Multimedia Interface is a connector and cable definition that supports high-quality and high-bandwidth streams of video and audio between devices.

MIPI DSI: MIPI Display Serial Interface defines a high-speed serial interface bewteen host processor and display module. The interface facilitates a high performance, low power and low EMI way to render brilliant color for the most dempanding image and video scenes.

To choose your product"s TFT LCD interface, besides above technical considerations, target use environment and bandwidth are two main factors as well. You can read more about how to choose LCD interfaces here, or consult with us. Topway has been manufacturing TFT LCD in the past 20s years. Our TFT LCD modules cover full spectrum of interfaces. And we surely can suggest a TFT LCD display that suits your use case.

TFT LCDs have become the norm for small-to-medium size displays in a variety of products within industrial, medical, POS and consumer applications. Compared to passive-addressed monochrome LCDs, TFT displays offer higher contrast, wider viewing angles, faster response time and full color. And, TFT LCDs are now on cost parity with similar size passive LCD displays.

A typical TFT LCD module product consists of a TFT LCD panel, one or more COG (chip-on-glass) driver ICs, a backlight unit, and an interface FPC. Several TFT display interface technologies coexist today. Picking the right technology depends on specific end-product concerns. Most often the display panel input will dictate that choice since TFT panels are designed to be COG bonding pad compatible with a very limited number of driver ICs. This article discusses the interfaces between TFT LCD modules and the typical CPUs found in embedded applications.

Typical TFT interfaces are determined by the particular TFT panel size and resolution, as shown in the below table. HDMI and eDP require interface converting boards and generally are not used for small to medium-size TFT LCDs.TFT LCD SizesResolutionsTypical Interfaces UsedUp to 3.5″128×160 to 240×320SPI, parallel MPU or RGB

Only the three SPI signals, a CS, and a reset signal are needed. Drawbacks are the inability to read from the display, only write. Also, the frame rate is low and unsuitable for displaying video or high-resolution images.

The LCD controller signals are two types: data signals and control signals. The data signals are connected to the LCD data bus and depend on the LCD color depth (8-bit, 9-bit, 16-bit, 18-bit). The control signals are used to define the operation type (read or write), and whether the operation involves in addressing LCD registers or the display RAM.

An RGB interface is a special kind of parallel interface. This interface works for displays without a frame buffer. The MCU is responsible for updating the display, by providing both the RGB sub-pixel data (16-bit, 18-bit, 24-bit) and the timing signals (HSYNC, VSYNC, DE, CLK).

LVDS interfacing has several benefits for TFT displays. It is much less susceptible to EMI and crosstalk issues, allowing the transmitting device to be located farther from the display. Also, LVDS generally consumes less power, pin counts are lower and there are far fewer worries about signal integrity.

High-speed serial interface commonly used on smartphones and tablets. By standardizing this interface, components may be developed that provide higher performance, lower power, less electromagnetic interference and fewer pins than current devices, while maintaining compatibility across products from multiple vendors.

Modern TFT driver ICs are highly integrated chips combining the source driver, gate driver and timing controller (TCON) – as well as other functional circuits such as memory, power circuit, and image processors – into one single IC die. Some driver ICs support multiple interfaces that are selectable on the module FPC or through initialization code firmware.

As a designer and manufacturer of custom LCD modules, New Vision Display works with customers to select the most appropriate and cost-effective TFT display and electronic interface solution for their particular requirement. New Vision Display has nearly 30 years of industry experience as one of the world’s leading TFT LCD screen manufacturers.

In this Display 101 article we discuss thedigital parallelRGB LCD display interface and how the row and column driving signals are generated from the digital parallel RGB interface.

An LCD display consists of an array of liquid crystal segments. The crystal itself doesn’t emit light. With no electrical field, crystals organize in a random pattern. When an electric field is applied, the crystals align to the electrical field. Various strength of electric fields works like a “gate” to pass different intensity of backlight through the crystals. If the crystals are aligned perpendicular to the backlight, then the backlight can’t pass through the crystals. [1]

How to generate a specific color for a pixel? Each pixel is composed of 3 segments that individually pass light through a red, green, and blue filter, to make an RGB display color pixel. For a 320*240 RGB TFT display, there are 960 (320*3) columns and 240 rows.

Most LCD displays have a digital parallel RGB interface. It works between the graphic controller as a signal source and the input of the RGB display module.

The image data is transmitted digitally as “0 ”or “1 “ by TTL voltage levels. For the RGB interface, each of the signals has a corresponding line. Below are the signal connections of the LCD RGB display interface of 24 bits per pixel.

Royal Display is one of the leading Parallel interface TFT LCD Display Modules, 8-bit Parallel Interface TFT LCD Display Module, 16-bit Parallel Interface TFT LCD Display Module, 24-bit Parallel Interface TFT LCD Display Module, CAN Interface TFT LCD Display Module, MIPI Interface TFT LCD Display Module, Arduino interface TFT LCD Display Module, Raspberry PI Touch display supplier, wholesaler, stockist, and exporter in Mumbai, India, sourcing products from trusted and reliable vendors.

Parallel interface TFT LCD Display Modules Latest price | Parallel interface TFT LCD Display Modules datasheet files| Parallel interface TFT LCD Display Modules stocks | Parallel interface TFT LCD Display Modules photos| Parallel interface TFT LCD Display Modules compatible models.

Royal Display is a custom Parallel interface TFT LCD Display Modules, 8-bit Parallel Interface TFT LCD Display Module, 16-bit Parallel Interface TFT LCD Display Module, 24-bit Parallel Interface TFT LCD Display Module, CAN Interface TFT LCD Display Module, MIPI Interface TFT LCD Display Module, Arduino interface TFT LCD Display Module, Raspberry PI Touch display manufacturer serving OEMs across many markets and have extensive market and product development experience. Parallel interface TFT LCD Display Modules are available at Royal Display from industry leading manufacturers. Royal Display is a reliable Parallel interface TFT LCD Display Modules supplier and exporter in India. We operate worldwide, service products, configure, and also offer logistics support to deliver products and services competitively. Royal Display is an authorized distributor for many Parallel interface TFT LCD Display Modules manufacturers.

Royal Display has built its reputation by offering advanced products and has a very wide range standard Parallel interface TFT LCD Display Modules and is open for any customized display requests. The Parallel interface TFT LCD Display Modules have been in demand in industries such as for the measurement of instruments, Electronic Panels, ATM terminals, PoS terminals, auto vending machines, Manufacturing, Automotive Display in Electric Vehicles, the digital videos, video games, and machine tool monitors, GPS, fish finders, POS systems, advanced imaging and colour reproduction technologies, mobile phones, elevator displays, and medical devices etc.

Parallel interface TFT LCD Display Modules Latest price | Parallel interface TFT LCD Display Modules datasheet files| Parallel interface TFT LCD Display Modules stocks | Parallel interface TFT LCD Display Modules photos| Parallel interface TFT LCD Display Modules compatible models.

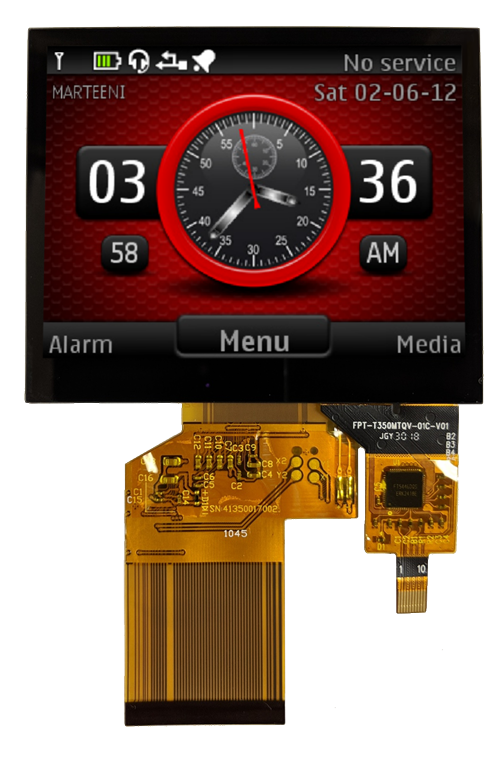

This graphic display module is a 2.4" diagonal, full color TFT. Suitable for embedded applications, it is low-power, uses a white LED backlight, and has an integrated touch panel which has its connection brought out to the main TAB connector for the display.

It has an on-board controller and 3v single voltage for supply and logic (backlight not included), so you can easily use any modern microcontroller to interface with this display. It uses an 8 or 16 bit parallel interface, specified via connections to the display.

The connector on the CFAF240320K-024T-TS is a flex tail mated with a "COG" (chip on glass) display construction. This style of connector is designed to be soldered directly to corresponding pads on your PCB by using a hot-bar soldering machine. High volume contract manufacturers will be familiar with this type of construction and its assembly methods. There are hot-bar soldering machines made that are designed for prototype, rework or repair work of TAB connections.

2129 lcd parallel interface products are offered for sale by suppliers on Alibaba.com, of which lcd modules accounts for 68%, lcd boards & accessories accounts for 1%.

The parallel interface typically controls the LCD via 8 data pins and 3 control lines. The control lines used are Enable (E), Register Select (RS), and Read/Write (R/W). RS tells the LCD module if the information being sent is an Instruction or Data. The Enable tells the LCD module that the data or instruction in the register is ready to be interpreted by the LCD Module. Some controllers may have more than one Enable Control Line. The Read/Write tells the module whether to write data or read data from the register.

Serial LCD controllers typically have one Serial Data Line that writes data and cannot read. Normally, a Register Select Line(Sometimes designated A0) is used to tell the controller whether the incoming data is display information or a controller command

SPI, or Serial Peripheral Interface bus, is a synchronous (data is synchronized to the clock) serial data link standard that operates in full duplex mode, which means that devices that can communicate with one another simultaneously. To do this, two data lines are required. With this standard, devices communicate in a master/slave mode, where the master device (host processor) initiates the data and the clock. The LCD module is the (or one of the) peripheral slave device(s) attached to the data bus. Multiple peripherals (display modules and other devices) are addressed on the same serial data bus. However, the LCD module will only listen to the data it sees when the Chip Select line is active (usually low). If the Chip Select line is inactive (usually High), the LCD module listens to the data on the bus, but ignores it. The SDO line is not active when this state occurs. The SPI bus is comprised of four logic signals, two control lines and two data lines and is commonly referred to as SPI (4 wire).

The chip select signal CS is optional for a single device system, because you could tie the CS input at the LCD Module low, if the other lines are dedicated to SPI use. This is sometimes called a 3 Wire SPI Interface.

SPI Data transmissions usually involve two shift registers. Most display module applications normally use 8-bit words. However, different size words, such as 12 bit, are also used. By convention, the most significant bit is shifted out of one shift register while the least significant bit is shifted in. The word is then written into memory if the CS (chip-select) is low (active). If not, the data is ignored.

Since the SPI interface protocol is a de facto standard, many variations of the standard protocol are used. For instance, chip manufacturers may use some of the parallel data lines when configuring the IC driver chip for serial communication. chip manufacturers may use some of the parallel data lines when configuring the IC driver chip for serial communication.

I2C uses only two bi-directional lines, Serial Data Line (SDA) and Serial Clock (SCL), which are both typically pulled up with resistors. Typical voltages used are +5 V or +3.3 V. One of the strengths of the I2C interface is that a micro can control multiple devices with just the two I/O pins and software. Because of the I2C design, it is only half-duplex. The interface generally transmits 8-bit words, sending the most significant bit first.

Connector ports for devices such like cameras, displays, basebands, and RF interfaces are standardized under MIPI Alliance specifications. These specifications include design, manufacturing costs, structural complexity, power consumption and degree of EMI.

Take your design to the next level with our range of TFT Displays including latest IPS TFT, circular and bar shape as well as large size TFT. With or without touch, these are fully customisable to your system requirements.

TFT-LCD technology is now fairly mature. As a result, manufacturing processes are efficient and production yields are high, leading to very competitive unit prices. Upgrading from a monochrome display to a TFT is now an affordable way to give your product an uplift.

Users of industrial display devices are wanting the same experience they have come to expect from a consumer device with all-round viewing angles. Switching to a superior IPS TFT display has become very cost effective as production increases and unit prices decrease.

Choosing a circular display for your next product design could really set you apart from your competition. Models are available from 1" to 4.2"in TFT, PMOLED and AMOLED, we have something to suit every application.

It is now possible to transform from a monochrome display to a colour display in space constrained systemsby using a letterbox shaped display. These ultra-wide displays are ideal for applications with restricted build height such as rack mount systems or landscape format front panels.

Large TFT display systems are increasingly being used for transportation information, retail signage and vending machines and kiosks. We can supply a large range of TFT solutions up to 65" diameter and in bar-style, square or rectangular configurations.

We are now offering increasing cover lens customisation options and processes to make your TFT LCD user interface truly stand out! Anders’ experienced marketers and engineers work with our manufacturing partners around the world to keep informed of the latest innovations, including mirrored glass,tinted glass, spot-facing, three dimension glass, and many more!

Here at Anders we don"t just strive to design a best in class display solution for your product, but we also want to make sure the display is driven with the right embedded system. We can help achieve a hardware solution that ensures your display works perfectly within your application. Hardware solutions include:

Get started quickly on your new user interface with our HMI development kits. The display, the processor and the OS work together out of the box with optimised QT GUI images. We"ll then optimise the kit to meet exactly your system requirements with our design services.

At Anders we understand that no two customers are the same, which is why we specialise in custom display solutionsand offer unique productstailored to your end application.

See below our range of TFT Displayswith sizes ranging from0.96" to 64.5" and including circular and bar type shape. All our displays can be tailored to suit your application antimicrobial coating technology,

We aim to offer reliable and long-term solutions to our B2B customers. If you are a business and would like to discuss your display and/or embedded system requirements please contact us below

A TFT display is a form of Liquid Crystal Display with thin film transistors for controlling the image formation. The TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen.

There are many display technologies, but do you know which one would be better for your application? Particularly when considering optimum viewing angle and contrast. We discuss 2 of the best options.

Compare IPS vs TFT displays - the TFT display is the display of choice for industrial designs, but it can have its limitations. A newer technology called IPS (in plane switching) offers better viewing angles and colours, but is it really the best choice - we discuss benefits and negatives of both types of TFT display.

Graphical displays can be more attractive when it comes to creating a flexible user interface. But, they require more CPU time to update the data than other display types, i.e., segmented or character displays.

The most popular type of interface used in display modules is the parallel interface. MCU (microcontroller unit) and RGB parallel interface are the two most common types of parallel interface.

MCU interfaces are available in two standard forms, Intel-8080 and Motorola-6800 series. These interfaces communicate through an integrated display controller and frame buffer.

We know that you might have some bubbling questions by now, such as, what is an Integrated display controller? What is a frame buffer? What do all of them get to do with the MCU interface? What is the difference between RGB and MCU interfaces?

The frame buffer is the memory space that holds the pixel data being displayed. There are internal frame buffers in smart displays that are stored on RAM. The MCU display interface reads the frame buffer every time to update the display.

The MCU interface progresses through frames at an increased rate to read pixels from the display controller. It can read and write data and display images directly from the internal memory.

Well, that completely depends on the deployable application of the displays. Different interfaces may exhibit diversified requirements in terms of processing speed and memory space.

Despite needing more pins, higher processing speed, and memory allocation, RGB display interfaces can be deployed easily in high-performance displays.

After a mutual comparison of features and working mechanisms, we can conclude that choosing parallel MCU can be more advantageous for displaying images. These are less expensive and easily controllable.

Microtips Technology, a US-based LCD display manufacturer and distributor with global exposure, has been using both RGB and MCU interfaces in their TFT display panels and touch panel displays. However, most of their deliverables feature MCU interfaces primarily.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

Different displays have different characteristics, just tell Panox Display your application, and operating environment, Panox Display will suggest a suitable display for you.

But Panox Display is not a school, if customers don`t know the basic knowledge to design circuit board, we suggest using our controller board to drive the display.

First, you need to check whether this display has On-cell or In-cell touch panel, if has, it only needs to add a cover glass on it. If not, it needs an external touch panel.

If you don`t know or don`t want to write a display program on Raspberry Pi, it`s better to get an HDMI controller board from us, and Panox Display will send a config.txt file for reference.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey