tft display parallel interface factory

This article about TFT display interfaces was written by Julia Nielsen. Julia Nielsen is a jack-of-all-trades writer, having written for newspapers, magazines, websites, and blogs for the last 15 years. When she’s not dabbling in the written word, she’s spending time with her beautiful granddaughter. She loves to hear from readers, especially when they offer chocolate.

Display technology has evolved at lightning speed for the last number of years, as opposed to when even the most sophisticated products incorporated numeric or segment displays and alphanumeric or character display technology. The same products also required buttons which have been replaced with resistive and capacitive touch panels.

When color TFT (Thin-Film Transistors) first came onto the stage, they created a buzz in the tech world that hasn’t stop buzzing since. TFT utilizes a type of display that controls each pixel with a transistor, allowing it to individually address each location.

As TFT yields improved with mass production, manufacturing, as well as healthy competition, TFT displays have soared in production performance and dived in price. Because of this, TFTs are considered the de facto standard of displays that boast of full color, brightly backlit (high NIT counts), high video speeds, better viewing angle, specifically for mobile devices and other small devices needing clear displays, such as phones, watches, security systems, and the like.

OLED (organic light-emitting diode) are increasing in popularity, but are still second to TFTs. Much of this is due to the long lead time and shorter half-life of the OLED displays. Although we offer OLED technology, we recommend TFT for the majority of the new design requests we receive.

There are several types of TFT display interfaces which have been designed in the last number of years for all variations of screen size, including LVDS, (Low-Voltage Differential Signaling) parallel, SPI (Serial Peripheral Interface) and I2C or I²C (aka I squared C) display.

LVDS is a differential signaling system, meaning it transmits information as the difference between the voltages on a pair of wires. Its popularity comes from the benefit of reducing noise levels and low power consumption, which results in even more benefits, such as lower heat dissipation and longer battery life; and because the differential drivers can be included on the LVD interface, smaller parts count, lowered parts cost, and increased reliability is a win-win for businesses and consumers.

Commercial and military, as well as aerospace applications also use LVDs in their products for a robust, long-term solution for high-speed data transmission needs. Flat panel displays, printers, digital copiers, and even cell phones incorporate LVDs to provide an excellent display quality. There are different types of LVDS protocols. When looking for the right LVDs, consider data rate, operating temperature range, and supply voltage, using these filters.

Note: Most TFT displays will operate down to -30C without the need of a heater. OLEDs will operate down to -40C without a heater, but OLEDs that are larger than 3.5” are much more expensive and have a longer lead time than TFTs.

Parallel interface or parallel port is a type of display interface found on computers for connecting peripherals. In the past, most people associated a ‘parallel’ interface with a printer port. This type of interface refers to a multi-line channel with each line capable of transmitting several bits of data on each simultaneously (bi-directional) or parallel to each line.

Newer PC’s have eliminated parallel interfaces in exchange for fire wire, USB2 and USB3. Parallel interfaces are still the most common for several LCD technologies such as character and monochrome graphics.

Parallel interface is nothing new, going back to the beginning of the 1970’s in its development and implementation. The first printer to use the interface was the Centronics 101 model printer, which became the standard at that time. But because a number of cables were required, Dataproducts and other developers had to create up to 50-pin connectors.

Fast forward to 1981 and IBM introduced their computers and printers with a 25-pin connector on the PC end and a 36-pin connector on the Centronics printer, thus the parallel interface had evolved to using both systems. In 1987, IBM introduced a bidirectional parallel interface. Since then, the parallel interface has evolved, with other companies developing their own, with even more parallel ports, including scanners.

Since technology has advanced exponentially in the last decade, so has the parallel interface, evolving to include supercomputers that allow for high-performance interfaces and network storage devices. These super performance display interfaces are capable of transferring billions of bits of data per second over short distances on local area networks. Graphical printers, along with a variety of other devices have been designed to communicate with the parallel ports including:External modems

Some of the early MP3 players and digital cameras also used a parallel port connection for transferring songs to a device, so you can see how far back the interface has been utilized in electronics.

Serial Peripheral Interface allows the serial (one bit at a time) exchange of data between two devices. A master, which controls one or more devices. Each device has its own slave connection. The master can interface with multiple slaves independently.

The term SPI was coined by Motorola and is typically used in communication systems between the CPU (Central Processing Unit) and peripheral devices (Any computer device not part of the essential computer, but situated close by). Serial interfaces have an advantage over parallel ones, that of simpler wiring. They can also have longer cables since there is much less interaction or crosstalk among the conductors in the cable. Many types of devices use SPI, such as:Shift registers

A key difference between SPI and Parallel is that with a serial interface, it only allows for transferring data one bit at a time but decreased the pins required, as opposed to the parallel, which allows multiple bits at a time, but requires more pins (8 data pins and 3 controllers). The downside with a SPI is that you can’t read from the display you can only write on it, and it’s typically slower.

I²C, Inter-integrated Circuit pronounced I-squared-C or I-2-C for a less technical term, is a serial protocol for two-wire interface to connect low-speed devices like micro-controllers, EEPROMS, A/D and D/A converters, I/O Interfaces and other peripherals in embedded systems. It was designed to allow easy communication between components which reside on the same circuit board. I²C only requires two wires: SCL (serial clock) and SDA (serial data). It is a multi-master, multi-slave, single-ended, serial-computer bus, (a communication system that transfers data between components inside a computer or between computers) and was invented by Phillips Semiconductor.

SMbus, (System Management Bus) developed by Intel in 1995, is a subset of I²C, which defines the protocols more strictly. Modern systems employ rules and policies from SMbus, sometimes supporting both systems, requiring minimum reconfiguration. Since 1982, there have been seven revisions to the I²C interface, and has evolved, as every other interface, with new technology always on the horizon.

As far as these two TFT display interfaces, we find that SPI is more popular than I2C when designing a custom LCD. We get hit with questions such as:Why is SPI more popular than I2C?

TFTs and OLEDs are standard, off-the-shelf displays that come with the interface already chosen for you. In many of the TFTS that Focus Display Solutions offers, the built-in controller allows the user to select from multiple display interfaces. Including RGB (Red, Green, Blue).

As a general rule, the larger the display the better it is to choose a LVDS interface since it transfers data so quickly. LVDS is more expensive than SPI, I2C, RGB and parallel. If you are not sure which display to use, try our online Quick LCD selector tool. The displays in this selector tool are in-stock and can ship the same day.

Need a LCD for a new project? Not sure which technology to choose? Contact a real human at Focus Displays now to begin your design process by calling us at 480-503-4295. Or, you can fill out the contact form and we"ll email or call you immediately.

A TFT LCD display module consists of a TFT LCD panel, one or more COG (chip-on-glass) or COB (chip-on-board) driver ICs, a backlight, and an interface. Several TFT display interface technologies exist today. Picking the right interface depends on specific end-product concerns. There are several types of TFT display interfaces which have been designed in the last number of years for various screen sizes, including LVDS, (Low-Voltage Differential Signaling) parallel, SPI (Serial Peripheral Interface) RGB and so on. Here is an overview of these display interfaces to give you a better idea of the variety of TFT LCD displays that are taking center stage.

SPI LCD Interface: Serial Peripheral Interface allows serial (one bit at a time) exchange of data between two devices. It has an advantage over parallel ones, that of simpler wiring. SPI also can have longer cables, since there is much less interaction or crosstalk in the cable. The downside of SPI is that you can"t read from the TFT LCD display, you can only write on it and it is slow. That"s why you normally see smaller TFT LCD screens use SPI.

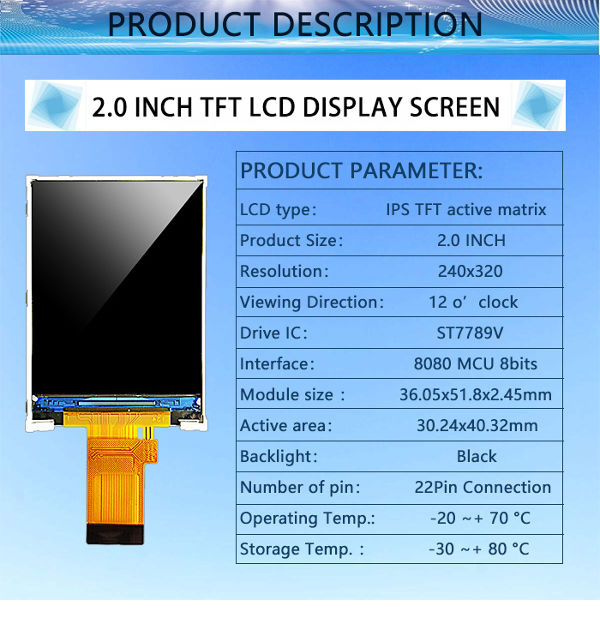

MCU Parallel Interface: Many modern MCUs have built-in LCD controller function. There are two types that are commonly used, 6800 and 8080. Generally, MCU/Parallel interface consist of data signal(4/8/9/16 bits) and control signal. MCU interface is simple, but requires display RAM.

RGB Interface: RGB interface is a special kind of parallel interface. It requires no display RAM. MCU directly updates the TFT screen, sending Red Green & Blue sub-pixel data (16/18/24 bits) and timing signals. RGB interface provides high speed communication to TFT LCD, but it needs more data wires and controlling is more complex.

LVDS Interface: Low-voltage differential signaling is an electrical digital signaling standard. Devices with LVDS interface can communicate at very high speeds over inexpensive twisted-pair copper cables. It is much less susceptible to EMI and crosstalk issues, allowing the transmitting device to be located farther from TFT LCD display.

UART/RS232/RS485: These serial interfaces are used in Topway"s Smart TFT LCD display module. Universal Asynchronous Receiver/Transmitter (UART) is a block of circuitry responsible for implementing serial communication. Essentially, the UART acts as an intermediary between parallel and serial interfaces. On one end of UART is a bus of eight-or-so data lines (plus some control pins), on the other is the two serial wires – RX and TX.

HDMI Interface: High Definition Multimedia Interface is a connector and cable definition that supports high-quality and high-bandwidth streams of video and audio between devices.

MIPI DSI: MIPI Display Serial Interface defines a high-speed serial interface bewteen host processor and display module. The interface facilitates a high performance, low power and low EMI way to render brilliant color for the most dempanding image and video scenes.

To choose your product"s TFT LCD interface, besides above technical considerations, target use environment and bandwidth are two main factors as well. You can read more about how to choose LCD interfaces here, or consult with us. Topway has been manufacturing TFT LCD in the past 20s years. Our TFT LCD modules cover full spectrum of interfaces. And we surely can suggest a TFT LCD display that suits your use case.

Orient Display sunlight readable TFT displays can be categorized into high brightness TFT displays, high contrast IPS displays, transflective TFT displays, Blanview TFT displays etc.

The brightness of our standard high brightness TFT displays can be from 700 to 1000 nits. With proper adding brightness enhancement film (BEF) and double brightness enhancement film (DBEF) and adjustment of the LED chips, Orient Display high brightness TFT products can achieve 1,500 to 2,000 nits or even higher luminance. Orient Display have special thermal management design to reduce the heat release and largely extend LED life time and reduce energy consumption.

Our high contrast and wide viewing angle IPS displays can achieve contrast ratio higher than 1000:1 which can make readability under strong sunlight with lower backlight luminance. High brightness IPS displays have been widely accepted by our customers with its superb display quality and it has become one of the best sellers in all our display category.Transflective display is an old monochrome display technology but it has been utilized in our color TFT line for sunlight readable application. Orient Display has 2.4” and 3.5” to choose from.

Blanview TFT displays are the new technology developed by Ortustech in Japan. It can provide around 40% of energy consumption for TFT panels which can use smaller rechargeable or disposable batteries and generate less heat. The price is also lower than traditional transflective TFT displays. Orient Display is partnering with the technology inventor to provide 4.3” and 5.0”.

Orient Display can also provide full customized or part customized solutions for our customers to enhance the viewing experience. Orient Display can provide all the different kinds of surface treatments, such as AR (Anti-reflection); AG (Anti-glare), AF (Anti-finger print or Anti-smudge); AS (Anti-smashing); AM (Anti-microbial) etc. Orient Display can also provide both dry bonding (OCA, Optical Clear Adhesive), or wet bonding (OCR, Optical Clear Resin and OCG, Optical Clear Glue) to get rid of light reflective in air bonding products to make the products much more readable under sunlight and be more robust.

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch.

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

Engineers are always looking for lower cost, faster, more convenient interfaces to transmit signals and to accept data and commands. The numbers of available interfaces available in the market can be dazzling. Orient Display follows market trends to produce various kind of interfaces for our customers to choose.

Genetic Interfaces: Those are the interfaces which display or touch controller manufacturers provide, including parallel, MCU, SPI(,Serial Peripheral Interface), I2C, RGB (Red Green Blue), MIPI (Mobile Industry Processor Interface), LVDS (Low-Voltage Differential Signaling), eDP ( Embedded DisplayPort) etc. Orient Display has technologies to make the above interface exchangeable.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

HGM9560 Bus Tie Mains Parallel Unit is designed for manual/auto parallel system which composed by gensets and one-way/multi-way mains. It allows automatic start/stop and parallel running function. It fit with LCD display, graphic display, optional Chinese, English and other languages interface, and it is reliable and easy to use.

HGM9560 Bus Tie Mains Parallel Unit has multiple running states when it is parallel with mains: Genset output fixed active power and fixed reactive power; Mains peak lopping; Provide fixed power to mains; Load takeover; No-break return to mains supply.

The powerful 32-bit Microprocessor contained within the unit allows for precision parameters measuring, fixed value adjustment, time setting and set value adjusting and etc..Majority parameters can be configured from front panel, and all parameters can be configured by USB interface (or RS485) to adjust via PC. It can be widely used in all types of automatic genset parallel system with compact structure, simple connections and high reliability.

2. 480x272 TFT LCD with backlight, multilingual interface (including English, Chinese or other languages) which can be chosen at the site, making commissioning convenient for factory personnel;

A: Small sized of displays generally support SPI,MCU,RGB,MIPI.Medium sized displays generally support LVDS,MIPI,EDP.Different specifications use different interfaces.

Have you ever asked yourself what LCD is? No worries, we are here for you. Therefore, like in any display gadget, liquid crystal display coordinates with a microprocessor or microcontroller. The MCPU and MCU send the brightness that every pixel should produce. It creates the required color of the pixel for your LCD screen.

However, the mode of communication between the MPU/MCU and an LCD segment is known as the interface. We shall discuss more of the LCD interface in this guide.

The LCD interface is a link between the flat panel display module and the multimedia processor. Therefore, the interface can be separated or incorporated as part of the structure on the chip. Additionally, the application produces an image, and then the screen displays it using an LCD interface for the user.

The Serial Peripheral Interface is a data bus with several lines for the data. It accurately harmonizes the two ends of the data transmission. Therefore, the signal clock rotates, indicating when to sample the data bits on the line.

Besides, the serial peripheral interface has another component known as the slave select (SS) or chip select. The function of the SS is to wake the peripheral to receive or send data. For instance, since the SPI can support several peripherals, the SS can wake particular peripherals instead of all. Finally, you can use the SPI in graphic, character, digit, and small TFT LCDs. It allows simple interfacing, affordable hardware, and faster speeds than in the SCI.

It is another serial interface in LCDs that resembles the SPI with slave, clock functions, and master. The I²C does not integrate the SS line as in SPI. Therefore, a process known as addressing is essential in selecting a slave to communicate. A frame of the signal is sent on the data bus to address a specific slave after the first bit. Nevertheless, the output signal gets to every slave connected with, although only the slave with the corresponding address to the signal will receive the message.

The MCU interface is essential because it can write and read data stored in the internal frame bugger or the gadget"s storage. Therefore, if you want to store images for future use, MCU is the best match for you.

Additionally, in MCU parallel interface for Liquid Crystal Displays, data signals are sent through data lanes on either 18-bit, 16-bit, 9-bit, or 8-bit data channels. Besides, the MCU interface is simple, although it requires a display RAM for its memory functionality. Also, you can use it in graphic LCDs, character LCDs, and small TFT LCDs.

LVDS is an acronym for Low-Voltage Differential Signaling. This type of interface is essential as a complement for large LCDs and peripherals that require high bandwidth, such as HD graphics and fast frame rates. Therefore, it is a good choice due to its fast data transmission while consuming low voltage. One of the LVDS interface wires carries the precise inverse of its companion. Additionally, the electric charge from one wire is correctly masked by the other wire, reducing the interference to the wireless system nearby. Finally, at the recipient end, a circuit checks the variation in voltage between the two wires.

Red Green and Blue (RGB) interface functions are to link with color displays. It transmits 8 bits of data for each of the colors in every clock oscillation. Therefore, this means there are 24 bits of data sent for every clock oscillation.

Currently, you must have seen an improvement in terms of performance as electronic devices become smaller and easy to use. Therefore, this has led to the introduction of an embedded display port. The interface connects a video device to a display device and carries USB, audio, and other data forms. Moreover, this display port offers a high-performance external A/V interface hence high display resolutions of 4K. Additionally, the motive behind the development of this interface is due to several computing requirements. First of all, the main requirement is hardware integration.

This is a new technology development from the MIPI alliance. Mobile Industry Processor Interface has become a preferred option for mobile developers. This interface uses the same signaling as in LVDS. It uses a clock pair and 1-8 data lanes. Mobile Industry Processor Interface supports complex rules that allow low power and high-speed modes. Additionally, it reads data coming from the display at low rates.

When choosing the correct display interface for your device, you need to consider several factors. Therefore, it requires you to know how to connect the display to your electronic system. Nevertheless, it would be best if you choose the correct interface for your display. Additionally, consider the amount of data transferred and the refresh rate your system requires.

Finally, we have made it easier as we have given you all the details on each display interface, including the pros and cons. Therefore, having gone through our guide, you will never have issues when making your choice.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey