tft lcd colour problem arduino factory

Can this be a fault in my wiring? (is it possible to connect the wires in such a way that this happens. Seems unlikely as there are no separate color connection pins on the tft unit)

Think is, before I try to modify any library to bend it for the STM32L0 I wanted simply to check my SPI configuration by issuing a simpliest thing, reading LCD ID registers. But that"s the thing, I do not receive any data from ILI9341. I guess all registers are accessible right after the proper reset of the ILI9341, right? So, here is my "init" procedure:

please, see attached screen from my logic analyzer. You can see, CS is brrought low followed by eight clock pulses (500 kHz period) on SCK and 0x04 MSB first on the MOSI and with the DC set low. Afterwards, there is sequence of 4 dummy 0xFF bytes to push out the desired data out from the ILI9341 SPI buffer with the DC set high. But as you can see, there are only zeros on MISO line. Of course, the CS is brought up at the end. I"ve checked the wiring 10 times and I don"t think it is the problem. Maybe, are really all register accessible right after the start of the ILI9341? Or do I have to wirte some data somewhere first?

one is a hardware fault, the other is a software problem. Although only these two big aspects but involved in the details of the aspect is very much, the following details about the display color abnormal possible reasons and solutions.

Monitor color is not normal, we recommend the first use of the elimination method, as far as possible to eliminate some simple problems. There are many reasons leading to the abnormal display of the display color, such as checking whether the display data line is normal, the display color control panelis not set well, poor contact, or rust of the display wire may lead to such problems.

A kinescope-tube failure can cause this problem, but it is not irreparable – minor electric shocks, serious rewound filament power supply windings, and sometimes the visual discharge power supply resistance of a particular electron gun is miswelded or broken or the resistance value is increased.

Some people think that this kind of fault is the problem of the line circuit of the monitor — it may be the poor thermal stability of the line tube, the reverse diode, reverse capacitor, and other components or the result of virtual welding. This is completely wrong because none of these components can affect the clarity of the image.

The real failure point of the type 1 fault phenomenon is usually due to the aging of the focusing knob of the FBT. You can try to replace an FBT first. Of course, if the monitor has been in use for more than six years, then we need to take into account the possibility of tube aging. In addition, it may be the tube seat of the picture tube and the large area of the negative copper foil leakage phenomenon caused by the displacer (after analysis like design problems), so sometimes into a maintenance dilemma after the replacement of a genuine tube seat try.

The type 2 fault phenomenon, is usually caused by the poor quality of the picture tube holder. You can solve the problem by replacing it with a new one.

The poor contact of the video card usually causes the failure of starting up and there is an alarm sound or the system is unstable resulting in a crash and other failures. The reason for the poor contact of the graphics card is that the gold finger of the graphics card is oxidized, dust, the quality of the graphics card is poor or the baffle of the case has a problem. For the golden finger oxidation caused by poor contact, can use an eraser to wipe the golden finger to solve; For dust caused by poor contact, general removal of dust can be solved; For the hardware quality caused by poor contact, usually through the replacement method to detect, generally replace the video card to solve; For the case baffle problem caused by poor contact, usually the video card can not be fully inserted into the video card slot, can be replaced by the case to eliminate.

The failure of the graphics driver usually causes the system unstable crash, flower screen, text image graphics card is not complete, and other fault phenomena. The video driver’s fault mainly includes the loss of the video driver, the video driver is incompatible with the system, the video driver is damaged, and the video driver cannot be installed. For the video card, driver failure generally first enter the “device manager” to see whether there is a video card driver, if not, re-install. If so, but the graphics driver has a “!”, the video card driver is not installed, the driver version is not correct, the driver and the system are not compatible. Generally, remove the video card driver reinstall, if installed after there are “!”, you can download the new version of the driver installation. If you cannot install a graphics driver, there is usually a problem with the driver or with the registry.

Video card over frequency problem refers to the time spent to improve the video card speed, improve the video card’s working frequency, and lead to computer failure. When a problem occurs, the frequency can be restored to the factory default.

If the fault is serious, the maintenance requires that you must have certain hands-on ability and professional knowledge, so the author suggests that if you still have not been repaired after eliminating the simple cause of the fault, please deliver it to the electrical maintenance department for treatment. Sometimes some magnetic objects (such as some low power box or ADSL cat power supply, etc.) placed near the display will cause a certain Angle flicker on the screen, so when this phenomenon to try to clear the display around the objects to see, usually the problem can be solved.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

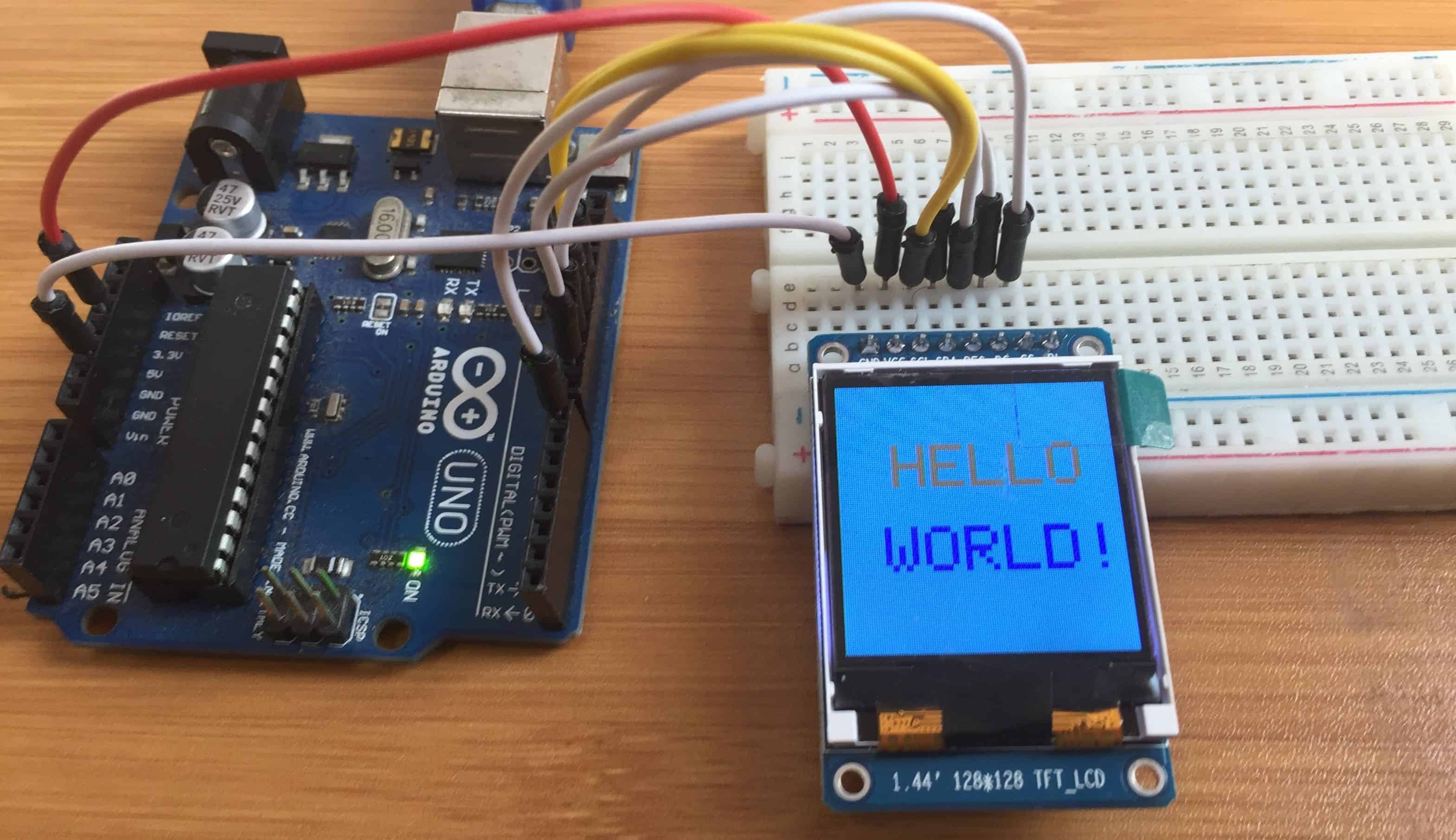

The purpose of this guide is to get your 0.96″ color LCD display successfully operating with your Arduino, so you can move forward and experiment and explore further types of operation with the display. This includes installing the Arduino library, making a succesful board connection and running a demonstration sketch.

Although you can use the display with an Arduino Uno or other boad with an ATmega328-series microcontroller – this isn’t recommended for especially large projects. The library eats up a fair amount of flash memory – around 60% in most cases.

So if you’re running larger projects we recommend using an Arduino Mega or Due-compatible board due to the increased amount of flash memory in their host microcontrollers.

(As the display uses the ST7735S controller IC, you may be tempted to use the default TFT library included with the Arduino IDE – however it isn’t that reliable. Instead, please follow the instructions below).

Please check that the library has been installed – to do this, select the Sketch > Include Libraryoption in the IDE and scroll down the long menu until you see “ER-TFTM0.96-1” as shown below:

The display uses the SPI data bus for communication, and is a 3.3V board. You can use it with an Arduino or other 5V board as the logic is tolerant of higher voltages.

The library used is based on the uTFT library by Henning Karlsen. You can find all the drawing and other commands in the user manual – so download the pdf and enjoy creating interesting displays.

I found the TFT screen and Uno on Banggood.com about a month ago and over the weekend I was messing with the pair and found the tftbmp draw code in the demo.. I extended it with the ability to read any bmp file on the SD card.. so all you do is put your bitmaps on the SD and plug it in.. Having to add/edit/recompile/reload the Uno everytime is BS... Here is my code:

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

Image sticking (Ghosting)Sometimes, you will find the previous image still appearing at the background even if you change to another image. It is also called burn in. This kind of failure doesn’t need to repair by professionals. You can simply shut off the display overnight, this kind of problem will go away. Please do remember that displaying a static image for a long time should be avoided.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD (Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

Sometimes it feels like everyone out there is using Arduino. It’s easy to find tutorials and libraries to get things working with Arduino, but if you want to use another platform you might have more trouble. [Tahmid] ran into this problem when he decided to try using a PIC32 to control a 2.2″ color TFT display from Adafruit.

Adafruit is really good about providing tutorials and Arduino libraries for their products. It makes it really easy to get up and running… if you are using Arduino. All of their libraries are open source, which means that the community can take them and modify them as needed. [Tahmid] decided to do exactly this and fork the Adafruit libraries over to the PIC32 platform in C. It’s a great learning experience. You get to see how (good or bad) other people code, and it immerses you in the differences between two different chip families.

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey