petroleum jelly lcd screen manufacturer

Magic erasers are usually used for cleaning up messes, but could they clean up scratches? Yup. It wiped out small scratches on the phone"s screen in just a few seconds. Taylor Martin has a tutorial on how to make your own magic erasers for just around $0.10 (£0.07 or AU$0.14) each.

Wiping a screen with toothpaste (not the gel kind) supposedly works for fixing scratched screens. All it did in my tests was make the screen shinier and seemed to add small abrasion marks. I also tried toothpaste on a plastic screen protector, such as the kind that comes with OtterBox phone cases. It worked great on that! So it"s a no for screens, but a yes for plastic screen protectors.

Car waxes and headlight lens creams are supposed to be effective at removing scratches on screens, so I gave Mothers PowerPlastic 4Lights headlight cream a try. It made the scratches fade significantly, and l liked the shine it gave my screen.

A paste of two parts baking soda to one part water has been bandied about as a great screen fixer. Nope. It just made the screen really shiny. Plus, the moisture in the paste could damage your device.

According to the internet, coconut oil can solve just about any problem. Shockingly, it didn"t work well on phone scratches. Like with the petroleum jelly, it just made the phone super slippery.

I wasn"t sure about this tip. Sites say to mix the corn starch with a little water to make a paste, rub it on the screen with a soft cloth, and then wipe it off. It didn"t do anything to the scratches, but it made the screen shiny.

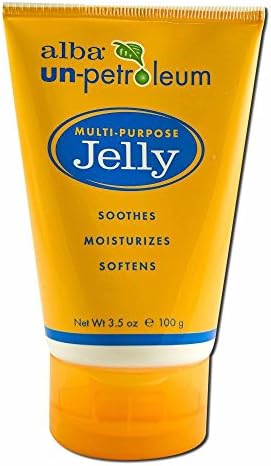

OK, this one freaked me out. A lot. Putting gooey, oily stuff on electronics is never a good idea, but I gave it a shot in the name of science. I dabbed a bit on as recommended, and rubbed it into the screen with a tissue. As I feared, all it did was make the test screen oily and sticky.

Why do people think it"s a good idea to rub food on their phones? Nope, rubbing a banana peel on your screen won"t help it. I tried it a couple different ways and it just left a crusty mess that is hard to remove.

Powdered cleanser like Bar Keepers Friend, Comet, Ajax and the like seem a good idea for buffing out scratches. They are slightly abrasive, so you"d think they"d polish your screen to a gleaming scratch-free shine. Well, they don"t. They can even leave new little scratches on your screen. Yah, this test didn"t go well.

With the importance of home entertainment in a fashion society, many people choose to take a place in a very flat environmentDue to the previous crt TV, screen TV has several advantages over the previous TV.However, these new, more advancedlooking flat-Screen TV will usually come back with high value and it will become even more scary once your TV stops running.Fortunately, it"s much easier to troubleshoot and fix flat-screen TV problems than you think.Of course, repairs may still require a lot of changes, or even help from professionals, but this is higher than buying a brand new flat-screen TV.When it comes to repairing an apartmentScreen TV, there are a series of problems that can cause problems.The most common problem people seem to have is the screen and the picturerelated.As long as no matter the damage to the screen, there is no penetration of the plasma layer or LCD pixel behind the screen, repair the tabletScreen TV is possible.If the damage is too deep, it is necessary to replace all the TV.For scratched screens, different strategies for fixing the TV can be used.This includes the use of scratch kits, automatic rubbing compounds, and transparent paint or Vaseline.Different instructions;Remove theNo matter where the scratched space is, there is a strong light coating on the screen and carefully re-coverKeep in mind that the third technique may be temporary repair;This will, however, involve less risk.For small cracks, you will use the above-Named petrolatum technology.First, clean the surface of the screen world and block the cracks with a rag in diluted alcohol.Then, use a clean optician cloth to apply a large amount of Vaseline to the cracked space of the screen.Make sure the jelly is smooth, again, take any excess jelly from the screen.Oil is a fast, simple and economical solution;However, this is not a permanent solution, usually only for tiny cracks that don"t look easy to see.For huge cracks or cracks within the main focus of the screen, you may be more than happy to swap the screen completely.There are 3 options for those with a broken screen: buy a brand new TV, change the screen yourself, or have an expert do it.If you want to replace it, position the frame screw first, then screw all the screws.Take the frame of the TV and put it aside.The next step is to disconnect any cables that connect the frame and screen.Make sure you note where the wires go.After removing the broken screen, place the new screen in place and go back to the steps, insert the wire, re-Assemble the frame and fix the frame with screws.A common drawback of flat panel LCD TVs, especially plasma TVs, is LCD distortion, which has problems such as pixel death and LCD burning.There are many different solutions, however one costAn efficient approach requires an external DVD player (even if the TV comes with a built-in DVD player) and a composition correction DVD.Disconnect all devices outside the DVD player from the TV.Use the TV menu to navigate to the resolution to select the LCD and select the best resolution supported by the TV.Insert the constituent correction DVD into the DVD player and select the fix you want to perform, or use the code wizard to guide you through this method.Whether you"re looking for a brand new flat panel LCD, Motherboard or an alternative flat panel LCD TV component, eBay is a place worth a try to search for components for several TV models.Simply enter the keyword "flat panel LCD TV replacement parts" in the search bar to get a list of available items.You can improve your search by entering a lot of specific keywords.Since flat-screen LCD TVs are usually expensive, they can cause huge headaches when they are broken.If you keep throwing the remote control on the TV during an active campaign, don"t be afraid;It"s also much easier to fix a flat-screen TV than you think

The portable nature of laptops make them very useful, but also more susceptible to damage. Repairing the damage is often also costly because all the laptop components are integrated. The LCD screen of a laptop is particularly prone to scratches. Instead of paying to replace the scratched screen, you may be able to repair the damage, provided that it is not too severe, and save your business some money. When attempting the repairs, take the proper precautions to avoid doing even more damage.

You use your computer daily for business-related tasks including checking email, balancing finances and working on projects. If your computer"s LCD monitor is scratched, it"s difficult to see what"s on the screen. Severe scratches get in the way of your work and can compromise your productivity. If your computer has a glossy case, it is also prone to scratching. Computer case scratches do not affect the machine"s performance but look unattractive and could affect its resale value. Petroleum jelly and plastic polish will help you remove scratches and make your computer look almost as good as new.

Finally, when nothing else seems to have a positive effect, using a simple eraser may be worth a try. What Home Theater claims that a simple pencil eraser, or any type of soft rubber material, can slowly erase a scratch on a flat-screen television. This technique, however, is not recommended to be used alone.

LCD screens are fragile and prone to scratches. These scratches cannot be repaired but can be made less noticeable by following some simple methods. We will discuss some of these methods to fix scratches on an LCD.

Take a tsp. of petroleum jelly on a microfiber cloth and buff it across the entire LCD screen. It will give a shine to the screen and will also camouflage the scratches.

LCD (Liquid Crystal Display) screens are known for their clarity, good picture quality, and energy-efficiency. This is the reason they are widely used in almost all the devices, such as computers, TV, mobile phones, etc. These screens are very delicate and must be handled with care. But, no matter how many precautions you take, they are bound to get scratched. These scratches cannot be removed or fixed completely, but can be made less apparent with the help of some simple but effective methods.

Before any fixation, check the LCD’s warranty period. If you are under the warranty, then you will get a free repairing service from the company. In case the scratch is deep and long, then it is better to get it repaired from a professional.

You cannot fix the scratches completely on an LCD TV but you can camouflage them for a pretty good period. Following are some of the methods that you can follow to get the scratches fixed.

Method: Clean the surface with the help of water and cloth. Let it dry for sometime. Now take about 1 tsp. petroleum jelly and fill the scratches. Once all the scratches are filled, take a clean cloth and gently wipe off the extra jelly. You will see that the scratches are lighter, if not completely invisible. You may have to reapply if it wears off.

Method: First of all, prepare a cleaning solution. Dilute 1 part isopropyl (rubbing) alcohol with 20 parts of water. Now clean the scratched area with a cotton cloth dabbed in water. Let it dry. Dip another cloth in the cleaning solution and work on the scratch, cleaning the area gently. Keep cleaning till the scratch disappears. Now take the swab which was dipped in water, and clean the alcohol from the screen. The cleaning solution helps remove the scratch by dissolving the anti-glare coating which fills the scratched area.

You can easily get LCD scratch repair kits in the market under different brand names. These kits are specially made to remove scratches from any LCD screen. These kits generally contain a polishing paste and microfiber cloth. This kit will have simple instructions which you can follow and get the scratch fixed.

★ Do not rub anything against the screen, like a dirty or wet cloth, or any other material that may damage the screen. Even while cleaning, do not apply more pressure.

All the methods mentioned in this HomeQuicks article are helpful in fixing only small scratches. If the scratches are long and deep, then you either need to give it for repair, or get the LCD screen replaced. The best way to prevent scratches is to get an LCD screen protector, which will not only save your screen, but can also be easily replaced in case of damage.

Another option if its just a surface scratch would be to apply a bit of vaseline / petroleum jelly to the scratch and wipe off the excess, which can similarly hide the scratch, though in a less permanent way.

The raw materials that are extracted for use in a television come from many different sources, which makes the beginning of the television’s life cycle one that starts at many different places. One of the main types of materials used in televisions are plastics, namely thermoplastics such as polyethylene. Thermoplastics like polyethylene are used because they can be melted down and remolded repeatedly, which is part of the process in making the exterior casing of a television. Polyethylene is made from the polymerization of ethylene. Ethylene is produced from the cracking of ethane gas, which can be separated from natural gas. When the polyethylene is ready, it is molded into the specific shape that is required to encase a television, and is then set into that shape by using a thermoset. The thermoset is used to fix the meltable plastic in the shape that the plastic has been molded in, meaning that once the thermoset is fixed onto the plastic, the plastic cannot be melted again. The fixing of thermosets is necessary for electronic appliances like televisions that produce a significant amount of heat, so that the plastic that encases the television will not melt down. The most common thermoset used in televisions is urea formaldehyde. Urea formaldehyde is made by obtaining urea, a solid crystal, from ammonia gas, and by obtaining formaldehyde from methane gas. The two are then chemically combined to make the resin-like material that is used as a thermoset. Another main material that is used in most television is glass. Glass is the essential material that makes up the screen of a television, and is made from the chemical compound silicon oxide. All these materials are extracted and made in factories spread throughout the world, adding to the complexity of manufacturing televisions.

While plastics and glass are the main materials that make up the exterior of a television, the interior parts of a television are made up of a greater range of materials. Plastics are also used in the interior of a television, but inside of a television are also found gases and minerals. Gases such as argon, neon, and xenon gas fill the television screen for the purpose of projecting colors into the screen, and are made visible by the phosphor coating that coats the inside of a television screen. Glass and lead are also found inside of a television screen. These two materials make up cathode ray tubes, which are the video display components of a television. Other components that are found inside of a television also require thermoplastics like polyethylene, including components such as light valves, which work together with cathode ray tubes to enable the electrons inside to be visible on screen. The main electrical components on the interior of a television require a large amount of silicon; these include components such as the logic board, circuit boards, and capacitors. Once again, these materials are extracted and processed on several different continents. Silicon can be found in many different places, but a large supply comes from California. Meanwhile, many plastics are manufactured in China, while factories in the United States manufacture glass. These materials can be manufactured or extracted in other countries as well, which also helps to make the life cycle of a television a complex and global circle.

Once the materials that will make up the television have been extracted and processed, the assembled television is ready to be distributed. Once again, the distribution process of televisions is spread out all around the world. In the case of Americans, televisions are no longer manufactured in the United States. This means that the televisions must be shipped oversea to the United States, which is done by both plane and boat. Thus, the diesel fuel used to power both planes and cargo boats are used as raw materials in the life cycle of a television. The diesel fuel used in planes and cargo boats are usually kerosene based, which is obtained by distilling petroleum. Additionally, when the televisions get to the United States, they must be distributed by means of shipping trucks, which means the natural gasoline that they use are another addition to the raw materials that are involved in the life cycle of a television. As a final step in the distribution process, the televisions are usually packaged in cardboard boxes, which are commonly made from recycled paper. More plastic is then used to protect the television in the form of protective wrap such as bubble wrap. Bubble wrap is also made from the polyethylene that makes up many components of the television, making plastic a material that is essential to every stage thus far of the life cycle of a television, as well as being a material that makes the life cycle difficult to analyze.

Televisions are globally one of the dominant selling products in the technology sector. China is the primary manufacturer, being home to many of the preeminent selling TV companies such as TCL, Skyworth and others that partner with Chinese manufacturers such as Samsung and LG. Although the number of televisions that are produced per year is not a record the public has access to, it is estimated that there are seven-hundred and fifty-nine point three million TV sets connected worldwide in 2018 [14]. The cradle-to-grave of television production has five steps: the acquisition of raw and synthetic materials, the manufacturing process, the distribution and transportation, the use of televisions, and the disposal and recycling [9]. Energy application is present in each of the five stages of the complete life cycle of televisions, specifically the Liquid Crystal Display (LCD) model. The entire life cycle of televisions uses and produces energy that is not environmentally safe to human and animal health and the atmosphere. Even though television companies claim to be decreasing the environmental consequences, the immense presence of energy use throughout the cradle-to-grave of television production continue to result in hazardous effects.

The first step of the television life cycle, the acquisition of the materials, produces and uses the largest amount of energy of the steps. The acquiring process of the materials includes obtainment, collection, extraction, combination, and transformation of the raw and synthetic materials. The main materials are plastics, circuits, circuit boards, glass, metals and various materials such as indium-tin oxide and liquid crystal. Plastics make up the exterior pieces and layout of the television, as well as a fewer small pieces inside. Plastic is formed from crude oil or natural gas like fossil fuels, which have to first be mined from the earth’s core and then must be processed before the polymerisation process can be carried out. This process is used to chemically combine carbon monomers in order to form carbon polymers which make up plastic and give it it’s individual properties. Overall, plastics require motion energy and electricity to be mined and chemical energy to turn oil or natural gas into plastic. Circuits make up the various circuit boards along with minor metal or plastic pieces. The circuits are originally made of silicon dioxide, or silica, which must be extracted from the earth’s crust. More modernly, silica is being replaced by quartz by some manufacturing companies. Silica and quartz are both extracted from the earth using electricity and thermal energy through mining and extraction. Silicon dioxide is used in the circuit boards because it is a semiconductor, so it must be processed with drilling or thermal techniques to obtain the desired shape and form. The obtainment of materials for the circuits involves thermal energy and electricity through the multiple steps. Silicon dioxide is also the main component in glass which is made from heating sand or quartz with waste glass and soda ash into a liquid mixture to be molded into the desired solid shape. Thermal energy is the prime energy source in the transformation process of glass, but also the minor electricity source for the silica. The various metals that are found scattered through modern televisions include gold, lead and copper. Each of these metals must be mined and extracted from the earth requiring electricity and thermal energy must be applied in order to change the form into liquid to modify the shape for parts. Liquid crystal that is used in the Liquid Crystal Display (LCD) panels is found in various mineral forms and must be extracted using electricity. Indium-tin oxide (ITO) is “a scattered and rare element” that is found in the Earth’s crust, but is “challenging to [extract]” [4]. It actually does not exist as an ore itself but it is “mainly produced as a by-product of zinc mining” or lead mining [11]. The zinc and lead are mined using electricity and then using smelting techniques, which apply thermal energy, indium-tin oxide is processed out of the ores. The collection of the materials involves the extensive energy application of the varying types of energy. Once the materials are acquired, the manufacturing stage begins and the precarious energy utilization continues to grow.

The manufacturing phase applies the second most impactful energy use behind the first step, emitting hazardous effects in large, concentrated volumes. The production processes vary by manufacturer, but they generally contain assembly lines, machine tools and technology, automated robots and packaging. The plastic parts found throughout the structure and the inner parts are made using the well-adopted injection molding process. This process uses thermal energy to liquify plastic in order to be injected into the definite molds [5]. After they cool, they must be cut and sized-down to perfection with saws and cleaned manually for safety as well as appeal [5]. This requires electricity to function the saws and kinetic energy in human movements for the manual work [9]. The LCD panels are composed of a variety of substances and materials, the most prominent being indium-tin oxide, liquid crystal and metal pieces [2]. The panels are manually made adding the liquid crystal layer, the ITO layer and a few other metal and glass layers using either adhesives or screws to connect them all together. This process of building the LCDs exerts immense kinetic and mechanical energy by human labor. The glass flat screen for the television must be laser-cut to shape utilizing thermal energy and electricity. All of this electricity and thermal energy that is used in manufacturing requires incredible amounts of coal or fossil fuel consumption. The greenhouse gas emissions (GHG) resulting from the energy application are inordinately unsafe for the Earth in the short and long term. They are destroying our atmosphere which can damage plant life and harm the human and animal health. The manufacturing phase, although it is the second step most in energy consumption and emission, the concentrated levels of emission make it detrimental nonetheless. This stage includes the packaging and loading of the finished television sets in order to be ready for the next step, transportation and distribution worldwide.

TV sets inevitably must be replaced, but disposal techniques are still being experimented in terms of safety, procurement of materials and the energy application, including the effects. If televisions are not recycled and disposed properly, the materials can leak into the ground contaminating clean water systems and the plant life or harm humans who do not disassemble the TVs safely [6]. The best method for dismantling has proven to be to retrace the manufacturing process backwards to disassemble it most cost-effectively and with the most recovery of materials [12]. A comprehensive study by Ardente and Mathieux (2014) initiated an ideal method that consists of five steps to dismantle LCD panels as well as other electronic devices: “reusability, recyclability, recoverability, recycled and use of hazardous substance” [15]. Experiments to retrieve and reuse all of the materials have yet to be successful, but a few of the materials have favorable results including plastics, precious metals, glass and ITO. The basis of the disassembly from LCD panels has the highest efficiency when dismantled and extracted manually rather than mechanically which applies large amounts of kinetic and mechanical energy [1]. The numerous plastic parts are best recycled using two techniques: energy recovery (or thermal recycling) and mechanical recycling (or material recycling) [10]. Energy recovery is incineration of plastic waste to be used as electricity involving kinetic and mechanical energy by manual labor, but mostly uses electricity and thermal energy to incinerate the plastics[10]. Mechanical recycling is plastic waste being recycled into other resources utilizing kinetic or mechanical energy by manual labor as well as potential energy and gravitational energy of the materials [10]. Precious metals and glass both use kinetic, mechanical and thermal energies to be extracted manually, crushed down and then typically sold to be melted down to reform for other products. Indium-tin oxide is the most recycled raw material in LCD panels and can be fully extracted by numerous techniques encompassing leaching [11], sorption [4], and pyrolysis [1]. These each include exposing the LCD panels to varying chemicals, high temperatures and a range of pressures [4]. Overall, the recovery of ITO by means of recycling involves intensive chemical, thermal and pressure energies. This final stage of disposal and recycling of LCD televisions has the most exposure to research and experimenting. It encompasses the second highest levels of energy application, relatively identical to the manufacturing phase, but there is vast potential to lower this energy consumption and waste to a more environmentally friendly approach.

[4]Assefi, Mohammad, et al. "Selective recovery of indium from scrap LCD panels using macroporous resins." Journal of Cleaner Production 180 (2018): 814-822.

The manufacturing of televisions has continuously been monitored as a part of the life cycle assessment in the modern day society. A television is simply a machine powered by electricity that displays images on a screen and sounds out of the speakers. Current models of TVs are mainly focused on the LCD TV, which is a liquid crystal display television. LEDs, light-emitting diodes, are the source for illuminating light by the movement of electrons on a semiconductor that gives off the variation of colors behind the display. Creating the televisions by incorporating LEDs and additional metal elements into a contained liquid crystal display with a plastic frame is the main concept for the TV. During the production of an LCD TV, the detrimental effects to the environment of the waste and emissions such as greenhouse gases from the materials of the metals can be observed through the assembly process of the television and the disposal of the substances.

As the amount of TVs are increasing for demand, the air pollution worsens in relations to the increase of metals for compact designs of the monitors. In the initial phase, the screen is created with silicon oxide and indium tin oxide that are used for polishing the glass layers. The silicon oxide is a colorless material consisting of quartz as the main ingredient while the indium tin oxide is a yellow colored substance that acts as a coating for clearness. According to the Laboratory Chemical Safety Summary, the National Institutes of Health states that silicon dioxide “may cause mechanical irritation to the eyes, respiratory tract and skin” (U.S. National Library of Medicine, 2008). The substance is hazardous as a solid form of dust particles that can be inhaled through the air. Though, silicon dioxide is applied to the glass screens in a liquid form ,which is not toxic to the workers, to smoothen the surface and correctly position the liquid crystals. Air borne inhalation of the chemical is not as harmful as the physical contact with the substance itself. Therefore, factories enforce workers to wear protective gear from the head to feet to prevent exposure to the liquids. Likewise, the indium tin oxide is cautioned with safety equipment and masks. In the Chemical Information Profile by the U.S. Department of Health and Human Services, indium tin oxide, ITO for short, also “may cause severe irritation and burns to the skin or eyes” (U.S. Department of Health and Human Services, 2009). Similarly, the substance is effective in a powdered form that may cause lung infection through inhalation. The screen is then made more transparent with ITO in a liquid state. Both substances obtain a fine quality of a glass screen and are not considered devastating to the surrounding. However, ingesting and direct contact with the chemicals can be severe with the side effects in mind. Refining the glass is not the most detrimental of the process but still requires attentive measures to prevent a high accumulation of the liquids.

Another substance that is harmful to the environment within the procedure mainly revolves around the nitrogen trifluoride on the LCD television. Nitrogen trifluoride is the main component for allowing the surfaces of the TV to be water and fingerprint resistant. The substance is physically applied by the hands of human workers. By adding on the substance to the screen, the fumes released in the factories are vacated through vacuums that lets the gas into the atmosphere of the earth. Otherwise, the chemicals may be trapped within the factories during production. The National Institutes of Health evaluated that the symptoms of inhaling nitrogen fluoride affects the “blood, liver, and kidneys” and targets humans and animals such as “dogs, monkeys, and rats” (U.S. National Library of Medicine, 2018). While workers wear a suit and gloves to protect themselves from the fumes in the factories, the concentration of the gas remains toxic to wildlife that breathe on land. Although the process of coating the glass pieces are done in a sealed room to prevent leakage of the scent from the nitrogen trifluoride to the rest of the factory, the outer perimeter of the buildings are not safe to breathe. In The Guardian, a report from Michael Prather, the director of the environment institute at the University of California, Irvine notes that “as a driver of global warming, nitrogen trifluoride is 17,000 times more potent than carbon dioxide” (Sample, 2008). Carbon dioxide is already a major role played in polluting the atmosphere including the carbon emissions of the trucks during the shipment process. The amount of nitrogen trifluoride released is not a widespread issue with the concentration from the substance being contained. However, the growth is noticeable that nitrogen trifluoride is listed as a major “greenhouse gas” reported from Michael Prather in the Four Materials Illustrate Hazards Of Electronics Manufacturing (Gordon, 2017). Additionally, the composition of the air quality depicts a growing accumulation of the gas as the development of monitors of the television continue to flourish. Nitrogen trifluoride is a crucial factor to protecting and prolonging the televisions’ lifespan but contains a cost that endangers humans and animals.

In the creation of the LCD TV, there are waste factors that take place in removing the product after its lifespan. The plastic frame of the television is salvageable such that the product can be melted and reused again. But, metal components and chemicals that are built upon the circuit boards and monitors remain difficult to reattain the materials. In fact, recycling the flat-screen TV is not possible with another material within the components of the circuit boards, which is mercury. Denise Wilson of the WEEE: Waste Electrical and Electronic Equipmentreports that “inhaling mercury can lead to a myriad of behavioral and neurological problems such as insomnia, memory loss, tremors, and cognitive dysfunction” (Wilson, 2016). Even a low concentration of mercury is fatal for humans to take in while attempting to dismantle the television for deconstruction. Since the materials are not replaceable through recycling the LCD TVs, material costs are risen due to the rarity of finding the natural raw materials such as gold, silver, and copper for the circuit boards. Other materials that include indium tin oxide are nonrenewable which also limits the maximum amount of TVs produced. Furthermore, removing the metals from the television has a drawback of releasing toxicity. Wilson adds that dioxins exposed from deconstructing LCD TVs “lead to impairment of the endocrine, immune and reproductive systems as well as alter liver function” (Wilson, 2016). Dioxins are a pollutant to the air that is toxic for humans to inhale. The collective chemicals can be seen through both the production for the screen and the elimination of the product after usage. To prevent the releases of the gases into the air, depleted televisions are brought into specialized recyclers to harvest the remains of the electronics. Despite the efforts of replenishing the components, factories that melt away the components are still in existence to removing the waste. According to the author of Recycle Nation, Sophia Bennett states that “as televisions are run over by crushing equipment in a landfill, or burned in an incinerator, they release those heavy metals that can seriously affect human health” (Bennett, 2014). The physical process of “crushing” the materials is a wasteful method of removing the scarce resources from the circuit boards. Meanwhile, the chemical process of burning the metals secretes carbon and dioxin emissions and leaves solid wastes of mineral compounds. With that in mind, the electronic device must carefully be readjusted to contain friendly environmental substances that are reusable and reduce the harmful symptoms to the atmosphere.

Transporting the product of the LCD TVs also contributes to the pollution of the environment with greenhouse gases after the assembly is finished. In the delivery phase, the televisions are encased in large cardboard boxes and can be shipped to designated locations on land, water, and air. Trucks, ships, and planes all produce carbon dioxide as fuel is burned within the respective engines for the mobile vehicles. For instance, the internal combustion engine for trucks burns diesel fuel to power the pistons while the ships use coal to supply energy to the propulsion engines. Planes have the similar effect with the design of an engine that requires diesel fuel or gas. The modes of transportation mentioned beforehand increase in relations to the rising production of LCD TVs for consumers which results in a higher output of carbon dioxide as well. Thus, the carbon emissions from transporting the television is observed as a factor of damaging the ecosystem from the shipment process of the vehicles.

In essence, acknowledging the existence of the chemical substances released into the atmosphere from the waste and emissions of manufacturing and deconstructing an LCD TV is crucial for an understanding of the environmental impact it has on humans and the wildlife. As the production of televisions continue to develop the flat screen panels that incorporate toxic materials, more waste is produced as a result of the amount of TVs needed for the increase in supply and demand. In fact, electronic devices that focus heavily upon the usage of the chemical substances involves not only televisions but any creations with screens and monitors. Recording the findings of the symptoms from the chemical activities within the factories and the atmosphere allow producers and consumers to identify safer and more reliable resources that reduces the harm to the environment and life on earth. The life cycle of the television remains as an important subject for careful observations of the advancements developed upon electronic devices towards the future.

Larsen, Rasmus. “How a Screen Is Manufactured and Assembled.” How a Screen Is Manufactured & Assembled - FlatpanelsHD, 30 June 2010, www.flatpanelshd.com/focus.php?id=1277885543&subaction=showfull.

Sample, Ian. “Environment: Climate Risk from Flat-Screen TVs.” The Guardian, Guardian News and Media, 2 July 2008, www.theguardian.com/science/2008/jul/03/scienceofclimatechange.climatechange.

Welcome to a guide on how to remove scratches on computer screens. Oh no! There is an ugly scratch mark on the screen, and it is very annoying every time you use the computer. Fear not. If the scratch is not too deep, there might still be hope with some “home and Internet remedies”.

Have a very dirty screen with a lot of small scratches everywhere? Then you will need to get a cleaning cloth, some cotton buds, a soft brush, and cleaning alcohol (90% isopropyl alcohol from pharmacies will also do the trick).

First, apply the alcohol evenly over the screen. Be careful of the edges around the screen, and not get the alcohol inside – It will damage the electronics. Wipe it down with the cleaning cloth, and use cotton buds to target stubborn spots. This should pretty much restore any old screens back into their “shiny state”.

Note – I know the above is not a “scratch repair” video, but that is a very good demonstration of how to restore an old computer screen using cleaning alcohol.

Lastly, apply the toothpaste to the screen, use a cleaning cloth and rub it in a circular manner – The whole idea is to use the toothpaste as a screen polish.

This is another trick that we techies use to hide the scratches, and yep, just about any petroleum jelly-based product will work. All we need is to gently rub the cream into the “scar”, it should start to “blend in” and fade the scratch mark. Take note though, that it seems to only work on matte plastic screens and not the glossy glass ones.

This is kind of an “enhanced method” of the above windscreen polish. If there are a lot of micro-scratches on the screen, you can try applying a wet piece of very fine sandpaper (2000 grit) in circular motions to get rid of them first.

Then, complete the treatment with windscreen polish and car wax. The whole process requires quite a lot of elbow grease and patience, but it does restore the screen back to its “default factory shiny state”… Maybe even better.

Once upon a time in the bronze age of the Internet, people would use mashed bananas and baking soda to repair the scratched CDs… A very eco-friendly way of repairing stuff, non-toxic too. If it works on the plastic of a CD, then it should also technically work on plastic computer screens.

Personally, a combination of cleaning alcohol and Vaseline seems to work the best; Cleaning alcohol to remove the gunk, and Vaseline to cover the micro scratches. But take note, this worked on plastic screens, not glass.

If you run your fingers across the scratch mark, and it catches your fingernail. That is probably too deep to be fixed with the above home remedies, and it’s better to replace the entire screen.

Scratched Computer Screen? A scratch on your computer monitor or LCD TV screen can be annoying and very noticeable. The scratch on your computer screen will seem even worse and more visible when the background is white. How can you make that big scratch disappear? We have a few tips below that will completely erase the scratch and make it invisible. You won’t even have to go buy anything to fix the screen. The things needed to fix your screen are already in your home.

This screen scratch repair method can be used on all Computer Screens, DLP Screens, Flat Screen TV’s, LCD Monitors, Laptop Screens, LED Screens, Plasma Screens and more.

NOTE: If you have a scratch on your screen or monitor that cannot be removed using the methods above, there are a few different scratch removers you can try.

The first product has been shown to have the best results for removing scratches on screens. It is called the NOVUS Plastic Polish Kit. This scratch kit contains 3 different compounds to repair scratches. Image of product is below…

The second product is called Displex Display Polish. This scratch repair kit is Made in Germany and has been proven to remove minor scratches on screens when used properly. Image of product is below…

If you have a scratch on your computer screen or TV screen you cannot repair or remove, let us know by asking your question below and we will help you find a solution to fixing a scratch on any type of screen.

TV screens seem to be proverbial honey pots for dust, dirt and finger streaks. And in order to get a truly clear picture, we need to take a pause from our marathon boxset sessions and reach for the nearest feather duster.

But with newer TV models seemingly coming out by the day, it"s no longer just a case of using what you have to hand to get your screen looking shiny once more. Today"s LED/LCD, PLASMA and OLED TVs all feature delicate screens – that while long lasting – may not be able to endure the have-a-go cleaning methods that were used on CRT glass TV screens popular from the sixties to the noughties.

Still where there"s a TV that needs TLC in the cleaning stakes, there"s a solution to match it. So why not put down your remote, roll up your sleeves and try out one of the tips on how to clean a TV screen below? We promise a streak-free shine.

While"s it"s tempting to get stuck into the job at hand straight away, there are a number of safety precautions you need to take before starting the process of cleaning your TV screen.

You can buy distilled water – water that has been purified of many impurities through a scientific process – from Amazon, eBay and a number of other online retailers for less than under £5 for a few litres. And this should be gentle enough for most screens.Pour the distilled water into a spray bottle

If you"re already a fan of filter coffee, then this tip of perfect for you. Put your coffee filters to use for something other than brewing up your favourite Columbian roast, and a reserve a few for cleaning your TV screen instead. Coffee filters are lint-free, and as a result are naturally anti-static, making them perfect for bringing your TV screen back to it"s best.Sweep a dry coffee filter over your TV screen in gentle, sweeping motions

If you"re LCD screen has a slight scratch it can be tempting to buy an lcd scratch repair kit. But a good old tub of Vaseline – or any other brand of petroleum jelly – may be able to do the job just as well.Dip a cotton bud into the petroleum jelly

If you"re TV manufacturer guidelines state that you can"t use generic cleaning solutions, or warn against it, then it may be best to use a dedicated multi-purpose screen cleaner or wipes that are suitable for all screen types. Check that these are alcohol-free and don"t contain any other harsh chemicals. Examples include the SCREEN CLEANER KIT By Pure Organics, which has garnered an average 4.5 star rating on Amazon. As an added bonus you should be able to use them on other devices such as smartphones, tablets and laptops.

Katherine Johnson has been writing for over 10 years. She served as the CEO of two companies in the technology and beauty industries. Her writing can be found on AOL Travel, Screen Junkies and other websites. Johnson holds a Bachelor of Science in computer science.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey