lcd screen test pattern made in china

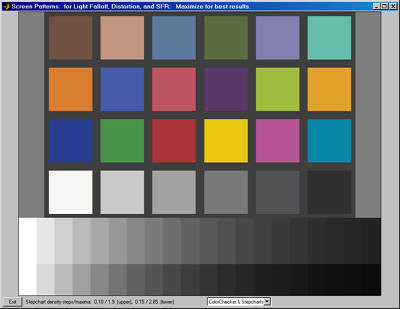

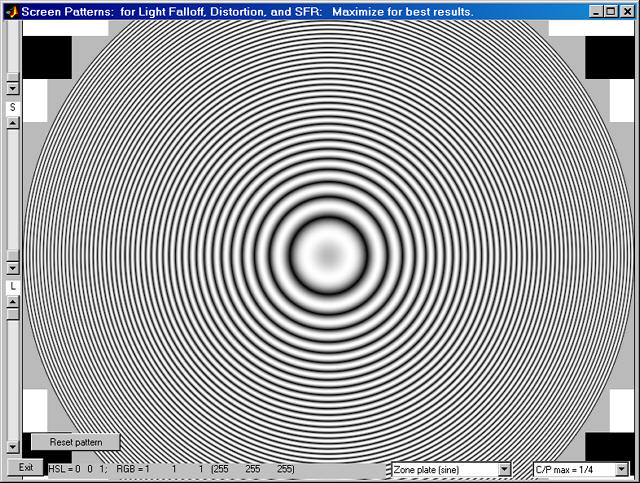

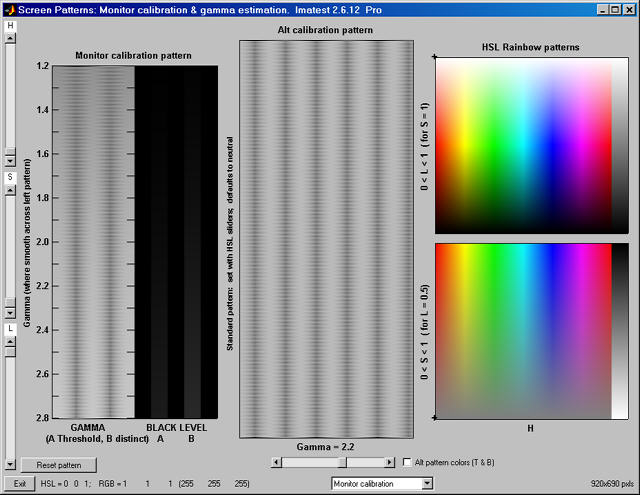

This selection contains several patterns that enable you to check your monitor’s calibration. The gamma patterns (left and middle) must be viewed on a monitor; they do not work in printed media. Reset pattern restores the default values, H = 0, S = 0, L = 1, and Gamma = 2.2.

This chart enables (shown below) you to set the black level (brightness) and estimate display gamma over a range of 1.2 to 2.8 with accuracy close to ±0.05. The gamma pattern is on the left; the black level pattern is on the right. Before using the chart, CRT monitors should be turned for on for at least 15 minutes. For flat screen (LCD) monitors, Screen resolution should be set to the monitor’s native resolution (right-click on the wallpaper, Properties, Settings).

Gamma is estimated by locating the position where the average luminance across the gamma pattern is constant. The corresponding gamma is shown on the left. You should be far enough from your monitor so the line pattern is not clearly visible. The example below shows what to look for.

Your monitor’s gamma should be set for 2.2 (for Windows systems).Gamma = 2.2 for the Internet-standard sRGB color space and the popular Adobe RGB (1998) color space. 1.8 was the standard for older Macintosh systems and prepress file interchange (Mac users, see Ian Lyons’ Mac Calibration page.).Most laptop LCD screens cannot be accurately calibrated because gamma is extremely sensitive to viewing angle.You can adjust gamma using Quickgamma (a great free program) or a hardware calibrator (details here).

Black level (brightness) Your monitor’s brightness control (which should actually be called black level) can be adjusted using the mostly black pattern on the right side of the chart. This pattern contains two dark gray vertical bars, A and B, which increase in luminance with increasing gamma. (If you can’t see them, your black level is way low.) The left bar (A) should be just above the threshold of visibility opposite your chosen gamma (2.2 or 1.8)– it should be invisible where gamma is lower by about 0.3. The right bar (B) should be distinctly visible: brighter than (A), but still very dark.

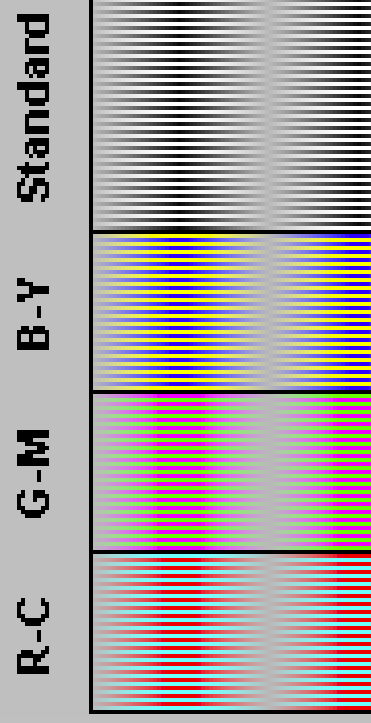

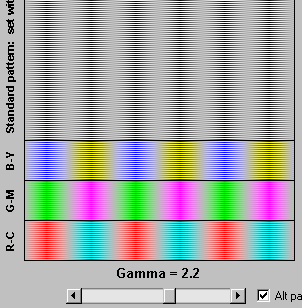

The image on the right shows the middle gamma pattern enlarged 4x. The upper part of this image, to the right of Standard, uses the same black-to-white sinusoidal variation as the Gamma and black level chart. The color patterns appear when the Alt pattern colors (T & B) box, located just to the right of the Gamma slider, is checked

When this image is displayed normal size (not enlarged; below) on a good quality monitor, the R-C, G-M, B-Y, and Standard patterns appear nearly identical.

Middle: Gamma pattern. This pattern will look uniform when the gamma slider (just below it) is set to the correct monitor gamma. It is very sensitive: it can measure gamma to better than ±0.05 accuracy: The spatial frequency of vertical bands is set close to the the frequency where the human eye’s Contrast Sensitivity Function is maximum for typical viewing situations.

A checkbox labeled Alt pattern colors (T & B) is located just to the right of the Gamma slider. When this box is checked, three bands (six total) appear near the top and bottom of the gamma pattern. Instead of the standard gamma pattern’s normal black-to-white sinusoidal variation, individual lines vary from Blue-to-Yellow, Green-to-Magenta, and Red-to-Cyan. In a normally functioning monitor these bands appear the same neutral gray as the standard pattern, but they could look strange in a defective or poorly calibrated monitor. Unchecking this box speeds image refresh.

Right: HSL rainbow patterns. These patterns are used for a rough visual estimate of the monitor’s color performance. They should appear well-saturated and have smooth color and tonal gradations (no abrupt changes). Laptops typically look very different from well-calibrated LCD or CRT monitors.

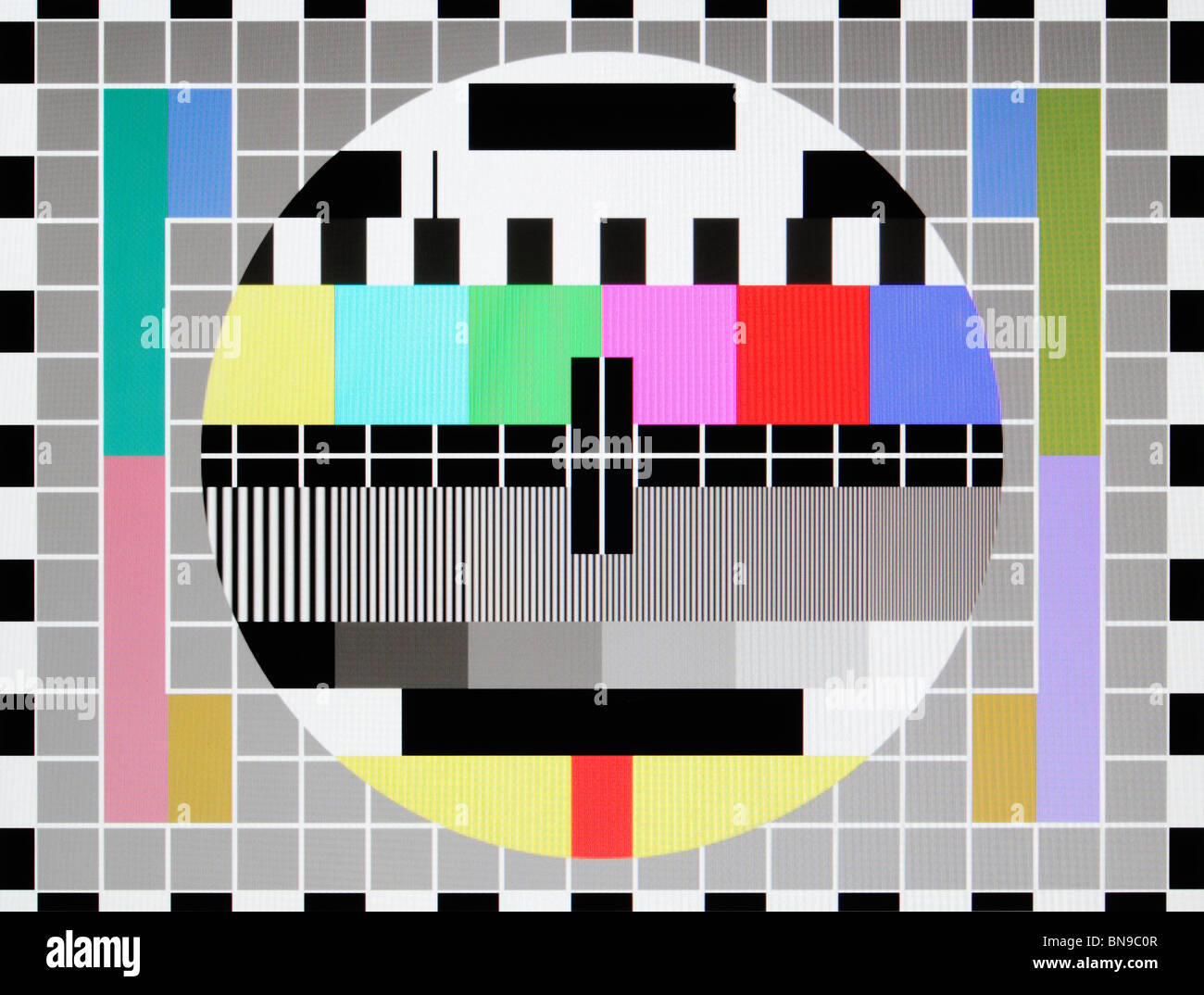

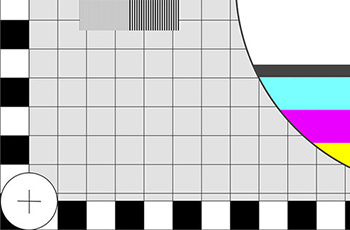

A test card, also known as a test pattern or start-up/closedown test, is a television test signal, typically broadcast at times when the transmitter is active but no program is being broadcast (often at sign-on and sign-off).

Used since the earliest TV broadcasts, test cards were originally physical cards at which a television camera was pointed, allowing for simple adjustments of picture quality.camcorders. From the 1950s, test card images were built into monoscope tubes which freed up the use of TV cameras which would otherwise have to be rotated to continuously broadcast physical test cards during downtime hours.

Electronically generated test patterns, used for calibrating or troubleshooting the downstream signal path, were introduced in the late-1960s. These are generated by test signal generators, which do not depend on the correct configuration (and presence) of a camera, and can also test for additional parameters such as correct color decoding, sync, frames per second, and frequency response.vectorscope, allowing precise adjustments of image equipment.

The audio broadcast while test cards are shown is typically a sine wave tone, radio (if associated or affiliated with the television channel) or music (usually instrumental, though some also broadcast with jazz or popular music).

Digitally generated cards came later, associated with digital television, and add a few features specific of digital signals, like checking for error correction, chroma subsampling, aspect ratio signaling, surround sound, etc. More recently, the use of test cards has also expanded beyond television to other digital displays such as large LED walls and video projectors.

Test cards typically contain a set of patterns to enable television cameras and receivers to be adjusted to show the picture correctly (see SMPTE color bars). Most modern test cards include a set of calibrated color bars which will produce a characteristic pattern of "dot landings" on a vectorscope, allowing chroma and tint to be precisely adjusted between generations of videotape or network feeds. SMPTE bars—and several other test cards—include analog black (a flat waveform at 7.5 IRE, or the NTSC setup level), full white (100 IRE), and a "sub-black", or "blacker-than-black" (at 0 IRE), which represents the lowest low-frequency transmission voltage permissible in NTSC broadcasts (though the negative excursions of the colorburst signal may go below 0 IRE). Between the color bars and proper adjustment of brightness and contrast controls to the limits of perception of the first sub-black bar, an analog receiver (or other equipment such as VTRs) can be adjusted to provide impressive fidelity.

They are also used in the broader context of video displays for concerts and live events. There are a variety of different test patterns, each testing a specific technical parameter: gradient monotone bars for testing brightness and color; a crosshatch pattern for aspect ratio, alignment, focus, and convergence; and a single-pixel border for over-scanning and dimensions.

The famous RCA Indian-head test pattern used mainly in North America from 1940 to the 1970s with its elements labelled, describing the use of each element in aligning a black & white analog TV receiver.

Test cards are as old as TV broadcasts, with documented use by the BBC in the United Kingdom in its early 30-line mechanical Baird transmissions from 1934Occupied France during World War II.Radiodiffusion-Télévision Française 819-line test card introduced in 1953.

In North America, most test cards such as the famous Indian-head test pattern of the 1950s and 1960s have long since been relegated to history. The SMPTE color bars occasionally turn up, but with most North American broadcasters now following a 24-hour schedule, these too have become a rare sight.

With the introduction of color TV, electronically generated test cards were introduced. They are named after their generating equipment (ex: Grundig VG1000,Philips PM5544,Telefunken FuBK,BBC test card) or organization (ex: SMPTE color bars, EBU colour bars).

Formerly a common sight, test cards are now only rarely seen outside of television studios, post-production, and distribution facilities. In particular, they are no longer intended to assist viewers in calibration of television sets. Several factors have led to their demise for this purpose:

Modern microcontroller-controlled analogue televisions rarely if ever need adjustment, so test cards are much less important than previously. Likewise, modern cameras and camcorders seldom need adjustment for technical accuracy, though they are often adjusted to compensate for scene light levels, and for various artistic effects.

Use of digital interconnect standards, such as CCIR 601 and SMPTE 292M, which operate without the non-linearities and other issues inherent to analog broadcasting, do not introduce color shifts or brightness changes; thus the requirement to detect and compensate for them using this reference signal has been virtually eliminated. (Compare with the obsolescence of stroboscopes as used to adjust the speed of record players.) On the other hand, digital test signal generators do include test signals which are intended to stress the digital interface, and many sophisticated generators allow the insertion of jitter, bit errors, and other pathological conditions that can cause a digital interface to fail.

Test cards including large circles were used to confirm the linearity of the set"s deflection systems. As solid-state components replaced vacuum tubes in receiver deflection circuits, linearity adjustments were less frequently required (few newer sets have user-adjustable "VERT SIZE" and "VERT LIN" controls, for example). In LCD and other deflectionless displays, the linearity is a function of the display panel"s manufacturing quality; for the display to work, the tolerances will already be far tighter than human perception.

For custom-designed video installations, such as LED displays in buildings or at live events, some test images are custom-made to fit the specific size and shape of the setup in question. These custom test images can also be an opportunity for the technicians to hide inside jokes for the crew to see while installing equipment for a show.

Rather than physical test cards, which had to be televised using a camera, television stations often used a special purpose camera tube which had the test pattern painted on the inside screen of the tube. Each tube was only capable of generating the one test image, hence it was called a monoscope.

Monoscopes were similar in construction to an ordinary cathode ray tube (CRT), only instead of displaying an image on its screen it scanned a built-in image. The monoscope contained a formed metal target in place of the phosphor coating at its "screen" end and as the electron beam scanned the target, rather than displaying an image, a varying electrical signal was produced generating a video signal from the etched pattern. Monoscope tubes had the advantage over test cards that a full TV camera was not needed, and the image was always properly framed and in focus. They fell out of use in the 1960s as they were not able to produce color images.

There are also test patterns kits and software developed specifically for many consumer electronics. The B&K Television Analyst was developed in the 1960s for testing monochrome TV sets in the NTSC standard and was later modified for European and Australian PAL standards. Among other uses, it consisted of a flying spot scanner on which a test pattern printed on a cellulose acetate slide was shown.

When CRT monitors were still commonly used on personal computers, specific test patterns were created for proper calibration of such monitors in the cases whereby multimedia images could not be shown properly on said monitors.VCD and DVD lens cleaner discs, such as the Kyowa Sonic lens cleaning kits from 1997–2001, also included test patterns as well.

Test patterns are also used to calibrate medical displays for telemedicine and medical diagnostic purposes, such as the SMPTE RP-133 medical diagnostic imaging test pattern specification for medical and surgical displays, created around 1983AAPM in 2001.X-ray machines, in particular those manufactured by Leeds Test Objects in England, also exist as well.

Television has had such an impact in today"s life that it has been the main motif for numerous collectors" coins and medals. One of the most recent examples is The 50 Years of Television commemorative coin minted on 9 March 2005, in Austria. The obverse of the coin shows the centre portion of the Telefunken T05 test card, while the reverse shows several milestones in the history of television.

The Philips Pattern is widely recognised as one of the iconic popular culture symbols of the 1980s and 1990s. Numerous novelty and collectible items has been patterned after the famous test card, including wall clocks, bedsheets, wristwatches, and clothing.

In Britain, music - rather than radio sound - was usually played with the test card. The music played by the BBC, and afterwards ITV, was library music, which was licensed on more favourable terms for frequent use than commercially available alternatives. Later, Channel 4 used UK library LPs from publishers like KPM, Joseph Weinberger and Ready Music.

Until September 1955, the BBC used live playing 78 RPM commercial records as an audio background to the test cards. After that date, they switched to using recorded music on tape.celesta). ITV (which began its first trade transmissions in 1957) continued to use commercially available recordings until the late 1960s, when it also began to make specially produced tapes.

During the 1980s, the test card was gradually seen less and less - it was pushed out first by Teletext pages, then extended programme hours. The same tapes were used to accompany both the test card and Ceefax on BBC channels, but some fans argue that new tapes introduced after Ceefax became the norm in 1983 were less musically interesting.

Associated-Rediffusion–Marconi "diamond" monochrome test card versions 1, 2 and 3RTV in British Hong Kong, TVM in Crown Colony of Malta and WNTV in the western part of Colonial Nigeria

The Test Card Circle, a UK fan site: details of the UK"s Trade Test Transmissions including the history of the BBC and ITA Test Cards, a look at the music used and full details about the Trade Test Colour Films shown from the late fifties to 1973.

SMPTE color bars are a television test pattern used where the NTSC video standard is utilized, including countries in North America. The Society of Motion Picture and Television Engineers (SMPTE) refers to the pattern as Engineering Guideline (EG) 1-1990.standard, and created by test pattern generators.signal has been altered by recording or transmission and what adjustments must be made to bring it back to specification. It is also used for setting a television monitor or receiver to reproduce NTSC chrominance and luminance information correctly.

A precursor to the SMPTE test pattern was conceived by Norbert D. Larky (1927–2018)RCA Laboratories and first published in RCA Licensee Bulletin LB-819 on February 7, 1951. U.S. patent 2,742,525 Color Test Pattern Generator (now expired) was awarded on April 17, 1956, to Larky and Holmes.EIA published a standard, RS-189A, which in 1976 became EIA-189A, which described a Standard Color Bar Signal, intended for use as a test signal for adjustment of color monitors, adjustment of encoders, and rapid checks of color television transmission systems.CBS Technology Center, described an improved color bar test signal developed at the center by Hank Mahler (1936–2021)SMPTE ECR 1-1978. Its development by CBS was awarded a Technology & Engineering Emmy Award in 2002.

Although color bars were originally designed to calibrate analog NTSC equipment, they remain widely used in transmission and within modern digital television facilities. In the current context color bars are used to maintain accurate chroma and luminance levels in CRT, LCD, LED, plasma, and other video displays, as well as duplication, satellite, fiber-optic and microwave transmission, and television and webcast equipment.

The bottom section contains a square of 100% intensity white and a rectangle of 7.5% intensity black, for use in setting the luminance range. More modern versions of the pattern feature a PLUGE pulse. The white square lines up so that it is below the yellow and cyan bars, on a waveform monitor this will show up with the white bar overlapping the peak of the yellow and cyan chroma at 100 IRE units. The pluge (short for picture line-up generation equipment) pulse is positioned within the black rectangle, below the red bar (it is present in the illustration but may be hard to see). It comprises three small vertical bars, a rightmost one with intensity 4% above black level (11.5 IRE), a middle one with intensity exactly equal to black (7.5 IRE), and a leftmost one with intensity 4% below black (super-black or blacker than black, 3.5 IRE). The pluge pulse aids in adjusting the bottom of the luminance range to avoid either washing out the black tones into grays or collapsing picture information into the signal clipping that occurs a small distance below the black level (known as crushing the blacks). When a monitor is properly adjusted, the rightmost pluge bar should be just barely visible, while the left two should appear indistinguishable from each other and completely black. Also in the bottom section are two sections that contain -In-phase and +Quadrature signals (see YIQ), centered on black level and having the same gain as the color burst signal; these show up on the pattern as a square of very dark blue, and a square of very dark purple. On a vectorscope, they appear as two short lines ninety degrees apart. These are used to ensure that the television receiver is properly demodulating the 3.58 MHz color subcarrier portion of the signal. The vectors for the -I and +Q blocks should fall exactly on the I and Q axes on the vectorscope if the chrominance signal is demodulated properly.

The colors below are presented using sRGB transfer of CSS. Since sRGB is the standard colorspace for webpages and computer screens, this gives only an idea of the intended colors. They are not completely representative of how they look on TV displays, since these follow the ITU-R BT.1886 standard, specifying a different gamma correction value, and thus colors below will look darker on such a display, and those darker colors will be the reference ones. The off-by-one errors (for example 254 instead of 255 and 1 instead of 0) happen because the 8 bit Y"PbPr values were used when decoding to R"G"B", if you use 10-bit Y"PbPr that does not happen.

An extended version of SMPTE Color Bars signal, developed by the Japanese Association of Radio Industry and Businesses as ARIB STD-B28 and standardized as SMPTE RP 219:2002HDTV signal with an aspect ratio of 16:9 that can be down converted to a SDTV color bar signal with an aspect ratio of either 4:3 or 16:9. The Color Bar signal is generated with unconventionally slow rise and fall time value to facilitate video level control and monitor color adjustments of HDTV and SDTV equipment. Digital test images generated following the SMPTE RP 219:2002 specifications and adapted to perfectly fit 114 standard and non-standard resolutions for both 16bpp and 8bpp, are freely available in the COLOR dataset of the TESTIMAGES archive.

The injection of ITO glass — glass CLEANING and drying — PR COAT — PREBREAK — DEVELOP MAIN CURE — ETCHING — STRIP CLEAN — TOP COAT — UV CURE — curing — MANICURE) – cleaning (CLEAN) – applied orientation agent (PI) PRINT – CURING (MAIN CURE), cleaning (CLEAN), silk screen printing (SEAL/SHORT PRINTING) – baking (CUPPING FURNACE), SPRAY packing material (SPACER SPRAY) – para pressing (ASSEMBLY) – CURING (SEAL MAIN CURING)

E.Exposure: Ultraviolet light (UV) is used to illuminate the surface of the photoresist through the pre-made electrode pattern mask, which causes the reaction of the photoresist layer. The photoresist is selectively exposed under an ultraviolet lamp by covering the photoresist on the glass coated with the photoresist (as shown in the figure).

H.Etching: With appropriate acid etching solution, the ITO film without photoresist covering is etched off. Thus, the required ITO electrode pattern is obtained.

In this process, two conductive glasses are stacked on top of each other, and sealed together, and cured to make a glass box with a specific thickness of clearance. The technology of box-making is one of the key technologies in LCD manufacturing. (Spacing of LIQUID crystal boxes must be strictly controlled)

SCRIBING — BREAK OFF — LC INJECTION — END seal — BREAK OFF — sharpen — VISUAL inspection — ELECTRICAL test — secondary cleaning special procedure (POLYGON) — BACK PRINTING — dry ink — POLARIZER ASSEMBLY — Thermal pressure — Inspection appearance test (FQC) — BIT PIN — FINAL test — PACKING — IN STOCK.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrialcontrol equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

Have you ever properly checked the display quality of the LCD you habitually use? Very often people become aware of previously unnoticed problems in display quality when they run a check using test patterns and so on. This time we are going to talk about the basic points used to assess LCD display quality, and show you a simple way to test it.

Below is the translation from the Japanese of the ITmedia article "The difference in image quality is perfectly obvious! – Let"s check the LCD"s monitor" published April 22, 2010. Copyright 2011 ITmedia Inc. All Rights Reserved.

First of all, bear with us in the following simple test. Below is image data of a row of three squares. In the center of each square is a letter so faint as to be barely distinguishable, so there are three letters in all. Read from the left they make up a word. Can you see that hidden word?

That"s right. The answer is "LCD" (it is displayed if you drag the space between the brackets). We assume that probably many users could read the letters concealed in the squares.

So, the next test is much more difficult. A word is concealed in the four squares below, just as in the image above. The letters are written in colors that are very similar to those of the boxes and we expect that, in many cases, it is hard to distinguish them in your browser. We would like you to download the image and check it closely in photo retouching software or a viewer that is capable of accurate color reproduction.

This time the answer is "EIZO" (it is displayed if you drag the space between the brackets). Depending on the lighting or the user"s environment it may be hard to make out but, if you can read these four letters, the display quality, or more accurately the still image gradation expression, of your LCD is extremely high.

Let"s get down to details then. "Image quality" is the top priority of the LCD, of course. However, recently LCD prices are fiercely competitive and there are surprisingly few products that insist on high image quality and performance. It may be nice to be able to get hold of a wide-screen monitor with full HD (1920 × 1080 dot) resolution or higher fairly cheaply, but it cannot be denied that such LCDs tend not to place too much importance on display quality.

On the other hand, the increasing opportunities to enjoy things like HD videos and games, and high resolution digital photographs on the computer make LCD display quality even more important. As far as possible it"s best to use an LCD with excellent display quality in order to fully enjoy the charms of the visual content.

Even so, perhaps you think that there can"t really be that much wrong with the LCDs that so many people are using at the moment. Here we would like to show you a simple method to check LCD display quality. You can get a good idea of whether the basic display quality is good or bad just by looking at how some simple test images are displayed, just like in the introductory quiz. First of all, we would like you to get a sense of how important it is that "image data can be properly displayed" by checking the display of the LCD that you currently use, (that"s right, the one you are using to view this page!).

The test items use color / monochrome patterned images to check gradation expression, and simple images to check brightness / chromaticity variation. Downloads are available of several test images, such as gradation patterns. We would like you to display the downloaded test images in photo retouching software or a viewer that can reproduce color accurately. As we mentioned at the start of this article, you have to be careful as in many cases colors cannot be displayed accurately in web browsers. (Currently only a few browsers such as Safari and Firefox 3.x can handle color management).

Before starting your visual check of the display quality, please return to your LCD"s setting to default, and select Adobe RGB or sRGB as the image quality mode. If these modes are not available it is fine to set the color temperature to 6500K and gamma to 2.2. If you cannot adjust the color temperature and gamma, simply adjust the brightness and contrast so that they are easier to discern. Of course, if it"s an LCD environment that has been color calibrated it"s OK to leave it as it is.

The average LCD takes some time for the monitor to stabilize after it is switched on so, after start up, please wait at least 30 minutes or so before doing the test. (Most EIZO monitors are an exception to this as they are equipped with our proprietary dimming function and the monitor stabilizes in a short time after start up.)

We would also like you to adjust the monitor stand so that things like the room"s lighting are not reflected on the screen. You have to be particularly careful with products that have a glare (glossy) type screen as they are highly reflective. Visual assessment is impeded when ambient light is reflected. It will be much easier to make an assessment if you turn off the room lights at night and exclude as much ambient light as possible. This applies for both glare and non-glare (matte) types.

The surface treatment of an LCD makes a difference to the background reflection. Glare panels impede the surface diffusion of backlight, which does make it easier to achieve high color purity, but also makes distinct reflections of the user or lighting much more likely (photo on the left).

For your reference, we ran a test on an EIZO 24.1-inch wide-screen LCD, the FlexScan SX2462W, for this article. The FlexScan SX series comes with a number of high image quality functions and boasts top class display quality as a general-purpose LCD intended for a computer.

When we displayed the quiz images (the more difficult ones, of course) on the FlexScan SX2462W, the four letters appeared faintly when we stared closely at the screen and we could read what they said. This indicates the high image quality level.

When checking the display quality of an LCD it is comparatively easy to understand the gradation expression capability by a visual check. Let"s display color and monochrome gradation images and check whether the entire image is smoothly reproduced. If there is a problem with the gradation expression it produces things like blocked-up shadows in dark areas and blown-out highlights in light areas, banding (vertical or horizontal stripes) in the middle gradations, and color cast, so you should check for problems like these.

Test images of color / monochrome gradations are shown below. Each test image is prepared for three resolution levels (1280 × 800 dots / 1680 × 1050 dots / 1920 × 1200 dots). When you click on an image it is displayed in that actual resolution. We would like you to download the images in the resolution which matches that of your current LCD. Gradation expression can vary according to whether the image is viewed horizontally or vertically, so it will be more effective if you rotate these images and view them vertically as well.

A gradation pattern where the colors red, green, blue, cyan, magenta and yellow go through 16 gradients as they change to white or black. This is an easy test image so we expect that it can be seen in most environments that each color bar is divided into 16 blocks.

A gradation pattern where the colors red, green, blue, cyan, magenta and yellow go through 64 gradients as they change to white or black. Each color bar is divided into 64 rectangular blocks. With this many gradients we expect that many LCDs will find it hard to make distinctions in the dark areas or the areas that are close to primary colors.

A smooth gradation pattern where the colors red, green, blue, cyan, magenta and yellow go through 256 gradients as they change to white or black. At this level of difficulty you cannot distinguish between adjoining colors from a distance but, if you have an LCD with excellent gradation expression, if you look closely you should be able to see that each color is divided into thin rectangular blocks.

A gradation pattern that changes from black to white. It is divided into 5 horizontal bars: from the top, smooth, 128 gradients, 64 gradients, 32 gradients and 16 gradients. Even if all the differences can be distinguished in the 16 and 32 gradient patterns near the bottom, we expect that there will be some parts in the 64 and 128 gradient patterns where it is hard to see the boundaries between adjoining colors. With this kind of monochrome test image you should also check whether any unnecessary colors are mixed with the gray.

On an average LCD gradations of gray that are close to black tend to appear as blocked-up shadows (gradations of gray that are close to white are displayed comparatively accurately). If your LCD"s OSD menu allows you to adjust the contrast, please try gradually turning down the contrast. Turning down the contrast often makes it possible to see gradations that had been subject to blocked-up shadows or blown-out highlights.

Probably most LCDs will be able to detect some degree of banding and color cast in the middle gradations. Banding in the middle gradations is tone jump (Missing gradations) and, along with color cast, means that the RGB gamma curves are unequal. Unlike blocked-up shadows or blown-out highlights, this is an area that it is hard to improve with adjustments made by the user.

When we looked at these test images on the FlexScan SX2462W, in the smooth gradation there was blocked-up shadows right next to the black but we could distinguish differences in gradations of gray until very close to the black area. When it comes to such subtle gradation distinctions the brightness of the room and the adaptability of the eye come into play, so the range that is visible will vary according to the environment and the individual. The gradation expression was excellent, with almost no blown-out highlights in light areas, middle gradation banding or color cast.

Smooth color and monochrome gradations displayed on the FlexScan SX2462W. This data is of screen displays photographed with a digital camera so some of the gradations may seem to have been destroyed, but they were cleanly represented when checked visually.

The answer is "The far right" (it is displayed if you drag the space between the brackets). If the other grays looked correct, color may not be being correctly recognized for a variety of reasons, such as the lighting environment or the LCD settings.

The two image patterns below are easy to understand examples of optical illusions. When you look at them you should be able to understand how heavily the human eye is influenced by surrounding colors.

Now let"s assess the gradation expression with some slightly different test images. Below are color patterns with a spread of pale colors in gradations close to the dark range and the light range. They are arranged so that a distinction cannot be made between adjoining colors on an LCD with insufficient gradation expression.

In this color pattern the colors gradually change from near-white pastels to gradations that are even closer to white. As the lightness of each color increases (the nearer it approaches to white), the more difficult it becomes to distinguish between adjoining colors.

A color pattern where the lightness and hue gradually change. As the lightness of each color decreases (the nearer it approaches to black), the more difficult it becomes to distinguish between adjoining colors.

We expect that you could roughly get the whole picture in the gradation patterns on the previous page, but in the patterns this time some parts that cannot be seen may have appeared in some cases. As we mentioned earlier, LCDs tend to display gradations close to black as a blocked-up shadows, and color patterns that are close to black are particularly hard to distinguish.

Since there are some parts that cannot be seen, the possibility arises subtle skin colors and tones cannot be accurately recognized when doing things like retouching photographs, though the misrecognition will vary according to the user"s eyesight. People who place importance on color reproduction should probably bear this in mind when they think about replacing their LCD or buying an extra one.

Incidentally, when we checked the FlexScan SX2462W with these tests we could distinguish everything in both the close to white and the close to black patterns. As well as no blown-out highlights or blocked-up shadows, we saw no unnatural color casts.

This shows the color patterns displayed on the FlexScan SX2462W. It was taken with a digital camera so some parts look a little patchy but they were accurately displayed when we did a visual check.

Along with gradation expression, it is easy to visually check brightness variation and chromaticity variation. Brightness variation scatters brightness around the screen and is easy to notice when you use full-screen display for things like drawing up documents or using spreadsheets. Chromaticity variation scatters color around the screen and is not as easily noticed as brightness variation, but it makes graphics-related displays unnatural and causes deterioration in color reproducibility.

Every LCD has some degree of brightness and chromaticity variation, but there are many products where the variations become more obvious when the brightness is lowered. A comparison of the brightness and chromaticity variation of a number of LCDs reveals that there is a fairly large difference between products, so this is a point to bear in mind.

Brightness and chromaticity variation can be checked with standard Windows or Mac OS X functions. All you need to do is to set the desktop background to "Monochrome" and look at the whole screen from a little way away. Your check will be perfect if you change the desktop background to black, white, gray, then 100% red, green, blue, cyan, magenta and yellow, and then any "near-white pale color".

If you actually try this test you may be surprised to find more variation than you expected when gray or a near-white pale color is displayed. Generally speaking, the center of an LCD screen is the brightest and it gradually gets darker towards the edges. This is no problem if there is not a big difference in brightness between the central and peripheral areas, but there are some products where this difference is very striking.

An example of Windows 7 settings. Set the desktop background to "Monochrome" and then click on "Other". Prepare a color on the "Color settings" screen and use it as the background. (The background color cannot be changed in Windows 7 Starter.)

Incidentally, this test is also an effective way to test the LCD for dot defects (normal lighting / unlit room). We would like you to check the black display in a darkened environment, for example by switching off all the room lights at night. Although you probably saw the whole screen as uniformly black in a light environment, very often in a dark environment you can find variations in some parts due to light leaks.

The FlexScan SX2462W got good results again when we tried it with the brightness and chromaticity variation tests. The brightness decreased slightly at the edges of the screen, particularly the lower edge, but overall the display was even and pleasing. It is installed with a "digital uniformity equalizer" that measures brightness and chromaticity throughout the screen and makes corrections so that the entire screen is uniform.

Monochrome full-screen displays on a FlexScan SX2462W. Only the screen display is shown. The bottom right is a near-white pale orange. There are not many LCDs that can display this kind of pale color as uniformly as this

However, the pitfall here is that it simply means that "the screen is visible". The thing is that the viewing angle specifications are permitted to use the term "visible" until the display contrast ratio drops to an extremely low 10:1 or 5:1 when the screen is viewed from an angle (the steeper the angle from which the LCD screen is viewed, the more the contrast generally declines). In other words, they do not take into account the display uniformity of the central and peripheral areas of the screen, or the level of chromatic change, when the screen is viewed from an angle.

The ideal viewing angles is that the brightness and chromaticity is very uniform and there is not much chromatic change, even when the screen is viewed from a slight angle. The viewing angles given in the specifications are not really very helpful, but you can judge the standard of the panel type that the LCD (liquid crystal panel) adopts. IPS liquid crystal panels have the least change in brightness or chromaticity when the screen is viewed from an angle, and they are followed by VA panels. An IPS or VA liquid crystal panel can be said to indicate the superior nature of the product itself, so this is often included in the catalog or specifications. It is probably a good idea to look through the catalogs of various products.

On the other hand, monitors installed with cost-effective TN liquid crystal panels are in fact the most numerous. However, the TN type lags far behind the IPS and VA types in terms of characteristic viewing angle changes in brightness and chromaticity. Simply viewing the screen from a slightly different angle makes the coloration change dramatically, and the screen looks completely different according to whether it is viewed vertically or horizontally. If the vertical and horizontal viewing angles in the specifications are different then it is a TN type. There are quite a few products with a 20-inch wide screen or larger where colors look different in the central and peripheral areas even when the screen is viewed straight on.

The display on a VA panel. Compared with the IPS panel the screen is a little whitish and the chromaticity has slipped, but it is a satisfactory viewing angle for actual use

The display on a TN panel. There is a very clear difference from the IPS and VA panels. The display throughout the entire screen lacks uniformity and there is a yellow cast

The gradation images and monochrome images from earlier in this article can be used as they are to check the viewing angles. Display an image on the whole screen, look at it straight on and check whether the brightness and colors are uniform at the top and bottom of the screen, and in the center and at both sides. Then gradually shift the angle from which you view the screen and check how the brightness and coloration change. If you do this with photographic data as well as the test images, you should be able to get a better sense of the difference in the display.

When we checked the viewing angles of the FlexScan SX2462W there was absolutely nothing to criticize since, in addition to the use of an IPS panel, it is equipped with many high image quality functions, including the afore-mentioned digital uniformity correction circuit. The brightness and chromaticity throughout the whole screen is very uniform, and the coloration hardly changed at all when the viewing angle was changed.

We explained here about easy ways to check LCD monitor quality. How were the results for your current LCD? We think that many people were probably very bothered by the blocked-up shadows and blown-out highlights when the test images to check gradation were displayed, by the middle gradation banding, and by the variations in brightness and chromaticity when the monochrome images were displayed.

As we mentioned at the beginning, recently the number of LCDs with excellent display quality is on the decline. Although we would not go so far as to say that the display quality of inexpensive products is poor. Of course a high quality LCD is indispensable if you want to enjoy using your computer, properly handle the needs of applications that require color reproducibility, and to fully enjoy all the benefits of rich content.

The EIZO FlexScan LCD series has excellent display quality in those regards, and we have no qualms about recommending them to everyone. The product line-up is diverse but each model is clearly ranked according to the purpose to which it is suited and its screen size, and they all guarantee above-standard display quality. They may cost a little more than you had budgeted for but the clear value they offer exceeds their price.

If, after trying these tests, you have doubts about the display quality of the LCD that you usually use, we would certainly urge you to consider an EIZO LCD. We would also recommend that you construct a multi-display environment by making the new LCD your main monitor and the one that you have been using your sub monitor.

Chroma 27013 is a portable tester that supports high resolution and large scale LCM with the signals, power supply and test patterns required for LCD Module test.

Users can edit various timing parameters and patterns on PC via software applications. Auto execution or one-key manual control on the device can switch the Timing, Pattern, Program mode rapidly. The easy and convenient operation along with compound key usage made the 27013 LCM Tester most applicable for R&D, Quality Assurance, Quality Verification, Services and Sales areas for LCM related tests.

The 27013 LCM Tester supports LVDS signal with pixel rate 330MHz (1 Link 135MHz/2 Link 270MHz/4 Link 330MHz ) that can test the screen resolution up to 2560x1600 pixels to meet the test requirements for standard test signal of various panels today and Full HD 120Hz (Double frame rate.)

The large capacity of memory provides 30 Timings, 64 Patterns with many built-in standard test patterns. The 27013 not only can generate the patterns of 10Bit grayscale, pure color, stripes, text and cross.

The panel of 27013 LCM Tester has several rapid one-key operation modes which include: R, G, B & Inversion signal separation and resume – it can separate or resume one of the RGB signals in the display screen; while the Inversion reverses the pattern display on the screen. Timing, Pattern, Program, Power mode – users can create the test program especially for UUT by the PC software application and conduct one-key operation from the panel directly. The VDD rapid key is able to switch the built-in 3 fixed voltage settings 3.3V/5V/12V directly to meet the power output conditions for most LCM tests rapidly.

27013 LCM Tester with PG MASTER Software can edit the test programs and upload/download edited data through the RS-232 interface data control box. Users can update test programs on different testers via the data control box directly without controlling by PC to save the time effectively.

Chroma 27013 carried complete test functions with highly accurate signals and power source. It adopts 20x4 LCD screen in compact size with friendly user interface, and its small-scale design can be used flexibly on various tests to satisfy the work unit that needs to move often. The powerful function and fast test speed make it the best tool for production test.

Remember, aftermarket replacement screens DO NOT provide the moisture seals, response, and drop performance so please use Apple Care or a Certified replacement brand such as eVero. Your iPhone is worth it.

If the screen abnormality is not present in the built-in self-test mode, see the Dell knowledge base article How to Troubleshoot Display or Video Issues on a Dell Monitor.

If the LCD built-in self-test (BIST) diagnostic test passed, the laptop LCD screen is working correctly. The display problem could be due to an outdated graphics driver or incorrect video settings. Follow the troubleshooting instructions in the Dell knowledge base article How to Troubleshoot Display or Video Issues on a Dell Laptop.

Figure 3 shows the average contrast-sensitivity curves where the error bar represents the scattering within one standard error around mean. For the low background patterns, the grayscale corresponding to 80% sensitivity was 113 and 188 for the monochrome and color LCDs, respectively, indicating that the former had better contrast discrimination ability than the latter. As for the high background patterns, the two curves decreased rapidly as the contrast between the sphere and background decreased. The sensitivities of the two monitors were both 100% when the grayscale difference exceeded 150. This means that both monitors have comparable performance under the high background condition, and it is easier to identify subtle changes in gray level under the high background condition than the low background condition.

(a) Under the low background, the grayscale at the threshold of 80% sensitivity was 188 and 113 for the color and monochrome LCDs, respectively. (b) Under the high background, the sensitivities for both monitors reached 100% when the grayscale difference between the background and the sphere exceeded 150. In Figs. 3–6, error bars show standard error, n = [100].

Figure 4 depicts the relationship between the average sensitivity and the actual object size displayed on the screen which is the product of the pixel number and pixel size. The commercial color LCD required 1.485 mm for the 80% sensitivity, while the medical monochrome LCD required 0.725 mm in diameter under the low background level. This result verifies that the medical LCD has better spatial resolution than the commercial LCD. Under the high background condition, the diameter difference between monitors was decreased markedly to 0.357 mm at the 80% sensitivity level. When the diameter exceeded 1 mm, both monitors had no observation errors.

(a) Under the low background, the diameter corresponding to 80% sensitivity was 1.485 mm and 0.725 mm for the color and monochrome LCDs, respectively. (b) Under the high background, when the diameter exceeded 1 mm, no errors can be found with both monitors.

Figure 5 illustrates the average sensitivity dependency on the standard deviation of the point spread function. In both conditions, the curves of the color LCD dropped more rapidly than those of the medical monochrome LCD as σ increased. Both monitors exhibited higher tolerance of σ for the high background condition than for the low background condition. The σ at the threshold of 80% sensitivity significantly increased by 0.756 mm for the color LCD and 0.994 mm for the monochrome LCD, respectively. This indicates that the effect of image blurring can be suppressed in the high background situation.

Figure 6 shows the relationship between the average sensitivity and the noise density. When salt noise was intentionally added to the low background pattern, the tolerable density of noise distribution was 0.55 for the monochrome LCD at the sensitivity level of 80%, and 0.38 for the color LCD. When pepper noise was added to the high background pattern, the monochrome LCD again surpassed the color LCD in performance. However, the tolerable noise density decreased to 0.31 and 0.05 respectively, implying that pepper noise affects image quality more heavily than salt noise. In other words, even a small amount of pepper noise can jeopardize the image quality in the high background condition when using the color LCD.

The ROTP test results provide a set of parametric combinations that shows significant differences between the average sensitivity curves of the two monitors (Table 2). This parametric setting was used to randomly add spheres to abdominal CT images. Figure 7 illustrates the ROC curves of five individual reviewers and average ROC curves for each LCD, while Table 3 lists the AUC and the OT for each reviewer. Though the average AUC of the color LCD was 3.1% lower than that of the monochrome LCD, the difference did not achieve statistical significance (p = 0.265). In addition, the average OT for the color LCD was approximately 14% higher than that for the monochrome LCD. Based on the paired samples t-test, this difference was not statistically significant (p = 0.07).

BEIJING (Reuters) - Two new Chinese LCD screens in Beijing’s imposing Great Hall of the People will replace screens made by a Japanese competitor, in a sign of resolve to supply the world with Chinese brands and not just Made in China products.Delegates arrive for the National People"s Congress (NPC), China"s annual parliament, in the Great Hall of the People in Beijing March 9, 2012. REUTERS/David Gray

The screens are made by Chinese electronics giant TCL. At 110 inches, they are the world’s largest high-definition 3-D LCD screens, just a touch wider than the 108-inch Panasonic models they will replace.

“We have broken through the Japanese and South Korean monopoly of big flat-screen TVs!” TCL chairman Li Dongsheng boasted at a launch ceremony on Friday. Officials from the Ministry of Commerce, Ministry of Science and Technology, Ministry of Industry and Information Technology (MIIT), and the government of Shenzhen, TCL’s hometown, clapped and nodded.

Problems like extremely poor display of shadow areas, blown-out highlights, or images prepared on Macs appearing too dark on Windows computers are often due to gamma characteristics. In this session, we"ll discuss gamma, which has a significant impact on color reproduction on LCD monitors. Understanding gamma is useful in both color management and product selection. Users who value picture quality are advised to check this information.

* Below is the translation from the Japanese of the ITmedia article "Is the Beauty of a Curve Decisive for Color Reproduction? Learning About LCD Monitor Gamma" published July 13, 2009. Copyright 2011 ITmedia Inc. All Rights Reserved.

In most cases, if a computer runs the Windows operating system, we can achieve close to ideal colors by using a monitor with a gamma value of 2.2. This is because Windows assumes a monitor with a gamma value of 2.2, the standard gamma value for Windows. Most LCD monitors are designed based on a gamma value of 2.2.

An example of the same image displayed at gamma values of 2.2 (photo at left) and 1.8 (photo at right). At a gamma value of 1.8, the overall image appears brighter. The LCD monitor used is EIZO"s 20-inch wide-screen EV2023W FlexScan model (ITmedia site).

Eizo Nanao"s LCD monitors allow users to configure the gamma value from the OSD menu, making this procedure easy. In addition to the initially configured gamma value of 2.2., one can choose from multiple settings, including the Mac OS standard of 1.8.

Given the proliferating use of color spaces like sRGB and Adobe RGB, plans call for the latest Mac OS scheduled for release by Apple Computer in September 2009, Mac OS X 10.6 Snow Leopard, to switch from a default gamma value of 1.8 to 2.2. A gamma value of 2.2 is expected to become the future mainstream for Macs.

On the preceding page, we mentioned that the standard gamma value in a Windows environment is 2.2 and that many LCD monitors can be adjusted to a gamma value of 2.2. However, due to the individual tendencies of LCD monitors (or the LCD panels installed in them), it"s hard to graph a smooth gamma curve of 2.2.

Traditionally, LCD panels have featured S-shaped gamma curves, with ups and downs here and there and curves that diverge by RGB color. This phenomenon is particularly marked for dark and light tones, often appearing to the eye of the user as tone jumps, color deviations, and color breakdown.

The internal gamma correction feature incorporated into LCD monitors that emphasize picture quality allows such irregularity in the gamma curve to be corrected to approach the ideal of y = x γ. Device specs provide one especially useful figure to help us determine whether a monitor has an internal gamma correction feature: A monitor can be considered compatible with internal gamma correction if the figure for maximum number of colors is approximately 1,064,330,000 or 68 billion or if the specs indicate the look-up table (LUT) is 10- or 12-bit.

An internal gamma correction feature applies multi-gradation to colors and reallocates them. While the input from a PC to an LCD monitor is in the form of color information at eight bits per RGB color, within the LCD monitor, multi-gradation is applied to increase this to 10 bits (approximately 1,064,330,000 colors) or 12 bits (approximately 68 billion colors). The optimal color at eight bits per RGB color (approximately 16.77 million colors) is identified by referring to the LUT and displayed on screen. This corrects irregularity in the gamma curve and deviations in each RGB color, causing the output on screen to approach the ideal of y = x γ.

Let"s look at a little more information on the LUT. The LUT is a table containing the results of certain calculations performed in advance. The results for certain calculations can be obtained simply by referring to the LUT, without actually performing the calculations. This accelerates processing and reduces the load on a system. The LUT in an LCD monitor identifies the optimal eight-bit RGB colors from multi-gradation color data of 10 or more bits.

An overview of an internal gamma correction feature. Eight-bit RGB color information input from the PC is subjected to multi-gradation to 10 or more bits. This is then remapped to the optimal eight-bit RGB tone by referring to the LUT. Following internal gamma correction, the results approach the ideal gamma curve, dramatically improving on screen gradation and color reproduction.

Eizo Nanao"s LCD monitors proactively employ internal gamma correction features. In models designed especially for high picture quality and in some models in the ColorEdge series designed for color management, eight-bit RGB input signals from the PC are subjected to multi-gradation, and calculations are performed at 14 or 16 bits. A key reason for performing calculations at bit counts higher than the LUT bit count is to improve gradation still further, particularly the reproduction of darker tones. Users seeking high-quality color reproduction should probably choose a monitor model like this one.

In conclusion, we"ve prepared image patterns that make it easy to check the gamma values of an LCD monitor, based on this session"s discussion. Looking directly at your LCD monitor, move back slightly from the screen and gaze at the following images with your eyes half-closed. Visually compare the square outlines and the stripes around them, looking for patterns that appear to have the same tone of gray (brightness). The pattern for which the square frame and the striped pattern around it appear closest in brightness represents the rough gamma value to which the monitor is currently configured.

Based on a gamma value of 2.2, if the square frame appears dark, the LCD monitor"s gamma value is low. If the square frame appears bright, the gamma value is high. You can adjust the gamma value by changing the LCD monitor"s brightness settings or by adjusting brightness in the driver menu for the graphics card.

Naturally, it"s even easier to adjust the gamma if you use a model designed for gamma value adjustments, like an EIZO LCD monitor. For even better color reproduction, you can set the gamma value and optimize color reproduction by calibrating your monitor.

The patterns labeled HSL show the color in rows (left to right) from 100% saturation (full color) to no color (greyscale). The columns (top to bottom) show the color from 100% luminance (white) to 0% luminance (black).

The patterns labeled HSV show the color in rows (left to right) from 100% saturation to no color (greyscale). The columns (top to bottom) show the color from 100% luminance to 0% luminance (black).

The patterns labeled RGB start with a specific color patch in the upper left corner. As you look at the patches from left to right or up or down the color is changing in hue. Diagonally from upper left to lower right the color changes in saturation.

AMOLED burn-in on screens and displays is permanent. Fortunately, you can slow it down and reduce its visibility by using a few simple tricks, which can also increase battery life.

For the AMOLED on most smartphones, red sub-pixels are the most durable, followed by green. Blue decays the fastest. When you see burn-in, it"s often caused by a weakening blue sub-pixel. All "fixes" aim at addressing the failing blue sub-pixel. Remember, there are also tools available to fix dead pixels.

Everyone with an OLED display has some burn-in. But often, it"s not fully visible unless you display a solid color at maximum brightness. The Android operating system has access to many apps that detect burn-in damage. The best of these is Screen Test.

Screen Test is ultra-simple: install and run the app. Touching the screen shifts between colors and patterns. If you see a persistent image impression or blotchy coloration, you have burn-in.

For my AMOLED phone, I"ve taken every precaution against screen burn-in. Even so, the display is still a little blotchy after over a year of use. Fortunately, there are no indications of burn-in where the navigation buttons are.

Android made it possible to get rid of the navigation bar in Android 10. Once enabled, gestures allow navigation by swiping your finger on the screen. You can enable Gesture mode by doing the following:

Some might notice that the stock wallpapers in Android aren"t usually suited for OLED screens. OLED screens consume very little energy when displaying the color black, and they do not burn-in when displaying black. Unfortunately, older Android versions don"t include a solid black wallpaper option.

If you don"t have Android 10 or newer, the default Android Launcher isn"t OLED friendly. In Android 5.0, it forces the App Drawer wallpaper to white (the worst color for OLED screens). One of the best launchers for darker colors is Nova Launcher. Not only is it more responsive, it offers better customization options.

Minma Icon Pack changes your bright, screen-damaging icons into a darker, OLED-friendly palette. Over 300 icons are available, which cover the default icons as well as many others.

There are a few other burn-in repair tools, but I don"t recommend them since they either require root access and/or can increase screen damage. However, for reference, you can read about them below and why using them is a bad idea. They fall into two categories:

I do not recommend using this option unless your screen is already trashed. It will cause additional damage but may reduce the appearance of already existing on-screen burn. Inverting colors simply reverses the colors displayed on your screen. Whites become blacks and vice-versa.

Several tools claim to reduce the appearance of burn-in by attempting to age the entirety of your OLED panel. These screen burn-in tools flash red, green, and blue (or other) colors on your screen.

None of these methods will stop the inevitable and slow destruction of your device"s screen. However, using all the recommended options in this article will dramatically decrease the rate at which it decays. That said, some of the oldest AMOLED phones have very little burn-in. The decay of organic LEDs is almost entirely aesthetic, particularly on newer phones.

New York, Jan. 24, 2022 (GLOBE NEWSWIRE) -- Reportlinker.com announces the release of the report "Global and China Automotive LCD Cluster and Center Console Industry Report, 2021" - https://www.reportlinker.com/p06219667/?utm_source=GNW

Automotive display is a key booster to the digital transformation of automotive cockpits. The better performance of on-board computers enables the central computing unit to support LCD cluster, high-resolution infotainment display, HUD, electronic rearview mirror and other display systems, and provides technical support for multi-display systems.

From the new models launched in recent two years, it can be seen that large-size display and multi-screen display have been trends for automotive displays. High-end models have begun to pack at least 4 displays. Products like co-pilot seat entertainment display, control display, rear row entertainment display and streaming media rearview mirror have started finding application, and the demand for large-size displays has been soaring.

The installation of clusters shows that about 60% of new vehicles carry LCD clusters. In the first three quarters of 2021, 6.544 million LCD clusters were installed in passenger cars, a like-on-like spurt of 44.5%, of which 12.0-inch (incl.) to 13.0-inch (excl.) LCD clusters were most installed, up to 2.512 million units, up by 35.0%, and 10.0-inch (incl.) to 12.0-inch (excl.) LCD clusters grew at the fastest pace with the installations rocketing by 173.8% to 1.186 million units.

Cockpit electronics are heading in the direction of multi-display integration. Early in 2019, emerging carma

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey