passive matrix lcd display manufacturer

Established in 2007, Raystar Optronics., Inc. is the leading manufacturer of PMOLED display (Passive Matrix OLED) and modules in Central Taiwan Science Park. Taiwan.

Raystar built its reputation by offering advanced technology, design services and manufacturing efficiency in Character OLED modules, Graphic OLED modules, TFT LCM display modules, Monochrome Character LCD modules, Graphic LCM display modules products. Our products are for small and medium sizes and covered in industrial and consumer applications.

Raystar has consistently experienced strong growth by building solid partnerships with our customers and suppliers. Our goal is to provide our customers with “Competitive Price”, “Highest Quality” and “In-time Services”. Raystar is ready to serve as your best partner of the display solutions.

For product design engineers and manufacturers, a custom display and touch solution is the best approach to meet their unique application needs. Turning to us to be your monochrome LCD manufacturer means you’ll gain the experience and expertise of our in-house engineering team. Our talented engineers can develop customized solutions using a wide range of LCD technologies:Custom TN LCD displays

As we work with you to design a custom monochrome display, we’ll provide you with data-based recommendations and dedicated support. The know-how we bring to our clients has resulted in a proven track record of success, even with the most demanding applications.

Alibaba.com features an exciting range of passive matrix lcd that are suitable for all types of residential and commercial requirements. These fascinating passive matrix lcd are of superior quality delivering unmatched viewing experience and are vibrant when it comes to both, picture quality and aesthetic appearances. These products are made with advanced technologies offering clear patterns with long serviceable lives. Buy these incredible passive matrix lcd from leading suppliers and wholesalers on the site for unbelievable prices and massive discounts.

The optimal quality passive matrix lcd on the site are made of sturdy materials that offer higher durability and consistent performance over the years. These top-quality displays are not only durable but are sustainable against all kinds of usages and are eco-friendly products. The passive matrix lcd accessible here are made with customized LED modules for distinct home appliances and commercial appliances, instruments, and have elegant appearances. These wonderful passive matrix lcd are offered in distinct variations and screen-ratio for optimum picture quality.

Alibaba.com has a massive stock of durable and proficient passive matrix lcd at your disposal that are worth every penny. These spectacular passive matrix lcd are available in varied sizes, colors, shapes, screen patterns and models equipped with extraordinary features such as being waterproof, heatproof and much more. These are energy-efficient devices and do not consume loads of electricity. The passive matrix lcd you can procure here are equipped with advanced LED chips, dazzling HD quality, and are fully customizable.

Save money by browsing through the distinct passive matrix lcd ranges at Alibaba.com and get the best quality products delivered. These products are available with after-sales maintenance and are also available as OEM orders. The products are ISO, CE, ROHS, REACH certified.

TFT is an LCD Technology which adds a thin-film transistor at each pixel to supply common voltages to all elements. This voltage improves video content frame rates. Displays are predominantly utilizing color filter layers and white LED backlighting.

IPS TFT is a deviation of a traditional TN TFT Display. The most fundamental difference is that light is not rotated in plane and passing through polarizer films, but instead perpendicular to shutter the light. This approach to the technology improves contrast and enables symmetrical viewing angles from all directions.

OLED Displays are emissive displays and do not utilize liquid crystal. Each pixel is emissive with light. Passive OLED displays multiplex power and logic through the IC. Active OLED displays add a transistor at each pixel to supply power directly to the pixels and the IC only performs logical functions.

![]()

This is another story just like those, except this one involves the very screen you’re probably looking at, especially if it’s based on LCD technology.

In the 1970s, a pair of engineers that worked for Westinghouse, T. Peter Brody and Fang-Chen Luo, came to develop the first active-matrix LCD screen. Brody, born in Hungary, had gained an interest in the fledgling technology of thin film transistors, an experimental technology that had come to be seen as a potential avenue for visually displaying content in a more compact form than a cathode-ray tube.

“It has been apparent for some time that a solid-state flat panel display is conceptually achievable,” the patent filing stated. “Efforts to utilize silicon technology to this end are limited by the size limitation problems of the silicon wafer, which negates achievement of large area displays.”

So instead, the creators used thin-film transistors on a substrate of glass, which allowed the device to be firm, but thinner, while also allowing light through. The thin film was held into place with an insulator layer with an electrode conducted over the screen. The device, a six-inch square, could display objects at a resolution of 20 lines per inch. (Comparatively, a MacBook Air has a resolution of about 227 lines per inch, and we also describe the result in pixels per inch today.)

While admitting the device was still relatively crude, and with “a resolution only good enough to display letters, numbers and simple images in silhouette,” it nonetheless highlighted the potential for flat screens to someday replace bulky CRTs. Brody described the modest device in the Time article as “probably the world’s largest integrated circuit,” rather than simply as a screen.

But it was the starting point of the technology that stuck. By the mid-1990s, active-matrix displays that relied on color became the norm in laptops, thanks to their combination of vivid color and thinness. But despite the concept coming from an American company’s R&D department and improved by other American R&D departments, nearly all panels were developed by Japanese manufacturers even at the beginning of their mainstream use cases.

In fact, Westinghouse’s efforts with the flat-panel LCD display ended way back in the 1970s, as did similar efforts at other large U.S. companies. “Both large corporations and venture capital-backed start-ups have quit the field, usually after hitting production difficulties,” authors Richard Florida and David Browdy wrote.

It uses thin film transistors that are arranged in a matrix on a glass surface. To control the voltage tiny switching transistors and capacitors are used at each pixel location.

OLEDs are made from organic light-emitting materials that emit light when electricity is applied. OLED displays are emissive. That is the reason that OLED displays do not require backlight or filtering that are used in LCDs. As a result, OLEDs can be made flexible and transparent while providing the best images and great contrast and view angles.

Similar to LCD displays having two types: Passive Matrix LCD and Active-Matrix LCD, OLED displays also has two types: PMOLED and AMOLED. The difference is in the driving electronics – it can be either Passive Matrix (PM) or Active Matrix (AM).

Similar to passive matrix LCD, a PMOLED display uses a simple control scheme in which you control each row (or line) in the display sequentially (one at a time). PMOLED electronics do not contain a storage capacitor and so the pixels in each line are actually off most of the time. Because of this ,more voltage is needed to make PMOLED brighter. If you have 10 lines, for example, you have to make the one line that is on 10 times as bright (the real number is less than 10, but that’s the general idea).

uses the light-modulating properties of liquid crystals (LCs) to provide images on a screen. This is good for a short answer; however, the LCD is a quite interesting invention that has built for itself a long and rich history.

The liquid crystal is the driving force of the LCD, and its discovery goes well back to 1888. Considered more of a random occurrence while examining the properties of cholesterol in carrots, Austrian botanist – Fredreich Rheinizer – happened across a fourth, liquid crystal state of matter.

By the early 1980s, PM-LCDs were being used in electronic typewriters and personal word processors. However, by the mid-1980s, PM-LCDs were being realized as ill-suited as the screen size increased. An improvement came in the form of supertwisted-nematic (STN) LCDs that improved the picture quality, viewing angles and contrast, which made the technology well-suited for use in laptops and word processors. Nonetheless, STN still had visibility problems, resulting in double supertwisted-nematic (D-STN) being developed in 1987. D-STN required the overlaying of two liquid crystal layers to solve the problem, thereby increasing the weight, thickness and cost of the screen. Triple supertwisted-nematic (T-STN) further improved the LCD, but with added weight, thickness and cost. Passive-matrix use in monitor screens was the norm up until the early-1990s when active-matrix (AM) LCDs emerged as a superior display.

TFTs were first developed in the United States during the 1960s, and it was later in that decade that such companies as RCA Labs and Westinghouse came up with the idea for using TFTs in displays and laid the foundations for today"s AM-LCD technology. While these U.S. companies were the pioneers in the field, they ended up walking away from the technology, and instead, placing their bets on passive matrix. It was the Japanese that took AM technology to the next level...

Still, throughout this time, the LCD was still more costly to manufacture compared with the CRT – this was particularly the case given the high defect rate during the manufacturing process. For instance, in the mid-1990s, the cost of a 20" NEC LCD was approximately US$8,000. Compare this with a comparable 20" Sony CRT monitor at $2,300. Moreover, the CRT maintained its market position through innovations of its own, such as HD, increased screen size, flat face, superb display quality and an unbeatable cost-performance ratio. This price differential gradually eroded until the manufacturing cost of an LCD matched that of a CRT in the mid-2000s.

The LCD has quickly gained dominance as the display technology of choice over the past few years to the point where it has become rare to find CRT monitors in use anywhere. The new display technology that has started to emerge on the scene is OLED (Organic Light Emitting Diode).

Liquid crystals (LCs) are state of matter that has properties between those of conventional liquids and those of solid crystals, in which the constituent molecules tend to align themselves relative to each other. Liquid crystal displays (LCD) use the unique character of Nematic LC which are optically active and align themselves with an applied field.

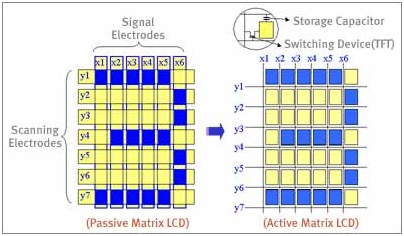

There are two ways to drive the working of LC in the electric field, either with a passive matrix or an active matrix grid. Therefore, LCD can be classified as Passive Matrix LCD (PMLCD) and Active Matrix LCD (AMLCD).

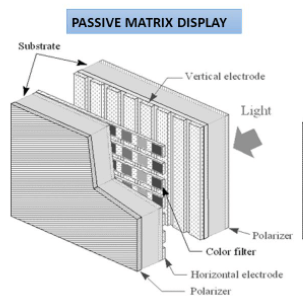

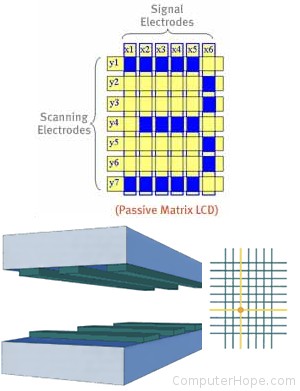

Passive matrix display is the first commercialized LCD technology, which is designed with a simple grid of row and column electrodes respective on the top and bottom plates to address the pixels.

The working principle of the passive display is to use the input signal to drive the electrodes of each row in turn, so when a row is selected, the electrodes on the column will be triggered to turn on those pixels located at the intersection of the row and the column.

Similar to the passive matrix LCD, the upper and lower layers of the active matrix LCD are also arranged vertically and horizontally with transparent electrodes made ofindium tin oxide (ITO).

Thus, high contrastis possible and a fast LC mixture can be used, since the pixel no longer has to respond to the average voltage over a whole frame period, as in PMLCDs. For the same reason, the phenomenon of crosstalk is also minimized.

Early passive matrix screens relied on twisted nematic (TN)designs. The polarizing directions of the upper and lower polarizing plates are at 90°, so the liquid crystal in the middle is twisted at 90°.

The resulting LCD panels have low contrast and slow response times. This method works well for low-information displays but not for computer displays.

To solve the color shift problem, double layer STN (DSTN) and further improved technology Film-compensated STN (FSTN)were developed with comparable display quality and low cost.

Since 2005, the picture quality of LCDs for TV surpassed that of CRTs, the milestone is Full High Definition (FHD) LC-modules with 1080 lines introduced into the market, which has good daylight contrast and high resolution.

Since the panel costof a TFT LCD module is relatively high, decreasing the cost of manufacturing an LC panel is one of the main issues. The most effective way is to enlarge the mother glass or substrate of the back and front plates.

Even though AMLCD (TFT LCD) takes advantage of the display technology and display quality, the cost of some modules can compete with the similar size of passive LCDs.

Passive Matrix LCDActive Matrix LCDWorking PrinciplePixels are addressed directly and they must retain their state between screen refreshes without the benefit of a steady electrical charge.A switch is placed at each pixel which decouples the pixel-selection function. Thin Film Transistor is the main technology of the AMLCD subgroup.

ApplicationNumerical displays, mono color word processors, mainly low cost, low power monochrome display, and graphic display.Mobile phones, computer screens, monitors, television, and mainstream color displaysFigure5: Comparison between PMLCD and AMLCD

With the benefit of the active matrix display technology and the technology development of related materials, components, and production in recent years, the TFT-LCD has attracted markets to adopt this technology.

In comparison with CRT, TFT LCD consumes about one-tenth of the power of a CRT display, and the reflective TFT LCD is even only about one-hundredth of that.

The power consumption of the TFT display is mainly from the backlight, accounting for about 90%. Reducing the power consumption of BL is the focus of the future development of TFT liquid crystal display, as well as improving its lifespan.

Because backlight is also the key factor that determines the service life of LCD. When the backlight turns dark while it reaches its maximum service life, the LCD screen will wear out. Even before then, the display quality will go down.

There are many different display technologies such as LCD, OLED, EPD, and ECD. They are all based on fundamentally different technologies with various driving requirements. That being said, all of them share some basic ideas of how to drive them. In this article, I will explain some fundamentals in display driving. This information is relevant whether you are a professional engineer designing display applications, a hacker exploring seven segment displays for your Arduino projects, or simply if you are just interested in this topic.

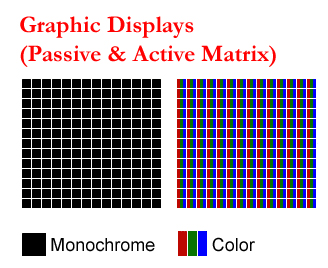

There are two main categories of displays; segmented (left picture) or graphical (right picture). In a segmented display, the content on the display has to be predetermined (it can be numbers, seven segment displays, symbols, characters), while a graphical display is generic and can represent any given picture. The segmented displays are generally cheaper (even if they are custom made) while graphical displays offer more flexibility in terms of the content displayed.

These display types can be driven by multiple methods with different degrees of complexity. A general guideline is that more pixels come with a higher driving complexity. There are two main types of driving, direct drive suitable for a low pixel count or matrix drive that can handle millions of pixels.

Direct drive is a common driving method for segmented displays such as seven segment displays. It is a very simple option where each display segment is connected to a pin. A segment is addressed simply by setting a voltage to the targeted segment. In some cases, this type of display can be driven directly from many microcontrollers, eliminating the need for a dedicated display driver. This, in turn, reduces the cost of the overall system. This is the case for the Rdot display which can be connected to practically any MCU with accurate driving voltage. An advantage with direct drive is the possibility to address all the pixels at the same time. For LCDs, direct drive is the driving method that offers the highest contrast.

The drawback with direct drive is the high pin count for a display with lots of segments. For a display with more than 100 segments direct drive is not recommended. From 30 to 100 segments, direct drive could be a good option. Below 30 segments a direct drive is very often the best choice. In the figure below I"m comparing direct drive and matrix drive in terms of electrodes required for different segment count.

To solve the issue with an unreasonable amount of electrodes, the segments, or pixels, has to be arranged in a structure according to the figure below. This can be done with both segmented and graphical displays. For example, addressing pixel 2 (P2) is done by addressing column 2 (C2) and row 1 (R1).

In a passive matrix display, pixels are addressed row by row, this is called time multiplexing. That means that all pixels on row 1 are updated first, then all pixels on row 2, etc.. meaning that for a display with three rows, each row is only addressed ⅓ of the total time. On retro displays, it is sometimes possible to see this effect as a continuous sweeping across the screen. For LCDs, this reduces the contrast of the display which, in turn, limits the total number of rows possible. This method is often called multiplex driving for segmented displays. Passive matrix drive is a cost-effective method to drive displays as it doesn"t require any additional hardware. However, just a few display technologies have the characteristics required for passive matrix drive.

The Rdot display technology has great potential to become the best passive matrix technology. This is because the technology is bistable (can maintain its state even when it is not addressed). This means that when one row is updated the driver can continue and update the other rows without losing the contrast on the first row. Passive matrix Rdot display is still under development but is planned to reach market during 2019. This display will be revolutionary to the display industry as it will be the first passive matrix display in high resolution and the first fully printed passive matrix display. In addition, it will still keep the low price point and maintain the bendability. If you want to follow the development, sign up for our newsletter!

The sophisticated display, that you most likely are looking at right now, is based on active matrix technology. In an active matrix, each pixel contains at least one transistor. More often, there are multiple transistors and capacitors. In an OLED for example, each pixel contains a quite sophisticated circuit with 5-10 transistors.

By adding transistors to the pixel, it can more easily be controlled. This is partly because transistors offer a threshold voltage which is an important feature for a display matrix to function properly. A capacitor, on the other hand, functions as an energy storage when the pixel is not addressed. In this way, all pixels can maintain their state even for a large number of rows. The Apple iMac display, for example, can in this way achieve 2880 rows without a problem. The drawback with active matrix is the high price point since the fabrication requires expensive deposition processes. For that reason, active matrix is mainly suitable for high-end displays.

There are two main display types; segmented and graphical. Direct drive is not suitable for graphical displays due to the high number of interconnections between the display and the controller. Matrix drive solves this problem with time multiplexing. There are two types of matrix drive; passive or active. Active drive is only suitable for high-end displays as it is an expensive technology. Passive matrix is a very inexpensive technology, but so far no high-resolution displays based on passive matrix have been demonstrated. Rdot will revolutionize the display industry during 2019 by introducing a passive matrix display that is both flexible and low-cost.

Microtips Technology is a leading custom lcd module manufacturer and we offer a full array of products and services. We have the most advances display technologies available to use in your design and if there is anything you want to change about one of our displays, we can make it happen. All of our displays are fully customizable to your specification and can include extra features like a capacitive touchscreen, an anti-reflective or anti-glare coating, or custom cover glass. Our sales and engineering staff will be with you through the entire process and will ensure our custom lcd display and your end product look their very best.

To create an LCD, you take two pieces ofpolarized glass. A special polymer that creates microscopic grooves in the surface is rubbed on the side of the glass that does not have the polarizing film on it. The grooves must be in the same direction as the polarizing film. You then add a coating of nematic liquid crystals to one of the filters. The grooves will cause the first layer of molecules to align with the filter"s orientation. Then add the second piece of glass with the polarizing film at a right angle to the first piece. Each successive layer of TN molecules will gradually twist until the uppermost layer is at a 90-degree angle to the bottom, matching the polarized glass filters.

If we apply an electric charge to liquid crystal molecules, they untwist. When they straighten out, they change the angle of the light passing through them so that it no longer matches the angle of the top polarizing filter. Consequently, no light can pass through that area of the LCD, which makes that area darker than the surrounding areas.

Building a simple LCD is easier than you think. Your start with the sandwich of glass and liquid crystals described above and add two transparent electrodes to it. For example, imagine that you want to create the simplest possible LCD with just a single rectangular electrode on it. The layers would look like this:

The LCD needed to do this job is very basic. It has a mirror (A) in back, which makes it reflective. Then, we add a piece of glass (B) with a polarizing film on the bottom side, and a common electrode plane (C) made of indium-tin oxide on top. A common electrode plane covers the entire area of the LCD. Above that is the layer of liquid crystal substance (D). Next comes another piece of glass (E) with an electrode in the shape of the rectangle on the bottom and, on top, another polarizing film (F), at a right angle to the first one.

The electrode is hooked up to a power source like a battery. When there is no current, light entering through the front of the LCD will simply hit the mirror and bounce right back out. But when the battery supplies current to the electrodes, the liquid crystals between the common-plane electrode and the electrode shaped like a rectangle untwist and block the light in that region from passing through. That makes the LCD show the rectangle as a black area.

TFT is an acronym for Thin Film Transistor, and it is a technology used in Liquid Crystal Display screens. It came about as an improvement to passive-matrix LCDs because it introduced a tiny, separate transistor for each pixel. The result? Such displays could keep up with quick-moving images, which passive-matrix LCDs could not do.

The technology improved on the TN (Twisted Nematic) LCD monitor because the shifting pattern of the parallel, horizontal liquid crystals gives wide viewing angles. Therefore, IPS delivers color accuracy and consistency when viewed at different angles.

Both TFT and IPS monitors are active-matrix displays and utilize liquid crystals to paint the images. Technically, the two are intertwined because IPS is a type of TFT LCD. IPS is an improvement of the old TFT model (Twisted Nematic) and was a product of Hitachi displays, which introduced the technology in 1990.

Impressive Display Effect: TFT displays use flat glass plates that create an effect of flat right angles. Combine this with the ability of LCDs to achieve high resolutions on small screen types, and you get a refreshing display quality.

Good Environmental Protection: The raw materials used to make TFT displays produce zero radiation and scintillation. Thus, the technology does not harm the user or the environment.

Liquid Crystal Display (LCD) is a front panel display that utilizes liquid crystals held between two layers of polarized glass to adjust the amount of blocked light. The technology does not produce light on its own, so it needs fluorescent lamps or white LEDs.

As explained earlier, TFT improved on the passive-matrix LCD design because it introduces a thin film transistor for each pixel. The technology reducescrosstalkbetween the pixels because each one is independent and does not affect the adjacent pixels.

LED screens are like the new kids on the block in the display market, and they operate very differently from LCDs. Instead of blocking light, LEDs emit light and are thinner, provide a faster response rate, and are more energy-efficient.

Since IPS is a type of TFT, when comparing the two, we are essentially looking at the old Thin-Film Transistor technology (Twisted Nematic) vs. the new (IPS). Even though TN is relatively old, this digital display type has its advantages, a vital one being the fast refresh rate. This feature makes such screens the preferred option by competitive gamers. If you have any inquiries about the technology,contact usfor more information.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey