passive matrix lcd display in stock

Alibaba.com features an exciting range of passive matrix lcd that are suitable for all types of residential and commercial requirements. These fascinating passive matrix lcd are of superior quality delivering unmatched viewing experience and are vibrant when it comes to both, picture quality and aesthetic appearances. These products are made with advanced technologies offering clear patterns with long serviceable lives. Buy these incredible passive matrix lcd from leading suppliers and wholesalers on the site for unbelievable prices and massive discounts.

The optimal quality passive matrix lcd on the site are made of sturdy materials that offer higher durability and consistent performance over the years. These top-quality displays are not only durable but are sustainable against all kinds of usages and are eco-friendly products. The passive matrix lcd accessible here are made with customized LED modules for distinct home appliances and commercial appliances, instruments, and have elegant appearances. These wonderful passive matrix lcd are offered in distinct variations and screen-ratio for optimum picture quality.

Alibaba.com has a massive stock of durable and proficient passive matrix lcd at your disposal that are worth every penny. These spectacular passive matrix lcd are available in varied sizes, colors, shapes, screen patterns and models equipped with extraordinary features such as being waterproof, heatproof and much more. These are energy-efficient devices and do not consume loads of electricity. The passive matrix lcd you can procure here are equipped with advanced LED chips, dazzling HD quality, and are fully customizable.

Save money by browsing through the distinct passive matrix lcd ranges at Alibaba.com and get the best quality products delivered. These products are available with after-sales maintenance and are also available as OEM orders. The products are ISO, CE, ROHS, REACH certified.

Since the Company’s inception by a team of enterprising academics at the University of Hong Kong in 1978, Varitronix have grown to become one of the leading manufacturers of Liquid Crystal Displays through years of innovation in research, design, production scalability, and technology advancement.

Through the following years of finding local success, Varitronix envisioned a much larger scale operation for the ever-increasing demand for displays. The trajectory plan eventually led the Company to be officially listed on the Hong Kong Stock Exchange in 1991 (HKSE code: 710), continuing its influence and strong presence to serve customers at the local, national, and global levels.

Nearly half a century later, BOE Varitronix continues its time-honored tradition in providing the one stop shop for the latest display technologies, backed up by solid research and commitment to quality, customized to the individual needs, and delivered economically and efficiently.

Global Passive Matrix Liquid Crystal Display Market, By Product (Manual, Automatic), Screen Size (Less Than 5, 5-10, >10), Type (Instrument Cluster Displays, Head-up Display, Centre Stack Display, Driver Information Display, Advanced Instrument Cluster Display, Rear- Seat Entertainment Touch Screen Display, Camera Information Display), Vehicle Type (Premium Passenger Cars, Compact Passenger Cars, Luxury Passenger Cars, Mid-Sized Passenger Cars, Heavy Commercial Vehicles, Light Commercial Vehicles), Application (Navigation, Telematics, Infotainment, Blind Spot Detection) – Industry Trends and Forecast to 2029.

Liquid Crystal Displays (LCDs) are widely used in various industries, including entertainment, corporate, transportation, retail, hospitality, education, and healthcare. These enable organizations to reach a larger audience. They also aid in the establishment of a centralized network for digital communications. Passive matrix liquid crystal displays are in high demand for displaying content.

Data Bridge Market Research analyses that the passive matrix liquid crystal display market which was growing at a value of 7.08 billion in 2021 and is expected to reach the value of USD 18.23 billion by 2029, at a CAGR of 12.55% during the forecast period of 2022-2029. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Product (Manual, Automatic), Screen Size (Less Than 5, 5-10, >10), Type (Instrument Cluster Displays, Head-up Display, Centre Stack Display, Driver Information Display, Advanced Instrument Cluster Display, Rear- Seat Entertainment Touch Screen Display, Camera Information Display), Vehicle Type (Premium Passenger Cars, Compact Passenger Cars, Luxury Passenger Cars, Mid-Sized Passenger Cars, Heavy Commercial Vehicles, Light Commercial Vehicles), Application (Navigation, Telematics, Infotainment, Blind Spot Detection)

Panasonic Corporation (Japan), LG DISPLAY CO., LTD (South Korea), AUO Corporation. (Taiwan), CHIMEI (Taiwan), SAMSUNG (South Korea), SHARP CORPORATION (Japan), Schneider Electric (France), Siemens (Germany), Mitsubishi Electric Corporation (Japan), SONY INDIA. (India), FUJITSU (Japan), Chunghwa Picture Tubes, LTD. (Taiwan), Barco.(Belgium), BOE Technology Group Co., Ltd. (China), Innolux Corporation (Taiwan), Advantech Co., Ltd (Taiwan)

A flat-panel display composed of a grid of horizontal and vertical wires. At the intersection of each grid is an LCD element representing a single pixel, allowing or blocking light. An active-matrix display, which is more expensive and of higher quality, uses a transistor to control each pixel. These lighting solutions are highly energy-efficient, have a longer lifespan than traditional lighting solutions, and have a lower environmental impact.

Passive matrix liquid crystal displays have several built-in advantages, including exceptional readability, light in a much narrower spectrum than other illumination sources, energy efficiency, low operating costs, and long life. These will be expected to reduce electronic power losses and increase market usage of competently used outdoor displays. Furthermore, using passive matrix liquid crystal displays for advertising, promoting sporting events and brands, and other types of events is a highly innovative and cost-effective method of promoting these types of events.

The increasing reliance on navigation systems is a critical factor driving market growth, as is continuous innovation in driver assistance solutions and enhancement of driver experience and safety features, among other factors driving the passive-matrix liquid crystal display market. Furthermore, significant technological advances and developments in the market will create new opportunities for the passive-matrix liquid crystal display market during the forecast period.

This increasing reliance on navigation systems is an important factor driving market growth, as is continuous innovation in driver assistance solutions and enhancement of driver experience and safety features, among other factors driving the passive-matrix liquid crystal display market.

Furthermore, significant technological advances and developments in the market will create new opportunities for the passive-matrix liquid crystal display market during the forecast period.

However, a lack of adoption and preference for implementing high-cost automotive displays, as well as rising concerns about the mobility functionality of touch screen displays in comparison to mechanical controls, are among the major factors that will limit market growth and further challenge the passive-matrix liquid crystal display market during the forecast period.

This passive matrix liquid crystal display market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the passive matrix liquid crystal display market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

The COVID-19 has had an impact on the digital liquid crystal display (LCD) market. Limited investment costs and a lack of employees hampered sales and production of liquid crystal display (LCD) technology. However, the government and key market players adopted new safety measures in order to develop the practices. As technology advanced, the sales rate of the li liquid crystal display (LCD) digital increased because it targeted the right audience. Increased device sales across the globe are expected to drive market growth in the post-pandemic scenario.

In September 2021, BNZSA, Europe"s leading IT B2B digital, data, and lead generation agency, announced the launch of programmatic display, allowing consumers to deepen relationships with potential clients using technographic techniques firmographic, and intent data to promote brand awareness and thought-leadership content.

In June 2021, Blackstone announced partnerships with Simpli.fi, a leading programmatic display advertising and agency management software. The company made a US$ 1.5 billion investment in the latter programmatic display agency firm, accounting for a majority stake.

The passive matrix liquid crystal display market is segmented on the basis of product, screen size, type, vehicle type and application. The growth amongst these segments will help you analyse meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

The passive matrix liquid crystal display market is analysed and market size insights and trends are provided by country, product, screen size, type, vehicle type and application as referenced above.

The countries covered in the passive matrix liquid crystal display market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

The passive matrix liquid crystal display market competitive landscape provides details by competitor. details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, Global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies" focus related to passive matrix liquid crystal display market.

There are many different display technologies such as LCD, OLED, EPD, and ECD. They are all based on fundamentally different technologies with various driving requirements. That being said, all of them share some basic ideas of how to drive them. In this article, I will explain some fundamentals in display driving. This information is relevant whether you are a professional engineer designing display applications, a hacker exploring seven segment displays for your Arduino projects, or simply if you are just interested in this topic.

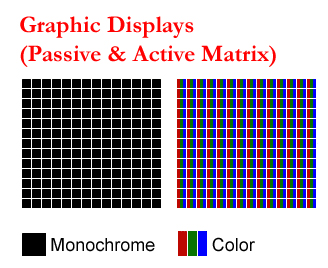

There are two main categories of displays; segmented (left picture) or graphical (right picture). In a segmented display, the content on the display has to be predetermined (it can be numbers, seven segment displays, symbols, characters), while a graphical display is generic and can represent any given picture. The segmented displays are generally cheaper (even if they are custom made) while graphical displays offer more flexibility in terms of the content displayed.

These display types can be driven by multiple methods with different degrees of complexity. A general guideline is that more pixels come with a higher driving complexity. There are two main types of driving, direct drive suitable for a low pixel count or matrix drive that can handle millions of pixels.

Direct drive is a common driving method for segmented displays such as seven segment displays. It is a very simple option where each display segment is connected to a pin. A segment is addressed simply by setting a voltage to the targeted segment. In some cases, this type of display can be driven directly from many microcontrollers, eliminating the need for a dedicated display driver. This, in turn, reduces the cost of the overall system. This is the case for the Rdot display which can be connected to practically any MCU with accurate driving voltage. An advantage with direct drive is the possibility to address all the pixels at the same time. For LCDs, direct drive is the driving method that offers the highest contrast.

The drawback with direct drive is the high pin count for a display with lots of segments. For a display with more than 100 segments direct drive is not recommended. From 30 to 100 segments, direct drive could be a good option. Below 30 segments a direct drive is very often the best choice. In the figure below I"m comparing direct drive and matrix drive in terms of electrodes required for different segment count.

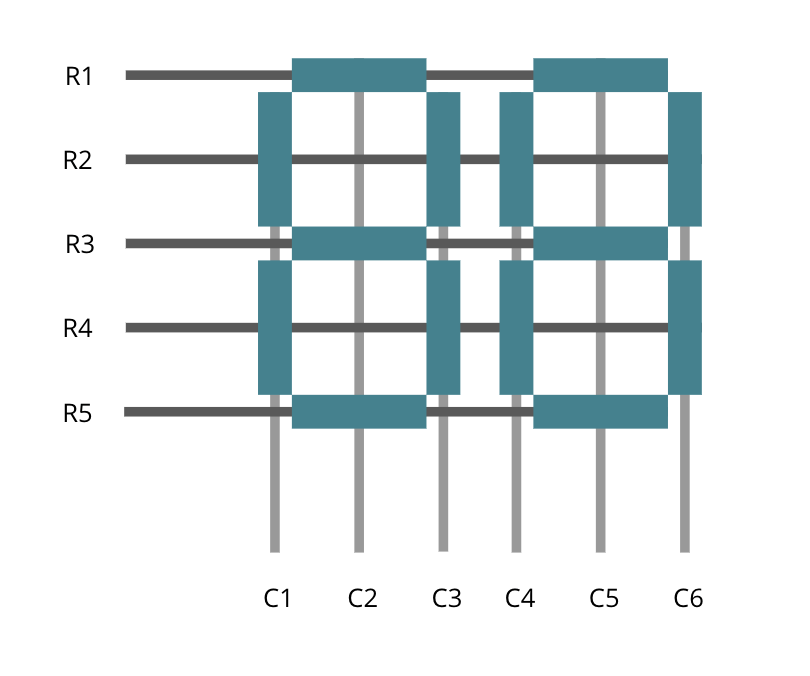

To solve the issue with an unreasonable amount of electrodes, the segments, or pixels, has to be arranged in a structure according to the figure below. This can be done with both segmented and graphical displays. For example, addressing pixel 2 (P2) is done by addressing column 2 (C2) and row 1 (R1).

In a passive matrix display, pixels are addressed row by row, this is called time multiplexing. That means that all pixels on row 1 are updated first, then all pixels on row 2, etc.. meaning that for a display with three rows, each row is only addressed ⅓ of the total time. On retro displays, it is sometimes possible to see this effect as a continuous sweeping across the screen. For LCDs, this reduces the contrast of the display which, in turn, limits the total number of rows possible. This method is often called multiplex driving for segmented displays. Passive matrix drive is a cost-effective method to drive displays as it doesn"t require any additional hardware. However, just a few display technologies have the characteristics required for passive matrix drive.

The Rdot display technology has great potential to become the best passive matrix technology. This is because the technology is bistable (can maintain its state even when it is not addressed). This means that when one row is updated the driver can continue and update the other rows without losing the contrast on the first row. Passive matrix Rdot display is still under development but is planned to reach market during 2019. This display will be revolutionary to the display industry as it will be the first passive matrix display in high resolution and the first fully printed passive matrix display. In addition, it will still keep the low price point and maintain the bendability. If you want to follow the development, sign up for our newsletter!

The sophisticated display, that you most likely are looking at right now, is based on active matrix technology. In an active matrix, each pixel contains at least one transistor. More often, there are multiple transistors and capacitors. In an OLED for example, each pixel contains a quite sophisticated circuit with 5-10 transistors.

By adding transistors to the pixel, it can more easily be controlled. This is partly because transistors offer a threshold voltage which is an important feature for a display matrix to function properly. A capacitor, on the other hand, functions as an energy storage when the pixel is not addressed. In this way, all pixels can maintain their state even for a large number of rows. The Apple iMac display, for example, can in this way achieve 2880 rows without a problem. The drawback with active matrix is the high price point since the fabrication requires expensive deposition processes. For that reason, active matrix is mainly suitable for high-end displays.

There are two main display types; segmented and graphical. Direct drive is not suitable for graphical displays due to the high number of interconnections between the display and the controller. Matrix drive solves this problem with time multiplexing. There are two types of matrix drive; passive or active. Active drive is only suitable for high-end displays as it is an expensive technology. Passive matrix is a very inexpensive technology, but so far no high-resolution displays based on passive matrix have been demonstrated. Rdot will revolutionize the display industry during 2019 by introducing a passive matrix display that is both flexible and low-cost.

This is another story just like those, except this one involves the very screen you’re probably looking at, especially if it’s based on LCD technology.

In the 1970s, a pair of engineers that worked for Westinghouse, T. Peter Brody and Fang-Chen Luo, came to develop the first active-matrix LCD screen. Brody, born in Hungary, had gained an interest in the fledgling technology of thin film transistors, an experimental technology that had come to be seen as a potential avenue for visually displaying content in a more compact form than a cathode-ray tube.

“It has been apparent for some time that a solid-state flat panel display is conceptually achievable,” the patent filing stated. “Efforts to utilize silicon technology to this end are limited by the size limitation problems of the silicon wafer, which negates achievement of large area displays.”

So instead, the creators used thin-film transistors on a substrate of glass, which allowed the device to be firm, but thinner, while also allowing light through. The thin film was held into place with an insulator layer with an electrode conducted over the screen. The device, a six-inch square, could display objects at a resolution of 20 lines per inch. (Comparatively, a MacBook Air has a resolution of about 227 lines per inch, and we also describe the result in pixels per inch today.)

While admitting the device was still relatively crude, and with “a resolution only good enough to display letters, numbers and simple images in silhouette,” it nonetheless highlighted the potential for flat screens to someday replace bulky CRTs. Brody described the modest device in the Time article as “probably the world’s largest integrated circuit,” rather than simply as a screen.

But it was the starting point of the technology that stuck. By the mid-1990s, active-matrix displays that relied on color became the norm in laptops, thanks to their combination of vivid color and thinness. But despite the concept coming from an American company’s R&D department and improved by other American R&D departments, nearly all panels were developed by Japanese manufacturers even at the beginning of their mainstream use cases.

In fact, Westinghouse’s efforts with the flat-panel LCD display ended way back in the 1970s, as did similar efforts at other large U.S. companies. “Both large corporations and venture capital-backed start-ups have quit the field, usually after hitting production difficulties,” authors Richard Florida and David Browdy wrote.

You’re almost certainly reading this blog on a display, which is likely to consist of millions of pixels, each capable of displaying around a million colours.

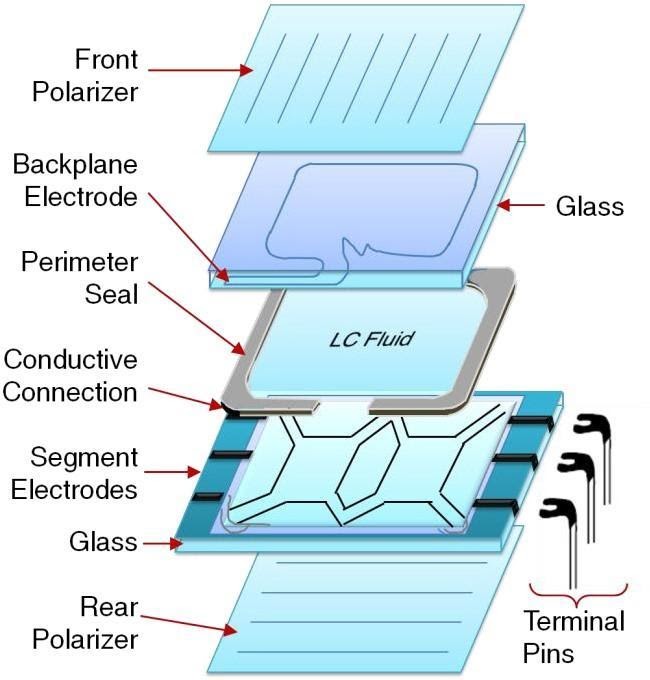

LCDs have been around for decades in various forms. These displays consist of two parts – a backplane that provides the connections and electrodes for each pixel, and the frontplane – the liquid crystal cell itself.

Whilst there are many variants in terms of design and operation of the liquid crystal cells that make LCDs possible, the basic mechanism is based on the ability of liquid crystals to rotate the polarization of light depending on the voltage is applied. This means that, for example, light with a horizontal polarization can pass through the liquid crystal and emerge with a vertical polarization. This cell can be used in conjunction with polarizers to create a display effect.

Polarizers are thin plastic films that are used to block light of a particular polarization, and are used in many applications such as sunglasses, displays, and many optical components. If you put two identical polarizer sheets on top of each other and rotate one 90 degrees, then no light passes through the pair – one polarizer stops light of vertical polarization, and the second stops light of horizontal polarization. However, putting the liquid crystal cell between these two crossed polarizers allows you to rotate the polarization of the light that makes it through the first polarizer, so that it can now pass through the second. You have now created an electo-optical switch that can be used to selectively turn “on” and “off” different regions (for example, the segments on a calculator display, or the pixels in a TV).

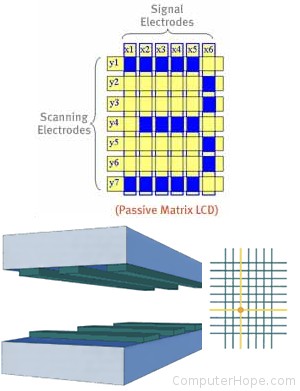

Pixelated LCDs have been around for many years. I’m old enough to remember the early smartphones in the 1990s such as the Nokia 5110 introduced in 1998. This featured an LCD display containing a whopping 4032 monochrome pixels (84pixels x 48pixels) with no greyscale – they were either ‘on’ or ‘off’. These displays were so-called “passive matrix” LCD displays – there were few enough rows of pixels so that you didn’t need transistors to drive the display – having few pixels that only went black or white (no grey) meant that video rate could be achieved and crosstalk could be minimised.

Naturally there was pressure to improve the display performance by making it higher resolution (i.e. making the pixels much smaller) and achieving colour and greyscale. This meant that the pixel count increased from thousands to hundreds of thousands and today there are millions of pixels in each display, each controllable to hundreds of grey levels. In order to control this many pixels accurately and independently, transistors are used. ‘Passive matrix’ therefore rapidly shifted to ‘active matrix’, where each pixel was actively controlled by its own transistor circuit.

There are different transistor circuits that can be used depending on the type of display, but in the most common circuit there is just one transistor controlling each pixel - acting like a light switch for that pixel, or perhaps more accurately, like a dimmer switch. Each transistor allows its respective pixel to be set to a particular brightness for the duration of a single frame of the video. The transistors therefore have two functions: to allow millions of pixels to be controlled at video rate, and to avoid crosstalk between the pixel (avoid the state of one pixel ‘upsetting’ its neighbour).

The transistors used in displays have historically mostly been made of silicon – and the high temperatures of silicon processing are one of the key reasons why displays are manufactured on glass.

FlexEnable has developed a transistor that is made of organic polymers, which can be processed at much lower temperatures and is inherently flexible. These transistors perform exactly the same function as the silicon ones that they replace, but because of their low manufacturing temperature (100°C), they can be built directly onto plastic films, giving the same performance while allowing conformed and shaped displays. We have called these displays Organic LCDs (OLCDs).

OLCDs have the same structure as glass LCDs with the benefit of being thinner, lighter and shatterproof. They work in the same way as glass LCDs and are manufactured using the same techniques and equipment. With LCD being the dominant technology today, OLCD is the next logical step for display manufacturers and end user companies in moving away from flat screens towards novel display shapes and designs.

![]()

T. P. Brody, J. A. Asars and G. D. Dixon: A 6× 6 inch 20 lines-per-inch liquid-crystal display panel. IEEE Trans. Electron Devices, ED-20, 995–1001, 1973.

T. Tsukada: State-of-the-art of a-Si TFT/LCD. Transaction of the Institute of Electronics, Information and Communication Engineers (Japan), J76-C-II, 177–183, 1993.

2.9 M. Ohta, M. Oh-e, K. Kondo: Development of Super-TFT-LCDs with in-plane-switching display mode, Proc. Int. Display Res. Conf., S30–2, 707–710, 1995 (Hamamatsu).

Y. Kaneko, A. Sasano, and T. Tsukada: Analysis and design of a-Si TFT/LCD panels with a pixel model. IEEE Transaction Electron Devices, ED-36, 2953–2958, 1989.

F. Morin: Electrooptical performance of a TFT-addressed TNLC panel. Proc. 3rd International Display Research Conference (Kobe, 1983). 412–414, California: SID, 1983.

Y. Kaneko, Y. Tanaka, N. Kabuto, and T. Tsukada: A new address scheme to improve the display quality of a-Si TFT/LCD panel. IEEE Transaction Electron Devices, ED-36, 2949–2952, 1989.

Y. Nanno, Y. Mino, E. Takeda, and S. Nagata: Characterization of sticking effects of TFT-LCD. In Digest of Technical Papers of the Society for Information Display International Symposium (Las Vegas, 1990), 404–407, California: SID, 1990.

Y. Kanemori, M. Katayama, K. Nakazawa, H. Kato, K. Yano, Y. Fukuoka, et al.: 10.4-in-diagonal color TFT-LCDs without residual images. In Digest of Technical Papers of the Society for Information Display International Symposium (Las Vegas, 1990), 408–411, California: SID, 1990.

Y. Nasu, S. Kawai, S. Kisumi, K. Oki, and K. Hori: Color LCD for character and TV display addressed by self-aligned a-Si:H TFT. In Digest of Technical Papers of the Society for Information Display International Symposium (San Diego, 1986), 289–292, California: SID, 1986.

K. Asama, T. Kodama, S. Kawai, Y. Nasu, and S. Yanagisawa: A self-alignment processed a-Si TFT matrix circuit for LCD SID panels. In Digest of Technical Papers of the Society for Information Display International Symposium (Philadelphia, 1983), 144–145, California: SID, 1983.

H. Yamamoto, H. Matsumaru, K. Tsutsui, N. Konishi, M. Nakatani, K. Shira-hashi, A. Sasano, and T. Tsukada: A new a-Si TFT with Al2O3/SiN double-layered gate insulator for 10.4-inch diagonal multicolor display. In Technical Digest of the International Electron Devices Meeting (San Francisco, 1990), 851–854, New York: IEEE, 1990.

W. H. Dumbaugh, P. L. Bocko: Substrate glasses for flat-panel displays. In Digest of Technical Papers of the Society for Information Display International Symposium (Las Vegas, 1990), 70–72, California: SID, 1990.

T. P. Brody, J. A. Asars, and G. D. Dixon: A 6x6 inch 20 lines-per-inch liquid-crystal display panel, IEEE Trans. Electron Devices, ED-20, 995–1001, 1973.

F-C. Luo, W. A. Hester, and T. P. Brody: Alphanumeric and video performance of a 6′× 6′ 30 lines-per-inch thin-film transistor-liquid crystal display panel, In Digest of Technical Papers of the Society for Information Display International Symposium (San Francisco, 1978). California: SID, 1978.

A. J. Snell, K. D. Mackenzie, W. E. Spear, and P. G. LeComber: Application of amorphous silicon field effect transistors in addressable liquid crystal display panels, Applied Physics, 24, 357–362, 1981.

Y. Okubo, T. Nakagiri, Y. Osada, M. Sugata, N. Kitahara, and K. Hatanaka: Large-scale LCDs addressed by a-Si TFT array, In Digest of Technical Papers of the Society for Information Display International Symposium (San Diego, 1982), California: SID, 1982.

M. Ohta, M. Tsumura, J. Ohida, J. Ohwada, and K. Suzuki: Active matrix network simulator considering non-linear C-V characteristics of TFTs intrinsic capacitances, In Proceedings of the 12th International Display Research Conference (Hiroshima, 1992), 431–434. California: SID, 1992.

M. Nakazato and T. Higuchi: Capacitance-voltage characteristics of a-Si TFTs, In Proceedings of the 12th International Display Research Conference (Hiroshima, 1992), 439–442, California: SID, 1992.

M. Katayama, H. Morimoto, S. Yasuda, T. Takamatu, H. Tanaka, M. Hi-jikigawa: High-resolution full-color LCDs addressed by double-layered gate-insulator a-Si TFTs, In Digest of Technical Papers of the Society for Information Display International Symposium (Anaheim, 1988), 310–313, California: SID, 1988.

2.44 S. Morozumi, T. Ohta, R. Araki, T. Sonehara, K. Kubota, Y. Ono, T. Nakazawa, H. Ohara: A 250 × 240 element LCD addressed by lateral MIM, Proc. Intn’l Display Res. Conf., 10–3, 404–407, 1983 (Kobe).

N. Szydlo, E. Chartier, J. N. Perbet, N. Proust, J. Magarino, and M. Hareng: Integrated matrix-addressed LCD using amorphous-silicon back-to-back diodes, Proc. SID (Society for Information Display), 265–268, 1984.

K. Katoh, S. Imagi and N. Kobayashi: Active-matrix-addressed color LCDs for avionic application. In Digest of Technical Papers of the Society for Information Display International Symposium (Anaheim, 1988), 238–241. California: SID, 1988.

F. Funada, M. Okada, N. Kimura and K. Awane: Selection and optimizing of liquid crystal display modes for the full color active-matrix LCDs, Journal of the Institute of Television Engineers, 42, 1029–1034, 1988 (In Japanese).

C. C. Yang: Two-domain twisted nematic and tilted homeotropic liquid crystal displays for active matrix applications. In Proc. International Display Research Conference (San Diego, 1991), 68–72, California: SID, 1991.

Y. Koike, T. Kamada, K. Okamoto, N. Ohashi, I. Tornita and M. Okabe: A full-color TFT-LCD with a domain-divided twisted-nematic structure. In Digest of Technical Papers of the Society for Information Display International Symposium (Boston, 1992), 798–801, California: SID, 1992.

2.64 R. Kiefer, C. Weber, F. Windscheid, G. Baur: In-plane switching of nematic liquid crystals, Proc. Intn’l Display Res. Conf., P 2–30, 547–550, 1992 (Hiroshima).

K. Ohmuro, S. Kataoka, T. Sasaki, Y. Koike: Development of super-high-image-quality vertical-alignment-mode LCD, Digest Tech. Papers Society for Information Display Intn’l Symposium, 845–848, 1997.

2.68 M. Ohta, M. Oh-e, K. Kondo: Development of Super-TFT-LCDs with in-plane switching display mode, Proc. Intn’l Display Res. Conf., S. 30–2, 707–710, 1995 (Hamamatsu).

J. Nehring, A. R. Kmetz: Ultimate limits for matrix addressing of rms-responding liquid-crystal displays, IEEE Transactions on Electron Devices, ED-26, 795–802, 1979.

F. Leenhouts and M. Schadt: Electro-optics of supertwist displays; dependence on liquid crystal material parameters, In Proc. 6th International Display Research Conference (Tokyo, 1986), 388–391. California: SID, Tokyo: ITE, 1986.

K. Kinugawa, Y. Kondo, M. Kanasaki, H. Kawakami and E. Kaneko: 640×480 pixel LCD using highly twisted birefringence effect with low pretilt angle, In Digest of Technical Papers of the Society for Informatio Display International Symposium (San Diego, 1986), pp. 122–125. California: SID, 1986.

From their discovery in 1888 to their first application within displays in the 1960s, liquid crystals have become a mainstream material choice with many impactful applications in the world of electronics.

As the key component behind liquid crystal displays (LCD), these materials change light polarization to create vibrant, high-resolution images on digital screens. The growth of LCD technology has helped propel the larger display panel market enormously, with industry valuation projected to reach $178.20 billion by 2026.

A prolific variety of LCD types has been developed to best meet their exact use-cases and end-environments. Displays may be optimized for power consumption, contrast ratio, color reproduction, optimal viewing angle, temperature range, cost, and more.

Passive Matrix LCDs are addressed with common and segment electrodes. A pixel or an icon is formed at the intersection where a common and a segment electrode overlap. Common electrodes are addressed one-at-a-time in a sequence. Segment electrodes are addressed simultaneously with the information corresponding to all pixels or icons connected to the current common electrode. This method is referred to as multiplexing.

Passive Matrix LCDs offer a cost advantage (both parts and tooling) and are highly customizable. The counterpart to Passive Matrix displays are Active Matrix displays.

Active-Matrix LCDs were developed to overcome some of the limitations of Passive Matrix LCDs – namely resolution, color, and size. Within an Active-Matrix LCD, an “active element” is added to each pixel location (the intersection between a horizontal row and vertical column electrode). These active elements, which can be diodes or transistors, create a threshold and allow control of the optical response of the liquid crystal structure to the applied voltage. Transistors are used as switches to charge a capacitor, which then provides the voltage to the pixel. Whenever a row is turned on, one at a time, all transistor switches in that row are closed and all pixel capacitors are charged with the appropriate voltage. The capacitor then keeps the voltage applied to the pixel after the row is switched off until the next refresh cycle.

Furthermore, the processes used for manufacturing Active-Matrix LCDs can create much finer details on the electrode structure. This allows splitting each pixel in three sub-pixels with different color. This together with the better voltage control allows full color displays.

The transistor switches used in Active Matrix Displays must not protrude significantly above the surface of the display substrates lest they might interfere with a uniform liquid crystal layer thickness. They must be implemented in thin films of suitable materials. Hence, the name Thin Film Transistors (TFT). While AM and TFT have a different meaning, they are often used interchangeably to indicate a higher performance display.

Currently the most common Electronics Display Technology on the market is LCD technology and among LCD technologies, TFT display technology is the most widely used across consumer applications (laptops, tablets, TVs, Mobile phones, etc.) as well as many industrial, automotive, and medical applications.

As the first commercially successful LCD technology, Passive Matrix Twisted Nematic (TN) LCDs use a 90° twist of the nematic LC fluid between two polarizers to display information. The twist of the LC fluid either blocks light from passing through the LCD cell or allows light to pass, depending on the applied voltage. The applied voltage changes the twisted nematic orientation into an orientation that does not change the polarization of tight. This is called the TN effect.

TN displays can be normally white (NW) when they use two orthogonal liner polarizers or normally black (NB) when parallel linear polarizers are used. ‘Normally’ refers to what happens when no voltage is applied.

Initially, Passive TN LCDs were used in segmented, icon, or character displays where an image element was turned “on” and “off” depending on how the fluid was driven. Improvements were made along the way to address the limited viewing angle of TN technology, which can suffer from contrast loss or even inversion at shallow angles.

It can be advantageous to twist the director of the nematic phase a bit more than 90 degrees, but less than 180 degrees. Displays like this are a subset of TN displays and are sometimes caller Hyper Twisted Nematic Displays.

The numbers of rows or icons that can be addressed in a TN display without Active Matrix addressing is very limited. This is related to how strongly the liquid crystal responds to the applied voltage. Twisting the LC nematic fluid more than 180 degrees (typically between 210 and 270 degrees) causes the display to require a much smaller voltage difference between on and off pixels. This in turn allows addressing of many more rows without an active matrix. Displays with a twist between 210 and 270 degrees are called Super Twisted Nematic displays.

The higher display resolution of STN displays comes at a price. The optical effect is no longer neutrally black and white as in a TN display. Rather these displays are naturally yellow and black or blue and white. The color can be somewhat compensated with colored polarizers, but that comes at the expense of brightness and contrast.

The color in STN displays is caused by birefringence. Adding the same birefringence in the opposite direction can compensate for the effect. Initially this was done by stacking two STN displays on top of each other. This is referred to as Double STN or DSTN, but this is of course thicker and more expensive.

The birefringence of an STN display can be approximated with a stretched transparent plastic film. Adding such a film to an STN display instead of the 2nd STN display is a lot more attractive and has almost the same performance. This is referred to as a Film Compensated STN display (FSTN, or sometimes if two films are used as FFSTN).

FSTN displays are used commonly in consumer, medical and industrial display applications that require low cost and do not need high resolution images or full color.

Another development to the TN display was to use the same concept as in FSTN displays on TN displays. However, the film cannot just be a stretched polymer. Instead, a twisted liquid crystal structure is made and polymerized into a film that is used as a compensation film for TN displays. As this method mostly improves the display characteristics at shallow viewing angles while preserving the excellent performance in straight on viewing, this technology is called Wide View Twisted Nematic (WVTN).

The above display technologies have liquid crystal molecules that are aligned nearly parallel to the display surface with more or less twisting when going from one substrate to the other. In VA (also called VAN) displays, the liquid crystal molecules are aligned vertically with respect to the display surface. Applying a voltage causes the molecules to lay flat, with or without twist.

The advantage of this arrangement is a very dark black state with very little light leakage. This allows making displays with a black mask and colored icons or symbols. These displays look like color displays with brilliant colors, however each image element or icon can only have its assigned color or black.

Due to the ability in AM displays to address one row while the other rows are isolated, the demands on the electro-optical performance of the Liquid Crystal Configuration are less stringent. In principle, all the above mentioned configurations can be used in AM displays. In practice, TN, and WVTN are frequently used as well as some versions of VA technology described below. (MVA, AIFF-MVA, PVA, ASV).

The advantage of these technologies is a much wider and more symmetrical viewing angle along with the elimination of the contrast inversion (or color shift) seen in TN TFT LCDs when viewed from various angles. IPS and FFS displays also are less sensitive to pressure, which is a big advantage in touchscreen displays.

Here, each color sub-pixel is further divided into zones (called domains) having a different direction of the molecular movement when voltage is applied. Again, the purpose is a much wider and more symmetric viewing performance and the elimination of color shifts and contrast inversion at shallow angles. MVA technology achieves that with carefully designed protrusions on the inside surfaces of the display, while PVA uses fine patterning of the electrodes on both substrates.

The integrated circuit is a patterned piece of silicon or other type of semiconducting material. A modern IC contains millions or even billions of tiny transistors. Their tiny size allows for the fabrication of smaller, faster, more efficient, and less expensive electronic circuits. The driver chips addressing electronics displays are ICs.

Legacy LCDs normally have the driver ICs (integrated circuit) mounted on a printed circuit board (PCBA) which consists of a flat sheet of insulating material used to mount and connect the driver IC and electronic periphery to the LCD. PCBs can be a single-sided, double-sided or multi-layer.

Often PCBAs are connected to the display with flexible printed circuits. It’s also possible to mount all necessary components on FPCs without the need of a PCBA in the display module.

Low Voltage Differential Signaling (LVDS) is an interface to the display, not a display technology itself. This technology is not specific to displays, as it’s used in many other applications as well. It’s a high-speed signal that provides some noise immunity for the display. It also allows for longer distances compared to parallel interfaces.

As display resolutions increase, data transmission rates must increase as well. At high frequencies, single-ended signaling circuits can begin to act as antennas to radiate and receive radiated noise. Low Voltage Differential Signaling (LVDS) addresses many of these shortcomings by using differential signaling at low voltages to transmit display data at high speeds.

Mobile Industry Processor Interface (MIPI®) is a high-speed Display Serial Interface (DSI) between the host processor and the display module. It has a low pin count, high bandwidth, and low Electro Magnetic Interference (EMI), and is commonly used in cameras, cell phones and tablets.

New Vision Display (NVD) has decades of experience designing and manufacturing custom display and touch panel assemblies for some of the world’s largest original equipment manufacturers (OEMs) in the automotive, medical, industrial, and consumer markets.

NVD’s state-of-the-art factories are equipped to build solutions using a wide range of display and touch technologies. To view our extensive portfolio, visit our Products Page.

With industry-leading certifications and expert engineers on staff, NVD can handle your design needs, even for the most rigorous and complex end environments. To learn more about what makes us the display manufacturer for your needs, contact us today.

Not EXACTLY what you need? We specialize in custom and semi-custom display solutions. Contact us about creating something that fits your exact specifications.

1. Passive Matrix LCD: It uses a grid of vertical and horizontal conductors comprised of Indium Tin Oxide to create an image. Each pixel is controlled by an intersection of two conductors. It represents the off state of LCD i.e the pixel is OFF.

2. Active Matrix LCD: It uses thin-film transistors that are arranged in a matrix on a glass surface. To control the voltage tiny switching transistors and capacitors are used at each pixel location. The active pixel is called so because it has the ability to control the individual pixels and switch them quickly. thin-filmwhich

Difference between Active Matrix LCD and Passive Matrix LCD:Active Matrix LCDPassive Matrix LCDIt uses thin film transistors that are arranged in a matrix on a glass surface. To control the voltage tiny switching transistors and capacitors are used at each pixel location.It uses grid of vertical and horizontal conductors such that the intersection of two of those conductors allows for controlling a single pixel.

Active matrix LCDs are used in full-color LCD TVs monitors, cell phones etc.They are used in calculators display or a digital wrist watches where the display contains a limited number of segment and does not require full color. They are often created for custom applications.

On an elaborative note, passive and active displays also have several types which run down their very own category. For example, passive LCDs may be of the following types:Monochrome TN (Twisted Nematic) – here the liquid crystal cells do not require any current to flow past them and automatically work with lower voltages provided by the batteries.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey