eaglecad tft lcd factory

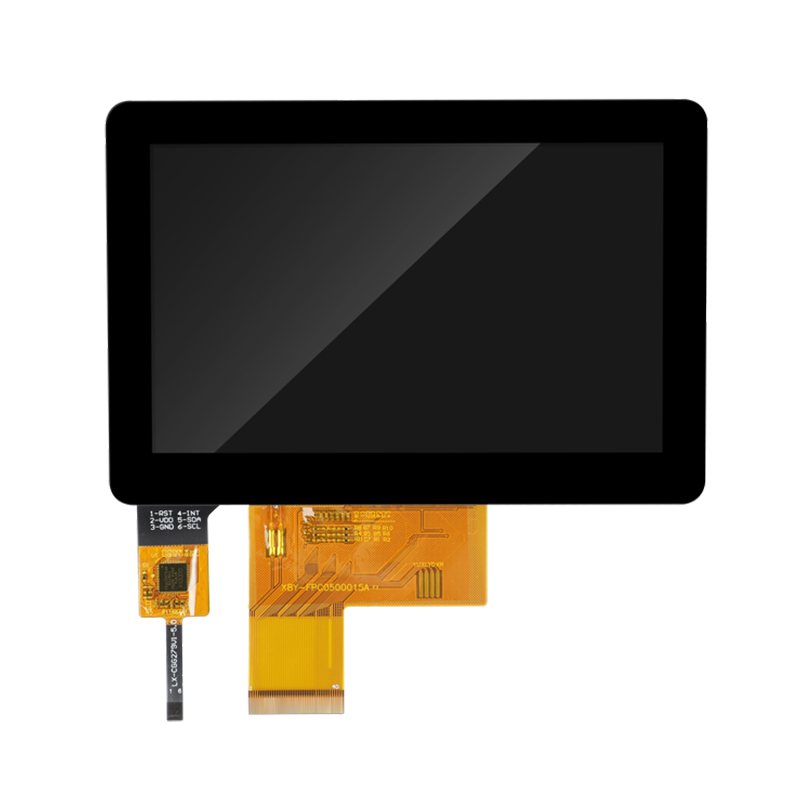

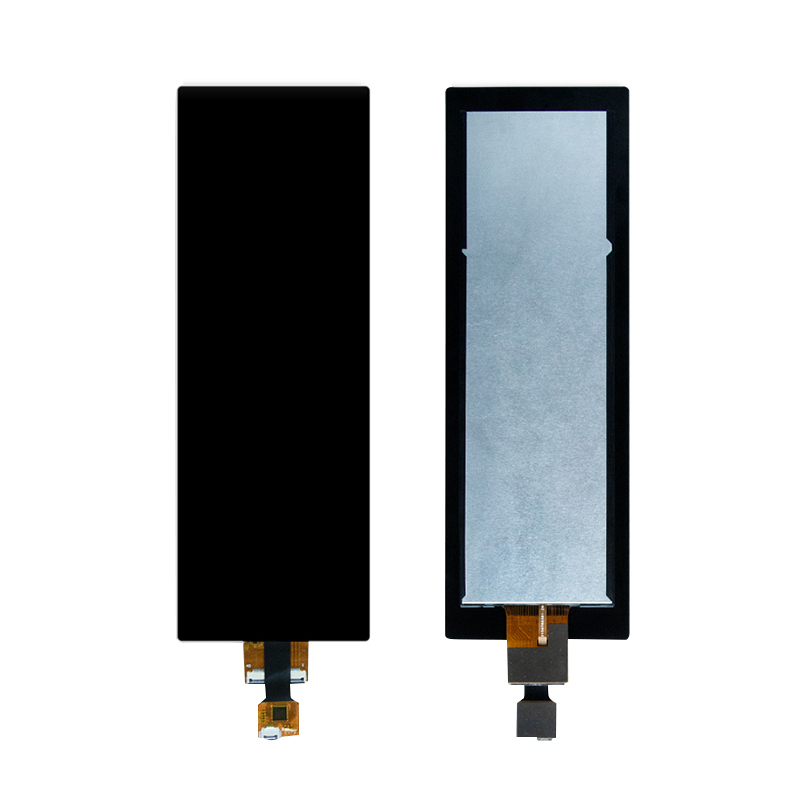

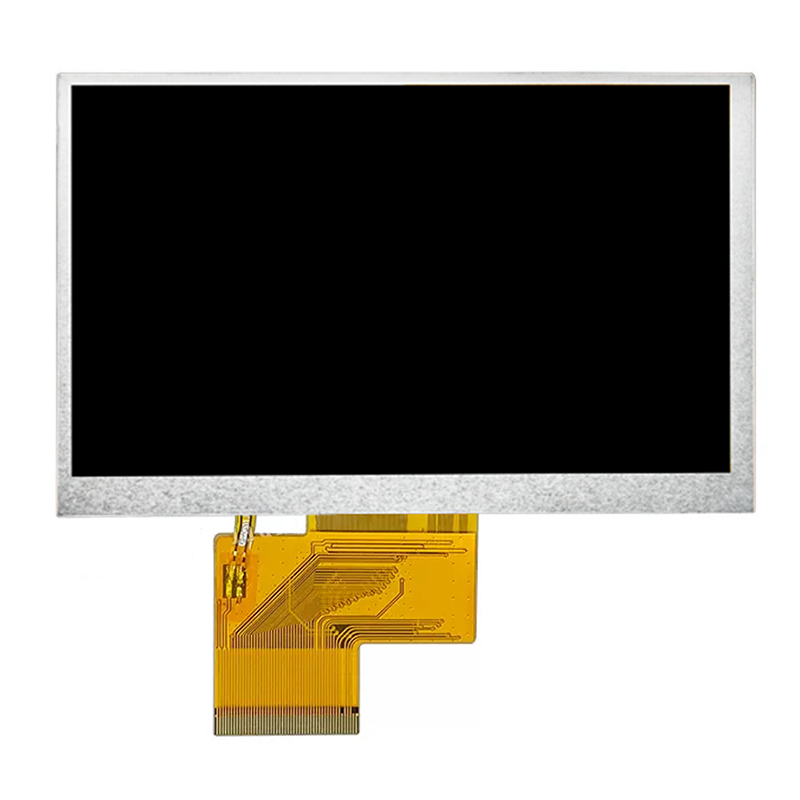

What sets us apart from our competitors is our professional and bespoke services. As an OEM manufacturer, our main product line revolves around touch TFT modules including Resistive touch screen/ PCAP touch screen and TFT LCD Modules. We can provide each component separately or as a complete set bonded together to suit the customer’s applications Our products are customized and designed according to a client"s specifications. This makes them feature-rich and has a specifically designed friendly user interface. They are also standalone in the market since they differ from one client to another.

We have customized touch displays for a variety of industrial applications, for example, we customized a 4.0” touch screen for an air cleaner in-home appliance field. We have also provided a custom touch screen and TFT LCD for the Smart home including 3.5” 7” 8” and 10.1”. We further customized touch screens, TFT LCD for EV chargers, and Hand-held devices for industrial applications. Additionally, we have provided AD boards to meet the displays customized. Our current aim is to provide customized all-in-one touch display solutions for both outdoor use and indoor use. Our experienced engineers also think in favour of our customers to provide the most suitable solutions based on the projects.

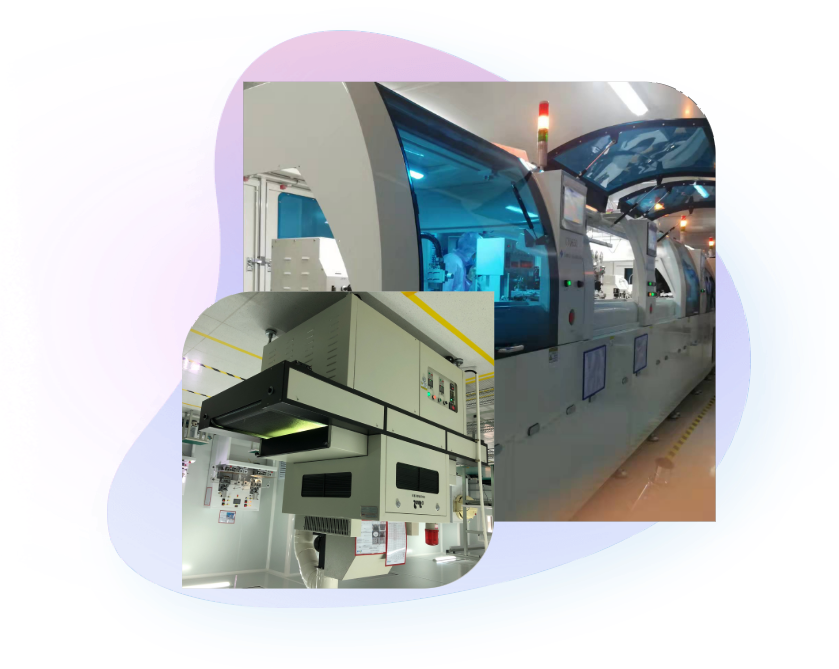

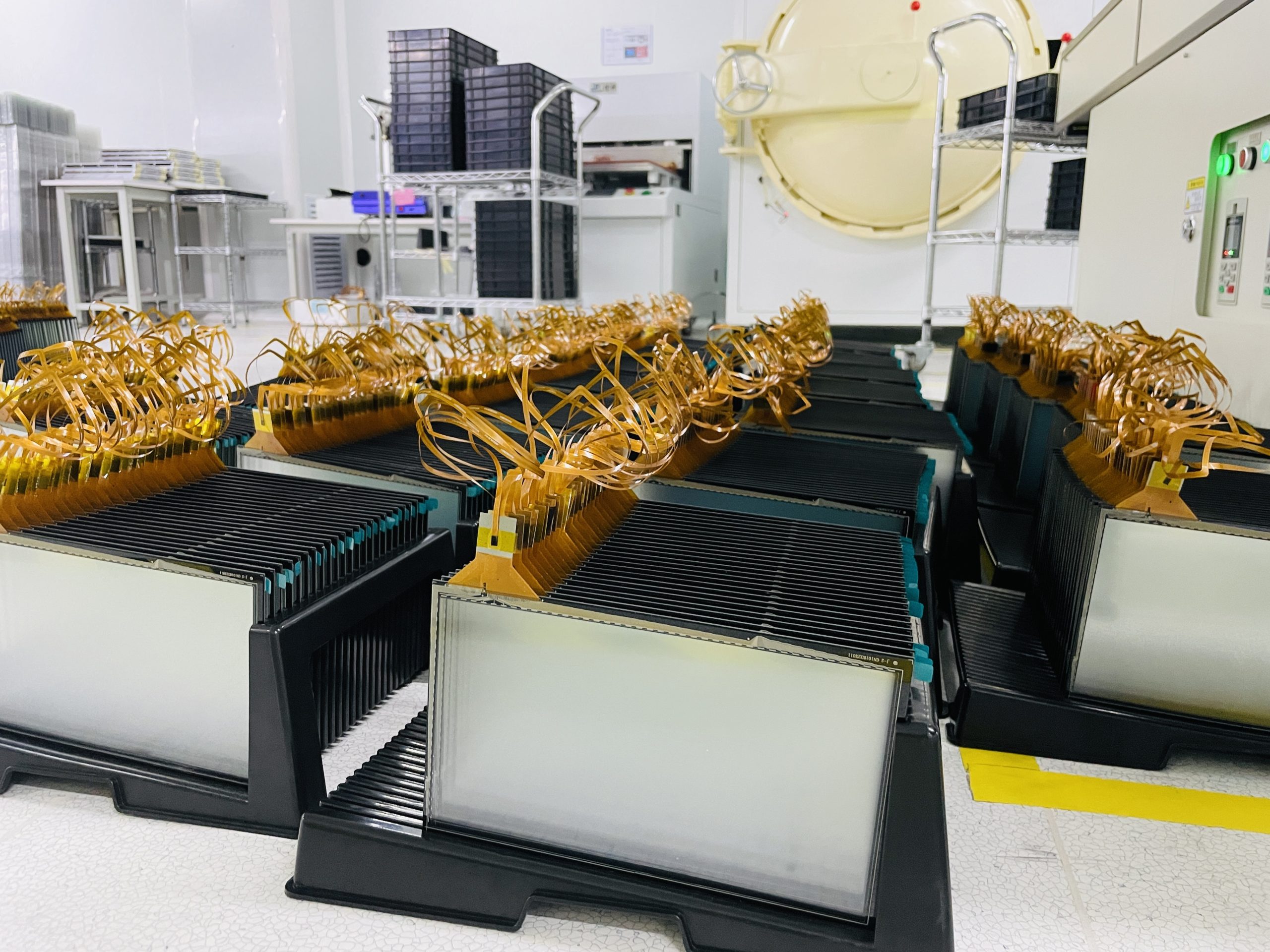

As a touch LCD display integrated supplier, EAGLE TECH not only customizes touch screens for customers but also can customize TFT LCD screens according to a customer’s needs. Our TFT LCD factory covers an area of 6,000 square meters and has a professional R&D team, laboratories, a standardized Electrostatic dust-free production workshop, and a perfect service team. Our products are in line with RoHS standards and have passed IATF16949 and ISO9001 quality management system certification.

We customize and provide standard TFT LCD Modules from 0.9" to 32" for both TN LCD and IPS LCD, according to the customer’s needs. The products are widely used in industrial automation, smart home, robots, face recognition, instrumentation, security, medical equipment, portable applications, and other product fields.

1.8\" TFT Display 128x160 Module ST7735S 1.44 V1.1 Series 128*128 TFT color screen 0.96\" I2C 128X64 OLED Display Module 0.96\" SPI Serial 128X64 OLED Display Module

Eagle Touch has its complete supply chains for the touch series products in every detail aspect including touch screen, TFT LCD (we are authorized SHARP TFT LCD module reseller), and even motherboards, plus the powerful R&D and technical supports teams. We are always on the way to provide customer stability in our products, innovative design, and customer satisfaction.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

The VA388 “talks” to the barista and shares all the information provided by the T3 and gravimetric systems. The TFT display gives the barista all data in real time to offer the customer the best espresso. The display for each group shows the barista the temperatures of the steam boilers, the coffee and the group, the delivery time and the amount of liquid in the cup.

If you don’t quite remember, the Foxconn project in Wisconsin was announced in 2017 as a massive deal to build the first “Generation 10.5” LCD factory in North America. It was also one of the first big moments in the Trump presidency, complete with President Trump holding a golden shovel at a lavish groundbreaking ceremony where he said the factory would be “the eighth wonder of the world.”

But it turned out that while Foxconn was putting on a great show, no LCD factory was actually getting built, even though Foxconn kept saying it was happening.

NP: Josh and I covered this project extensively at The Verge the whole time, and we have both read the book. If you just read this book cover to cover, you would end fully believing that there is a Generation 10.5 LCD factory in southeastern Wisconsin. There is not a factory. What happened?

NP: That attack was rooted in the exact thing you said, which is that the market for LCDs was being overwhelmed by Chinese suppliers. No one could see the business case for an LCD factory in Wisconsin at higher labor rates and without the supply of workers to staff such a factory. The criticism was that this does not make economic sense.

When you go back to what we said before, I still believe today — and five years from now — there is a tremendous need for a TFT LCD fab in the United States. When we built in Wisconsin and signed the contract, people became a lot less supportive, not because they did not want the investment, but because it became political. Articles came out attacking us so that they may score a point or two, and that was not very helpful.

The idea that it is the Evers administration, that business climate changed, or that Wisconsin was the wrong choice — which is what you are suggesting right now — that is all on Foxconn. If you chose wrong and should have chosen Ohio because of politics, it is still on Foxconn. If you decided 10.5 was not going to work out and Gen 6 was better, and you could not convince the Evers administration that you were actually going to build an LCD factory. What we have heard from that administration is that you never engaged or told them anything. So where is the accountability here for there not being a factory?

NP: There was an enormous amount of client publicity, though. We were told that Briggo was going tobuild coffee robots there. We were told that Google was going to build servers there. We were told there was going to be a Gen 6 LCD factory there. We were told thatyou were going to build ventilators. None of that stuff happened.

I talked to a lot of people who really believed those promises and they left good jobs to be part of a revival of US manufacturing. You mentioned patriots when you started; I talked to a lot of people who felt very patriotic about this idea. Then they got there and saw it was not happening. There was no attempt to invest in an LCD factory, and no willingness to invest in really much of any manufacturing there. They felt that it was all optics, that there was no plan. cxd was all just announcements of big things that were going to happen that never did and they felt betrayed. How do you answer these people?

Manufacturers of electronic components choose Eagle Glass because of its high-quality thermal and optical properties. In addition to its high-quality properties, it also boasts the lowest cost. With its excellent thermal and optical properties, Eagle Glass is the perfect choice for high-volume production. Its low-cost manufacturing makes it an excellent choice for LCD display panels and microelectronics. Although soda lime is the most common type of glass used in the semiconductor industry, it is still a great choice for curved displays, mirrors, and other optical components.

When it comes to high-volume manufacturing, Eagle Glass is the best choice. This type of glass is dimensionally stable, making it a perfect fit for the manufacturing process of LCD displays. The high-quality glass produced by Corning Eagle Glass is the best option for ultrabooks and other applications. They are also affordable and offer the highest-quality for LCD displays. These are the benefits of using Corning Eagle Glass for your LCD applications.

The company introduces advanced laser equipment and ultrasonic instruments to manufacture its glass wafers. Its highly skilled technicians also ensure that the glass is as smooth as possible. EAGLE XG glass wafers are ideal for the Ultrabook product category, which allows users to consume content on a computer with a thin, lightweight form factor. Its dimensional stability makes it an essential component in the LCD display manufacturing process.

Corning Eagle Glass Wafers are the perfect choice for LCD display manufacturing. Unlike other materials, they have very low manufacturing costs and high quality. Therefore, they are the preferred choice for manufacturers of high-end flat panels. However, they are also very affordable. You can choose from a wide range of different brands in the market, so you can select the right one for your needs. You can even order customised Eagle Glass Wafers if you need them for a custom application.

As well as its low cost, EAGLE XG Slim Glass offers a high degree of flexibility and environmental compatibility. It is also very thin, which makes it ideal for many applications. Its high coefficient of expansion closely matches that of silicon, making it ideal for semiconductor-like processing. So, whether you"re in the market for glass for LCD display panels, or are interested in learning more about this innovative technology, you will be amazed by how EAGLE glass wafers can help you.

Some of the things you use every day have thin film transistors (TFTs) in them. Thin film transistors are made from semiconductor materials, not metals like regular transistors. In a TFT, the semiconductor material is put on a special kind of glass called Corning EAGLE XG glass. The glass has a thin layer of metal on it. The metal is called the gate electrode. The gate electrode controls the flow of electrons through the semiconductor material. When the gate electrode is turned on, electrons can flow through the semiconductor material. When the gate electrode is turned off, electrons cannot flow through the semiconductor material.

The industry"s first LCD glass substrate is free of heavy metals, and the thin glass substrates enable a wide range of applications, such as high-resolution displays and smartphone displays. [Sources: 4]

It has been a few years since Corning announced a new type of glass for the display industry. For many years display glass was dominated by glass designed specifically for amorphous Si-TFT LCD panels, but this has changed with the introduction of powerful thin film LCD substrates. This means that high-performance glass can be used in LCD and OLED technology and for a wide range of applications. [Sources: 0, 4]

CCPD chose Astra Glass for its backplane substrate because it has the ability to produce high-temperature oxide TFT technology for high-performance immersive displays. CCPD"s advanced oxide-to-Tft process utilizes high temperatures and electron mobility as well as high thermal conductivity. The high-temperature OxidtFT technology helps panel manufacturers significantly to achieve higher resolutions and at the same time offers attractive panel economy, especially for large form factors. [Sources: 6]

While the initial focus is on making high-performance, ultra-low-cost Eagle Glass backplanes, Corning will add additional gene sizes over time to support larger applications such as LCD televisions. Currently, most plate manufacturers start with a thin layer of glass and then use an expensive thinning process using chemicals to reduce glass thickness. Corning has developed its own fusion process, in which glass is created in the air and then drawn into a highly transparent and highly efficient substrate for backlighting LCD televisions. [Sources: 1, 5]

We continue to push the development of thinner, stronger and more durable glass, which is finding more and more applications. In the Corning Lotus Glass family, this high-performance glass is used in a variety of applications, such as OLED, which provides much higher resolution and resolution than traditional LCD TVs. Corning has developed four types of LCD glass in recent years, which are used for many different applications. [Sources: 1]

Eagle XG (r) is a borosilicate glass specially developed for high performance LCDs. MR10 sheets combine the impact strength of LEXAN polycarbonate sheets with its own abrasion-resistant and UV-resistant surface, which is similar in performance to glass. [Sources: 2]

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey