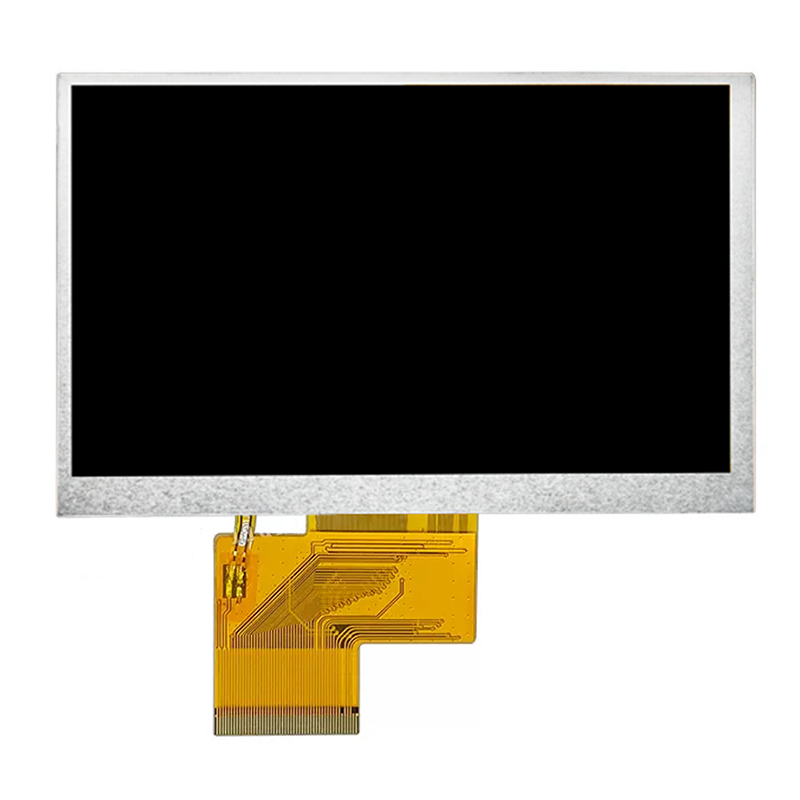

eaglecad tft lcd made in china

As a touch LCD display integrated supplier, EAGLE TECH not only customizes touch screens for customers but also can customize TFT LCD screens according to a customer’s needs. Our TFT LCD factory covers an area of 6,000 square meters and has a professional R&D team, laboratories, a standardized Electrostatic dust-free production workshop, and a perfect service team. Our products are in line with RoHS standards and have passed IATF16949 and ISO9001 quality management system certification.

We customize and provide standard TFT LCD Modules from 0.9" to 32" for both TN LCD and IPS LCD, according to the customer’s needs. The products are widely used in industrial automation, smart home, robots, face recognition, instrumentation, security, medical equipment, portable applications, and other product fields.

What sets us apart from our competitors is our professional and bespoke services. As an OEM manufacturer, our main product line revolves around touch TFT modules including Resistive touch screen/ PCAP touch screen and TFT LCD Modules. We can provide each component separately or as a complete set bonded together to suit the customer’s applications Our products are customized and designed according to a client"s specifications. This makes them feature-rich and has a specifically designed friendly user interface. They are also standalone in the market since they differ from one client to another.

We have customized touch displays for a variety of industrial applications, for example, we customized a 4.0” touch screen for an air cleaner in-home appliance field. We have also provided a custom touch screen and TFT LCD for the Smart home including 3.5” 7” 8” and 10.1”. We further customized touch screens, TFT LCD for EV chargers, and Hand-held devices for industrial applications. Additionally, we have provided AD boards to meet the displays customized. Our current aim is to provide customized all-in-one touch display solutions for both outdoor use and indoor use. Our experienced engineers also think in favour of our customers to provide the most suitable solutions based on the projects.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

If you don’t quite remember, the Foxconn project in Wisconsin was announced in 2017 as a massive deal to build the first “Generation 10.5” LCD factory in North America. It was also one of the first big moments in the Trump presidency, complete with President Trump holding a golden shovel at a lavish groundbreaking ceremony where he said the factory would be “the eighth wonder of the world.”

But it turned out that while Foxconn was putting on a great show, no LCD factory was actually getting built, even though Foxconn kept saying it was happening.

NP: Josh and I covered this project extensively at The Verge the whole time, and we have both read the book. If you just read this book cover to cover, you would end fully believing that there is a Generation 10.5 LCD factory in southeastern Wisconsin. There is not a factory. What happened?

NP: That attack was rooted in the exact thing you said, which is that the market for LCDs was being overwhelmed by Chinese suppliers. No one could see the business case for an LCD factory in Wisconsin at higher labor rates and without the supply of workers to staff such a factory. The criticism was that this does not make economic sense.

When you go back to what we said before, I still believe today — and five years from now — there is a tremendous need for a TFT LCD fab in the United States. When we built in Wisconsin and signed the contract, people became a lot less supportive, not because they did not want the investment, but because it became political. Articles came out attacking us so that they may score a point or two, and that was not very helpful.

The idea that it is the Evers administration, that business climate changed, or that Wisconsin was the wrong choice — which is what you are suggesting right now — that is all on Foxconn. If you chose wrong and should have chosen Ohio because of politics, it is still on Foxconn. If you decided 10.5 was not going to work out and Gen 6 was better, and you could not convince the Evers administration that you were actually going to build an LCD factory. What we have heard from that administration is that you never engaged or told them anything. So where is the accountability here for there not being a factory?

NP: There was an enormous amount of client publicity, though. We were told that Briggo was going tobuild coffee robots there. We were told that Google was going to build servers there. We were told there was going to be a Gen 6 LCD factory there. We were told thatyou were going to build ventilators. None of that stuff happened.

I talked to a lot of people who really believed those promises and they left good jobs to be part of a revival of US manufacturing. You mentioned patriots when you started; I talked to a lot of people who felt very patriotic about this idea. Then they got there and saw it was not happening. There was no attempt to invest in an LCD factory, and no willingness to invest in really much of any manufacturing there. They felt that it was all optics, that there was no plan. cxd was all just announcements of big things that were going to happen that never did and they felt betrayed. How do you answer these people?

By the slight adjustment of oxides constituting thin film transistor-liquid crystal display (TFT-LCD) substrate glass, including equal mole fraction substitution of Al2O3, GeO2, B2O3, P2O5 and ZrO2 for SiO2, as well as the substitution of CaO for SrO with the total contents unchanged, the structural and physico-chemical properties of the glass was investigated by Raman spectroscopy and other measurements. The results showed that the short-range disorder brought by the substitution of GeO2, B2O3 and P2O5 for SiO2 could weaken the stability and compactness of the glass network, and the physico-chemical properties deteriorated, while the process of glass melting would become easier accordingly. The short-range disorder by the substitution of ZrO2 for SiO2 with 1% mole fraction showed a little difference with other samples. Finally, the substitution of modified cations, such as CaO and SrO, showed a smaller variation compared with the substitution of network formers. On the condition of 1% mole fraction substitution of oxides investigated, the variation of samples showed a reasonable change and the performance was basically all satisfied for the use of TFT-LCD substrate.

Thin film transistor-liquid crystal display (TFT-LCD) substrate glass is a kind of substrate for electronic display [1,2]. In order to meet the demand of the process of LCD devices, the glass needs to be alkali-free. The international representative products such as Corning Eagle XG™ and Asahi AN100™ mainly contain some conventional oxides, such as SiO2, Al2O3, B2O3, MgO, CaO and SrO [3,4]. The influence of some unconventional oxides on the structural and physico-chemical properties of alkali-free glass deserve further study for the improvement of the glass industry. For example, some glass network formers, such as GeO2 and P2O5, and the modified cations ZrO2, the substitution of them for SiO2 could play an important role in shaping the glass network and improving the performance of glass. Herein, we studied the influence of the slight adjustment of oxides mentioned above. To investigate the structural and physico-chemical properties of the glass, Raman spectroscopy, as well as some physico-chemical measurements were used to evaluate the effects of the slight adjustment of oxides.

Seven kinds of the chemical compositions of alkali-free glass for TFT-LCD substrate are summarized in table 1, wherein sample 1 is the reference sample for the other six samples, which are acquired by the slight adjustment of oxides from sample 1. The details are as follows: sample 2 is acquired by 1% mole fraction substitution of Al2O3 for SiO2 with equal total amount compared with sample 1, and the other samples are acquired in the same way as sample 2, including 1% mole fraction substitution of GeO2 for SiO2 for sample 3, 1% mole fraction substitution of B2O3 for SiO2 for sample 4, 1% mole fraction substitution of P2O5 for SiO2 for sample 5, 1% mole fraction substitution of SrO and CaO for sample 6 and 1% mole fraction substitution of ZrO2 for SiO2 for sample 7. By the slight adjustment of the oxides, the structural along with the physico-chemical properties were investigated.

Table 6 shows the logarithm volume resistivity of samples measured at 25°C and 250°C, respectively. TFT-LCD substrate glass is a kind of alkali-free glass and the alkali-earth ions are the primary conductive elements, which show a lower conductivity than alkaline ions. This is why the volume resistivity of TFT-LCD substrate glass is larger than conventional soda lime glass. At a temperature of 25°C, the logarithm volume resistivities of the TFT-LCD substrate glass is between 15.1 Ω cm and 15.9 Ω cm. When the samples were heated, the energy of alkali-earth ions increased, and the number of ions with high enough energy in the glass network that could migrate in the electric field also increased, causing the decrease of the resistivity to around 13 Ω cm at 250°C shown in table 5, which declined about 100 times compared with that at 25°C.

By the slight adjustment of oxides of the TFT-LCD substrate glass, including equal mole fraction substitution of Al2O3, GeO2, B2O3, P2O5 and ZrO2 for SiO2, as well as the substitution of CaO for SrO with the total contents unchanged, the structure and physico-chemical properties of glass was investigated. The results were as follows.(i) The architecture of the glass network did not show too much difference with the substitution of 1% mole fraction for network formers and modified cations. The low frequency bending vibration of Si–Ob in Si–Ob–Si bonds dominated in alkali-free glass, and B3+ was mainly found in the form of a [BO3] triangle owing to its inferiority to Al3+ coordinated by oxygen ions and fewer alkali-earth ions. As for the [SiO4] tetrahedron, Q3 and Q4 units accounted for the most in four kinds of [SiO4] units. With the substitution of oxides for SiO2, Q3 decreased and Q4 increased, but the disorder degree of network increased, embodied in the lower frequency shift of the Raman peak. Sample 7 with Zr4+ showed more peak shift than others, mainly owing to the high electric of Zr4+ that can significantly affect the glass network.

I2C is okay for a character based LCD but it is waaayyy too slow to drive a TFT, it"s by far the worst choice, even with the 400khz high speed version. SPI is a reasonable choice if I/O pins are in short supply, SPI with DMA is even better.

A display shield is the fastest and easiest way to get a TFT LCD up and running on an Arduino. There is an undefined "standard" for this, ultilizing a 20x2 header pin connection to the LCD, a typical example:

The graphics drivers are on the LCD board, common types are the SSD1963 and RA8875. Buydisplay sells both driver types with the standard 20x2 connector and shields as well. It"s probably worth a mention that there are far more driver choices in smaller displays but when you get to the higher pixel counts, the field narrows rapidly.

The Eagle One Pro comes with an LCD color display with an NFC card reader. The display is pretty accurate with the speedometer, and we found it to be only one mph off. I was able to get it up to 42 mph on the display, and our Dragy system said 41 mph.

While I was looking for a TFT display for a project with Arduino, I found on several webstores some displays based on the ST7735 chip by Sitronix (datasheet).

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey