small tft display size comparison factory

These wide viewing angle Small Format TFT LCDs with optional touch are industrial grade and cost competitive. Therefore these products are a popular display choice to integrate in many projects for example for use in ticket vending machines (TVMs) and other custom projects.

Using only high-tech factories that we partner with, we provide clients with the service of designing liquid crystal display panel (LCD) and liquid crystal display module(LCM), and is committed to the customized service, R&D, sales, after-sales service of display products. Our factories have hundreds of engineers focusing on creating the highest quality displays including monochrome LCD (TN, STN), colour LCD (CSTN and TFT), Custom LCD’s, LCD module (both COG* and COB*) which are widely used in mobile phones and many other applications.

Our state of the art factory produces High Resolution TFT glass panel cells, has TN, HTN, STN and TFT technologies for LCD panels. The Factory has class 1000 clean rooms, high accuracy bonding, pre bonding and heat seal machinery, many production lines specifically for TFT production, OCA and OCF bonding machines, In-House LCD glass cleansing process, output thousands of pieces per month.

Touchscreen overlay cover glass only available (so you do not have to purchase the display)These displays can come with: touchscreen components, touchscreen overlays, industrial touch screen,Wide LCDs, LED TFTs, and TFT Colour displays.

Other options are: LCD drivers, LVDS Touchscreen displays, automotive LCD Display, TFT high resolution screens, TFT LCD capacitive touchscreens, TFT capacitive touchscreens, high brightness LCDs, Letterbox Displays, small VGA Displays, LCD panel without backlights,Variations of our Small Format TFT LCDs include: TFT Display touchscreens, TFT IPS Display, monochrome displays, TFT or LCD, embedded components, LCD components, TFT Drivers, industrial range of Displays,

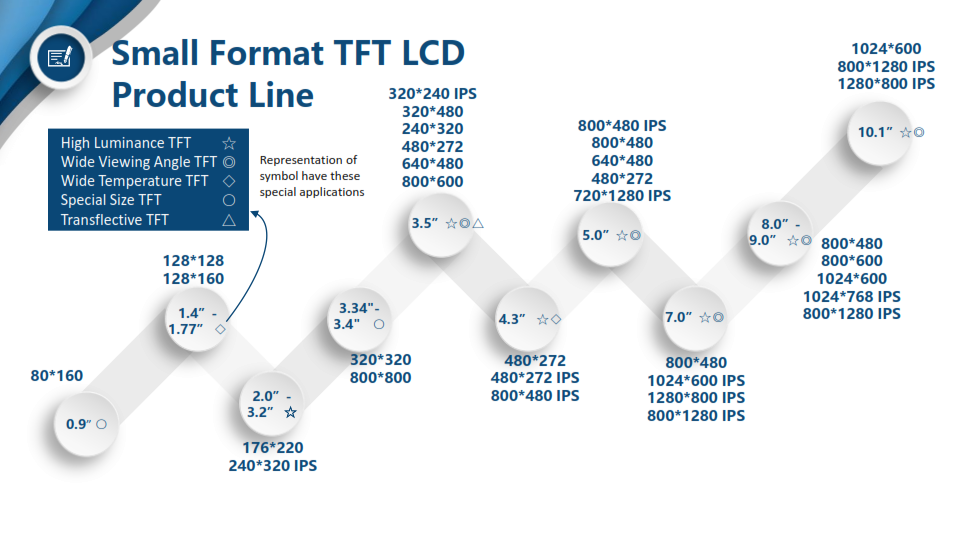

CDS also offers industrial TFT LCDs,Our displays are used in: touch screen vending machines, automotive touch screen displays, vending machine display panel, Touch screen vending, TFT Automotive, LCD Dislay panel kits, Touch screen TFT monitors, LCD Display components, LCD Screen components, and POS LCD Displays.As you can see from the tables above we have sizes including: 8.8 inches, 4.3 inch LCD Display, 10.1″ TFT LCD, 3.5 inch LCD Display, 4.3 inch display, 3.5 inch TFT LCD Display, 4.3″ screen, 7 inch LCD panel, 3 inch LCD Displays, and 4.3″ TFT LCDs as well as other small LCD Display screens.We have options on and equivalents to the following displays and TFT panel manufacturers: Raystar, Kingtech LCD, Digital View, OLED modules, OLED products, Powertip LCD Displays, Data Vision LCD, LG TFT Display, Tianma NLT, Powertip Displays, Mitsubishi LCD Displays, DMC components, Kyocera LCDs, NLT Technologies Ltd, Sharp LCD TFT modules, LCD manufacturers in the USA, PMOLED Displays, innolux display corp, Industrial touchscreens, A Grade TFT LCD Displays, Panoramic TFT Displays, Samsung TFT Displays, Touchscreen components, Transparent TFT Displays, Touchscreen components, TFT LCD controllers, as well as other TFT LCD manufacturers and Liquid crystal Display manufacturers.

CDS offers the widest range of displays and touchscreens including Abon touchscreens, Ampire LCD distributor, alternative Prisma interface baord supplier including Prisma iiia, Solomon Goldentek, Panasonic TFT, Winmate display, USB IO, and Apollo monitors

Our range includes AMOLED, circular displays, circular monitors, circular screens, circular TFT screens, round displays, Round TFT LCD displays, TFT AMOLEDs, TFT and IPS, TFT display interface microcontroller, TFT LCD or AMOLED, TFT LCD super AMOLED, WXGA TFT Displays, and WXGA TFT screens

As well as large format displays CDS also offers DSI TFT Display, large monochrome LCD displays, mono displays, mono OLEDC displays, mono TFT LCDs, monochrome displays, PCT Touchscreens, projected capacitive touch PCT technology, sq monitors and squid IDS.

CDS added a number of additional controller boards nd accessories which include TFT adaptor boards, TFT boards, TFT display controller boards, USB c LCD controller, USB touch kit, resistive touch screen, TFT accessories com, LCD controller board, LCD controller board USB c, LCD controller board, HDMI to MiPi DSI board, HDMI to MiPi DSI bridge, HDMI to MiPi LCD controller board, EDP adaptor bard, elite C microcontroller, Displaylink DL 3000 .

Whether it be bar type LCDs or any of CDS display solutions or many TFT displays we can help with comparing mipi dsi vs lvds interfces or mipi to edp wch can include use on pos shelf displays and rgb epaper for example.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

Replacing organic material with inorganic GaN material eliminates the need of polarizing and encapsulation layer, found in OLED. Micro LED is smaller and thinner, consumes less power.

1599 custom size tft display products are offered for sale by suppliers on Alibaba.com, of which lcd modules accounts for 48%, segment displays accounts for 1%.

A wide variety of custom size tft display options are available to you, such as original manufacturer, odm and agency.You can also choose from datasheet, custom size tft display,as well as from tft, ips, and standard custom size tft display,

Get rich colors, detailed images, and bright graphics from an LCD with a TFT screen. Our standard Displaytech TFT screens start at 1” through 7” in diagonal size and have a variety of display resolutions to select from. Displaytech TFT displays meet the needs for products within industrial, medical, and consumer applications.

TFT displays are LCD modules with thin-film transistor technology. The TFT display technology offers full color RGB showcasing a range of colors and hues. These liquid crystal display panels are available with touchscreen capabilities, wide viewing angles, and bright luminance for high contrast.

Our TFT displays have LVDS, RGB, SPI, and MCU interfaces. All Displaytech TFT LCD modules include an LED backlight, FPC, driver ICs, and the LCD panel.

We offer resistive and capacitive touch screens for our 2.8” and larger TFT modules. Our TFT panels have a wide operating temperature range to suit a variety of environments. All Displaytech LCDs are RoHS compliant.

We also offer semi-customization to our standard TFT screens. This is a cost-optimized solution to make a standard product better suit your application’s needs compared to selecting a fully custom TFT LCD. Customizations can focus on cover glass, mounting / enclosures, and more - contact us to discuss your semi-custom TFT solution.

TFT (Thin Film Transistor) LCD (Liquid Crystal Display) dominates the world flat panel display market now. Thanks for its low cost, sharp colors, acceptable view angles, low power consumption, manufacturing friendly design, slim physical structure etc., it has driven CRT(Cathode-Ray Tube) VFD ( Vacuum Fluorescent Display) out of market, squeezed LED (Light Emitting Diode) displays only to large size display area. TFT LCD displays find wide applications in TV, computer monitors, medical, appliance, automotive, kiosk, POS terminals, low end mobile phones, marine, aerospace, industrial meters, smart homes, handheld devices, video game systems, projectors, consumer electronic products, advertisement etc. For more information about TFT displays, please visit our knowledge base.

There a lot of considerations for how to choose a most suitable TFT LCD display module for your application. Please find the check list below to see if you can find a right fit.

It is the start point for every project. There aretwo dimensions to consider: outside dimension (width, height, thickness) and AA (active area or pixel area). Orient Display’s standard product line ranges from 1.0” to 32”. Our OLED size can go down to 0.66” which fit for wearable devices.

Resolution will decide the clearance. Nobody likes to see a display showing pixel clearly. That is the reason for better resolution, going from QVGA, VGA to HD, FHD, 4K, 8K. But higher resolution means higher cost, power consumption, memory size, data transfer speed etc. Orient Display offers low resolution of 128×128 to HD, FHD, we are working on providing 4K for our customers. For full list of resolution available, please see Introduction: LCD Resolution

TFT screen brightness selection is very important. You don’t want to be frustrated by LCD image washout under bright light or you drain the battery too fast by selecting a super brightness LCD but will be used indoor only. There are general guidance listed in the table below.

Orient Display offers standard brightness, medium brightness , high brightness, and high end sunlight readable IPS TFT LCD display products for our customers to choose from.

If the budget is tight, TN type TFT LCD can be chosen but there is viewing angle selection of either 6 o’clock or 12 o’clock. Gray scale inversion needs to be taken of carefully. If a high-end product is designed, you can pay premium to select IPS TFT LCD which doesn’t have the viewing angle issue.

It is similar to viewing angle selection, TN type TFT LCD has lower contrast but lower cost, while IPS TFT LCD has much high contrast but normally with higher cost. Orient Display provides both selections.

Normal TFT LCD displays provide wide enoughtemperature range for most of the applications. -20 to 70oC. But there are some (always) outdoor applications like -30 to 80oC or even wider, special liquid crystal fluid has to be used. Heater is needed for operating temperature requirement of -40oC. Normally, storage temperature is not an issue, many of Orient Display standard TFT display can handle -40 to 85oC, if you have any questions, feel free to contact our engineers for details.

Power consideration can be critical in some hand-held devices. For a TFT LCD display module, backlight normally consumes more power than other part of the display. Dimming or totally shutdown backlight technology has to be used when not in use. For some extreme power sensitive application, sleep mode or even using memory on controller consideration has to be in design. Feel free to contact our engineers for details.

Genetic Interfaces: Those are the interfaces which display or touch controller manufacturers provide, including parallel, MCU, SPI(,Serial Peripheral Interface), I2C, RGB (Red Green Blue), MIPI (Mobile Industry Processor Interface), LVDS (Low-Voltage Differential Signaling), eDP ( Embedded DisplayPort) etc. Orient Display has technologies to make the above interface exchangeable.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

If you can’t find a very suitable TFT LCD Display in our product line, don’t be discouraged. The products listed on our website is only small part of standard products. We have thousands of standard products in our database, feel free to contact our engineers for details.

If you like to have a special display, Orient Display is always flexible to do partial custom solution. For example, to modify the FPC to different length or shape, or use as fewer pinouts as possible, or design an ultra-bright LCD display, or a cover lens with your company logo on it, or design an extreme low power or low cost TFT display etc. our engineers will help you to achieve the goals. The NER cost can start from hundreds of dollars to Thousands. In rare case, it can be tens of thousands of dollars.

A fully custom TFT LCD panel can have very high NRE cost. Depending on the size of the display, quantity and which generation production line to be used. The tooling cost can start from $100,000 to over $1M.

Pixel, also called Picture Element, A pixel is the smallest unit of a digital image or graphic that can be displayed and represented on a digital display device. A pixel is the basic logical unit in digital graphics. Pixels are combined to form a complete image, video, text, or any visible thing on a computer display

LCD display doesn’t operate the same way as CRT displays , which fires electrons at a glass screen, a LCD display has individual pixels arranged in a rectangular grid. Each pixel has RGB(Red, Green, Blue) sub-pixel that can be turned on or off. When all of a pixel’s sub-pixels are turned off, it appears black. When all the sub-pixels are turned on 100%, it appears white. By adjusting the individual levels of red, green, and blue light, millions of color combinations are possible

The pixels of the LCD screen were made by circuitry and electrodes of the backplane. Each sub-pixel contains a TFT (Thin Film Transistor) element. These structures are formed by depositing various materials (metals and silicon) on to the glass substrate that will become one part of the complete display “stack,” and then making them through photolithography. For more information about TFT LCDs, please refer to “

The etched pixels by photolith process are the Native Resolution. Actually, all the flat panel displays, LCD, OLED, Plasma etc.) have native resolution which are different from CRT monitors

Although we can define a LCD display with resolution, a Full HD resolution on screen size of a 15” monitor or a 27” monitor will show different. The screen “fineness” is very important for some application, like medical, or even our cell phone. If the display “fineness” is not enough, the display will look “pixelized” which is unable to show details.

PPI stands for number of pixels per inch. It is kind of pixel density. PPI describes the resolution of a digital image, not a print. PPI is used to resize images in preparation for printing

But you see other lower resolution available, that is because video cards are doing the trick. A video card can display a lower LCD screen resolution than the LCD’s built-in native resolution. The video cards can combine the pixels and turn a higher resolution into lower resolution, or just use part of the full screen. But video cards can’t do the magic to exceed the native resolution.

Special names by individual companies: Apple Macbook Pro Retina 6K display, Acer Nitro, ASUS Pro Art , ViewSonic Elite, ASUS TUF ,Samsung edge Infinity-O Display etc.

Flexible display manufacturing techniques are bringing display customisation processes previously only economic for high volume consumer designs within reach of much lower volume industrial and specialist electronic systems.

TFT displays of a custom size, and optically bonded displays for example, are becoming available with initial non-recurring engineering (NRE) charges a fraction of those associated with a full custom display and the minimum economic order is low.

For example, designers everywhere are keen to eliminate drab LCD character modules from their systems and replace them with colour graphic displays, often including touch control.

However, TFT displays are made in standard formats and until now, the cost of manufacturing a custom size has been uneconomic for most industrial applications.

Manufacturers now have flexible processes which make it is possible to cut standard small format TFT displays to a specified height, opening up new application areas.

The ability to customise displays means that standard 4.3-inch and 2.8-inch colour TFT displays can be cut to a specified height to suit the space available.

Optical bonding is a well-established technology which dramatically reduces the reflections in displays by eliminating air gaps between the layers using an optically matched filler adhesive. Using this technique, reflections can be reduced from 13.5% of the incident light to just 0.2%. This makes a huge difference to readability, especially in brightly lit and outdoor environments.

Manufacturing processes now allow optical bonding to be offered on displays of 2.8-inch to 23.6-inch sizes with a very low minimum order quantity. The entire bonding process is carried out under one roof, at the site where the modules are manufactured ensuring both an extremely high standard of quality and a low cost of around one-third the normal price.

This optical bonding can be offered on display modules with integrated touch controllers, scratch resistant or anti-reflective coatings, or protected by vandal proof glass.

It is also possible to specify IP65/67 sealed panels for use in wet environments, as well as display panels that are compliant with PCI standards for payment terminals.

It is important to ensure this work is done to high standards to maintain the quality and integrity of the original display. It needs to be carried out at an ISO9001 accredited site, with the appropriate clean room facilities. The entire process resizing or optical bonding process is ideally carried out at a single site, often the same location at which the original display was manufactured.

With the continual development of LCD technologies, TFTs have become widely available at a lower price point. The manufacturing process of TFTs has been standardized which has changed the industry for display applications, making TFTs a feasible replacement option for graphic LCDs. This application note will discuss the options for replacing a graphic LCD with a TFT LCD. Considerations of price, size, features and functions will be analyzed to evaluate the options for TFT displays in place of a graphic LCD.

The two displays that will be reviewed in this application are described in the table below. These displays are similar in size and cost but vary in features and technical specifications.

Graphic LCDs are common for industrial applications where the features of TFTs are not justified by price. In recent years, TFT manufacturing has broadened its standard manufacturing process, making TFTs a competitor in typical graphic LCD applications.

TFTs offer additional features that graphic LCDs cannot provide. Such features consist of high color and resolution. TFTs also have the benefit of integrating capacitive and resistive touch functions to the display. If you are considering replacing a current graphic LCD, it may be time to switch to a TFT.

Graphic LCDs are a common display for industrial applications where vivid and high-resolution graphics are not essential to the application. Graphic displays typically have an 8-bit parallel interface which does not require a high frequency clock to communicate with the display. The graphic display in this example has 128 x 64 dots of resolution. This means the memory requirement of the frame buffer for this display is small and is provided by the IC on the display. Graphic LCDs do not offer RGB pixel color and display pixels as either on or off.

Significant limiting factors for graphic LCDs include the resolution and color depth of the display. The options for what can be displayed is restricted to a small area, in this example 128x64 pixels. This means that the image must be very low resolution and text must be very small. Typical graphic LCD applications display text or small user interface option.

The dimensions of G12864B-BW-LW63 are reviewed below. This graphic LCD is close in size to E30RA-FW400-N, the main differences being the mounting of the backlight and the depth of the displays. This graphic LCD is transmissive, STN blue, with a white LED backlight. The demo images will be displayed with white pixels and a blue background.

An example application for this graphic LCD will be reviewed in comparison with the TFT. The graphic LCD is interfaced over an 8-bit parallel connection. The display controller IC, ST7565, provides 8 pages of display RAM, an internal oscillator, and power regulation functions. This makes it easy to control a graphic LCD with a simple 8-bit controller because the main functions are provided internally.

The graphic LCD will display a menu followed by a temperature measurement screen. This is to provide an example of a typical graphic LCD application. Below is an example of the menu and the temperature measurement screen before they are uploaded onto the display.

Pixel size is limited for graphic LCDs. The full page consists of 128x64 pixels so the images must be low resolution and small. The amount of RAM provided by the embedded IC of the display will support 8 full pages of display data. The images must be black and white but will appear as white and blue once uploaded to the display. Below are the images of the display with these example applications uploaded.

The individual pixels can be seen on the graphic LCD and can be altered to project a monochrome image. STN blue graphic LCDs will display white pixels over a blue background. The amount that can be displayed in one page is restricted to 128x64 pixels. Simple icons and characters are common options for graphic display applications.

The design for graphic displays must be simplified to low resolution texts and icons. When you get down to a low resolution, such as 128x64 pixels, every pixel counts in creating a coherent image. This is why there is a standard set of icons used, and you will see them across graphic display applications. These icons are reminiscent of an early Windows computer era, 1980’s/1990’s. Most of these applications have already transferred to higher resolution and colored TFTs.

TFTs have begun to replace graphic LCDs in many applications. This is largely due to the price decrease of the displays and the electronics required to support them. The price of microprocessors and memory chips has substantially decreased, making TFTs a competitive alternative to graphic LCDs. TFT displays have the benefit of higher graphics quality, color, and speed for no extra cost.

The TFT used in this application is close in size to the graphic display. The display can be used both vertically and horizontally by changing the scan direction register. This can also be done by changing the page and column addresses before writing to RAM. The dimensions of the TFT are reviewed below from a vertical reference.

TFT displays offer a higher resolution and color depth. The TFT in this application has a resolution of 480x854 and can display up to 16.7 million colors. The combinations of color and the number of available pixels drastically increases the options for what can be displayed.

The TFT’s size is similar to the graphic LCD, but the resolution area is over six times larger. This makes a significant difference in image quality and available area. Below are the two graphic LCD demos displayed on the TFT.

Both graphic LCD demos can fit in the TFT display resolution and only take up a fraction of the total area available. The resolution of the TFT is highlighted by the amount of data that can be stored in one frame of the display area. Each pixel makes up only a small part of the image which means high resolution images can be portrayed. The same image is uploaded on both the graphic LCD and the TFT below.

TFTs also differ from graphic LCDs because they can display colors. This display supports 24-bits of color data for each pixel. This mean there are 16.7 million colors to select from. The graphic LCD writes to each pixel as on or off. The TFT assigns each pixel 24-bits of color data which means there are 16.7M unique colors that can be displayed.

TFTs have become increasingly standard for most display applications. Even if the application does not require high definition for its intended function, the comparable price for each display type makes the graphics quality an added bonus.

E30RA-FW400-N uses a 24-bit parallel interface and renders 24-bpp of color data for each pixel. This interface is fast enough to support this resolution and color depth to maintain a frame rate of 60 Hz. The only draw-back to this interface is the number of data pins that must be connected to a controller. TFTs come with many different interfaces depending on the resolution.

The graphic LCD demo can be recreated for the TFT to display more complex elements and colors. The addition of color and an increased pixel area gives the display more flexibility on what can be displayed and the quality of the image. TFT displays also have the benefit of touch interface options which can incorporate the user interface on the screen. Below is the example displayed on the TFT.

Some considerations should be made when switching from a graphic LCD to a TFT. A higher resolution means more pixels per frame. An increase in color depth means there is more data assigned to each of the pixels. The memory cost for one page of data can add up quickly depending on size and color depth chosen. The TFT in this example needs a minimum of 1.23MB if using the 24-bpp color depth. A lower color depth can be chosen through commands if you want to reduce memory costs.

The display also requires a higher speed interface to support its resolution and color depth. This display can be interfaced over a 16, 18 or 24-bit parallel interface with a clock cycle of 24.5MHz. This is the minimum speed required to maintain a frame rate of 60Hz. A high-speed controller is also required for this. Since high-speed controllers are becoming more affordable, these constraints are not as significant of a factor as they used to be.

LTPS fabrication process is the recrystallization of a-Si molecules to Polycrystalline Silicon with the help of an Excimer laser annealing process. The process occurs at relatively low temperatures when compared with High-Temperature Polycrystalline Silicon, which is why it is called Low-Temperature Polysilicon. This results in higher electron mobility i.e., more than 100 times faster than amorphous silicon (a-Si) which gives faster switching display panels. One of the advantages with LTPS Technology is that it offers high aperture ratio in LCD Display panels, which helps reduce backlight power consumption.

Also, due to the fabrication of small TFT size in LTPS Backplanes, power consumption is also very less. The prominent feature in the LTPS technology is that accessibility of CMOS (Complementary Metal oxide semiconductor) technology that includes both n-channel type and p-channel type thin film transistors for fabrication of Backplanes which is not available in a-Si technology (only n-MOS structure) and Oxide technology (only n-MOS structure). Also, LTPS Backplane offers high ON current which gives faster switching and less parasitic capacitance (due to small size transistors) which combinedly makes it more suitable for high resolution and better refresh rate display panels. But the large complexities in the manufacturing processes, and high materials costs makes it more challenging towards fabricating big sized display panels. Therefore, LTPS backplanes are mostly used in small and medium sized high-end LCD and OLED display panels for smartphones, and wearable devices.

On the other hand, Oxides TFT’s backplanes uses Amorphous Indium Gallium Zinc Oxide (a-IGZO), and other types of Amorphous Oxide semiconductor materials as active layer or channel layer. Oxide TFT backplanes (a-IGZO) having better electron mobility (around 20 to 50 times more as compared with a-Si TFT backplanes), small transistor sizes (as compared with amorphous silicon backplanes) enable low power consumption and low manufacturing costs (as compared with LTPS backplanes) and make them promising candidate over huge display panels market. Also, a-IGZO TFT backplanes offers wide band gap, hence small OFF current as compared with a-Si TFT backplanes or LTPS backplanes results less power dissipation.

Oxide TFT backplanes can be highly scalable to big-sized high resolution display panels with less manufacturing cost as compared with LTPS backplanes. Several research are ongoing in oxide TFT technologies and LTPS TFT technology to improve the display panels in terms of refresh rate, manufacturing costs, power dissipation etc.

LTPO (Low-Temperature Polycrystalline Oxide), which is now-a-days, a new emerging technology and is basically a combination of both LTPS TFT’s and Oxide TFT’s Technology. In this, some TFT’s are fabricated using LTPS technology and some TFT’s are fabricated using Oxide (a-IGZO) technology. LTPO backplanes having variable refresh rates and improved power consumption efficiency make them useful in high-end flagship devices. Apple introduced this technology first in September 2014, as LTPO backplane in the Apple Watch series 4. Samsung, also having a similar type of technology (so called HOP technology, short form of hybrid oxide and polycrystalline silicon) introduced LTPO backplane in the Galaxy Note series smartphones. LG display also has a similar type of technology.

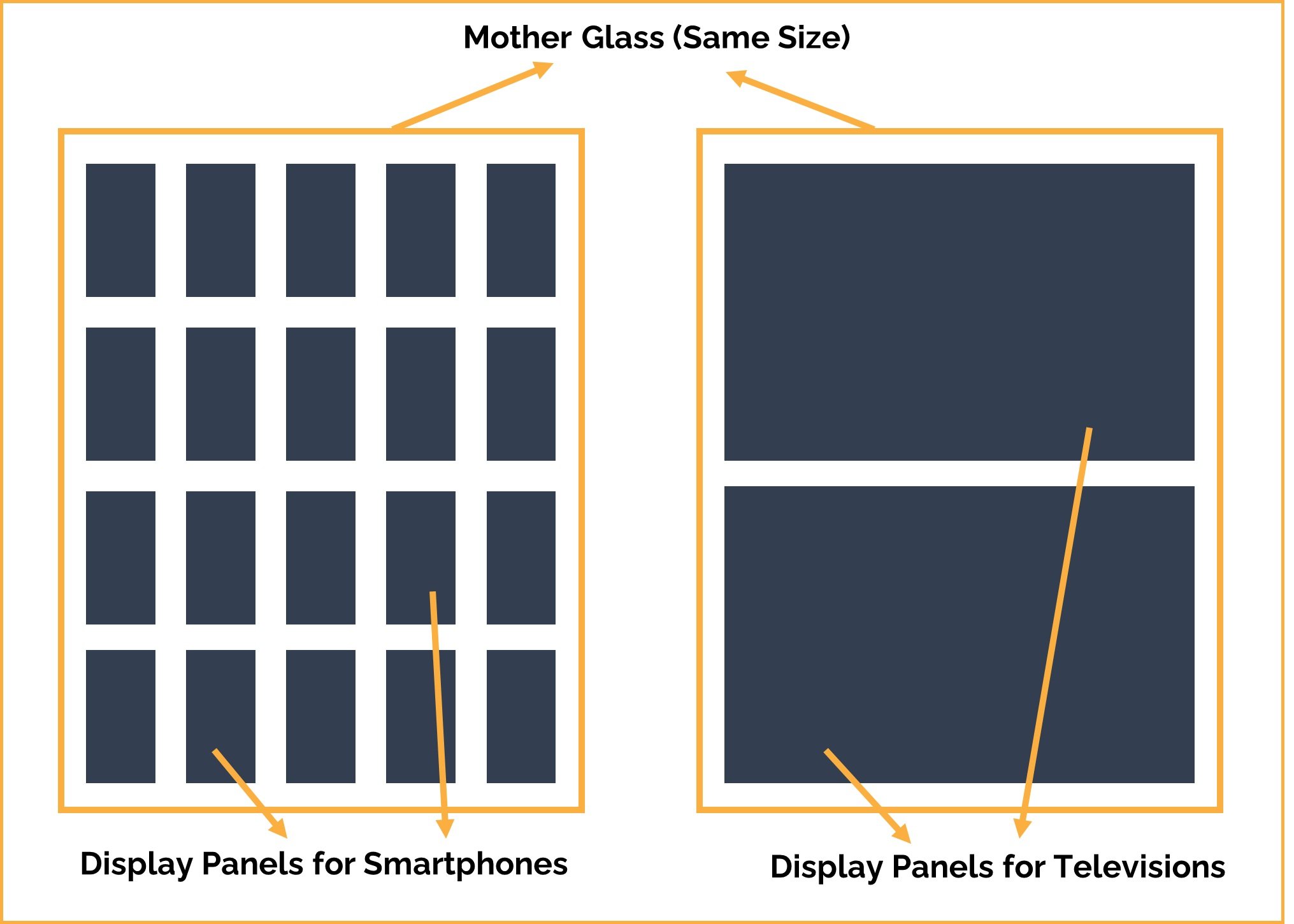

Several research are ongoing in the TFT domain w.r.t. its top gate structures, self-aligned structures, fabrication processes with using different materials to make better TFT backplanes on a glass substrate (mother glass), flexible substrates, etc. Now, the next thing that can come in our mind is the glass substrate and Mother glass as used for the displays. Let’s discuss about these two terms.

Display glass substrate plays an important role in manufacturing TFT backplanes. These glass substrates are a specific type of glass which are thermally stable, strong, durabile and can support most of the TFT technologies while achieving the required resolution. As the current market requirements moves continuously from mid-size to large-size display panels for televisions and other electronic devices, this creates new challenges and opportunities for display glass substrate manufacturers to increase the yields, maximize throughput with low manufacturing costs.

The basic properties which the glass substrates should fulfil are that it must have minimum total thickness variations (TTV), low sag, and low total pitch variations (TPV). During TFT Backplane manufacturing process, display glass substrate will go through several fabrication processes and between these processes, glass substrate will deform in term of shape or size (also called as strain) that arises the term variation in total pitch (TPV). Less variation in total pitch gives better display glass substrate. Also, during the TFT backplane manufacturing process, display glass substrate will go through several depositions and naturally bend due to their weight, which defines the term Sag. Low sag property of big sized display glass substrate gives better stability and durability with low manufacturing costs. When we talk about big sized display glass substrates, the variation in thickness of glass defines the term total thickness variation (TTV). Minimum total thickness variations give uniform layer thickness with better control during TFT backplane fabrication processes.

Now, at this point of time, we all know that display glass substrate will act as a base for making TFT backplanes. Mother glass is a term which indicates a very large size of glass substrate which goes through different fabrication processes, and at last, cut into several sizes which is individually used in as Display glass substrates in smartphones, televisions, wearables, automobile industry etc. Size of the “Mother glass” is determined by the term “Generation”. Newer generation represents bigger size of mother glass when compared with older generations. For example, Gen 10 glass has a very large size of mother glass compared to Gen 1 glass.

In these videos, the SPI (GPIO) bus is referred to being the bottleneck. SPI based displays update over a serial data bus, transmitting one bit per clock cycle on the bus. A 320x240x16bpp display hence requires a SPI bus clock rate of 73.728MHz to achieve a full 60fps refresh frequency. Not many SPI LCD controllers can communicate this fast in practice, but are constrained to e.g. a 16-50MHz SPI bus clock speed, capping the maximum update rate significantly. Can we do anything about this?

The fbcp-ili9341 project started out as a display driver for the Adafruit 2.8" 320x240 TFT w/ Touch screen for Raspberry Pi display that utilizes the ILI9341 controller. On that display, fbcp-ili9341 can achieve a 60fps update rate, depending on the content that is being displayed. Check out these videos for examples of the driver in action:

Given that the SPI bus can be so constrained on bandwidth, how come fbcp-ili9341 seems to be able to update at up to 60fps? The way this is achieved is by what could be called adaptive display stream updates. Instead of uploading each pixel at each display refresh cycle, only the actually changed pixels on screen are submitted to the display. This is doable because the ILI9341 controller, as many other popular controllers, have communication interface functions that allow specifying partial screen updates, down to subrectangles or even individual pixel levels. This allows beating the bandwidth limit: for example in Quake, even though it is a fast pacing game, on average only about 46% of all pixels on screen change each rendered frame. Some parts, such as the UI stay practically constant across multiple frames.

Good old interlacing is added into the mix: if the amount of pixels that needs updating is detected to be too much that the SPI bus cannot handle it, the driver adaptively resorts to doing an interlaced update, uploading even and odd scanlines at subsequent frames. Once the number of pending pixels to write returns to manageable amounts, progressive updating is resumed. This effectively doubles the maximum display update rate. (If you do not like the visual appearance that interlacing causes, it is easy to disable this by uncommenting the line #define NO_INTERLACING in file config.h)

A number of other micro-optimization techniques are used, such as batch updating rectangular spans of pixels, merging disjoint-but-close spans of pixels on the same scanline, and latching Column and Page End Addresses to bottom-right corner of the display to be able to cut CASET and PASET messages in mid-communication.

This driver does not utilize the notro/fbtft framebuffer driver, so that needs to be disabled if active. That is, if your /boot/config.txt file has lines that look something like dtoverlay=pitft28r, ..., dtoverlay=waveshare32b, ... or dtoverlay=flexfb, ..., those should be removed.

If you have been running existing fbcp driver, make sure to remove that e.g. via a sudo pkill fbcp first (while running in SSH prompt or connected to a HDMI display), these two cannot run at the same time. If /etc/rc.local or /etc/init.d contains an entry to start up fbcp at boot, that directive should be deleted.

When using one of the displays that stack on top of the Pi that are already recognized by fbcp-ili9341, you don"t need to specify the GPIO pin assignments, but fbcp-ili9341 code already has those. Pass one of the following CMake directives for the hats:

-DPIRATE_AUDIO_ST7789_HAT=ON: If specified, targets a Pirate Audio 240x240, 1.3inch IPS LCD display HAT for Raspberry Pi with ST7789 display controller

-DKEDEI_V63_MPI3501=ON: If specified, targets a KeDei 3.5 inch SPI TFTLCD 480*320 16bit/18bit version 6.3 2018/4/9 display with MPI3501 display controller.

If you connected wires directly on the Pi instead of using a Hat from the above list, you will need to use the configuration directives below. In addition to specifying the display, you will also need to tell fbcp-ili9341 which GPIO pins you wired the connections to. To configure the display controller, pass one of:

-DILI9341=ON: If you are running on any other generic ILI9341 display, or on Waveshare32b display that is standalone and not on the FreeplayTech CM3/Zero device, pass this flag.

-DILI9340=ON: If you have a ILI9340 display, pass this directive. ILI9340 and ILI9341 chipsets are very similar, but ILI9340 doesn"t support all of the features on ILI9341 and they will be disabled or downgraded.

-DILI9486L=ON: If you have a ILI9486L display, pass this directive. Note that ILI9486 and ILI9486L are quite different, mutually incompatible controller chips, so be careful here identifying which one you have. (or just try both, should not break if you misidentified)

-DGPIO_TFT_DATA_CONTROL=number: Specifies/overrides which GPIO pin to use for the Data/Control (DC) line on the 4-wire SPI communication. This pin number is specified in BCM pin numbers. If you have a 3-wire SPI display that does not have a Data/Control line, set this value to -1, i.e. -DGPIO_TFT_DATA_CONTROL=-1 to tell fbcp-ili9341 to target 3-wire ("9-bit") SPI communication.

-DGPIO_TFT_RESET_PIN=number: Specifies/overrides which GPIO pin to use for the display Reset line. This pin number is specified in BCM pin numbers. If omitted, it is assumed that the display does not have a Reset pin, and is always on.

-DGPIO_TFT_BACKLIGHT=number: Specifies/overrides which GPIO pin to use for the display backlight line. This pin number is specified in BCM pin numbers. If omitted, it is assumed that the display does not have a GPIO-controlled backlight pin, and is always on. If setting this, also see the #define BACKLIGHT_CONTROL option in config.h.

fbcp-ili9341 always uses the hardware SPI0 port, so the MISO, MOSI, CLK and CE0 pins are always the same and cannot be changed. The MISO pin is actually not used (at the moment at least), so you can just skip connecting that one. If your display is a rogue one that ignores the chip enable line, you can omit connecting that as well, or might also be able to get away by connecting that to ground if you are hard pressed to simplify wiring (depending on the display).

To get good performance out of the displays, you will drive the displays far out above the rated speed specs (the rated specs yield about ~10fps depending on display). Due to this, you will need to explicitly configure the target speed you want to drive the display at, because due to manufacturing variances each display copy reaches a different maximum speed. There is no "default speed" that fbcp-ili9341 would use. Setting the speed is done via the option

-DSPI_BUS_CLOCK_DIVISOR=even_number: Sets the clock divisor number which along with the Pi core_freq= option in /boot/config.txt specifies the overall speed that the display SPI communication bus is driven at. SPI_frequency = core_freq/divisor. SPI_BUS_CLOCK_DIVISOR must be an even number. Default Pi 3B and Zero W core_freq is 400MHz, and generally a value -DSPI_BUS_CLOCK_DIVISOR=6 seems to be the best that a ILI9341 display can do. Try a larger value if the display shows corrupt output, or a smaller value to get higher bandwidth. See ili9341.h and waveshare35b.h for data points on tuning the maximum SPI performance. Safe initial value could be something like -DSPI_BUS_CLOCK_DIVISOR=30.

-DBACKLIGHT_CONTROL=ON: If set, enables fbcp-ili9341 to control the display backlight in the given backlight pin. The display will go to sleep after a period of inactivity on the screen. If not, backlight is not touched.

-DDISPLAY_CROPPED_INSTEAD_OF_SCALING=ON: If set, and source video frame is larger than the SPI display video resolution, the source video is presented on the SPI display by cropping out parts of it in all directions, instead of scaling to fit.

-DDISPLAY_BREAK_ASPECT_RATIO_WHEN_SCALING=ON: When scaling source video to SPI display, scaling is performed by default following aspect ratio, adding letterboxes/pillarboxes as needed. If this is set, the stretching is performed breaking aspect ratio.

-DDISPLAY_SWAP_BGR=ON: If this option is passed, red and blue color channels are reversed (RGB<->BGR) swap. Some displays have an opposite color panel subpixel layout that the display controller does not automatically account for, so define this if blue and red are mixed up.

-DDISPLAY_INVERT_COLORS=ON: If this option is passed, pixel color value interpretation is reversed (white=0, black=31/63). Default: black=0, white=31/63. Pass this option if the display image looks like a color negative of the actual colors.

-DLOW_BATTERY_PIN=

Here is a full example of what to type to build and run, if you have the Adafruit 2.8" 320x240 TFT w/ Touch screen for Raspberry Pi with ILI9341 controller:

If the above does not work, try specifying -DSPI_BUS_CLOCK_DIVISOR=8 or =10 to make the display run a little slower, or try with -DUSE_DMA_TRANSFERS=OFF to troubleshoot if DMA might be the issue. If you are using another display controller than ILI9341, using a much higher value, like 30 or 40 may be needed. When changing CMake options, you can reissue the CMake directive line without having to reclone or recreate the build directory. However you may need to manually delete file CMakeCache.txt between changing options to avoid CMake remembering old settings.

If the size of the default HDMI output /dev/fb0 framebuffer differs from the resolution of the display, the source video size will by default be rescaled to fit to the size of the SPI display. fbcp-ili9341 will manage setting up this rescaling if needed, and it will be done by the GPU, so performance should not be impacted too much. However if the resolutions do not match, small text will probably appear illegible. The resizing will be done in aspect ratio preserving manner, so if the aspect ratios do not match, either horizontal or vertical black borders will appear on the display. If you do not use the HDMI output at all, it is probably best to configure the HDMI output to match the SPI display size so that rescaling will not be needed. This can be done by setting the following lines in /boot/config.txt:

These lines hint native applications about the default display mode, and let them render to the native resolution of the TFT display. This can however prevent the use of the HDMI connector, if the HDMI connected display does not support such a small resolution. As a compromise, if both HDMI and SPI displays want to be used at the same time, some other compatible resolution such as 640x480 can be used. See Raspberry Pi HDMI documentation for the available options to do this.

The refresh speed of the display is dictated by the clock speed of the SPI bus that the display is connected to. Due to the way the BCM2835 chip on Raspberry Pi works, there does not exist a simple speed=xxx Mhz option that could be set to define the bus speed. Instead, the SPI bus speed is derived from two separate parameters: the core frequency of the BCM2835 SoC in general (core_freq in /boot/config.txt), and the SPI peripheral CDIV (Clock DIVider) setting. Together, the resulting SPI bus speed is then calculated with the formula SPI_speed=core_freq/CDIV.

Adjust the CDIV value by passing the directive -DSPI_BUS_CLOCK_DIVISOR=number in CMake command line. Possible values are even numbers 2, 4, 6, 8, .... Note that since CDIV appears in the denominator in the formula for SPI_speed, smaller values result in higher bus speeds, whereas higher values make the display go slower. Initially when you don"t know how fast your display can run, try starting with a safe high setting, such as -DSPI_BUS_CLOCK_DIVISOR=30, and work your way to smaller numbers to find the maximum speed the display can cope with. See the table at the end of the README for specific observed maximum bus speeds for different displays.

Perhaps a bit counterintuitively, underclock the core. Setting a smaller core frequency than the default turbo 400MHz can enable using a smaller clock divider to get a higher resulting SPI bus speed. For example, if with default core_freq=400 SPI CDIV=8 works (resulting in SPI bus speed 400MHz/8=50MHz), but CDIV=6 does not (400MHz/6=66.67MHz was too much), you can try lowering core_freq=360 and set CDIV=6 to get an effective SPI bus speed of 360MHz/6=60MHz, a middle ground between the two that might perhaps work. Balancing core_freq= and CDIV options allows one to find the maximum SPI bus speed up to the last few kHz that the display controller can tolerate. One can also try the opposite direction and overclock, but that does then of course have all the issues that come along when overclocking. Underclocking does have the drawback that it makes the Pi run slower overall, so this is certainly a tradeoff.

On the other hand, it is desirable to control how much CPU time fbcp-ili9341 is allowed to use. The default build settings are tuned to maximize the display refresh rate at the expense of power consumption on Pi 3B. On Pi Zero, the opposite is done, i.e. by default the driver optimizes for battery saving instead of maximal display update speed. The following options can be controlled to balance between these two:

If your SPI display bus is able to run really fast in comparison to the size of the display and the amount of content changing on the screen, you can try enabling #define UPDATE_FRAMES_IN_SINGLE_RECTANGULAR_DIFF option in config.h to reduce CPU usage at the expense of increasing the number of bytes sent over the bus. This has been observed to have a big effect on Pi Zero, so is worth checking out especially there.

If the SPI display bus is able to run really really really fast (or you don"t care about frame rate, but just about low CPU usage), you can try enabling #define UPDATE_FRAMES_WITHOUT_DIFFING option in config.h to forgo the adaptive delta diffing option altogether. This will revert to naive full frame updates for absolutely minimum overall CPU usage.

In display.h there is an option #define TARGET_FRAME_RATE

A pleasing aspect of fbcp-ili9341 is that it introduces very little latency overhead: on a 119Hz refreshing ILI9341 display, fbcp-ili9341 gets pixels as response from GPIO input to screen in well less than 16.66 msecs time. I only have a 120fps recording camera, so can"t easily measure delays shorter than that, but rough statistical estimate of slow motion video footage suggests this delay could be as low as 2-3 msecs, dominated by the ~8.4msecs panel refresh rate of the ILI9341.

This does not mean that overall input to display latency in games would be so immediate. Briefly testing a NES emulated game in Retropie suggests a total latency of about 60-80 msecs. This latency is caused by the NES game emulator overhead and extra latency added by Linux, DispmanX and GPU rendering, and GPU framebuffer snapshotting. (If you ran fbcp-ili9341 as a static library bypassing DispmanX and the GPU stack, directly linking your GPIO input and application logic into fbcp-ili9341, you would be able to get down to this few msecs of overall latency, like shown in the above GPIO input video)

Interestingly, fbcp-ili9341 is about ~33msecs faster than a cheap 3.5" KeDei HDMI display. I do not know if this is a result of the KeDei HDMI display specifically introducing extra latency, or if all HDMI displays connected to the Pi would have similar latency overhead. An interesting question is also how SPI would compare with DPI connected displays on the Pi.

Unfortunately a limitation of SPI connected displays is that the VSYNC line signal is not available on the display controllers when they are running in SPI mode, so it is not possible to do vsync locked updates even if the SPI bus bandwidth on the display was fast enough. For example, the 4 ILI9341 displays I have can all be run faster than 75MHz so SPI bus bandwidth-wise all of them would be able to update a full frame in less than a vsync interval, but it is not possible to synchronize the updates to vsync since the display controllers do not report it. (If you do know of a display that does actually expose a vsync clock signal even in SPI mode, you can try implementing support to locking on to it)

You can however choose between two distinct types of tearing artifacts: straight line tearing and diagonal tearing. Whichever looks better is a bit subjective, which is why both options exist. I prefer the straight line tearing artifact, it seems to be less intrusive than the diagonal tearing one. To toggle this, edit the option #define DISPLAY_FLIP_ORIENTATION_IN_SOFTWARE in config.h. When this option is enabled, fbcp-ili9341 produces straight line tearing, and consumes a tiny few % more CPU power. By default Pi 3B builds with straight line tearing, and Pi Zero with the faster diagonal tearing. Check out the video Latency and tearing test #2: GPIO input to display latency in fbcp-ili9341 and tearing modes to see in slow motion videos how these two tearing modes look like.

Another option that is known to affect how the tearing artifact looks like is the internal panel refresh rate. For ILI9341 displays this refresh rate can be adjusted in ili9341.h, and this can be set to range between ILI9341_FRAMERATE_61_HZ and ILI9341_FRAMERATE_119_HZ (default). Slower refresh rates produce less tearing, but have higher input-to-display latency, whereas higher refresh rates will result in the opposite. Again visually the resulting effect is a bit subjective.

To get tearing free updates, you should use a DPI display, or a good quality HDMI display. Beware that cheap small 3.5" HDMI displays such as KeDei do also tear - that is, even if they are controlled via HDMI, they don"t actually seem to implement VSYNC timed internal operation.

Having no vsync is not all bad though, since with the lack of vsync, SPI displays have the opportunity to obtain smoother animation on content that is not updating at 60Hz. It is possible that content on the SPI display will stutter even less than what DPI or HDMI displays on the Pi can currently provide (although I have not been able to test this in detail, except for the KeDei case above).

The main option that affects smoothness of display updates is the #define USE_GPU_VSYNC line in config.h. If this is enabled, then the internal Pi GPU HDMI vsync clock is used to drive frames onto the display. The Pi GPU clock runs at a fixed rate that is independent of the content. This rate can be discovered by running tvservice -s on the Pi console, and is usually 59Hz or 60Hz. If your application renders at this rate, animation will look smooth, but if not, there will be stuttering. For example playing a PAL NES game that updates at 50Hz with HDMI clock set at 60Hz will cause bad microstuttering in video output if #define USE_GPU_VSYNC is enabled.

If USE_GPU_VSYNC is disabled, then a busy spinning GPU frame snapshotting thread is used to drive the updates. This will produce smoother animation in content that does not maintain a fixed 60Hz rate. Especially in OpenTyrian, a game that renders at a fixed 36fps and has slowly scrolling scenery, the stuttering caused by USE_GPU_VSYNC is particularly visible. Running on Pi 3B without USE_GPU_VSYNC enabled produces visually smoother looking scrolling on an Adafruit 2.8" ILI9341 PiTFT set to update at 119Hz, compared to enabling USE_GPU_VSYNC on the same setup. Without USE_GPU_VSYNC, the dedicated frame polling loop thread "finds" the 36Hz update rate of the game, and then pushes pixels to the display at this exact rate. This works nicely since SPI displays disregard vsync - the result is that frames are pushed out to the SPI display immediately as they become available, instead of pulling them at a fixed 60Hz rate like HDMI does.

There are two other main options that affect frame delivery timings, #define SELF_SYNCHRONIZE_TO_GPU_VSYNC_PRODUCED_NEW_FRAMES and #define SAVE_BATTERY_BY_PREDICTING_FRAME_ARRIVAL_TIMES. Check out the video fbcp-ili9341 frame delivery smoothness test on Pi 3B and Adafruit ILI9341 at 119Hz for a detailed side by side comparison of these different modes. The conclusions drawn from the four tested scenarios in the video are:

The codebase captures screen framebuffers by snapshotting via the VideoCore vc_dispmanx_snapshot() API, and the obtained pixels are then routed on to the SPI-based display. This kind of polling is performed, since there does not exist an event-based mechanism to get new frames from the GPU as they are produced. The result is inefficient and can easily cause stuttering, since different applications produce frames at different paces. Ideally the code would ask the VideoCore API to receive finished frames in callback notifications immediately after they are rendered, but this kind of functionality does not exist in the current GPU driver stack. In the absence of such event delivery mechanism, the code has to resort to polling snapshots of the display framebuffer using carefully timed heuristics to balance between keeping latency and stuttering low, while not causing excessive power consumption. These heuristics keep continuously guessing the update rate of the animation on screen, and they have been tuned to ensure that CPU usage goes down to 0% when there is no detected activity on screen, but it is

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey