develop display screens akin factory

One of today’s modern technological wonders is the flat-panel liquid crystal display (LCD) screen, which is the key component we find inside televisions, computer monitors, smartphones, and an ever-proliferating range of gadgets that display information electronically.What most people don’t realize is how complex and sophisticated the manufacturing process is. The entire world’s supply is made within two time zones in East Asia. Unless, of course, the factory proposed by Foxconn for Wisconsin actually gets built.

Liquid crystal display (LCD) screens are manufactured by assembling a sandwich of two thin sheets of glass.On one of the sheets are transistor “cells” formed by first depositing a layer of indium tin oxide (ITO), an unusual metal alloy that you can actually see through.That’s how you can get electrical signals to the middle of a screen.Then you deposit a layer of silicon, followed by a process that builds millions of precisely shaped transistor parts.This patterning step is repeated to build up tiny little cells, one for each dot (known as a pixel) on the screen.Each step has to be precisely aligned to the previous one within a few microns.Remember, the average human hair is 40 microns in diameter.

LCD fabs have to maintain strict standards of cleanliness inside.Any dust particles in the air could cause defects in the finished displays – tiny dark spots or uneven intensities on your screen.That means the air is passed through elaborate filtration systems and pushed downwards from the ceiling constantly.Workers have to wear special clean room protective clothing and scrub before entering to minimize dust particles or other contamination.People are the largest source of particles, from shedding dead skin cells, dust from cosmetic powders, or smoke particles exhaled from the lungs of workers who smoke.Clean rooms are rated by the number of particles per cubic meter of air.A class 100 cleanroom has less than 100 particles less than 0.3 microns in diameter per cubic meter of air, Class 10 has less than 10 particles, and so on. Fab 9 has hundeds of thousands of square meters of Class 100 cleanroom, and many critical areas like photolithography are Class 10.In comparison, the air in Harvard Square in Cambridge, MA is roughly Class 8,000,000, and probably gets substantially worse when an MBTA bus passes through.

Since most display manufacturing has to be done in a cleanroom and handling the glass requires such precision, the factory is heavily automated.As you watch the glass come in, it is placed into giant cassettes by robot handlers, and the cassettes are moved around throughout the factory.At each step, robots lift a piece of glass out of the cassette, and position it for the processing machines.Some of the machines, like the ones that deposit silicon or ITO, orient the glass vertically, and put them inside an enormous vacuum chamber where all the air is first pumped out before they can go to work.And then they somehow manage to deposit micrometer thin layers that are extremely uniform.It is a miracle that any of this stuff actually works.

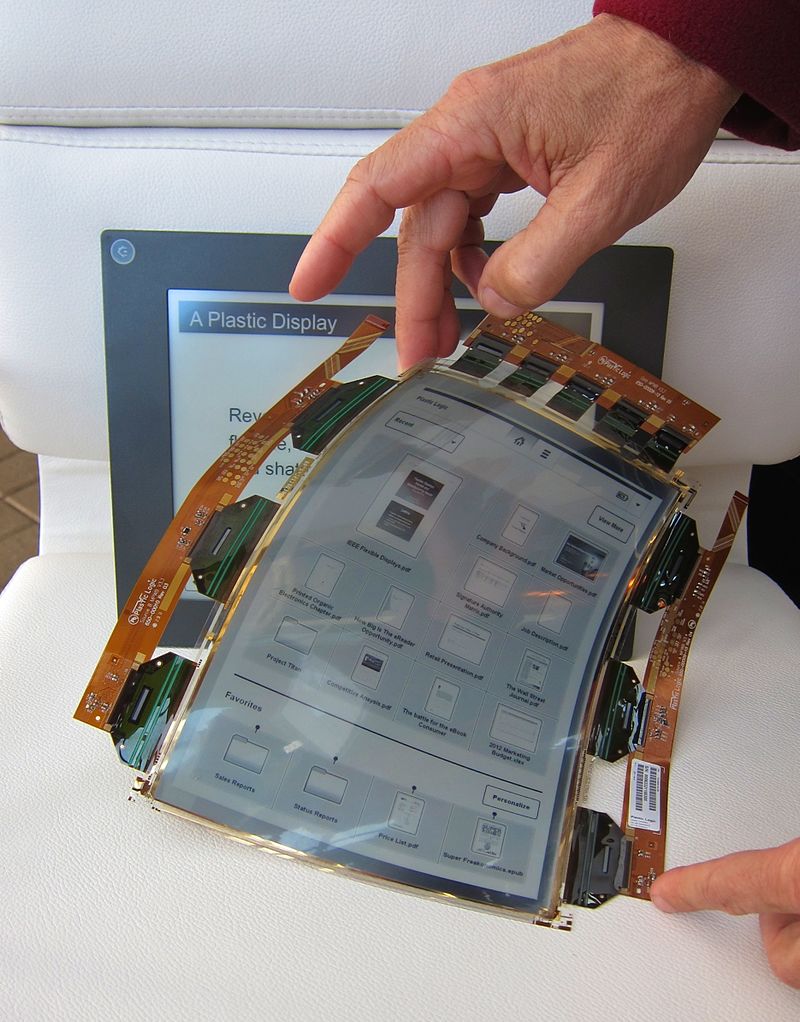

Announced in a press release on Thursday, the stretchable display has a resolution of 100ppi and is capable of displaying full-color RGB. The prototype was created using micro LEDs with a sub-40μm pixel pitch that were built into a silicon substrate typically used in contact lenses. According to LG Display, this gives it a consistency “similar to that of a rubber band” and allows it to be stretched in any direction by up to 20 percent.

Other styles of flexible display technology have been commercially available for some time, such as LG’s own rollable OLEDTV or the LG G Flex phone. Foldable devices also often utilize a malleable screen, though this new stretchable display technology is theoretically more flexible while providing better durability — supposedly capable of comfortably withstanding heavy external impacts.

“Stretchable displays are not only thin and light, but also can be attached to curved surfaces such as skin, clothing, and furniture,” LG Display says in a press release. The company hasn’t announced any products that will feature the technology but expect it will eventually be utilized within industries such as wearables, mobility, smart devices, gaming, and fashion. This stretchable screen is the first prototype being developed by LG Display as part of a government-led development project, with the Korean-based company hoping to improve on the display technology by 2024.

LG Display isn’t the only company exploring stretchable displays. Samsung has previously showcased the viability of the tech in real-world applications after creating a stretchable OLED screen in a prototype heart rate monitor back in June 2021.

As a leader in SAP security solutions, ERP Maestro contracted The Skins Factory to redefine their UX/UI Design for a small subset of screens. We voluntarily scope creep-ed the project ourselves, when our team designed multiple analytic dashboard color themes.

The core focus was to re-imagine the usability experience, while redesigning the visual design language for this 340B management application. We also focused on a design language that deploys subtle modern trends, while making sure usability was simple and expedient.

Credibly, a provider of small business loans and working capital financing, contracted The Skins Factory to redesign the core UX/UI Design for their online, one-page loan calculator. Taking cues from their brand identity color palette, as we worked in close collaboration with the Credibly team.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

A flexible display or rollable display is an electronic visual display which is flexible in nature, as opposed to the traditional flat screen displays used in most electronic devices.e-readers, mobile phones and other consumer electronics. Such screens can be rolled up like a scroll without the image or text being distorted.electronic ink, Gyricon, Organic LCD, and OLED.

Electronic paper displays which can be rolled up have been developed by E Ink. At CES 2006, Philips showed a rollable display prototype, with a screen capable of retaining an image for several months without electricity.pixel rollable display based on E Ink’s electrophoretic technology.flexible organic light-emitting diode displays have been demonstrated.electronic paper wristwatch. A rollable display is an important part of the development of the roll-away computer.

With the flat panel display having already been widely used more than 40 years, there have been many desired changes in the display technology, focusing on developing a lighter, thinner product that was easier to carry and store. Through the development of rollable displays in recent years, scientists and engineers agree that flexible flat panel display technology has huge market potential in the future.

Flexible electronic paper (e-paper) based displays were the first flexible displays conceptualized and prototyped. Though this form of flexible displays has a long history and were attempted by many companies, it is only recently that this technology began to see commercial implementations slated for mass production to be used in consumer electronic devices.

The concept of developing a flexible display was first put forth by Xerox PARC (Palo Alto Research Company). In 1974, Nicholas K. Sheridon, a PARC employee, made a major breakthrough in flexible display technology and produced the first flexible e-paper display. Dubbed Gyricon, this new display technology was designed to mimic the properties of paper, but married with the capacity to display dynamic digital images. Sheridon envisioned the advent of paperless offices and sought commercial applications for Gyricon.

In 2005, Arizona State University opened a 250,000 square foot facility dedicated to flexible display research named the ASU Flexible Display Center (FDC). ASU received $43.7 million from the U.S. Army Research Laboratory (ARL) towards the development of this research facility in February 2004.demonstration later that year.Hewlett Packard demonstrated a prototype flexible e-paper from the Flexible Display Center at the university.

Between 2004–2008, ASU developed its first small-scale flexible displays.U.S. Army funds ASU’s development of the flexible display, the center’s focus is on commercial applications.

This company develops and manufactures monochrome plastic flexible displays in various sizes based on its proprietary organic thin film transistor (OTFT) technology. They have also demonstrated their ability to produce colour displays with this technology, however they are currently not capable of manufacturing them on a large scale.Dresden, Germany, which was the first factory of its kind to be built – dedicated to the high volume manufacture of organic electronics.plastic and do not contain glass. They are also lighter and thinner than glass-based displays and low-power. Applications of this flexible display technology include signage,wristwatches and wearable devices

In 2004, a team led by Prof. Roel Vertegaal at Queen"s University"s Human Media Lab in Canada developed PaperWindows,Organic User Interface. Since full-colour, US Letter-sized displays were not available at the time, PaperWindows deployed a form of active projection mapping of computer windows on real paper documents that worked together as one computer through 3D tracking. At a lecture to the Gyricon and Human-Computer Interaction teams at Xerox PARC on 4 May 2007, Prof. Vertegaal publicly introduced the term Organic User Interface (OUI) as a means of describing the implications of non-flat display technologies on user interfaces of the future: paper computers, flexible form factors for computing devices, but also encompassing rigid display objects of any shape, with wrap-around, skin-like displays. The lecture was published a year later as part of a special issue on Organic User InterfacesCommunications of the ACM. In May 2010, the Human Media Lab partnered with ASU"s Flexible Display Center to produce PaperPhone,MorePhone

Research and development into flexible OLED displays largely began in the late 2000s with the main intentions of implementing this technology in mobile devices. However, this technology has recently made an appearance, to a moderate extent, in consumer television displays as well.

Nokia first conceptualized the application of flexible OLED displays in mobile phone with the Nokia Morph concept mobile phone. Released to the press in February 2008, the Morph concept was project Nokia had co-developed with the University of Cambridge.nanotechnology, it pioneered the concept of utilizing a flexible video display in a consumer electronics device.London, alongside Nokia’s new range of Windows Phone 7 devices.

Sony Electronics expressed interest for research and development towards a flexible display video display since 2005.RIKEN (the Institute of Physical and Chemical Research), Sony promised to commercialize this technology in TVs and cellphones sometime around 2010.TFT-driven OLED display.

In January 2013, Samsung exposed its brand new, unnamed product during the company"s keynote address at CES in Las Vegas. Brian Berkeley, the senior vice president of Samsung"s display lab in San Jose, California had announced the development of flexible displays. He said "the technology will let the company"s partners make bendable, rollable, and foldable displays," and he demonstrated how the new phone can be rollable and flexible during his speech.

During Samsung"s CES 2013 keynote presentation, two prototype mobile devices codenamed "Youm" that incorporated the flexible AMOLED display technology were shown to the public.OLED screen giving this phone deeper blacks and a higher overall contrast ratio with better power efficiency than traditional LCD displays.LCD displays. Samsung stated that "Youm" panels will be seen in the market in a short time and production will commence in 2013.

The Flexible Display Center (FDC) at Arizona State University announced a continued effort in forwarding flexible displays in 2012.Army Research Lab scientists, ASU announced that it has successfully manufactured the world"s largest flexible OLED display using thin-film transistor (TFTs) technology.

In January 2019, Chinese manufacturer Xiaomi showed a foldable smartphone prototype.Xiaomi demoed the device in a video on the Weibo social network. The device features a large foldable display that curves 180 degrees inwards on two sides. The tablet turns into a smartphone, with a screen diagonal of 4,5 inch, adjusting the user interface on the fly.

Flexible displays have many advantages over glass: better durability, lighter weight, thinner as plastic, and can be perfectly curved and used in many devices.glass and rollable display is that the display area of a rollable display can be bigger than the device itself; If a flexible device measuring, for example, 5 inches in diagonal and a roll of 7.5mm, it can be stored in a device smaller than the screen itself and close to 15mm in thickness.

Flexible screens can open the doors to novel and alternative authentication schemes by emphasizing the interaction between the user and the touch screen. In “Bend Passwords: Using Gestures to Authenticate on Flexible Devices,” the authors introduce a new method called Bend Passwords where users perform bending gestures and deform the touch screen to unlock the phone. Their work and research points to Bend Passwords possibly becoming a new way to keep smartphones secure alongside the popularization of flexible displays.

Flexible displays using electronic paper technology commonly use Electrophoretic or Electrowetting technologies. However, each type of flexible electronic paper vary in specification due to different implementation techniques by different companies.

The flexible electronic paper display technology co-developed by Arizona State University and HP employs a manufacturing process developed by HP Labs called Self-Aligned Imprint Lithography (SAIL).

The flexible electronic paper display announced by AUO is unique as it is the only solar powered variant. A separate rechargeable battery is also attached when solar charging is unavailable.

Many of the e-paper based flexible displays are based on OLED technology and its variants. Though this technology is relatively new in comparison with e-paper based flexible displays, implementation of OLED flexible displays saw considerable growth in the last few years.

In May 2011, Human Media Lab at Queen"s University in Canada introduced PaperPhone, the first flexible smartphone, in partnership with the Arizona State University Flexible Display Center.

At CES 2013, Samsung showcased the two handsets which incorporates AMOLED flexible display technology during its keynote presentation, the Youm and an unnamed Windows Phone 8 prototype device.Galaxy Note Edge,Samsung Galaxy S series devices.

LG Electronics and Samsung Electronics both introduced curved OLED televisions with a curved display at CES 2013 hours apart from each other.The Verge noted the subtle curve on 55" Samsung OLED TV allowed it to have a "more panoramic, more immersive viewing experience, and actually improves viewing angles from the side."

Crawford, Gregory P., ed. (2005). Flexible flat panel displays (Reprinted with corrections. ed.). Chichester, West Sussex, England: John Wiley & Sons. p. 2. ISBN 978-0470870488.

Thryft, Ann R. (7 June 2012). "All-Plastic Electronics Power Flexible Color Display". Design News. Archived from the original on 31 March 2019. Retrieved 24 April 2013.

Lahey, Byron; Girouard, Audrey; Burleson, Winslow and Vertegaal, Roel (May 2011). PaperPhone: Understanding the Use of Bend Gestures in Mobile Devices with Flexible Electronic Paper Displays, Proceedings of the SIGCHI Conference on Human Factors in Computing Systems, Pages 1303–1312.

Lee, Reuben (10 January 2013). "Samsung shows off flexible display phones at CES keynote". CNET. Archived from the original on 17 February 2013. Retrieved 12 February 2013.

Sasaoka, Tatsuya; Sekiya, Mitsunobu; Yumoto, Akira; Yamada, Jiro; Hirano, Takashi; Iwase, Yuichi; Yamada, Takao; Ishibashi, Tadashi; Mori, Takao; Asano, Mitsuru; Tamura, Shinichiro; Urabe, Tetsuo (1 January 2001). "24.4L: Late-News Paper: A 13.0-inch AM-OLED Display with Top Emitting Structure and Adaptive Current Mode Programmed Pixel Circuit (TAC)". SID Symposium Digest of Technical Papers. 32 (1): 384. doi:10.1889/1.1831876. S2CID 59976823.

Drzaic, P.; Comiskey, B.; Albert, J. D.; Zhang, L.; Loxley, A.; Feeney, R.; Jacobson, J. (1 January 1998). "44.3L: A Printed and Rollable Bistable Electronic Display". SID Symposium Digest of Technical Papers. 29 (1): 1131. doi:10.1889/1.1833686. S2CID 135723096.

Lowensohn, Josh (9 January 2013). "Eyes-on: Samsung"s Youm flexible-display tech at CES 2013". CNET. Archived from the original on 26 November 2013. Retrieved 12 February 2013.

In these last few years, things have been evolving a lot in what concerns the workplace. More recently, and because of the pandemic, many companies accelerated their evolution into the digital world. In what concerns our business, we’ve been seeing more and more companies starting to use touchscreens to gather teams into more collaborative work. And let’s face it, it makes things way easier to explain, share ideas and get everyone involved.

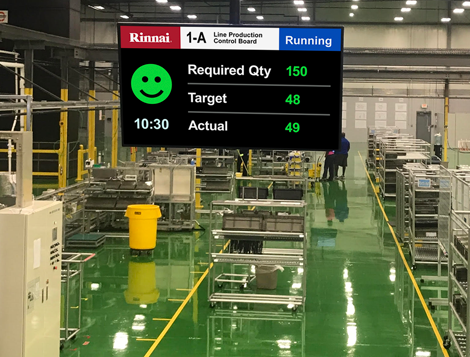

Nowadays they’re using DISPLAX TILE as a collaboration tool on their production floor. “It’s a four-panel interactive employee information display developed for the company by the Vienna-based creative technology shop Wetouch” using our Video Wall Touch Displays.

Screens are the logical solution, and if part of the goal is making work teams aware of how they’re doing, all of that information can be on these sorts of displays, and updated as needed.

DISPLAX TILE is a Bezel-less 55” Touch Display, specially engineered with an ultra-slim bezel for the build-up of seamless and unlimited interactive video walls to empower true collaboration. It has active touch from edge to edge, meaning that it can even detect touch on the bezel, and has an incredible and reliable touch performancewith 100 simultaneous touch points, operating 24/7. TILE is a robust product already present in thousands of installations all over the world, with proven reliability. Find out more HERE.

The natural evolution from black and white to color is a well-worn path for both product design and media of all kinds. E Ink has continued to develop its color technology, listening to customers along the way to get feedback and make improvements to meet market needs.

Your smartphone could one day be replaced by an electronic display laminated to the back of your hand, if the inventors of a new ultrathin "e-skin" have their way.

For the first time, Japanese scientists have demonstrated a superflexible electronic skin (or e-skin) display, made from organic electronics, that doesn"t degrade when exposed to air. And crucially, the researchers used processes similar to the way organic light-emitting diode (OLED) displays are manufactured for conventional smartphones and TVs.

Now, a team from the University of Tokyo has developed a unique method to create a protective coating that can shield the electronic components from the air while remaining thin enough to stay flexible.

Previous organic electronic displays have been built using glass or plastic base materials, or substrates, but their flexibility was limited by their thickness. Other, thinner versions have been manufactured, however, these materials have not been stable enough to endure in air for more than a few hours.

The scientists also created both digital and analog displays that could be laminated to the skin, and all of the devices were flexible enough to distort and crumple in response to body movement, without losing their functionality.

"The potential uses range from information display to optical characterization of the skin," said John Rogers, a professor of materials science and engineering at the University of Illinois, who also works on developing e-skin but was not involved with the new study. "Opportunities for future research in this context include the development of power supply systems and of wireless schemes for data communication and control."

By employing materials and processes that are already used in the industrial production of OLED displays, Someya said the group"s work should be able to transition smoothly to large-scale production.

Chemical engineer Zhenan Bao and her team of researchers at Stanford have spent nearly two decades trying to develop skin-like integrated circuits that can be stretched, folded, bent and twisted – working all the while – and then snap back without fail, every time. Such circuits presage a day of wearable and implantable products, but one hurdle has always stood in the way.

This method has worked for decades in the semiconductor industry but, to date, the chemicals used to dissolve and wash away the light-resistant materials also wash away the skin-like polymers that are the foundation of stretchable circuits. By developing new photochemistries that work on these stretchable materials, Bao’s team is teaching tried-and-true manufacturing equipment to do new tricks. In fact, the Stanford process even does away with some of the steps necessary in silicon manufacturing. It all adds up to a remarkable result.

The team used the new process to produce flexible circuits of roughly the same electrical performance as transistors used for current computer displays – useful for practical applications – then tested their materials for durability and performance. Stretching the circuits to double their original dimensions, both parallel and perpendicular to the circuit direction, the newly printed materials showed no cracks, delamination or, most important, decline in function. Electrically, the transistors remained stable, even after 1,000 repeated stretches.

Our scientists are developing proprietary ingredients made of specific plant stem cells in fine suspension and stem cultures. These ingredients are available in bulk in addition to being incorporated into our formulations.

As you’re looking into how to start a skin care line, remember to factor in lead time. It takes no less than 12 weeks to develop a skin care product. However, most skin care lines require much more time for research, development, testing, and go-to-market. Skin care products also require comprehensive testing, which takes time.

When Megan developed her skin care brand, she ordered every top-rated lash enhancer on Amazon. She also pored over the MIT research paper database and found that essential fatty acids showed promise in studies, but no other company was using them in lash products at the time.

While the product development cycle has sped up in recent years, it can’t always keep up with flash-in-the-pan trends. “You"re already four months behind,” Megan says she tells these clients. “By the time you actually hit the market, that trend might be over.”

Before you even consider product development, decide what you stand for. You can develop your skin care brand and grow an audience well before you manufacture products or launch an online store. This period will let you get to know your audience, gather feedback, and build trust. Use this time to hone your brand story and generate hype around your upcoming launch.

Visual brand identity is also extremely important in the skin care industry. Compelling packaging that speaks to your target audience’s aesthetic gives your brand a professional edge. Be sure to develop a clear set of brand guidelines to ensure that wherever your brand shows up, it’s adhering to a set of rules.

There are a few methods for formulating products: making them by hand at home, renting a dedicated manufacturing space, working with a lab to create custom products, or taking a private label or white label approach with a beauty manufacturer.

White labeling involves applying your own branding and limited customizations to an existing product. This is a beneficial method for those looking to monetize a personal brand (but have less interest in product development). Popular creators and influencers often use this method to monetize their large audiences.

Private label skin care lines work in a similar way but are more customized to brand and product specifications. They are generally developed in partnership with a private label lab like Genie Supply. With these models, you can still start your own skin care line with zero experience.

Like starting a food business, launching in the skin care industry carries risk—you are making products that could potentially harm people. It’s important to educate yourself on preservatives, shelf life, allergens, and proper storage and handling of skin care products. And to research labs carefully so you know you’re working with a partner knowledgeable in these areas.

Legal requirements can be daunting for those starting a skin care line from scratch—and each country or region will have their own rules. Megan, who had the experience of navigating these laws on her own, developed a visual guide on Genie Supply’s website to help her clients. “I would’ve killed for a guide like this five years ago,” she says. “That’s why I made it.”

Megan started her first business to solve a personal pain point: after she destroyed her natural eyelashes with extensions, she couldn’t find a restorative product that worked. The science-turned-business student went into research mode and found a gap in the market, developing her own line of lash serums.

The cost to start a skin care line varies depending on your production method. Even if you plan to start a skin care business from home, you will need a small investment for materials, packaging, and other business expenses. Expect to budget more if you want to work with a manufacturer, as many require minimum order quantities, and product development can be costly.

Known as FAST — “Flexible Autonomous Sensor measuring Tumors” — the wearable device developed by Dr. Abramson and his team consists of a stretchy skin-like polymer membrane embedded with a layer of gold circuitry. The sensor adheres to the skin above where a cancerous tumor is currently located. The sensor also has a small electronic “backpack” holding its battery.

Backlight: Controls the level of screen brightness by adjusting the back light. The closer to 100 the brighter. For those who have their TV in a dark room or basement, this setting won’t need to be terribly high. For those in brighter rooms, more backlight intensity will be desired. Try to avoid making this adjustment while sun is shining directly on the screen, as this will result in an unnaturally high setting. Instead, make your adjustments when room light is at its average for when you watch, and pick a program or movie scene with a lot of white in it, a daylight scene on a snow-covered mountain, for example. If after watching the scene for 10 minutes you begin to squint, the backlight is too strong. Reduce the backlight and repeat until you are happy.

Color: Tones down or up the colors displayed on the screen. The closer to 100 the deeper the color. Without a calibration disc and an optical filter (or the ability to defeat the red and green output of the television) it can be tough to know if you’ve got the color just right. Just how green should a leaf look, anyway? For this reason, a calibration disc is highly recommended to achieve the most accurate color settings. We do have a couple of tricks to offer, though. First, find out if your TV offers a color-temperature adjustment. Settings for color temperature are usually expressed in terms of cool or warm. Choose the warmest setting you have available to you as a starting point. From there, find a scene with plenty of faces in it, then press pause. Turn the color all the way up and notice how it appears everyone has jaundice or a fresh sunburn. You don’t want that. Now, turn the color nearly all the way down and notice how everyone looks as if they belong in the morgue. You don’t want that either. Now adjust the color back up until faces look natural. Each person’s face should have its own distinct hue. If it looks like real skin tone, you’ll know you’ve gotten close.

Tint: Adjusts the color balance between red and green displayed on the screen. The closer to Red 50, the redder the color will be. The closer to Green 50, the greener the color will be.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey