lcd panel conversion manufacturer

Every LCD screen eventually fails, usually due to the backlight behind the screens. That is why we have a backlight solution for every LCD screen on the market. Plazmo currently has the single largest global stock of drop-in CCFL and LED backlight assemblies.

Each of our assemblies comes complete with a pre-wired harness, OEM connector plug, silicone end caps and an optional metal rail. Nearly every LCD screen has a unique model design and we have developed the molds and manufacturing specifically to fit more than 200,000 LCD screen models in use today.

Plazmo also has robust manufacturing capabilities and specializes in perfectly replicating OEM backlight assemblies. Using our LED and CCFL backlight assemblies, we pass on savings to our customers while helping keep their LCD screens running smoothly.

This is a universal LED kit that includes 2 high brightness LED strips, a DC-DC LED driver, and a wire harness. The LED strips can be easily trimmed in designated increments every 3 LEDs, to fit any size LCD from 10"-24". This is known as a cut-to-fit model. This LED bar can be used for LED replacement or CCFL conversion.

NOTE: CCFL Warehouse does not have user manuals because every model of LCD power supply board is different. The customer must have some technical expertise to identify the power source on the monitor power supply board.

This product is commonly used for replacing backlights in a variety of different LCD panels found in gaming machines, POS, ATM and many other applications.

The upstream materials or components of the LCD panel industry mainly include liquid crystal materials, glass substrates, polarizing lenses, and backlight LEDs (or CCFL, which accounts for less than 5% of the market).

The middle reaches is the main panel factory processing and manufacturing, through the glass substrate TFT arrays and CF substrate, CF as upper and TFT self-built perfusion liquid crystal and the lower joint, and then put a polaroid, connection driver IC and control circuit board, and a backlight module assembling, eventually forming the whole piece of LCD module. The downstream is a variety of fields of application terminal-based brand, assembly manufacturers. At present, the United States, Japan, and Germany mainly focus on upstream raw materials, while South Korea, Taiwan, and the mainland mainly seek development in mid-stream panel manufacturing.

With the successive production of the high generation line in mainland China, the panel production capacity and technology level have been steadily improved, and the industrial competitiveness has been gradually enhanced. Nowadays, the panel industry is divided into three parts: South Korea, mainland China, and Taiwan, and mainland China is expected to become the no.1 in the world in 2019.

In the past decade, China’s panel display industryhas achieved leapfrog development, and the overall size of the industry has ranked among the top three in the world. Chinese mainland panel production capacity is expanding rapidly, although Japanese panel manufacturers master a large number of key technologies, gradually lose the price competitive advantage, compression panel production capacity. Panel production is concentrated in South Korea, Taiwan, and China, which is poised to become the world’s largest producer of LCD panels.

Up to 2016, BOE‘s global market share continued to increase: smartphone LCD, tablet PC display, and laptop display accounted for the world’s first market share, and display screen increased to the world’s second, while TV LCD remained the world’s third. In LCD TV panels, Chinese panel makers have accounted for 30 percent of global shipments to 77 million units, surpassing Taiwan’s 25.5 percent market share for the first time and ranking second only to South Korea.

In terms of the area of shipment, the area of board shipment of JD accounted for only 8.3% in 2015, which has been greatly increased to 13.6% in the first half of 2016, while the area of shipment of hu xing optoelectronics in the first half of 2015 was only 5.1%, which has reached 7.8% in the first half of 2016. The panel factories in mainland China are expanding their capacity at an average rate of double-digit growth and transforming it into actual shipments and areas of shipment. On the other hand, although the market share of South Korea, Japan, and Taiwan is gradually decreasing, some South Korean and Japanese manufacturers have been inclined to the large-size HD panel and AMOLED market, and the production capacity of the high-end LCD panel is further concentrated in mainland China.

Domestic LCD panel production line capacity gradually released, overlay the decline in global economic growth, lead to panel makers from 15 in the second half began, in a low profit or loss, especially small and medium-sized production line, the South Korean manufacturers take the lead in transformation strategy, closed in medium and small size panel production line, South Korea’s 19-panel production line has shut down nine, and part of the production line is to research and development purposes. Some production lines are converted to LTPS production lines through process conversion. Korean manufacturers are turning to OLED panels in a comprehensive way, while Japanese manufacturers are basically giving up the LCD panel manufacturing business and turning to the core equipment and materials side. In addition to the technical direction of the research and judgment, more is the LCD panel business orders and profits have been severely compressed, Korean and Japanese manufacturers have no desire to fight. Since many OLED technologies are still in their infancy in mainland China, it is a priority to move to high-end panels such as OLED as soon as possible. Taiwanese manufacturers have not shut down factories on a large scale, but their advantages in LCD technology and OLED technology have been slowly eroded by the mainland.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

Samsung Display’s LCD factory A4-2 line (L7-2), which was closed early last year, is being converted to a 6th-generation OLED production line. The company introduced display processing equipment in the first quarter. According to reports, Samsung will commenceoperations in the third quarter.

According to ETNews, Samsung Display has invested about 1 trillion won in the plant and plans toincrease the annual production capacity of 6th-generation OLED panels by 180,000 pieces through a new OLED production line.

The equipment industry welcomes Samsung Display’s expanding OLED investment. After the large-scale investment of display panel companies has been silent for a period of time, it is expected that from A4-2, equipment investment will officially start. The A4-2 plant ensures an additional output of 180,000 panels per year. If there are additional orders, it is expected that there will be large-scale equipment orders similar to this additional investment.

Several Chinese panel manufacturers have surpassed Samsung and LG to become the main LCD panel manufacturers in recent years. Korean companies are no longer able to compete. Samsung will stop the production of LCD panels half a year ahead of schedule. Samsung originally planned to stop the production of LCD panels by the end of 2020. However, the LCD panel market started to increase prices in the past year or so. This made Samsung’s LCD factory continue to operate for another two years. However, the company originally plans to exit the market at the end of 2022. Nevertheless, the LCD panel market has changed since the end of last year. The price has been falling significantly and it is now on a free fall. By January this year, the average price of a 32 -inch panel was only $ 38, a 64% drop relative to January last year.

What are the differences between these twoelectric bikedisplay types and why should we prefer LED or LCD? What additional features does an LCD display offer us? Why should we pay more? These are the questions most clients ask when it comes to choosing a display.

The SW900 LCD display offers much more than a digital screen and fancy look, it allows users to editcontroller parameters, control all functions on your ebike from speed to wheel size and even an external headlight.

Which do we prefer? We certainly recommend an LCD display if the client is using their eBike often and therefore taking advantage of it’s extra features everyday, whether it’s commuting to work or enjoying a casual ride.

LG Display CEO said on Wednesday that the company was open to converting its liquid crystal display (LCD) TV production lines in South Korea to those dedicated to OLED.

LG Display CEO Jeong Ho-young, speaking at an event hosted by the Korea Display Industry Association, an organization he is currently the chairman of, told reporters that it will take some time to consider when to convert LCD lines to OLED lines.

LG Display had said back in July during their second quarter conference call that it was downsizing LCD TV lines that have a limited capacity to differentiate against competitors.

On the high inventory levels of display panel makers in general, the CEO said this was mostly caused by factory halts in Shanghai during the second quarter and should be considered a temporary problem. LG Display will aim to normalize this by the end of the year, Jeong said.

What are the differences between these twoelectric bikedisplay types and why should we prefer LED or LCD? What additional features does an LCD display offer us? Why should we pay more? These are the questions most clients ask when it comes to choosing a display.

The SW900 LCD display offers much more than a digital screen and fancy look, it allows users to editcontroller parameters, control all functions on your ebike from speed to wheel size and even an external headlight.

Which do we prefer? We certainly recommend an LCD display if the client is using their eBike often and therefore taking advantage of it’s extra features everyday, whether it’s commuting to work or enjoying a casual ride.

That shift represents a move away from displays that use shuttered, transmissive light with color filters, such as liquid-crystal displays (LCDs), to emissive displays that produce colors of light via high-intensity emissions of photons, such as organic and inorganic light-emitting diodes (OLEDs and iLEDS), along with enhancements like quantum dots (QDs).

LCDs have been with us for over a quarter-century in consumer televisions and commercial displays, and long before that as simpler, alphanumeric indicators in products like calculators. But R&D on the underlying technology has essentially plateaued: You can now purchase a 70-inch LCD Ultra HDTV with “smart” Internet functionality for less than $600, compared to the $15,000 price tag on a 28-inch VGA LCD TV 20+ years ago.

Prices for finished LCD panels have dropped so low that they are basically consumable and disposable items. The handful of companies that manufacture LCD panels (mostly in China) are cautious about investing substantial sums of money in the technology. And two of the largest players, Samsung Display Company (SDC) and LG Display (LGD), are now winding down LCD panel production in favor of next-generation emissive displays.

Going forward, LGD has placed its bets on large OLED panels(opens in new tab). These panels use underlying IP licensed from Kodak (of all people), based on patents from the mid-1980s. An array of white OLED emitters (made up of blue and yellow compounds) generates bright light that then passes through red, green, and blue color filters. Additional white pixels provide a luminance boost.

The advantages of such a display are many. Emissive displays have much wider viewing angles than transmissive displays. Unlike LCDs, color saturation and contrast is consistent for any viewer at any angle. While OLEDs can’t quite achieve the peak brightness of a full-backlight-array LCD, they can smoothly reproduce very low levels of luminance right down to a deep black. And OLED pixels have faster on-off cycles than LCD pixels, making for sharper rendering of motion images. Plus, they can reproduce over 20 f-stops of light, more than enough for high dynamic range imaging.

We’re also seeing some interesting hybrid emissive display designs, such as Samsung Displays’ new quantum dot OLED hybrid (QD-OLED), which made its debut at CES 2022. SDC was looking for a new product to replace its sunsetting LCD panel fabrication business, and the QD-OLED fits the bill nicely. It combines a blue OLED emitter (manufactured by sister company Samsung Mobile Display) with a layer of red and green quantum dots.

On paper, the QD-OLED could be a real game changer. It has only four layers in its “stack,” compared to five in a WOLED panel and typically 10 in an LCD panel. This design (in theory) should simplify manufacturing complexity and costs, and (again, in theory) get production and manufacturing yields up to usable levels in less time. As of this writing, however, reports from some Asian electronics industry sites cite very low yields on both the QD-OLED layer and the oxide (presumably IGZO) transistor pixel switching layer.

Indicators are that the next generation of direct-view displays will all feature emissive architectures, and for now, it appears they’ll use OLEDs and/or iLEDs to generate light, with or without quantum dots. To be sure, LCD displays aren’t going away any time soon—but their days do appear to be numbered.

![]()

LG Display saw a decrease in panel shipments in the fourth quarter due to worsening macroeconomic conditions, as set makers’ inventory adjustments further impacted demand in the high-end product sector which had been solid.

The company recorded a quarter-on-quarter increase in revenues by 8% thanks to increased panel shipments for mobile devices, while reporting an operating loss due to a continuous decline in mid-sized panel prices and a high-intensity action plan of utilization adjustment to decrease inventory.

Panels for TVs accounted for 25% of revenues in the fourth quarter, while panels for IT devices including monitors, laptops and tablet PCs accounted for 34%, panels for mobile and other devices accounted for 34%, and those for automobiles accounted for 7%.

With respect to the market-to-order business which now accounts for 30% of its revenue, LG Display will expand its share in revenue by over 40% in 2023 and 50% in 2024 to establish a stable profit structure resilient to market conditions. In addition, the company will further strengthen its position in the automotive display sector and continue to lead the mid-sized OLED market including tablet PCs, as the rise in smartphone panel shipments in the second half of 2023 is expected to add positive fuel to its efforts to enhance its market-to-order business.

After the company’s decision to end its LCD TV panel production in Korea, LG Display"s large-sized OLED business was evaluated by an external institution and divided into separate cash-generating unit in accordance with related accounting standards and objective procedures. The company’s large-sized OLED business was reflected KRW 1,331 billion as asset impairment loss after calculated by an external institution, causing the net loss to expand. Considering it occurred only in the financial statement without actually affecting business operations, it is in turn expected to remove possible uncertainties in the company’s businesses in the future.

For its large-sized OLED business, LG Display will further strengthen its profit structure by improving competitiveness in products and costs while concentrating continuously on qualitative growth. In addition, the company will make efforts to enhance its market position by further improving its fundamental competitiveness with its OLED technology, as well as expanding its market-creating business with high growth potential such as Transparent and Gaming OLED panels.

A plasma display panel (PDP) is a type of flat panel display that uses small cells containing plasma: ionized gas that responds to electric fields. Plasma televisions were the first large (over 32 inches diagonal) flat panel displays to be released to the public.

Until about 2007, plasma displays were commonly used in large televisions (30 inches (76 cm) and larger). By 2013, they had lost nearly all market share due to competition from low-cost LCDs and more expensive but high-contrast OLED flat-panel displays. Manufacturing of plasma displays for the United States retail market ended in 2014,

Plasma displays are bright (1,000 lux or higher for the display module), have a wide color gamut, and can be produced in fairly large sizes—up to 3.8 metres (150 in) diagonally. They had a very low luminance "dark-room" black level compared with the lighter grey of the unilluminated parts of an LCD screen. (As plasma panels are locally lit and do not require a back light, blacks are blacker on plasma and grayer on LCD"s.)LED-backlit LCD televisions have been developed to reduce this distinction. The display panel itself is about 6 cm (2.4 in) thick, generally allowing the device"s total thickness (including electronics) to be less than 10 cm (3.9 in). Power consumption varies greatly with picture content, with bright scenes drawing significantly more power than darker ones – this is also true for CRTs as well as modern LCDs where LED backlight brightness is adjusted dynamically. The plasma that illuminates the screen can reach a temperature of at least 1,200 °C (2,190 °F). Typical power consumption is 400 watts for a 127 cm (50 in) screen. Most screens are set to "vivid" mode by default in the factory (which maximizes the brightness and raises the contrast so the image on the screen looks good under the extremely bright lights that are common in big box stores), which draws at least twice the power (around 500–700 watts) of a "home" setting of less extreme brightness.

Plasma screens are made out of glass, which may result in glare on the screen from nearby light sources. Plasma display panels cannot be economically manufactured in screen sizes smaller than 82 centimetres (32 in).enhanced-definition televisions (EDTV) this small, even fewer have made 32 inch plasma HDTVs. With the trend toward large-screen television technology, the 32 inch screen size is rapidly disappearing. Though considered bulky and thick compared with their LCD counterparts, some sets such as Panasonic"s Z1 and Samsung"s B860 series are as slim as 2.5 cm (1 in) thick making them comparable to LCDs in this respect.

Wider viewing angles than those of LCD; images do not suffer from degradation at less than straight ahead angles like LCDs. LCDs using IPS technology have the widest angles, but they do not equal the range of plasma primarily due to "IPS glow", a generally whitish haze that appears due to the nature of the IPS pixel design.

Superior uniformity. LCD panel backlights nearly always produce uneven brightness levels, although this is not always noticeable. High-end computer monitors have technologies to try to compensate for the uniformity problem.

Uses more electrical power, on average, than an LCD TV using a LED backlight. Older CCFL backlights for LCD panels used quite a bit more power, and older plasma TVs used quite a bit more power than recent models.

Fixed-pixel displays such as plasma TVs scale the video image of each incoming signal to the native resolution of the display panel. The most common native resolutions for plasma display panels are 852×480 (EDTV), 1,366×768 and 1920×1080 (HDTV). As a result, picture quality varies depending on the performance of the video scaling processor and the upscaling and downscaling algorithms used by each display manufacturer.

Early high-definition (HD) plasma displays had a resolution of 1024x1024 and were alternate lighting of surfaces (ALiS) panels made by Fujitsu and Hitachi.

A panel of a plasma display typically comprises millions of tiny compartments in between two panels of glass. These compartments, or "bulbs" or "cells", hold a mixture of noble gases and a minuscule amount of another gas (e.g., mercury vapor). Just as in the fluorescent lamps over an office desk, when a high voltage is applied across the cell, the gas in the cells forms a plasma. With flow of electricity (electrons), some of the electrons strike mercury particles as the electrons move through the plasma, momentarily increasing the energy level of the atom until the excess energy is shed. Mercury sheds the energy as ultraviolet (UV) photons. The UV photons then strike phosphor that is painted on the inside of the cell. When the UV photon strikes a phosphor molecule, it momentarily raises the energy level of an outer orbit electron in the phosphor molecule, moving the electron from a stable to an unstable state; the electron then sheds the excess energy as a photon at a lower energy level than UV light; the lower energy photons are mostly in the infrared range but about 40% are in the visible light range. Thus the input energy is converted to mostly infrared but also as visible light. The screen heats up to between 30 and 41 °C (86 and 106 °F) during operation. Depending on the phosphors used, different colors of visible light can be achieved. Each pixel in a plasma display is made up of three cells comprising the primary colors of visible light. Varying the voltage of the signals to the cells thus allows different perceived colors.

In a monochrome plasma panel, the gas is mostly neon, and the color is the characteristic orange of a neon-filled lamp (or sign). Once a glow discharge has been initiated in a cell, it can be maintained by applying a low-level voltage between all the horizontal and vertical electrodes–even after the ionizing voltage is removed. To erase a cell all voltage is removed from a pair of electrodes. This type of panel has inherent memory. A small amount of nitrogen is added to the neon to increase hysteresis.phosphor. The ultraviolet photons emitted by the plasma excite these phosphors, which give off visible light with colors determined by the phosphor materials. This aspect is comparable to fluorescent lamps and to the neon signs that use colored phosphors.

Every pixel is made up of three separate subpixel cells, each with different colored phosphors. One subpixel has a red light phosphor, one subpixel has a green light phosphor and one subpixel has a blue light phosphor. These colors blend together to create the overall color of the pixel, the same as a triad of a shadow mask CRT or color LCD. Plasma panels use pulse-width modulation (PWM) to control brightness: by varying the pulses of current flowing through the different cells thousands of times per second, the control system can increase or decrease the intensity of each subpixel color to create billions of different combinations of red, green and blue. In this way, the control system can produce most of the visible colors. Plasma displays use the same phosphors as CRTs, which accounts for the extremely accurate color reproduction when viewing television or computer video images (which use an RGB color system designed for CRT displays).

Plasma displays are different from liquid crystal displays (LCDs), another lightweight flat-screen display using very different technology. LCDs may use one or two large fluorescent lamps as a backlight source, but the different colors are controlled by LCD units, which in effect behave as gates that allow or block light through red, green, or blue filters on the front of the LCD panel.

Each cell on a plasma display must be precharged before it is lit, otherwise the cell would not respond quickly enough. Precharging normally increases power consumption, so energy recovery mechanisms may be in place to avoid an increase in power consumption.LED illumination can automatically reduce the backlighting on darker scenes, though this method cannot be used in high-contrast scenes, leaving some light showing from black parts of an image with bright parts, such as (at the extreme) a solid black screen with one fine intense bright line. This is called a "halo" effect which has been minimized on newer LED-backlit LCDs with local dimming. Edgelit models cannot compete with this as the light is reflected via a light guide to distribute the light behind the panel.

Image burn-in occurs on CRTs and plasma panels when the same picture is displayed for long periods. This causes the phosphors to overheat, losing some of their luminosity and producing a "shadow" image that is visible with the power off. Burn-in is especially a problem on plasma panels because they run hotter than CRTs. Early plasma televisions were plagued by burn-in, making it impossible to use video games or anything else that displayed static images.

In 1983, IBM introduced a 19-inch (48 cm) orange-on-black monochrome display (Model 3290 Information Panel) which was able to show up to four simultaneous IBM 3270 terminal sessions. By the end of the decade, orange monochrome plasma displays were used in a number of high-end AC-powered portable computers, such as the Compaq Portable 386 (1987) and the IBM P75 (1990). Plasma displays had a better contrast ratio, viewability angle, and less motion blur than the LCDs that were available at the time, and were used until the introduction of active-matrix color LCD displays in 1992.

Due to heavy competition from monochrome LCDs used in laptops and the high costs of plasma display technology, in 1987 IBM planned to shut down its factory in Kingston, New York, the largest plasma plant in the world, in favor of manufacturing mainframe computers, which would have left development to Japanese companies.Larry F. Weber, a University of Illinois ECE PhD (in plasma display research) and staff scientist working at CERL (home of the PLATO System), co-founded Plasmaco with Stephen Globus and IBM plant manager James Kehoe, and bought the plant from IBM for US$50,000. Weber stayed in Urbana as CTO until 1990, then moved to upstate New York to work at Plasmaco.

In 1995, Fujitsu introduced the first 42-inch (107 cm) plasma display panel;Philips introduced the first large commercially available flat-panel TV, using the Fujitsu panels. It was available at four Sears locations in the US for $14,999, including in-home installation. Pioneer also began selling plasma televisions that year, and other manufacturers followed. By the year 2000 prices had dropped to $10,000.

In late 2006, analysts noted that LCDs had overtaken plasmas, particularly in the 40-inch (100 cm) and above segment where plasma had previously gained market share.

Until the early 2000s, plasma displays were the most popular choice for HDTV flat panel display as they had many benefits over LCDs. Beyond plasma"s deeper blacks, increased contrast, faster response time, greater color spectrum, and wider viewing angle; they were also much bigger than LCDs, and it was believed that LCDs were suited only to smaller sized televisions. However, improvements in VLSI fabrication narrowed the technological gap. The increased size, lower weight, falling prices, and often lower electrical power consumption of LCDs made them competitive with plasma television sets.

At the 2010 Consumer Electronics Show in Las Vegas, Panasonic introduced their 152" 2160p 3D plasma. In 2010, Panasonic shipped 19.1 million plasma TV panels.

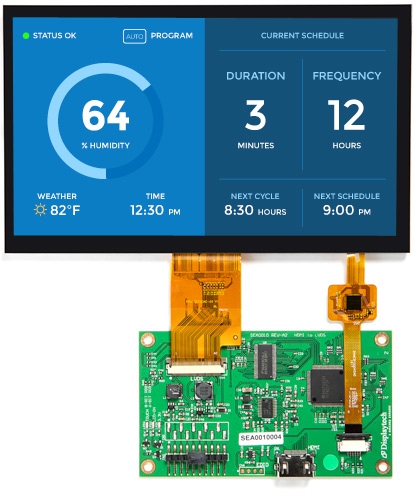

The LCD controller board is often called the Analog/Digital (A/D) board. As a type of hardware processor, it allows for various video source inputs to be connected, selected, and displayed on the LCD screen. It does this by converting the different video input signals into a format manageable by the LCD panel.

In conjunction with the LCD controller, the LCD driver is a form of software that is the interface of and dependent on the controller piece. Combined, the two form an LCD controller driver board. As the controller connects the computer to the operating system (OS), the driver facilitates that communication. Though there is typically just one display controller per LCD, there can be added drivers to extend the reach of the drive to further segments of the LCD.

To generalize the process, the LCD controller/driver adjusts the input signal, scaling resolution if needed, and then outputs the signal for the LCD monitor to use. Some of these output interfaces are low-voltage differential signaling (LVDS), SPI, I2C, and Parallel.

In most LCD controller/driver boards, there are two other input/output systems. Both these systems, however, are two-way pathways. One involves controlling and monitoring options, such as controls for brightness, image, and color using the on-screen display (OSD) control panel. The other is for communication via connections like Ethernet, Bluetooth, or IP.

To delve deeper into the details, consider the previously mentioned input signals. There are a variety of signals that LCD technology processes, such as VGA, HDMI, DVI, and DisplayPort. These computer display standards vary in format and characteristics like aspect ratio, display size, display resolution, color depth, and refresh rate. One of the biggest differences between these standards is their usage of analog signals or digital signals.

The HDMI is a combination of digital audio and digital video transmission. There are many HDMI connectors, such as the standard, dual-link, and micro. These connectors are what the input signal travels through to reach the LCD controller and to direct what to display.

And last from the list of examples of input signals is the DisplayPort. It is similar to HDMI in its purpose to replace outdated VGA and DVI as well as its transmission of audio and video through its interface. The DisplayPort does not have as much variation in cables and connectors as the HDMI, with only one cable and two types of connectors. From the DisplayPort, there is a growing technology called the embedded DisplayPort interface, or eDP interface. LCD manufacturers have begun to gravitate towards this interface due to its fewer connections, smaller size, and ability to quickly transmit high quality displays.

Bringing the subject back to LCD controllers, with the various types of computer display standards, the video signal inputs can be a challenge to accommodate and translate for the LCD panel, but with the help of adapters and the growth of these standard types, displays continue to become faster and develop with greater resolutions.

LCD stands for “liquid crystal display,” while CRT is “cathode ray tube.” LCD is newer while CRT is an older technology. In a color CRT computer monitor, a metal filament is heated, causing the surface of the filament to emit electrons. These electrons accelerate by an electron gun fired at the screen. The inside of the display becomes coated with “phosphors,” or materials that emit light when they are exposed to radiation, such as ultraviolet light or electrons. By controlling which pixels glow, the CRT produces images, in a similar manner to how dots on a newspaper page make up pictures. By contrast, LCD works by filtering. A lamp or series of lamps that emits light, usually white light, placed behind the screen. Each pixel on the LCD screen is capable of filtering out many different wavelengths of light. By filtering specific wavelengths of light, the pixel can be changed to many different colors. By controlling which pixels filter certain wavelengths, the LCD can generate colored images.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey