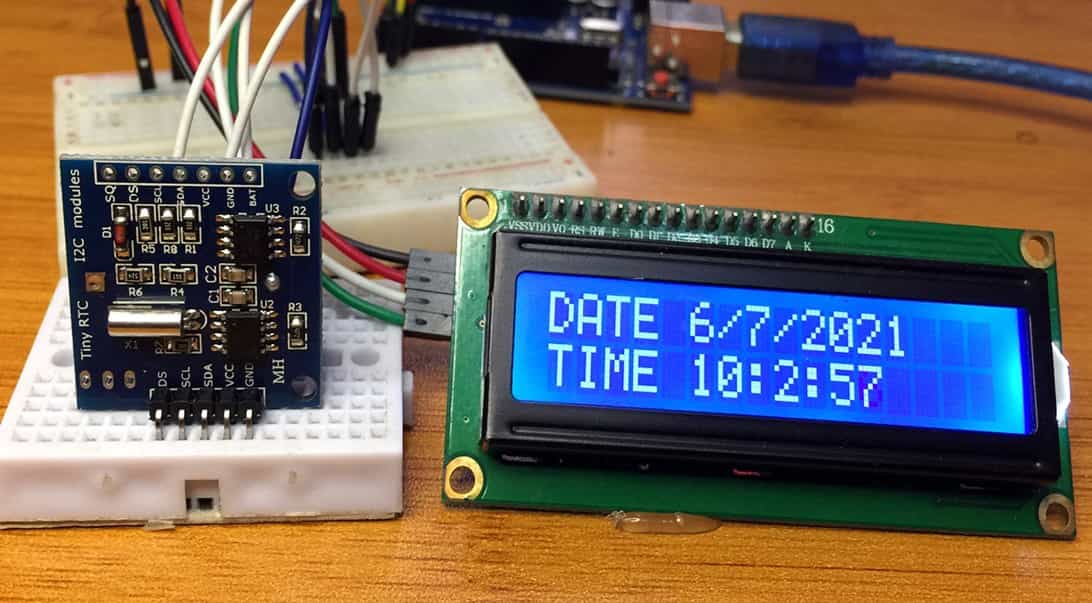

arduino with a ds1307 rtc and lcd display factory

you can use the basic structure of this project. We have already made various Arduino projects, Embedded projects, and Arduino tutorials on our website. You can visit them if you are new to the world of electronics and Arduino.

to display the time. You can make an Automatic pet Feeder, Automatic Light, time-based plant watering system, and much more using this. This reduces the manual stress on us.

the module is capable of counting seconds, minutes, hours, days, weeks, months, and years. Arduino uses the I2C communication protocol to send data to the LCD display,

which we are using here to display the time. The display updates every second to tell the most accurate time since the module is much accurate to tell the time.

The module is capable of running for more than 5 years continuously without affecting the count in time. this is possible because of the in-built cell.

the most professional PCB manufacturer for prototyping and low-volume production to work with in the world. With more than a decade in the field, PCBWAY committed to meeting the needs of customers from different industries in terms of quality, delivery, cost-effectiveness, and any other demanding requests. As one of the most experienced PCB manufacturers and SMT Assemblers in China, we pride ourselves to be your best business partners as well as good friends in every aspect of your PCB needs. They strive to make your R&D work easy and hassle-free.

NOTE- You need to install the three libraries LiquidCrystal_I2C.h, Wire.h, and DS1307.hwhich can be downloaded from HERE into your Arduino IDE before uploading the code.

Once the uploading of code is complete, LCD Display will be able to show the Time as per the code uploaded. I hope you found this guide helpful in making the project. If you have any doubts, you can put them in the comment section below.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Now that I look again, you are right... BUT.. the actual address is 0x3F! I"m not sure that makes sense either but because I believe the lowest bit is considered the R/(not)W bit. Since its a write only device, I"d think it should be ox3E if anything, but that"s the address needed, so I guess the LCD library I"m using overrides the low bit. And now that you mention it, I see that the board does have places for jumpers (or zero hom SMD parts) to further configure the address. It means I can now drive multiple displays (up to 8) if I even needed to.

Very interesting Thanks! So the likelihood of two devices with completely different purposes using the same addess range is fairly low, and like my DS1882 audio pot chips, they will usually allow the user to configure 3 bits within the lower nibble of the address.

For an i2c based clock/RTC module would use a DS3231 instead of a DS1307. The price is about the same and it is much more accurate. DS3231 modules on ebay (starting at just under $1.50 USD shipped) are cheaper than the price shown on that link you provided to the DS1307.

You do need to be careful with most of these low cost RTC modules in the they have a little charging circuit on them for using with a LIR2032. If you use a 2032 instead, you should cut a trace on the module to disable the charging circuit.

Well that one I linked seems very convenient, and I probably wouldn"t need even 1/10th of it current functions. But I"ll investigate the S3231 too! For my projects, I just need a way to re-set the time if power has been lost for a while. Currently I detect eminent power fail, save the current time in EEprom, and retrieve it on power up. This is just to survive very typical power losses that only last minutes, without resetting to a stupid time like 12:00AM like most household devices do. But I"ll never need millisecond accuracy for any current projects.

And yes... I"ve been meaning to check out those nifty esp8266 modules too, for other projects. I was wondering though (even though its another subject), can they be used without coding them, just using external commands? I"m thinking of the major hassles and expense getting any kind of FCC approval, should I ever use such a module in a product. From my research, if a module has already passed FCC muster with its existing code, and you don"t alter its code, you may have a slightly cheaper path to approval.

Hi, and welcome to this tutorial, it’s about another RTC (Real Time Clock) module, it’s the DS1307, previously I did a tutorial about the DS1302, and a project where I set it up using a keypad, then an Alarm Clock project based on that module, I also did a tutorial about the DS3132.

But today we’re about the DS1307, and I’m gonna use it with Arduino UNO board and I’ll also use a LCD i²c screen and OLED display, to show time and date in different formats.

“The DS1307 serial real-time clock (RTC) is a lowpower, full binary-coded decimal (BCD) clock/calendar plus 56 bytes of NV SRAM. Address and data are transferred serially through an I2C, bidirectional bus. The clock/calendar provides seconds, minutes, hours, day, date, month, and year information. The end of the month date is automatically adjusted for months with fewer than 31 days, including corrections for leap year.”

OLED libraries: – Download here Adafruit OLED SSD1306 library – Download here Adafruit GFX Library

Important !! First time you must wire the module and upload the “SetTime” example, it sets the module to the compiling time of the code which is technically your real time and date.

N.B: If you are testing the module with multiple things it’s better to close the “SetTime” example, open it again and upload to the board, otherwise your module will be programmed with the first time the “SetTime” example was compiled, and you may think that your module doesn’t work well !!

When autocomplete results are available use up and down arrows to review and enter to select. Touch device users, explore by touch or with swipe gestures.

Along 3 years I have been trying several leg mechanism, at first I decided to do a simple desing with tibial motor where placed on femur joint.This design had several problems, like it wasn"t very robust and the most importat is that having the motor (with big mass) that far from the rotating axis, caused that in some movements it generate unwanted dynamics to the robot body, making controlability worse.New version have both motors of femur/tibial limb at coxa frame, this ends with a very simple setup and at the same time, the heaviest masses of the mechanism are centered to the rotating axis of coxa limb, so even though the leg do fast movements, inertias won"t be strong enough to affect the hole robot mass, achieving more agility.Inverse Kinematics of the mechanismAfter building it I notice that this mechanism was very special for another reason, at the domain the leg normally moves, it acts as a diferential mecanism, this means that torque is almost all the time shared between both motor of the longer limbs. That was an improvent since with the old mechanism tibial motor had to hold most of the weight and it was more forced than the one for femur.To visualize this, for the same movement, we can see how tibial motor must travel more arc of angel that the one on the new version.In order to solve this mechanism, just some trigonometry is needed. Combining both cosine and sine laws, we can obtain desired angle (the one between femur and tibia) with respect to the angle the motor must achieve.Observing these equations, with can notice that this angle (the one between femur and tibia) depends on both servos angles, which means both motors are contributing to the movement of the tibia.Calibration of servosAnother useful thing to do if we want to control servo precisely is to print a calibration tool for our set up. As shown in the image below, in order to know where real angles are located, angle protactor is placer just in the origin of the rotating joint, and choosing 2 know angles we can match PWM signal to the real angles we want to manipulate simply doing a lineal relation between angles and PWM pulse length.Then a simple program in the serial console can be wrtten to let the user move the motor to the desired angle. This way the calibration process is only about placing motor at certain position and everything is done and we won"t need to manually introduce random values that can be a very tedious task.With this I have achieved very good calibrations on motors, which cause the robot to be very simetrial making the hole system more predictable. Also the calibration procedure now is very easy to do, as all calculations are done automatically. Check Section 1 for the example code for calibration.More about this can be seen in the video below, where all the building process is shown as well as the new leg in action.SECTION 1:In the example code below, you can see how calibration protocol works, it is just a function called calibrationSecuence() which do all the work until calibration is finished. So you only need to call it one time to enter calibration loop, for example by sending a "c" character thought the serial console.Also some useful function are used, like moving motor directly with analogWrite functions which all the calculations involved, this is a good point since no interrupts are used.This code also have the feature to calibrate the potentiometer coming from each motor.#define MAX_PULSE 2500 #define MIN_PULSE 560 /*---------------SERVO PIN DEFINITION------------------------*/ int m1 = 6;//FR int m2 = 5; int m3 = 4; int m4 = 28;//FL int m5 = 29; int m6 = 36; int m7 = 3;//BR int m8 = 2; int m9 = 1; int m10 = 7;//BL int m11 = 24; int m12 = 25; int m13 = 0;//BODY /*----------------- CALIBRATION PARAMETERS OF EACH SERVO -----------------*/ double lowLim[13] = {50, 30, 30, 50, 30, 30, 50, 30, 30, 50, 30, 30, 70}; double highLim[13] = {130, 150, 150, 130, 150, 150, 130, 150, 150, 130, 150, 150, 110}; double a[13] = { -1.08333, -1.06667, -1.07778, //FR -1.03333, 0.97778, 1.01111, //FL 1.03333, 1.05556, 1.07778, //BR 1.07500, -1.07778, -1.00000, //BL 1.06250 }; double b[13] = {179.0, 192.0, 194.5, //FR 193.0, 5.5, -7.5, //FL 7.0, -17.0, -16.0, //BR -13.5, 191.5, 157.0, //BL -0.875 }; double ae[13] = {0.20292, 0.20317, 0.19904 , 0.21256, -0.22492, -0.21321, -0.21047, -0.20355, -0.20095, -0.20265, 0.19904, 0.20337, -0.20226 }; double be[13] = { -18.59717, -5.70512, -2.51697, -5.75856, 197.29411, 202.72169, 185.96931, 204.11902, 199.38663, 197.89534, -5.33768, -32.23424, 187.48058 }; /*--------Corresponding angles you want to meassure at in your system-----------*/ double x1[13] = {120, 135, 90, 60, 135 , 90, 120, 135, 90, 60, 135, 90, 110}; //this will be the first angle you will meassure double x2[13] = {60, 90, 135, 120, 90, 135, 60, 90, 135, 120, 90, 135, 70};//this will be the second angle you will meassure for calibration /*--------You can define a motor tag for each servo--------*/ String motorTag[13] = {"FR coxa", "FR femur", "FR tibia", "FL coxa", "FL femur", "FL tibia", "BR coxa", "BR femur", "BR tibia", "BL coxa", "BL femur", "BL tibia", "Body angle" }; double ang1[13] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; double ang2[13] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; float xi[500]; float yi[500]; float fineAngle; float fineL; float fineH; int motorPin; int motor = 0; float calibrationAngle; float res = 1.0; float ares = 0.5; float bres = 1.0; float cres = 4.0; float rawAngle; float orawAngle; char cm; char answer; bool interp = false; bool question = true; bool swing = false; int i; double eang; int freq = 100; // PWM frecuency can be choosen here. void connectServos() { analogWriteFrequency(m1, freq); //FR coxa digitalWrite(m1, LOW); pinMode(m1, OUTPUT); analogWriteFrequency(m2, freq); //femur digitalWrite(m2, LOW); pinMode(m2, OUTPUT); analogWriteFrequency(m3, freq); //tibia digitalWrite(m3, LOW); pinMode(m3, OUTPUT); analogWriteFrequency(m4, freq); //FL coxa digitalWrite(m4, LOW); pinMode(m4, OUTPUT); analogWriteFrequency(m5, freq); //femur digitalWrite(m5, LOW); pinMode(m5, OUTPUT); analogWriteFrequency(m6, freq); //tibia digitalWrite(m6, LOW); pinMode(m6, OUTPUT); analogWriteFrequency(m7, freq); //FR coxa digitalWrite(m7, LOW); pinMode(m7, OUTPUT); analogWriteFrequency(m8, freq); //femur digitalWrite(m8, LOW); pinMode(m8, OUTPUT); analogWriteFrequency(m9, freq); //tibia digitalWrite(m9, LOW); pinMode(m9, OUTPUT); analogWriteFrequency(m10, freq); //FR coxa digitalWrite(m10, LOW); pinMode(m10, OUTPUT); analogWriteFrequency(m11, freq); //femur digitalWrite(m11, LOW); pinMode(m11, OUTPUT); analogWriteFrequency(m12, freq); //tibia digitalWrite(m12, LOW); pinMode(m12, OUTPUT); analogWriteFrequency(m13, freq); //body digitalWrite(m13, LOW); pinMode(m13, OUTPUT); } void servoWrite(int pin , double angle) { float T = 1000000.0f / freq; float usec = float(MAX_PULSE - MIN_PULSE) * (angle / 180.0) + (float)MIN_PULSE; uint32_t duty = int(usec / T * 4096.0f); analogWrite(pin , duty); } double checkLimits(double angle , double lowLim , double highLim) { if ( angle >= highLim ) { angle = highLim; } if ( angle <= lowLim ) { angle = lowLim; } return angle; } int motorInfo(int i) { enc1 , enc2 , enc3 , enc4 , enc5 , enc6 , enc7 , enc8 , enc9 , enc10 , enc11 , enc12 , enc13 = readEncoders(); if (i == 0) { rawAngle = enc1; motorPin = m1; } else if (i == 1) { rawAngle = enc2; motorPin = m2; } else if (i == 2) { rawAngle = enc3; motorPin = m3; } else if (i == 3) { rawAngle = enc4; motorPin = m4; } else if (i == 4) { rawAngle = enc5; motorPin = m5; } else if (i == 5) { rawAngle = enc6; motorPin = m6; } else if (i == 6) { rawAngle = enc7; motorPin = m7; } else if (i == 7) { rawAngle = enc8; motorPin = m8; } else if (i == 8) { rawAngle = enc9; motorPin = m9; } else if (i == 9) { rawAngle = enc10; motorPin = m10; } else if (i == 10) { rawAngle = enc11; motorPin = m11; } else if (i == 11) { rawAngle = enc12; motorPin = m12; } else if (i == 12) { rawAngle = enc13; motorPin = m13; } return rawAngle , motorPin; } void moveServos(double angleBody , struct vector anglesServoFR , struct vector anglesServoFL , struct vector anglesServoBR , struct vector anglesServoBL) { //FR anglesServoFR.tetta = checkLimits(anglesServoFR.tetta , lowLim[0] , highLim[0]); fineAngle = a[0] * anglesServoFR.tetta + b[0]; servoWrite(m1 , fineAngle); anglesServoFR.alpha = checkLimits(anglesServoFR.alpha , lowLim[1] , highLim[1]); fineAngle = a[1] * anglesServoFR.alpha + b[1]; servoWrite(m2 , fineAngle); anglesServoFR.gamma = checkLimits(anglesServoFR.gamma , lowLim[2] , highLim[2]); fineAngle = a[2] * anglesServoFR.gamma + b[2]; servoWrite(m3 , fineAngle); //FL anglesServoFL.tetta = checkLimits(anglesServoFL.tetta , lowLim[3] , highLim[3]); fineAngle = a[3] * anglesServoFL.tetta + b[3]; servoWrite(m4 , fineAngle); anglesServoFL.alpha = checkLimits(anglesServoFL.alpha , lowLim[4] , highLim[4]); fineAngle = a[4] * anglesServoFL.alpha + b[4]; servoWrite(m5 , fineAngle); anglesServoFL.gamma = checkLimits(anglesServoFL.gamma , lowLim[5] , highLim[5]); fineAngle = a[5] * anglesServoFL.gamma + b[5]; servoWrite(m6 , fineAngle); //BR anglesServoBR.tetta = checkLimits(anglesServoBR.tetta , lowLim[6] , highLim[6]); fineAngle = a[6] * anglesServoBR.tetta + b[6]; servoWrite(m7 , fineAngle); anglesServoBR.alpha = checkLimits(anglesServoBR.alpha , lowLim[7] , highLim[7]); fineAngle = a[7] * anglesServoBR.alpha + b[7]; servoWrite(m8 , fineAngle); anglesServoBR.gamma = checkLimits(anglesServoBR.gamma , lowLim[8] , highLim[8]); fineAngle = a[8] * anglesServoBR.gamma + b[8]; servoWrite(m9 , fineAngle); //BL anglesServoBL.tetta = checkLimits(anglesServoBL.tetta , lowLim[9] , highLim[9]); fineAngle = a[9] * anglesServoBL.tetta + b[9]; servoWrite(m10 , fineAngle); anglesServoBL.alpha = checkLimits(anglesServoBL.alpha , lowLim[10] , highLim[10]); fineAngle = a[10] * anglesServoBL.alpha + b[10]; servoWrite(m11 , fineAngle); anglesServoBL.gamma = checkLimits(anglesServoBL.gamma , lowLim[11] , highLim[11]); fineAngle = a[11] * anglesServoBL.gamma + b[11]; servoWrite(m12 , fineAngle); //BODY angleBody = checkLimits(angleBody , lowLim[12] , highLim[12]); fineAngle = a[12] * angleBody + b[12]; servoWrite(m13 , fineAngle); } double readEncoderAngles() { enc1 , enc2 , enc3 , enc4 , enc5 , enc6 , enc7 , enc8 , enc9 , enc10 , enc11 , enc12 , enc13 = readEncoders(); eang1 = ae[0] * enc1 + be[0]; eang2 = ae[1] * enc2 + be[1]; eang3 = ae[2] * enc3 + be[2]; eang4 = ae[3] * enc4 + be[3]; eang5 = ae[4] * enc5 + be[4]; eang6 = ae[5] * enc6 + be[5]; eang7 = ae[6] * enc7 + be[6]; eang8 = ae[7] * enc8 + be[7]; eang9 = ae[8] * enc9 + be[8]; eang10 = ae[9] * enc10 + be[9]; eang11 = ae[10] * enc11 + be[10]; eang12 = ae[11] * enc12 + be[11]; eang13 = ae[12] * enc13 + be[12]; return eang1 , eang2 , eang3 , eang4 , eang5 , eang6 , eang7 , eang8 , eang9 , eang10 , eang11 , eang12 , eang13; } void calibrationSecuence( ) { //set servos at their middle position at firstt for (int i = 0; i <= 12; i++) { rawAngle , motorPin = motorInfo(i); servoWrite(motorPin , 90); } // sensorOffset0 = calibrateContacts(); Serial.println(" "); Serial.println("_________________________________SERVO CALIBRATION ROUTINE_________________________________"); Serial.println("___________________________________________________________________________________________"); Serial.println("(*) Don"t send several caracter at the same time."); delay(500); Serial.println(" "); Serial.println("Keyboard: "x"-> EXIT CALIBRATION. "c"-> ENTER CALIBRATION."); Serial.println(" "i"-> PRINT INFORMATION. "); Serial.println(" "); Serial.println(" "n"-> CHANGE MOTOR (+). "b" -> CHANGE MOTOR (-)."); Serial.println(" "m"-> START CALIBRATION."); Serial.println(" "q"-> STOP CALIBRATION."); Serial.println(" "); Serial.println(" "r"-> CHANGE RESOLUTION."); Serial.println(" "p"-> ADD ANGLE. "o"-> SUBTRACT ANGLE. "); Serial.println(" "s"-> SAVE ANGLE."); delay(500); Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); while (CAL == true) { if (Serial.available() > 0) { cm = Serial.read(); if (cm == "x") { Serial.println("Closing CALIBRATION program..."); CAL = false; secuence = false; startDisplay(PAGE); angleBody = 90; anglesIKFR.tetta = 0.0; anglesIKFR.alpha = -45.0; anglesIKFR.gamma = 90.0; anglesIKFL.tetta = 0.0; anglesIKFL.alpha = -45.0; anglesIKFL.gamma = 90.0; anglesIKBR.tetta = 0.0; anglesIKBR.alpha = 45.0; anglesIKBR.gamma = -90.0; anglesIKBL.tetta = 0.0; anglesIKBL.alpha = 45.0; anglesIKBL.gamma = -90.0; } else if (cm == "i") { // + Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println("(*) Don"t send several caracter at the same time."); delay(500); Serial.println(" "); Serial.println("Keyboard: "x"-> EXIT CALIBRATION. "c"-> ENTER CALIBRATION."); Serial.println(" "i"-> PRINT INFORMATION. "); Serial.println(" "); Serial.println(" "n"-> CHANGE MOTOR (+). "b" -> CHANGE MOTOR (-)."); Serial.println(" "m"-> START CALIBRATION."); Serial.println(" "q"-> STOP CALIBRATION."); Serial.println(" "); Serial.println(" "r"-> CHANGE RESOLUTION."); Serial.println(" "p"-> ADD ANGLE. "o"-> SUBTRACT ANGLE. "s"-> SAVE ANGLE."); Serial.println(" "); delay(500); Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println(" "); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); Serial.println("Actual parameters of the motor: "); Serial.print("High limit: "); Serial.print(highLim[motor]); Serial.print(" Low limit: "); Serial.print(lowLim[motor]); Serial.print(" Angle 1: "); Serial.print(ang1[motor]); Serial.print(" Angle 2: "); Serial.println(ang2[motor]); Serial.println("---------------------------------------------------------------------------------------------------"); } else if (cm == "m") { // + secuence = true; } else if (cm == "s") { // + } else if (cm == "n") { // + motor++; if (motor >= 13) { motor = 0; } Serial.print("SELECTED MOTOR: "); Serial.println(motorTag[motor]); } else if (cm == "b") { // + motor--; if (motor < 0) { motor = 13 - 1; } Serial.print("SELECTED MOTOR: "); Serial.println(motorTag[motor]); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } } if (secuence == true) { Serial.print("Starting secuence for motor: "); Serial.println(motorTag[motor]); for (int i = 0; i <= 30; i++) { delay(20); Serial.print("."); } Serial.println("."); while (question == true) { unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 100000) { previousMicros = currentMicros; if (Serial.available() > 0) { answer = Serial.read(); if (answer == "y") { question = false; interp = true; secuence = true; } else if (answer == "n") { question = false; interp = false; secuence = true; } else { Serial.println("Please, select Yes(y) or No(n)."); } } } } answer = "t"; question = true; if (interp == false) { Serial.println("___"); Serial.println(" | Place motor at 1ts position and save angle"); Serial.println(" | This position can be the higher one"); rawAngle , motorPin = motorInfo(motor); calibrationAngle = 90; //start calibration at aproximate middle position of the servo. while (secuence == true) { /* find first calibration angle */ if (Serial.available() > 0) { cm = Serial.read(); if (cm == "p") { // + Serial.print(" | +"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle + res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "o") { // - Serial.print(" | -"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle - res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } else if (cm == "q") { // quit secuence secuence = false; Serial.println(" | Calibration interrupted!!"); } else if (cm == "s") { // save angle ang1[motor] = calibrationAngle; secuence = false; Serial.print(" | Angle saved at "); Serial.println(calibrationAngle); } } } if (cm == "q") { Serial.println(" |"); } else { secuence = true; Serial.println("___"); Serial.println(" | Place motor at 2nd position and save angle"); Serial.println(" | This position can be the lower one"); } while (secuence == true) { /* find second calibration angle */ if (Serial.available() > 0) { cm = Serial.read(); if (cm == "p") { // + Serial.print(" | +"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle + res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "o") { // - Serial.print(" | -"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle - res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } else if (cm == "q") { // quit secuence secuence = false; Serial.println(" | Calibration interrupted!!"); } else if (cm == "s") { // save angle ang2[motor] = calibrationAngle; secuence = false; Serial.print(" | Angle saved at "); Serial.println(calibrationAngle); } } } /*--------------------start calibration calculations------------------*/ if (cm == "q") { Serial.println("___|"); Serial.println("Calibration finished unespected."); Serial.println(" Select another motor."); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); } else { Serial.println("___"); Serial.println(" |___"); Serial.print( " | | Interpolating for motor: "); Serial.println(motorTag[motor]); secuence = true; //real angle is calculated interpolating both angles to a linear relation. a[motor] = (ang2[motor] - ang1[motor]) / (x2[motor] - x1[motor]); b[motor] = ang1[motor] - x1[motor] * (ang2[motor] - ang1[motor]) / (x2[motor] - x1[motor]); Serial.println(" | |"); } interp = true; } /*---------------------------make swing movement to interpolate motor encoder-----*/ if (interp == true and secuence == true) { delay(200); double x; int k = 0; int stp = 180; swing = true; i = 0; orawAngle , motorPin = motorInfo(motor); previousMicros = 0; while (swing == true) { // FIRST unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor] + float(i) * (x1[motor] - x2[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // SECOND unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor] + float(i) * (x2[motor] - x1[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // FIRST unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor] + float(i) * (x1[motor] - x2[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // SECOND unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } Serial.println(" | | Interpolation finished!"); /*-------Calculate linear interpolation of the encoder from 60 meassures done in swing------*/ double sx = 0; double sy = 0; double sx2 = 0; double sy2 = 0; double sxy = 0; double xmean = 0; double ymean = 0; int n = 300; for (int i = 0 ; i < n ; i++) { sx += xi[i+10]; sy += yi[i+10]; sx2 += xi[i+10] * xi[i+10]; sy2 += yi[i+10] * yi[i+10]; sxy += xi[i+10] * yi[i+10]; } ae[motor] = (n * sxy - sx * sy) / (n * sx2 - sx * sx); //sxy / sx2; // be[motor] = (sy - ae[motor] * sx) / n; //ymean - ae[motor] * xmean; Serial.println(" | | Moving back to ZERO position."); // turn the motor back to middle position swing = true; i = 0; while (swing == true) { unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor] + float(i) * (90 - x1[motor]) / 60; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); eang = ae[motor] * rawAngle + be[motor]; if ((i % 4) == 0) { Serial.print(" | | Servo ang: "); Serial.print(calibrationAngle); Serial.print(" -> Real ang: "); Serial.print(x); Serial.print(" -> Encoder ang: "); Serial.println(eang); } if (i >= 60) { swing = false; } i++; } } Serial.println("___|___|"); Serial.println(" | "); Serial.println("___"); Serial.println(" | Calibration finished satisfactory. Results data:"); Serial.print(" | HIGH lim: "); Serial.print(highLim[motor]); Serial.print(" LOW lim: "); Serial.println(lowLim[motor]); Serial.print(" | angle 1: "); Serial.print(ang1[motor]); Serial.print(" angle 2 "); Serial.println(ang2[motor]); Serial.print(" | Regression Motor a: "); Serial.print(a[motor], 5); Serial.print(" b: "); Serial.println(b[motor], 5); Serial.print(" | Regression Encoder a: "); Serial.print(ae[motor], 5); Serial.print(" b: "); Serial.println(be[motor], 5); Serial.println(" |"); Serial.println(" | ______________________________________________________________"); Serial.println(" | | |"); Serial.println(" | | This code won"t be able to save the updated parameters |"); Serial.println(" | | once the robot is shutted down. |"); Serial.println(" | | |"); Serial.println(" | | Please, write down the results |"); Serial.println(" | | and save them in the definition of each variable. |"); Serial.println(" | |_____________________________________________________________|"); Serial.println(" |"); Serial.println("___|"); Serial.println(" Select another motor."); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); } interp = false; secuence = false; } } SAFE = false; Serial.println("Calibration killed"); } // END OF CALIBRATION

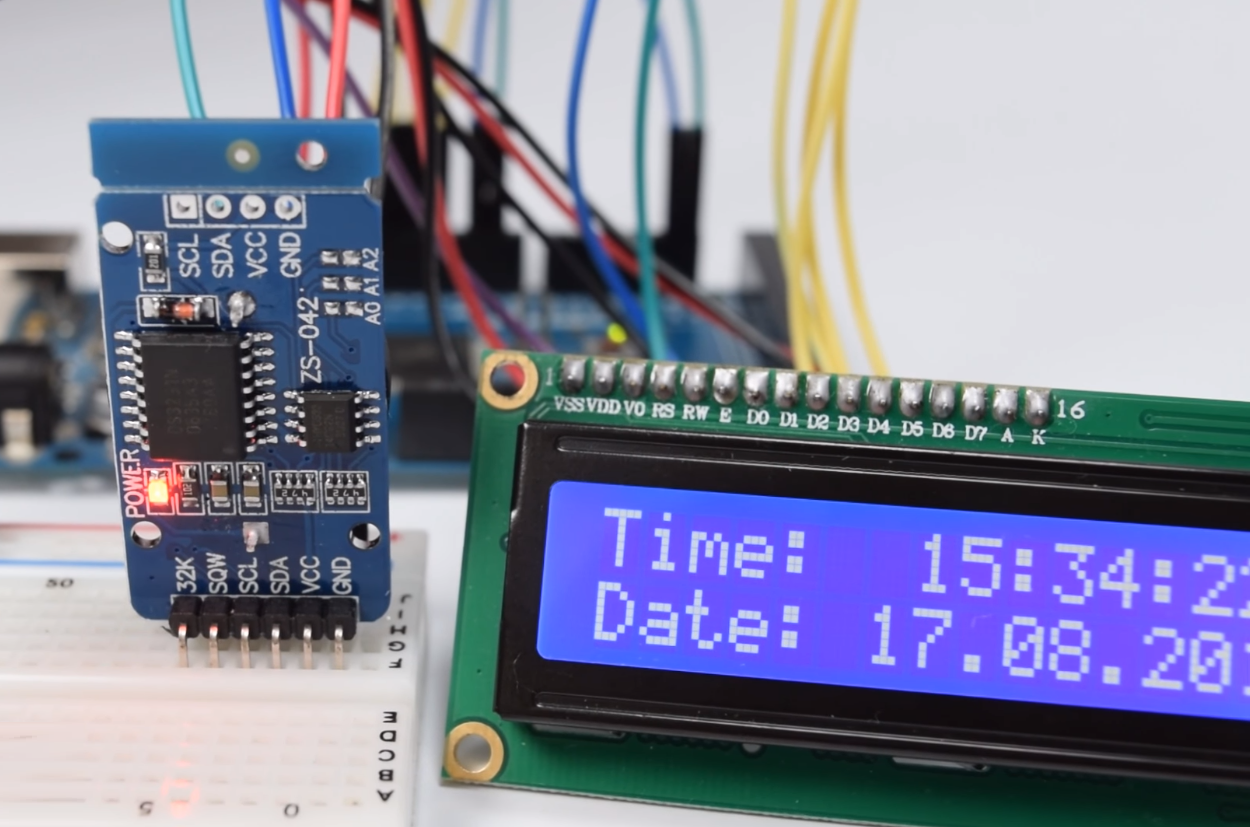

Real time clocks are required in applications where we need to keep track of the current time for example in data logging. In this tutorial I will look at the DS1307 RTC which is one of the common Real Time Clocks, the other one being DS3231 RTC.

Most microcontrollers, including the Arduino, have a built-in timer that can keep track of longer time periods like minutes or days. However, this timer only keeps track of time since the microcontroller was last powered which means that whenever the power is turned off, the timer is set back to zero!

Real time Clocks on the other hand are simply watches that keep track of date and time even when the power supply to the microcontroller is turned off because they have power backups.

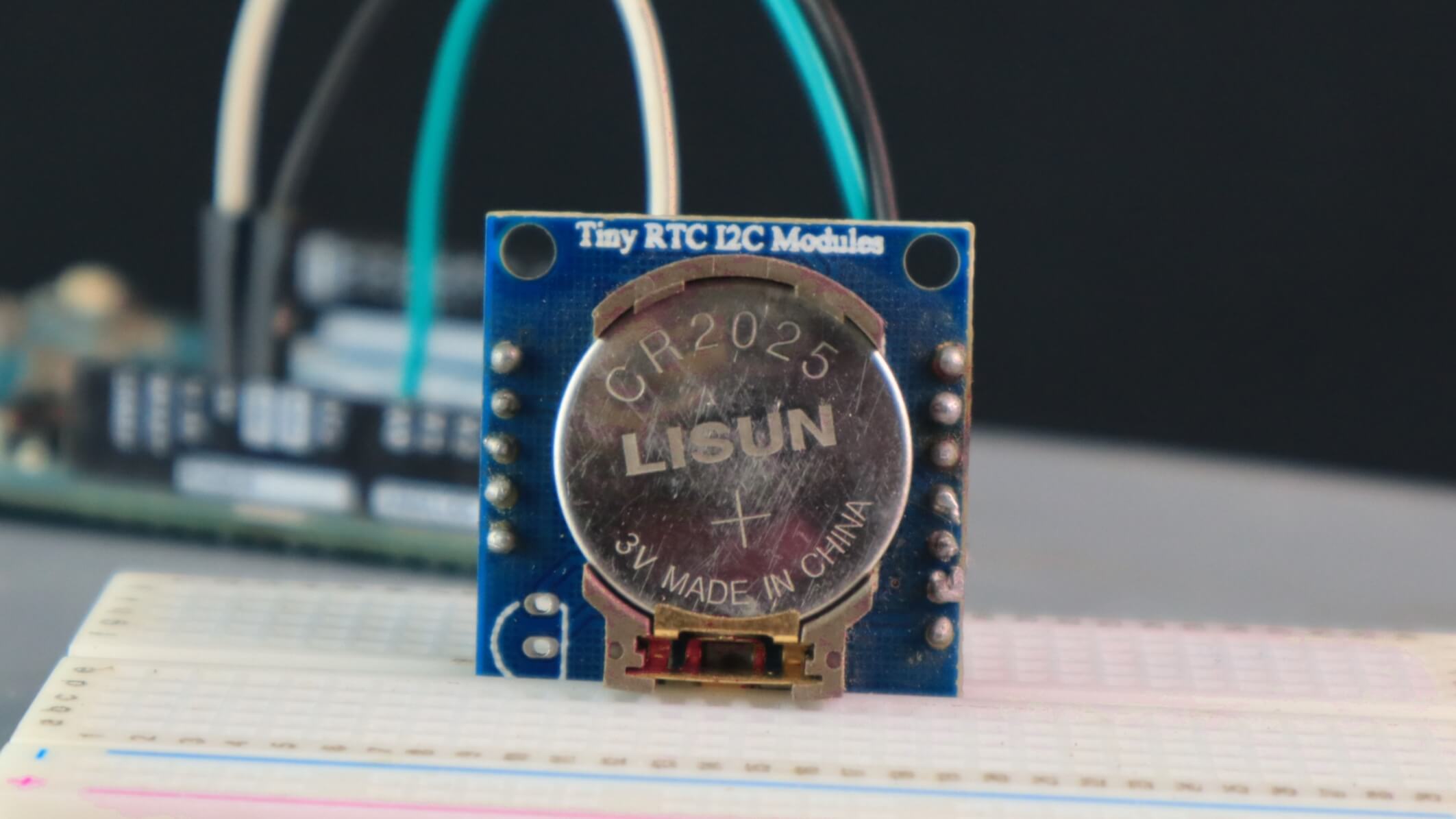

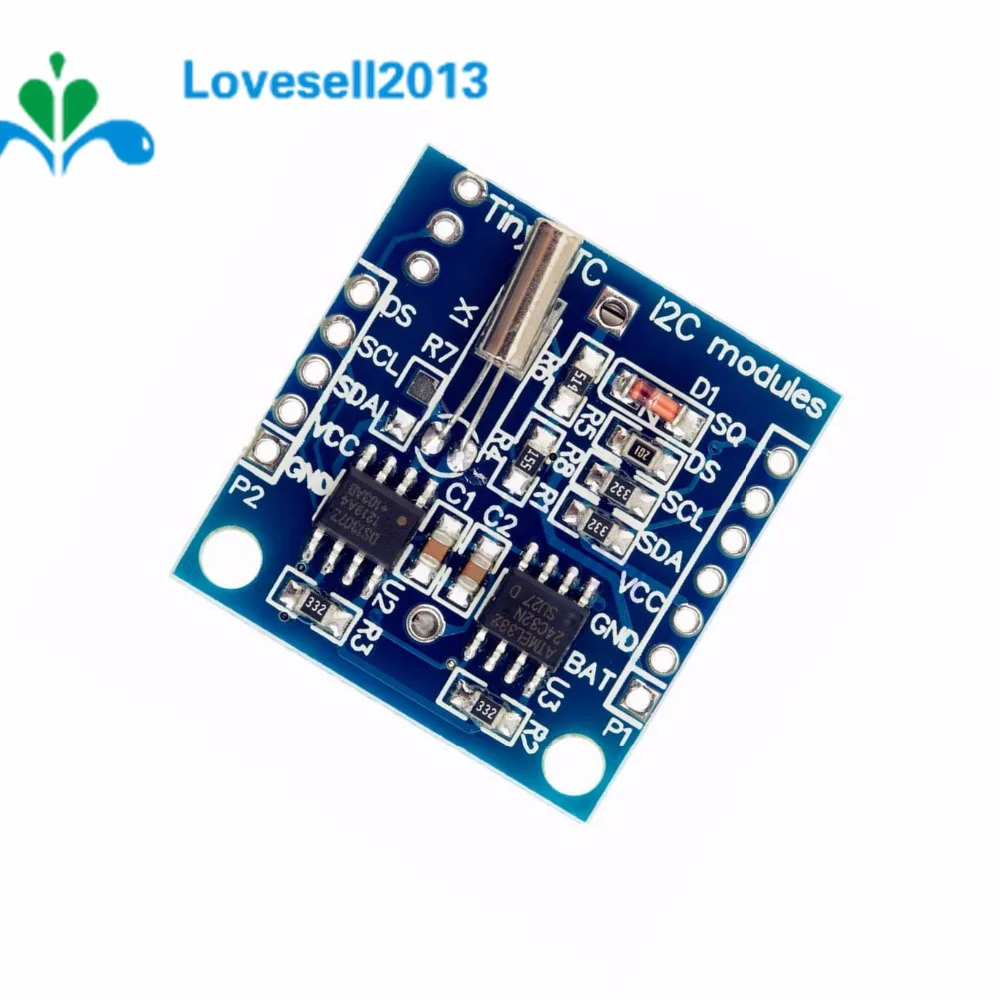

The DS1307 RTC module (Tiny RTC) comes with I/O pins on either side. These pins configuration is similar and you can use whichever side you prefer depending on the application.

DS1307 RTC chip: This is the main IC for the device and keeps track of time in both 12-hour and 24-hour format, date, days of the week, months and years with accuracy of one second. It even does automatic adjustment of number of days in a month and leap years.

This DS1307 RTC module has a CR2032 3V Lithium coin cell battery attached to a built-in power-sense circuit that detects power off at the main power supply and automatically switches to the backup supply in order not to disrupt the time keeping process.

Since the Crystal Oscillator is external. its oscillation frequency is affected by external temperature which in the long run leads to loss of some minutes in the time keeping process. This is a major downside of using the DS1307 RTC as you may need to reset the time after some period to do correction for the lost minutes.

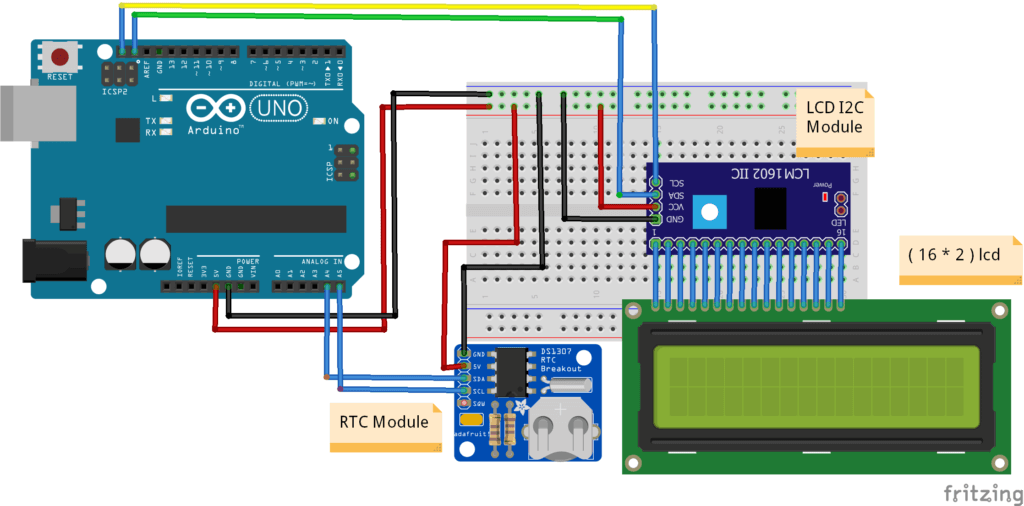

SCL and SDA are connected to the I2C pins of the Arduino in use. Note that I2C communication is supported at specific pins depending on the type of Arduino but in this example am using Arduino UNO therefore the I2C pins are A5 and A4 for SCL and SDA respectively.

There are a number of libraries that have been developed to be able to use the DS1307 RTC with Arduino. I’ll use the RTClib library from Adafruit which can be installed from the Arduino IDE Library Manager.

The Wire.h library is needed for I2C communication and the RTClib.h library contains the classes and methods that enable us to read data from the RTC module.

Then an object rtc is created from the RTC_DS1307 class which is part of the RTClib library. Also a 2D character array for storing the days of the week is defined.

In the setup section, we initialize the RTC module using the begin() method and the isrunning() method is for preparing the DS1307 chip to reset the time.

After setting the desired time these functions should be commented out of the code sketch to avoid repetitive resetting of the time and date whenever you want to upload a new program

TimeSpan() function is used to add or subtract time to or from the current time. For example now() + TimeSpan(seconds) returns the future time with seconds added into current time.

I’ll now demonstrate how to display the time and date from the DS1307 RTC on an I2C LCD. The setup is done as shown below with both the RTC and LCD connected to analog pins A5 and A4 of the Arduino for SCL and SDA respectively.

After learning the basic structure of DS1307 RTC module and how to interface it with Arduino, I’ll now demonstrate how to use this real time clock module for making a digital clock using Arduino and MAX7219 LED Matrix display. Before proceeding you must have prior knowledge on how to interface the MAX7219 LED matrix with Arduino. You can use the link below as reference.

As earlier pointed out that the DS1307 RTC loses some minutes as time goes by, this is the reason why I have included the three push buttons so that we can be able to adjust the time manually. However the best way to keep more accurate time readings is to use the DS3231 RTC module

Most of the libraries used have already been discussed when describing the modules involved apart from the Font_Data.h library which can be downloaded using the link I have provided below. This library should be saved as an h-file and saved in the folder containing other Arduino IDE libraries.

When this code is uploaded to the Arduino board, the current time is displayed. The buttons can be used to adjust the brightness of the led display and to change the time and date. https://youtu.be/uSOpftD8VwU

When this code is uploaded to the Arduino board, the current time is displayed. The buttons can be used to adjust the brightness of the led display and to change the time and date.

The Arduino is an amazing device. It’s useful for prototyping and can also be used to construct a complete project. It has an analog to digital converters (ADC), digital I/O pins, it handles interrupts and it can communicate via a serial port, SPI, and I2C.

A “real time clock” is essentially a digital clock whose output can be read by a computer or microcontroller. It has its own oscillator that it uses to count time and it has registers that allow you to set the current time and date.

The device you are using to read this article likely has a real time clock and if you are attached to the Internet you probably are synchronizing this to a network time server (if your device is a phone it may be time synchronized to your telephone companies carrier signal instead).

Unix time is the number of seconds that have elapsed since midnight January 1, 1970 (which was a Thursday if you’re interested). If you are on Linux (or at the terminal on a Mac, which uses Unix as its underlying operating system) you can type “date +%s” to get the current Unix time.

Unix time is useful when you are writing a program that needs to calculate the time difference between two dates and times, as it involves simple addition and subtraction, without having to worry about days, months and years.

The issue with leap seconds is generally taken care of by synchronizing your real time clock with a local or network time source, which itself will have compensated for leap seconds.

The problem with 2038 is likely to be resolved within the next 19 years, I suspect just shifting to a 64-bit standard would resolve this for several millennia!

One chip is theDS3231, a highly accurate real time clock that uses an I2C interface. This chip has its own internal crystal oscillator, so no external crystal is required.

Another very popular chip is theDS1307. Like the DS3231 it also communicates using the I2C bus, however, this chip requires an external timing crystal.

The board contains the DS1307 chip and all the support electronics, including the timing crystal. It also has a battery holder for a coin cell, this sits underneath the board.

If you order your Tiny RTC online from an overseas source it likely won’t have the battery installed, this is due to international shipping regulations regarding lithium batteries. The module uses a widely available coin cell battery.

As the Tiny RTC uses the I2C bus it is very easy to hook it up to an Arduino. The I2C bus provides power, clock and data signals, so only four connections are required.

Before you hook up your real time clock module it would be a good idea to install the coin cell battery, if you haven’t already. That way you will ensure that the device will keep time even after you power down the Arduino.

Some Arduino clones also have separateSDAandSCLpins, usually located on the same side as the digital I/O pins above theAREFpin. You can use these connections instead of the analog pins if you wish, they are actually just duplicates.

There are several libraries available that will work with the Tiny RTC. I’m going to use two libraries that were contributed by Paul Stoffregen, a well-known figure in the Arduino community.

The Arduino Library Manager can be also used to install two updated versions of these libraries, these were updated by Michael Margolis. You can find them as follows:

Once you have the libraries installed open your Arduino IDE and select theFilemenu item and selectExamples. A sub-menu will appear, scroll down until you get to theExamples from Custom Librariessection.

As you might have guessed from its name theSetTimesketch sets the time on the Tiny RTC module. You’ll need to run this, or something similar, before you can use the clock.

SetTime uses two functions, getTime and getDate, to retrieve the time and date respectively from your computer clock. As most Internet-connected computers synchronize to a network time protocol (NTP) server this will probably be very accurate.

Without using a data structure the time will be reported in Unix time, which I described earlier. ThetmElements_tdata structure breaks this down into elements like seconds, minutes, hours, days, months and years.

Otherwise, the sketch is fairly straightforward. It gets the current system time from the computer running the IDE and writes it to the DS1307 chip on the Tiny RTC module. It does all of this in the Setup section so there is no code in the loop.

We start by including the Wire library, which is the built-in library that facilitates communications using I2C. We then include the two libraries we installed earlier.

Al that is left is to read those time values and print them to the serial monitor. A function calledprint2digitsis used for the hours, minutes and seconds to format the display nicely, with leading zeros for numbers below 10.

The two sketches we have just looked at illustrate how to set and read the time from the Tiny RTC module, and they accomplish this very well. But the module has an additional function, the ability to output a square wave.

You can use this square wave as a timing source for another circuit. It could be used to drive a stepper motor to create an analog clock. And, as I will show you here, it can be used to generate an interrupt for your Arduino.

These frequencies are selected by writing to an internal control register in the DS1307. By default, the device is programmed at the factory for a 32 KHz frequency.

To use the square wave output as an interrupt for your Arduino you will need to connect the SQ output on the Tiny RTC module to one of the interrupt pins on the Arduino.

An LED is also connected to the Arduino to indicate when an interrupt is being serviced. This is actually optional as it is connected to pin 13 and the Uno also has a built-in LED connected to that pin. If you wish you can leave it out and just monitor the LED on your Uno board.

I found a great sketch that shows how to use the square wave output, it was originally published by Robert Ulbricht on theArduino Slovakia website. Fortunately, there is an English translation available.

The functionsetSQWis really where the “action” is. This function writes to the control register in the DS1307 and sets the square wave frequency to 1Hz.

ThehandleIntfunction is the interrupt handler. Every time a pulse is received on the D2 pin it will be called. This is set up in the Setup function using theArduino attachInterrupt function.

The previous sketch illustrated how to use the SQ square wave output from the Tiny RTC module as an interrupt. And while it does a great job of displaying interrupt operation it really doesn’t have many practical uses.

After all, there are many simpler methods of blinking an LED. In fact, if you really wanted to use the Tiny RTC to blink an LED you could just attach it directly to the SQ output, eliminating the Arduino entirely (although you’d need the Arduino to set the SQ output to 1Hz first).

Take another look at theReadTestsketch from the DS1307RTC examples. You’ll notice that it reads the time and then adds two delays that total exactly one second. It then does it all over again.

If you’re just building a clock this will work well, as every second you’ll read the time and it will have advanced one second. But what if you want to do something else in the Loop after you read and display the time?

If the ”something else” takes less than a second then you’ll be displaying the same time more than once. On a display like an LCD or OLED this is not such a bad thing as you might never notice it, but on the serial monitor it will stand out.

If the “something else” takes more than one second you’ll miss reading the clock and it wil skip one or more seconds. You can alleviate this problem somewhat by simply not displaying seconds but still, your minutes may not change at precisely the right time.

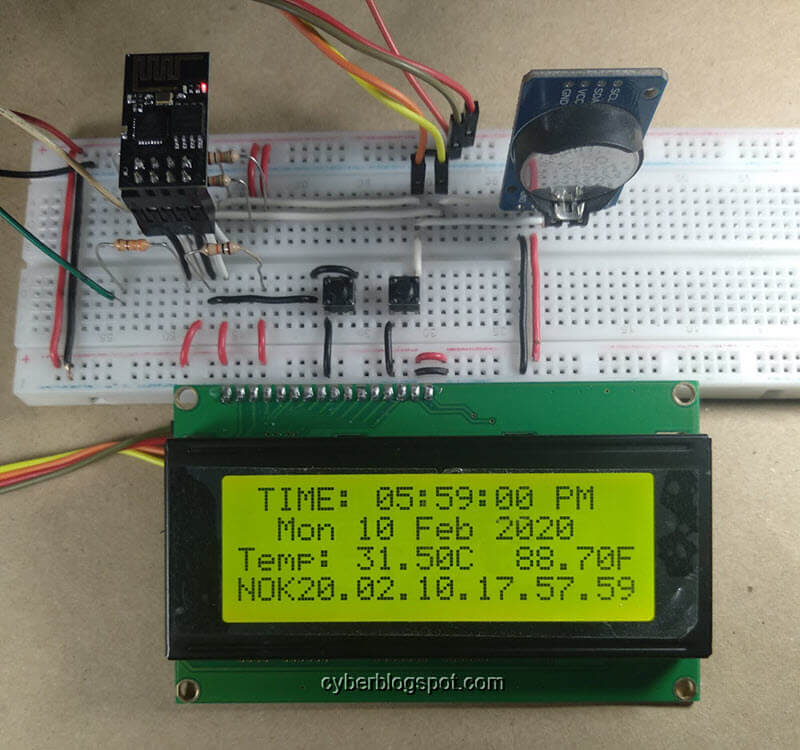

To illustrate how to take advantage of interrupts to solve the timing problem I’m going to build a temperature and humidity meter that can also tell time. I’m going to stick to the serial monitor for my display, but you could easily modify the code to use an OLED or LCD display.

The AM2320 is an I2C temperature and humidity sensor. Physically it looks identical to a DHT11 or DHT22, the difference is that it uses the I2C bus to send data to its host.

If you wish you could modify the sketch to use the DHT22 or DHT11, I used the AM2320 because I was already using I2C for the real time clock and because I had one handy!

No matter which sensor you choose for your design you’ll encounter the same dilemma – these temperature and humidity sensors require at least two seconds between readings to stabilize. And so if you read it in the Loop you’ll get an erratic display.

You’ll need another couple of libraries to run this sketch to handle the temperature and humidity sensor. Both can be installed using the Library Manager.

The latter library is not called directly in the sketch, instead, it is used by the AM2320 Library. Without it installed your sketch will fail to compile.

Next, we create a couple of variables that count “ticks”. I’m defining a “tick” as a one second period. Theold_tick_valuevariable will be used to check if the tick value has changed since we last used it.

In the Setup routine we attach the interrupt to the interrupt handler, as we did earlier. I kept the same name for the interrupt handler but have changed its function.

Next we initialize the temperature and humidity sensor, delay for two seconds and then read the temperature and humidity values. This is so we already have a first reading before we enter the loop.

TheprintCurrentTimefunction prints the time, date, temperature and humidity to the serial monitor. It takes the temperature and humidity as an input and reads the real time clock, it then writes everything to the serial monitor.

In the Loop we first check the number of ticks by reading the tick count. If it is 10 then we read the humidity and temperature, then reset the tick counter to zero.

By doing this we only read the temperature and humidity sensor every 10 seconds, which gives it plenty of time to stabilize. You can reduce this number if you wish, but don’t go below two seconds.

We then check to see if the tick count is the same as it was before. If it is then we don’t do anything. If it isn’t then it means a second has elapsed, so we callprintCurrentTimeto read the time and write everything to the serial monitor.

Load the sketch and give it a test. Note that since the temperature and humidity are only updated every 10 seconds it won’t immediately respond to a change in these values. In normal situations this shouldn’t really be an issue.

Adding a real time clock to an Arduino makes it possible to build devices that are aware of the current time and date. This can allow you to create fancy timers and delay circuits, or just build a really cool and unique digital clock.

A Real Time Clock can be added to your Arduino project in order to tell the time. Today I will show you how to use the Tiny RTC, a real time clock based upon the popular DS1307 chip.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

After several months "Out of Stock", DS1307 RTC module has a big upgrade. It comes with a Gravity IIC interface, and the size is also reduced to fit miniaturization application. Gravity I2C DS1307 RTC module is a easy-to-use Real Time Clock module. It is cheap and affordable in most applications such as time clock, data logger, etc.. The new version DS1307 RTC module adopts high precision crystal oscillator which reduces time error dramatically. The test conducted shows the time error is only about 1 second in 24 hours (the average time error of Mechanical Watches is about 20s). The module is powered by single cell CR1220 (service life: 3~5 years). It is smaller and keeps EEPROM 4KB ROM to record information related to alarm clocks and events. Besides, you can set the IIC address by resistance adjustment. The Gravity DS1307 RTC module uses Gravity I2C interface and you can plug it on the DFRobot Gravity IO expansion shield directly. Cooperate with Arduino DS1307 library developed by DFRobot, it is easy to realize functions like setting time and time display. It can be widely used in DA (Data Acquisition).

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A digital clock is a great invention in electronics science. Nowadays, digital clocks are used everywhere. The analog clocks are quite old-fashioned. So the digital clock takes its place day by day. The Arduino digital clock is looking very modern. It has many additional features also like temperature, alarm, timer, etc.

In this electronics project, we are going to build an Arduino digital clock with or without an RTC (Real Time Clock) module. The first circuit represents without RTC module and the second circuit represents with RTC module. The components we used in this project are quite basic and a little expensive. The circuit connection is very easy.

We build this digital clock with an Arduino, RTC module, and LCD display in this project. Here the clock we made is 24 hours clock. This means the time shows by the clock is 00.00 AM to 23.59. After 23.59 it resets to 0 again.

Arduino is one of the most popular electronics prototyping boards based on the ATmega328P microcontroller. ATmega328P is an AVR architecture based 8-bit microcontroller. Here I am using Arduino Nano for this project to give it a compact look.

A 16×2 LCD display is the most commonly used display unit for microcontroller-based applications. It supports 16 characters in a row with two such rows. It also supports special characters and even custom characters.

I2C Module has an inbuilt PCF8574 I2C chip that converts I2C serial data to parallel data for the 16 pins LCD display. It is currently available with a default I2C address of either 0x27 or 0x3F. With this I2C LCD module, we can able to show data via only 2 wires that are SDA and SCL pins.

The DS1307 real-time clock (RTC) is a low power, full binary-coded decimal (BCD) clock plus 56 bytes of NV SRAM. Address and data are transferred serially through an I2C bus. This clock provides seconds, minutes, hours, days, dates, months, and years.

A serial I2C bidirectional bus made a communication between the Arduino and the DS1307 RTC module. The I2C protocol is a technique for communicating a faster device (master mode) and a slower device (slave mode).

To make the circuit compact and give a professional look, I have designed the PCB after testing all the features of the Arduino Digital Clock Circuit PCB on the breadboard. I will explain in detail how we can design and order PCB for our project.

This project is sponsored by PCBWay.com. PCBWay is a Chinese-based PCB (printed circuit board) prototype, PCB assembly, SMD Stencil, and Flexible PCB manufacturer. They ship to more than 170 countries worldwide and process more than 2100 PCB orders a day. It feels like PCBWay gives an excellent price and customer service factor in one single serving. The quality of the PCB is awesome and its thickness is really great. What is also spectacular about PCBWay to me, as a maker and customer, is their service. From their friendly support staff to their intuitive, user-friendly website features, it all counts towards what makes PCBWay an ideal company and brand for any electronic hobbyists In this article, I will state that how can we order PCB from PCBWay with step by step guide.

They are not only producing FR-4 and Aluminum boards, but also advanced PCB like Rogers, HDI, Flexible and Rigid-Flex boards, at a very reasonable price.

SMT & THT assembly starts from only $30 with a free stencil and free worldwide shipping. The components can be sourced and provided by PCBWay, or by clients themselves.

With a real-time clock module, this circuit is working in automatic mode. Although we can manually set the time as our requirements through Arduino code. As we say that this is an automatic clock so the system can set time and date itself like a computer.

First of all, connect all two push buttons’ any one terminal to the ground. Then other terminals of the two buttons are connected to analog pins D8 and D9 of the Arduino respectively.

To make the circuit compact and give a professional look, I have designed the PCB after testing all the features of the Arduino Digital Clock on the breadboard. I will explain in detail how we can design and order PCB for our project.

The first button is for setting up the hour by sending a signal to the D8 pin. The second button is for setting up the minutes by sending a signal to the D9 pin of the Arduino.

The whole circuit is working as a continuous sequence. When the power goes out, the circuit will reset to its initial position. Then we need to again set the time via the push button. So this is a major drawback for this circuit.

For this project, it needs to set the real-time into Arduino code when uploading. But after that, we need not set the time every time when better die. Just remove the old battery and put the new one that’s it.

Yes, there is a few Arduino real-time clock (RTC) libraries in the library manager of the Arduino IDE software. These help to compile Arduino code and upload it into the Arduino board.

To make this clock is too easy. But the only drawback of this clock is when the power cut down, we need to set the time again from the beginning. To build this clock go to this blog and check out the second circuit.

The main purpose of using an RTC or a real-time clock is to provide a precise time and date which is very accurate. RTC is an electronic device in the form of an Integrated Chip (IC) available in various packaging options. It is powered by an internal lithium-ion battery.

An RTC maintains its clock by counting the cycles of an oscillator (32.768KHz Crystal Oscillator) circuit, an internal capacitor-based oscillator, or even an embedded quartz crystal. Some RTCs maintain the oscillator setting at the last known point before it went out of the lock with the power input.

With compact design, the board can integrate the real-time clock module DS1307, EEPROM memory AT24C32 and digital temperature sensor DS18B20 (not supplied on the board) which are connected via I2C bus together on a 27mm*28mm*8.4mm board.

DS1307 is a low-power real-time clock chip with 56 bytes of non-volatile RAM, full BCD code clock and calendar. The address and data will be transmitted via a two-wire bidirectional

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey