arduino with a ds1307 rtc and lcd display made in china

you can use the basic structure of this project. We have already made various Arduino projects, Embedded projects, and Arduino tutorials on our website. You can visit them if you are new to the world of electronics and Arduino.

to display the time. You can make an Automatic pet Feeder, Automatic Light, time-based plant watering system, and much more using this. This reduces the manual stress on us.

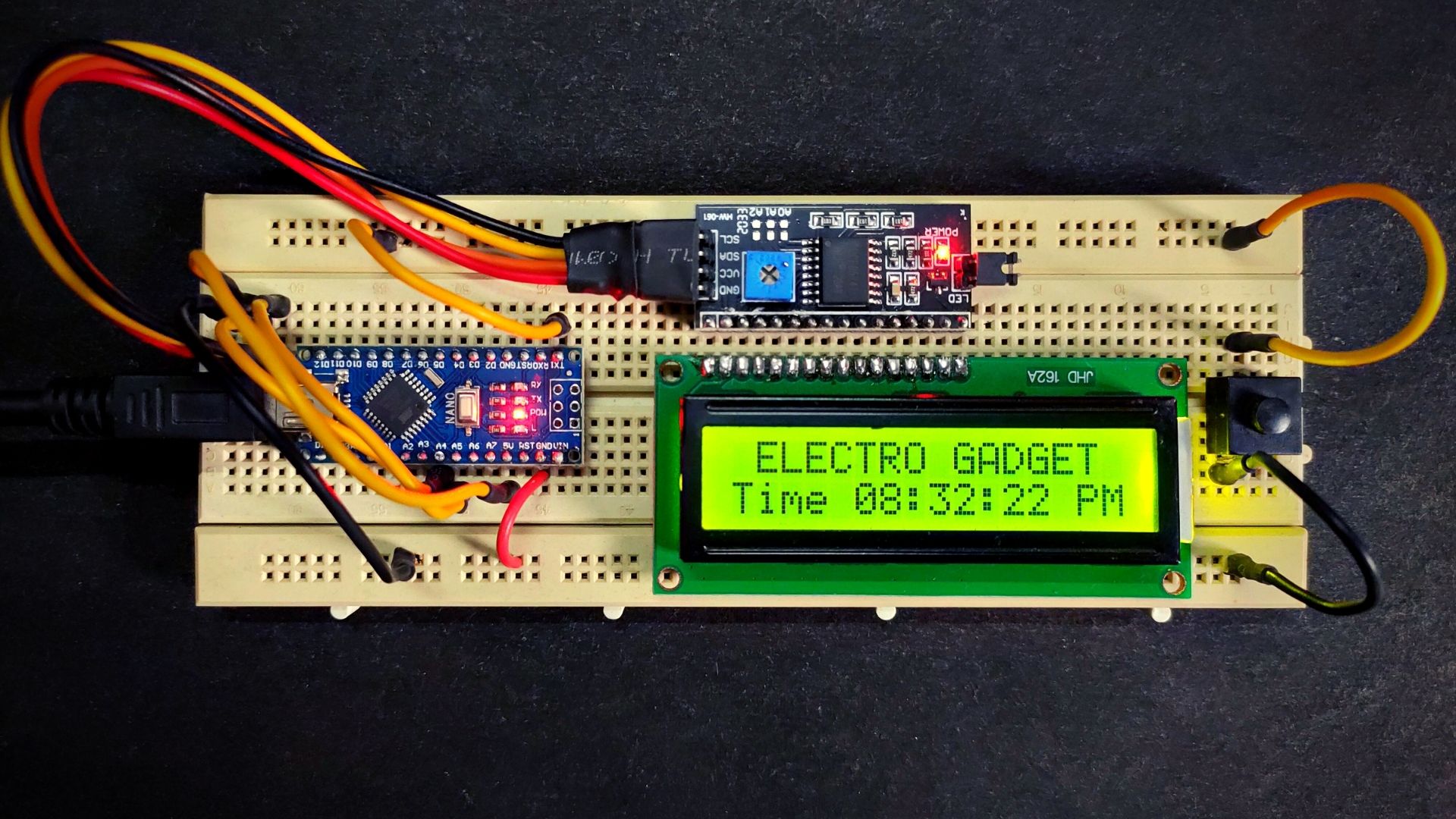

the module is capable of counting seconds, minutes, hours, days, weeks, months, and years. Arduino uses the I2C communication protocol to send data to the LCD display,

which we are using here to display the time. The display updates every second to tell the most accurate time since the module is much accurate to tell the time.

The module is capable of running for more than 5 years continuously without affecting the count in time. this is possible because of the in-built cell.

the most professional PCB manufacturer for prototyping and low-volume production to work with in the world. With more than a decade in the field, PCBWAY committed to meeting the needs of customers from different industries in terms of quality, delivery, cost-effectiveness, and any other demanding requests. As one of the most experienced PCB manufacturers and SMT Assemblers in China, we pride ourselves to be your best business partners as well as good friends in every aspect of your PCB needs. They strive to make your R&D work easy and hassle-free.

NOTE- You need to install the three libraries LiquidCrystal_I2C.h, Wire.h, and DS1307.hwhich can be downloaded from HERE into your Arduino IDE before uploading the code.

Once the uploading of code is complete, LCD Display will be able to show the Time as per the code uploaded. I hope you found this guide helpful in making the project. If you have any doubts, you can put them in the comment section below.

Along 3 years I have been trying several leg mechanism, at first I decided to do a simple desing with tibial motor where placed on femur joint.This design had several problems, like it wasn"t very robust and the most importat is that having the motor (with big mass) that far from the rotating axis, caused that in some movements it generate unwanted dynamics to the robot body, making controlability worse.New version have both motors of femur/tibial limb at coxa frame, this ends with a very simple setup and at the same time, the heaviest masses of the mechanism are centered to the rotating axis of coxa limb, so even though the leg do fast movements, inertias won"t be strong enough to affect the hole robot mass, achieving more agility.Inverse Kinematics of the mechanismAfter building it I notice that this mechanism was very special for another reason, at the domain the leg normally moves, it acts as a diferential mecanism, this means that torque is almost all the time shared between both motor of the longer limbs. That was an improvent since with the old mechanism tibial motor had to hold most of the weight and it was more forced than the one for femur.To visualize this, for the same movement, we can see how tibial motor must travel more arc of angel that the one on the new version.In order to solve this mechanism, just some trigonometry is needed. Combining both cosine and sine laws, we can obtain desired angle (the one between femur and tibia) with respect to the angle the motor must achieve.Observing these equations, with can notice that this angle (the one between femur and tibia) depends on both servos angles, which means both motors are contributing to the movement of the tibia.Calibration of servosAnother useful thing to do if we want to control servo precisely is to print a calibration tool for our set up. As shown in the image below, in order to know where real angles are located, angle protactor is placer just in the origin of the rotating joint, and choosing 2 know angles we can match PWM signal to the real angles we want to manipulate simply doing a lineal relation between angles and PWM pulse length.Then a simple program in the serial console can be wrtten to let the user move the motor to the desired angle. This way the calibration process is only about placing motor at certain position and everything is done and we won"t need to manually introduce random values that can be a very tedious task.With this I have achieved very good calibrations on motors, which cause the robot to be very simetrial making the hole system more predictable. Also the calibration procedure now is very easy to do, as all calculations are done automatically. Check Section 1 for the example code for calibration.More about this can be seen in the video below, where all the building process is shown as well as the new leg in action.SECTION 1:In the example code below, you can see how calibration protocol works, it is just a function called calibrationSecuence() which do all the work until calibration is finished. So you only need to call it one time to enter calibration loop, for example by sending a "c" character thought the serial console.Also some useful function are used, like moving motor directly with analogWrite functions which all the calculations involved, this is a good point since no interrupts are used.This code also have the feature to calibrate the potentiometer coming from each motor.#define MAX_PULSE 2500 #define MIN_PULSE 560 /*---------------SERVO PIN DEFINITION------------------------*/ int m1 = 6;//FR int m2 = 5; int m3 = 4; int m4 = 28;//FL int m5 = 29; int m6 = 36; int m7 = 3;//BR int m8 = 2; int m9 = 1; int m10 = 7;//BL int m11 = 24; int m12 = 25; int m13 = 0;//BODY /*----------------- CALIBRATION PARAMETERS OF EACH SERVO -----------------*/ double lowLim[13] = {50, 30, 30, 50, 30, 30, 50, 30, 30, 50, 30, 30, 70}; double highLim[13] = {130, 150, 150, 130, 150, 150, 130, 150, 150, 130, 150, 150, 110}; double a[13] = { -1.08333, -1.06667, -1.07778, //FR -1.03333, 0.97778, 1.01111, //FL 1.03333, 1.05556, 1.07778, //BR 1.07500, -1.07778, -1.00000, //BL 1.06250 }; double b[13] = {179.0, 192.0, 194.5, //FR 193.0, 5.5, -7.5, //FL 7.0, -17.0, -16.0, //BR -13.5, 191.5, 157.0, //BL -0.875 }; double ae[13] = {0.20292, 0.20317, 0.19904 , 0.21256, -0.22492, -0.21321, -0.21047, -0.20355, -0.20095, -0.20265, 0.19904, 0.20337, -0.20226 }; double be[13] = { -18.59717, -5.70512, -2.51697, -5.75856, 197.29411, 202.72169, 185.96931, 204.11902, 199.38663, 197.89534, -5.33768, -32.23424, 187.48058 }; /*--------Corresponding angles you want to meassure at in your system-----------*/ double x1[13] = {120, 135, 90, 60, 135 , 90, 120, 135, 90, 60, 135, 90, 110}; //this will be the first angle you will meassure double x2[13] = {60, 90, 135, 120, 90, 135, 60, 90, 135, 120, 90, 135, 70};//this will be the second angle you will meassure for calibration /*--------You can define a motor tag for each servo--------*/ String motorTag[13] = {"FR coxa", "FR femur", "FR tibia", "FL coxa", "FL femur", "FL tibia", "BR coxa", "BR femur", "BR tibia", "BL coxa", "BL femur", "BL tibia", "Body angle" }; double ang1[13] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; double ang2[13] = {0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0}; float xi[500]; float yi[500]; float fineAngle; float fineL; float fineH; int motorPin; int motor = 0; float calibrationAngle; float res = 1.0; float ares = 0.5; float bres = 1.0; float cres = 4.0; float rawAngle; float orawAngle; char cm; char answer; bool interp = false; bool question = true; bool swing = false; int i; double eang; int freq = 100; // PWM frecuency can be choosen here. void connectServos() { analogWriteFrequency(m1, freq); //FR coxa digitalWrite(m1, LOW); pinMode(m1, OUTPUT); analogWriteFrequency(m2, freq); //femur digitalWrite(m2, LOW); pinMode(m2, OUTPUT); analogWriteFrequency(m3, freq); //tibia digitalWrite(m3, LOW); pinMode(m3, OUTPUT); analogWriteFrequency(m4, freq); //FL coxa digitalWrite(m4, LOW); pinMode(m4, OUTPUT); analogWriteFrequency(m5, freq); //femur digitalWrite(m5, LOW); pinMode(m5, OUTPUT); analogWriteFrequency(m6, freq); //tibia digitalWrite(m6, LOW); pinMode(m6, OUTPUT); analogWriteFrequency(m7, freq); //FR coxa digitalWrite(m7, LOW); pinMode(m7, OUTPUT); analogWriteFrequency(m8, freq); //femur digitalWrite(m8, LOW); pinMode(m8, OUTPUT); analogWriteFrequency(m9, freq); //tibia digitalWrite(m9, LOW); pinMode(m9, OUTPUT); analogWriteFrequency(m10, freq); //FR coxa digitalWrite(m10, LOW); pinMode(m10, OUTPUT); analogWriteFrequency(m11, freq); //femur digitalWrite(m11, LOW); pinMode(m11, OUTPUT); analogWriteFrequency(m12, freq); //tibia digitalWrite(m12, LOW); pinMode(m12, OUTPUT); analogWriteFrequency(m13, freq); //body digitalWrite(m13, LOW); pinMode(m13, OUTPUT); } void servoWrite(int pin , double angle) { float T = 1000000.0f / freq; float usec = float(MAX_PULSE - MIN_PULSE) * (angle / 180.0) + (float)MIN_PULSE; uint32_t duty = int(usec / T * 4096.0f); analogWrite(pin , duty); } double checkLimits(double angle , double lowLim , double highLim) { if ( angle >= highLim ) { angle = highLim; } if ( angle <= lowLim ) { angle = lowLim; } return angle; } int motorInfo(int i) { enc1 , enc2 , enc3 , enc4 , enc5 , enc6 , enc7 , enc8 , enc9 , enc10 , enc11 , enc12 , enc13 = readEncoders(); if (i == 0) { rawAngle = enc1; motorPin = m1; } else if (i == 1) { rawAngle = enc2; motorPin = m2; } else if (i == 2) { rawAngle = enc3; motorPin = m3; } else if (i == 3) { rawAngle = enc4; motorPin = m4; } else if (i == 4) { rawAngle = enc5; motorPin = m5; } else if (i == 5) { rawAngle = enc6; motorPin = m6; } else if (i == 6) { rawAngle = enc7; motorPin = m7; } else if (i == 7) { rawAngle = enc8; motorPin = m8; } else if (i == 8) { rawAngle = enc9; motorPin = m9; } else if (i == 9) { rawAngle = enc10; motorPin = m10; } else if (i == 10) { rawAngle = enc11; motorPin = m11; } else if (i == 11) { rawAngle = enc12; motorPin = m12; } else if (i == 12) { rawAngle = enc13; motorPin = m13; } return rawAngle , motorPin; } void moveServos(double angleBody , struct vector anglesServoFR , struct vector anglesServoFL , struct vector anglesServoBR , struct vector anglesServoBL) { //FR anglesServoFR.tetta = checkLimits(anglesServoFR.tetta , lowLim[0] , highLim[0]); fineAngle = a[0] * anglesServoFR.tetta + b[0]; servoWrite(m1 , fineAngle); anglesServoFR.alpha = checkLimits(anglesServoFR.alpha , lowLim[1] , highLim[1]); fineAngle = a[1] * anglesServoFR.alpha + b[1]; servoWrite(m2 , fineAngle); anglesServoFR.gamma = checkLimits(anglesServoFR.gamma , lowLim[2] , highLim[2]); fineAngle = a[2] * anglesServoFR.gamma + b[2]; servoWrite(m3 , fineAngle); //FL anglesServoFL.tetta = checkLimits(anglesServoFL.tetta , lowLim[3] , highLim[3]); fineAngle = a[3] * anglesServoFL.tetta + b[3]; servoWrite(m4 , fineAngle); anglesServoFL.alpha = checkLimits(anglesServoFL.alpha , lowLim[4] , highLim[4]); fineAngle = a[4] * anglesServoFL.alpha + b[4]; servoWrite(m5 , fineAngle); anglesServoFL.gamma = checkLimits(anglesServoFL.gamma , lowLim[5] , highLim[5]); fineAngle = a[5] * anglesServoFL.gamma + b[5]; servoWrite(m6 , fineAngle); //BR anglesServoBR.tetta = checkLimits(anglesServoBR.tetta , lowLim[6] , highLim[6]); fineAngle = a[6] * anglesServoBR.tetta + b[6]; servoWrite(m7 , fineAngle); anglesServoBR.alpha = checkLimits(anglesServoBR.alpha , lowLim[7] , highLim[7]); fineAngle = a[7] * anglesServoBR.alpha + b[7]; servoWrite(m8 , fineAngle); anglesServoBR.gamma = checkLimits(anglesServoBR.gamma , lowLim[8] , highLim[8]); fineAngle = a[8] * anglesServoBR.gamma + b[8]; servoWrite(m9 , fineAngle); //BL anglesServoBL.tetta = checkLimits(anglesServoBL.tetta , lowLim[9] , highLim[9]); fineAngle = a[9] * anglesServoBL.tetta + b[9]; servoWrite(m10 , fineAngle); anglesServoBL.alpha = checkLimits(anglesServoBL.alpha , lowLim[10] , highLim[10]); fineAngle = a[10] * anglesServoBL.alpha + b[10]; servoWrite(m11 , fineAngle); anglesServoBL.gamma = checkLimits(anglesServoBL.gamma , lowLim[11] , highLim[11]); fineAngle = a[11] * anglesServoBL.gamma + b[11]; servoWrite(m12 , fineAngle); //BODY angleBody = checkLimits(angleBody , lowLim[12] , highLim[12]); fineAngle = a[12] * angleBody + b[12]; servoWrite(m13 , fineAngle); } double readEncoderAngles() { enc1 , enc2 , enc3 , enc4 , enc5 , enc6 , enc7 , enc8 , enc9 , enc10 , enc11 , enc12 , enc13 = readEncoders(); eang1 = ae[0] * enc1 + be[0]; eang2 = ae[1] * enc2 + be[1]; eang3 = ae[2] * enc3 + be[2]; eang4 = ae[3] * enc4 + be[3]; eang5 = ae[4] * enc5 + be[4]; eang6 = ae[5] * enc6 + be[5]; eang7 = ae[6] * enc7 + be[6]; eang8 = ae[7] * enc8 + be[7]; eang9 = ae[8] * enc9 + be[8]; eang10 = ae[9] * enc10 + be[9]; eang11 = ae[10] * enc11 + be[10]; eang12 = ae[11] * enc12 + be[11]; eang13 = ae[12] * enc13 + be[12]; return eang1 , eang2 , eang3 , eang4 , eang5 , eang6 , eang7 , eang8 , eang9 , eang10 , eang11 , eang12 , eang13; } void calibrationSecuence( ) { //set servos at their middle position at firstt for (int i = 0; i <= 12; i++) { rawAngle , motorPin = motorInfo(i); servoWrite(motorPin , 90); } // sensorOffset0 = calibrateContacts(); Serial.println(" "); Serial.println("_________________________________SERVO CALIBRATION ROUTINE_________________________________"); Serial.println("___________________________________________________________________________________________"); Serial.println("(*) Don"t send several caracter at the same time."); delay(500); Serial.println(" "); Serial.println("Keyboard: "x"-> EXIT CALIBRATION. "c"-> ENTER CALIBRATION."); Serial.println(" "i"-> PRINT INFORMATION. "); Serial.println(" "); Serial.println(" "n"-> CHANGE MOTOR (+). "b" -> CHANGE MOTOR (-)."); Serial.println(" "m"-> START CALIBRATION."); Serial.println(" "q"-> STOP CALIBRATION."); Serial.println(" "); Serial.println(" "r"-> CHANGE RESOLUTION."); Serial.println(" "p"-> ADD ANGLE. "o"-> SUBTRACT ANGLE. "); Serial.println(" "s"-> SAVE ANGLE."); delay(500); Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); while (CAL == true) { if (Serial.available() > 0) { cm = Serial.read(); if (cm == "x") { Serial.println("Closing CALIBRATION program..."); CAL = false; secuence = false; startDisplay(PAGE); angleBody = 90; anglesIKFR.tetta = 0.0; anglesIKFR.alpha = -45.0; anglesIKFR.gamma = 90.0; anglesIKFL.tetta = 0.0; anglesIKFL.alpha = -45.0; anglesIKFL.gamma = 90.0; anglesIKBR.tetta = 0.0; anglesIKBR.alpha = 45.0; anglesIKBR.gamma = -90.0; anglesIKBL.tetta = 0.0; anglesIKBL.alpha = 45.0; anglesIKBL.gamma = -90.0; } else if (cm == "i") { // + Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println("(*) Don"t send several caracter at the same time."); delay(500); Serial.println(" "); Serial.println("Keyboard: "x"-> EXIT CALIBRATION. "c"-> ENTER CALIBRATION."); Serial.println(" "i"-> PRINT INFORMATION. "); Serial.println(" "); Serial.println(" "n"-> CHANGE MOTOR (+). "b" -> CHANGE MOTOR (-)."); Serial.println(" "m"-> START CALIBRATION."); Serial.println(" "q"-> STOP CALIBRATION."); Serial.println(" "); Serial.println(" "r"-> CHANGE RESOLUTION."); Serial.println(" "p"-> ADD ANGLE. "o"-> SUBTRACT ANGLE. "s"-> SAVE ANGLE."); Serial.println(" "); delay(500); Serial.println(" "); Serial.println("---------------------------------------------------------------------------------------------------"); Serial.println(" "); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); Serial.println("Actual parameters of the motor: "); Serial.print("High limit: "); Serial.print(highLim[motor]); Serial.print(" Low limit: "); Serial.print(lowLim[motor]); Serial.print(" Angle 1: "); Serial.print(ang1[motor]); Serial.print(" Angle 2: "); Serial.println(ang2[motor]); Serial.println("---------------------------------------------------------------------------------------------------"); } else if (cm == "m") { // + secuence = true; } else if (cm == "s") { // + } else if (cm == "n") { // + motor++; if (motor >= 13) { motor = 0; } Serial.print("SELECTED MOTOR: "); Serial.println(motorTag[motor]); } else if (cm == "b") { // + motor--; if (motor < 0) { motor = 13 - 1; } Serial.print("SELECTED MOTOR: "); Serial.println(motorTag[motor]); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } } if (secuence == true) { Serial.print("Starting secuence for motor: "); Serial.println(motorTag[motor]); for (int i = 0; i <= 30; i++) { delay(20); Serial.print("."); } Serial.println("."); while (question == true) { unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 100000) { previousMicros = currentMicros; if (Serial.available() > 0) { answer = Serial.read(); if (answer == "y") { question = false; interp = true; secuence = true; } else if (answer == "n") { question = false; interp = false; secuence = true; } else { Serial.println("Please, select Yes(y) or No(n)."); } } } } answer = "t"; question = true; if (interp == false) { Serial.println("___"); Serial.println(" | Place motor at 1ts position and save angle"); Serial.println(" | This position can be the higher one"); rawAngle , motorPin = motorInfo(motor); calibrationAngle = 90; //start calibration at aproximate middle position of the servo. while (secuence == true) { /* find first calibration angle */ if (Serial.available() > 0) { cm = Serial.read(); if (cm == "p") { // + Serial.print(" | +"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle + res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "o") { // - Serial.print(" | -"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle - res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } else if (cm == "q") { // quit secuence secuence = false; Serial.println(" | Calibration interrupted!!"); } else if (cm == "s") { // save angle ang1[motor] = calibrationAngle; secuence = false; Serial.print(" | Angle saved at "); Serial.println(calibrationAngle); } } } if (cm == "q") { Serial.println(" |"); } else { secuence = true; Serial.println("___"); Serial.println(" | Place motor at 2nd position and save angle"); Serial.println(" | This position can be the lower one"); } while (secuence == true) { /* find second calibration angle */ if (Serial.available() > 0) { cm = Serial.read(); if (cm == "p") { // + Serial.print(" | +"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle + res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "o") { // - Serial.print(" | -"); Serial.print(res); Serial.print(" : "); calibrationAngle = calibrationAngle - res; servoWrite(motorPin , calibrationAngle); Serial.println(calibrationAngle); } else if (cm == "r") { // + if (res == ares) { res = bres; } else if (res == bres) { res = cres; } else if (res == cres) { res = ares; } Serial.print("SELECTED RESOLUTION: "); Serial.println(res); } else if (cm == "q") { // quit secuence secuence = false; Serial.println(" | Calibration interrupted!!"); } else if (cm == "s") { // save angle ang2[motor] = calibrationAngle; secuence = false; Serial.print(" | Angle saved at "); Serial.println(calibrationAngle); } } } /*--------------------start calibration calculations------------------*/ if (cm == "q") { Serial.println("___|"); Serial.println("Calibration finished unespected."); Serial.println(" Select another motor."); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); } else { Serial.println("___"); Serial.println(" |___"); Serial.print( " | | Interpolating for motor: "); Serial.println(motorTag[motor]); secuence = true; //real angle is calculated interpolating both angles to a linear relation. a[motor] = (ang2[motor] - ang1[motor]) / (x2[motor] - x1[motor]); b[motor] = ang1[motor] - x1[motor] * (ang2[motor] - ang1[motor]) / (x2[motor] - x1[motor]); Serial.println(" | |"); } interp = true; } /*---------------------------make swing movement to interpolate motor encoder-----*/ if (interp == true and secuence == true) { delay(200); double x; int k = 0; int stp = 180; swing = true; i = 0; orawAngle , motorPin = motorInfo(motor); previousMicros = 0; while (swing == true) { // FIRST unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor] + float(i) * (x1[motor] - x2[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // SECOND unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor] + float(i) * (x2[motor] - x1[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // FIRST unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // moving unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x2[motor] + float(i) * (x1[motor] - x2[motor]) / stp; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 6) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } swing = true; i = 0; while (swing == true) { // SECOND unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor]; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); if ((i % 3) == 0) { yi[k+1] = x; xi[k] = rawAngle; Serial.print(" | | Real ang: "); Serial.print(x); Serial.print(" -> Servo ang: "); Serial.print(calibrationAngle); Serial.print(" Enc: "); Serial.println(rawAngle); k++; } if (i >= stp) { swing = false; } i++; } } Serial.println(" | | Interpolation finished!"); /*-------Calculate linear interpolation of the encoder from 60 meassures done in swing------*/ double sx = 0; double sy = 0; double sx2 = 0; double sy2 = 0; double sxy = 0; double xmean = 0; double ymean = 0; int n = 300; for (int i = 0 ; i < n ; i++) { sx += xi[i+10]; sy += yi[i+10]; sx2 += xi[i+10] * xi[i+10]; sy2 += yi[i+10] * yi[i+10]; sxy += xi[i+10] * yi[i+10]; } ae[motor] = (n * sxy - sx * sy) / (n * sx2 - sx * sx); //sxy / sx2; // be[motor] = (sy - ae[motor] * sx) / n; //ymean - ae[motor] * xmean; Serial.println(" | | Moving back to ZERO position."); // turn the motor back to middle position swing = true; i = 0; while (swing == true) { unsigned long currentMicros = micros(); if (currentMicros - previousMicros >= 10000) { // save the last time you blinked the LED previousMicros = currentMicros; x = x1[motor] + float(i) * (90 - x1[motor]) / 60; calibrationAngle = a[motor] * x + b[motor]; servoWrite(motorPin , calibrationAngle); rawAngle , motorPin = motorInfo(motor); eang = ae[motor] * rawAngle + be[motor]; if ((i % 4) == 0) { Serial.print(" | | Servo ang: "); Serial.print(calibrationAngle); Serial.print(" -> Real ang: "); Serial.print(x); Serial.print(" -> Encoder ang: "); Serial.println(eang); } if (i >= 60) { swing = false; } i++; } } Serial.println("___|___|"); Serial.println(" | "); Serial.println("___"); Serial.println(" | Calibration finished satisfactory. Results data:"); Serial.print(" | HIGH lim: "); Serial.print(highLim[motor]); Serial.print(" LOW lim: "); Serial.println(lowLim[motor]); Serial.print(" | angle 1: "); Serial.print(ang1[motor]); Serial.print(" angle 2 "); Serial.println(ang2[motor]); Serial.print(" | Regression Motor a: "); Serial.print(a[motor], 5); Serial.print(" b: "); Serial.println(b[motor], 5); Serial.print(" | Regression Encoder a: "); Serial.print(ae[motor], 5); Serial.print(" b: "); Serial.println(be[motor], 5); Serial.println(" |"); Serial.println(" | ______________________________________________________________"); Serial.println(" | | |"); Serial.println(" | | This code won"t be able to save the updated parameters |"); Serial.println(" | | once the robot is shutted down. |"); Serial.println(" | | |"); Serial.println(" | | Please, write down the results |"); Serial.println(" | | and save them in the definition of each variable. |"); Serial.println(" | |_____________________________________________________________|"); Serial.println(" |"); Serial.println("___|"); Serial.println(" Select another motor."); Serial.print("SELECTED MOTOR: "); Serial.print(motorTag[motor]); Serial.print(". SELECTED RESOLUTION: "); Serial.println(res); } interp = false; secuence = false; } } SAFE = false; Serial.println("Calibration killed"); } // END OF CALIBRATION

Now that I look again, you are right... BUT.. the actual address is 0x3F! I"m not sure that makes sense either but because I believe the lowest bit is considered the R/(not)W bit. Since its a write only device, I"d think it should be ox3E if anything, but that"s the address needed, so I guess the LCD library I"m using overrides the low bit. And now that you mention it, I see that the board does have places for jumpers (or zero hom SMD parts) to further configure the address. It means I can now drive multiple displays (up to 8) if I even needed to.

Very interesting Thanks! So the likelihood of two devices with completely different purposes using the same addess range is fairly low, and like my DS1882 audio pot chips, they will usually allow the user to configure 3 bits within the lower nibble of the address.

For an i2c based clock/RTC module would use a DS3231 instead of a DS1307. The price is about the same and it is much more accurate. DS3231 modules on ebay (starting at just under $1.50 USD shipped) are cheaper than the price shown on that link you provided to the DS1307.

You do need to be careful with most of these low cost RTC modules in the they have a little charging circuit on them for using with a LIR2032. If you use a 2032 instead, you should cut a trace on the module to disable the charging circuit.

Well that one I linked seems very convenient, and I probably wouldn"t need even 1/10th of it current functions. But I"ll investigate the S3231 too! For my projects, I just need a way to re-set the time if power has been lost for a while. Currently I detect eminent power fail, save the current time in EEprom, and retrieve it on power up. This is just to survive very typical power losses that only last minutes, without resetting to a stupid time like 12:00AM like most household devices do. But I"ll never need millisecond accuracy for any current projects.

And yes... I"ve been meaning to check out those nifty esp8266 modules too, for other projects. I was wondering though (even though its another subject), can they be used without coding them, just using external commands? I"m thinking of the major hassles and expense getting any kind of FCC approval, should I ever use such a module in a product. From my research, if a module has already passed FCC muster with its existing code, and you don"t alter its code, you may have a slightly cheaper path to approval.

By continuing to use AliExpress you accept our use of cookies (view more on our Privacy Policy). You can adjust your Cookie Preferences at the bottom of this page.

Afghanistan, Algeria, American Samoa, Andorra, Angola, Argentina, Armenia, Bahrain, Bangladesh, Belarus, Benin, Bermuda, Bhutan, Bolivia, Botswana, Brunei Darussalam, Burkina Faso, Burundi, Cambodia, Cameroon, Cape Verde Islands, Central African Republic, Central America and Caribbean, Chad, China, Comoros, Cook Islands, Côte d"Ivoire (Ivory Coast), Democratic Republic of the Congo, Djibouti, Egypt, Equatorial Guinea, Eritrea, Ethiopia, Falkland Islands (Islas Malvinas), Fiji, French Guiana, French Polynesia, Gabon Republic, Gambia, Georgia, Ghana, Gibraltar, Greenland, Guam, Guernsey, Guinea, Guinea-Bissau, Guyana, Hong Kong, Iceland, India, Indonesia, Iraq, Jersey, Jordan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Macau, Madagascar, Malawi, Mali, Marshall Islands, Mauritania, Mauritius, Mayotte, Micronesia, Mongolia, Morocco, Mozambique, Namibia, Nauru, Nepal, New Caledonia, Niger, Nigeria, Niue, Oman, Pakistan, Palau, Papua New Guinea, Qatar, Republic of the Congo, Reunion, Russian Federation, Saint Helena, Saint Pierre and Miquelon, San Marino, Saudi Arabia, Senegal, Seychelles, Sierra Leone, Solomon Islands, Somalia, South Africa, Sri Lanka, Suriname, Svalbard and Jan Mayen, Swaziland, Tajikistan, Tanzania, Togo, Tonga, Tunisia, Turkmenistan, Tuvalu, Uganda, Ukraine, United Arab Emirates, Uzbekistan, Vanuatu, Vatican City State, Venezuela, Vietnam, Wallis and Futuna, Western Sahara, Western Samoa, Yemen, Zambia, Zimbabwe

In the Arduino Real Time Clock Tutorial, we will learn about Real Time Clock (RTC) and how Arduino and Real Time Clock IC DS1307 are interfaced as a time keeping device. If you recall, we have already implemented an Arduino Alarm Clock using RTC DS1307 in an earlier project.

But that project didn’t cover the basics of Real Time Clock or RTC, the specifications of DS1307 RTC IC and how to interface a Real Time Clock like DS1307 or DS3231 with Arduino.

An RTC or Real Time Clock is a Timekeeping device, usually in the form of an Integrated Circuit (IC). An RTC is battery powered and keeps track of the current time even when there is no power.

Real Time Clock ICs are present in computers, servers, many embedded systems and in fact they are used wherever it is required to keep an accurate time.

Even though Arduino and almost all microcontrollers have built-in timers and timekeepers (millis () in case of Arduino), they are power dependent i.e. they run as long as there is power supply. Once the power is turned off (manually or due to power outage), all the timers are reset to 0.

While timekeeping using internal timers is acceptable for simple projects, we need an alternative in projects like data loggers, clocks, alarms, etc. where the timer runs independently irrespective of the external power or if the Microcontroller (or Arduino) is reprogrammed.

Here comes the use of Real Time Clock ICs. Almost all RTC ICs are low-current devices that run for years on a single lithium cell (usually CR2032). One of the popular and most commonly used RTC ICs is the DS1307 Real Time Clock.

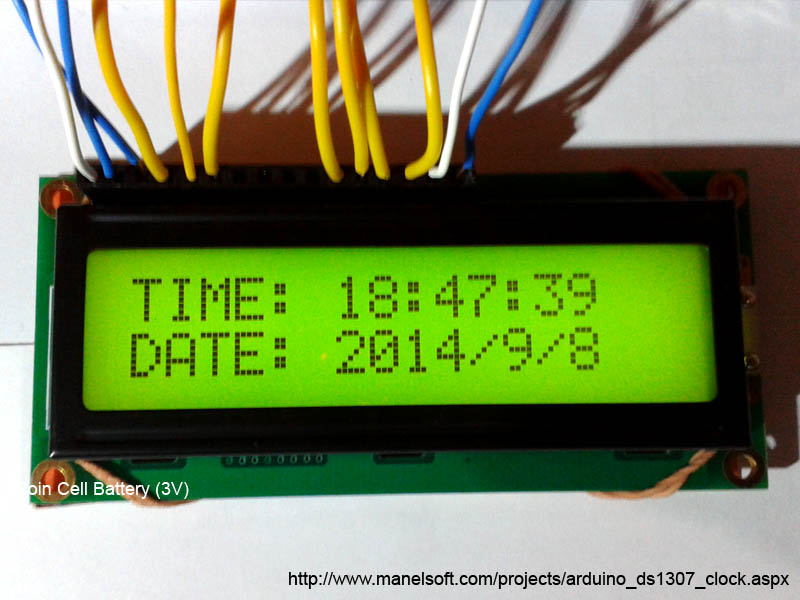

The DS1307 RTC is a low cost, low power real time clock IC that can maintain full clock and calendar i.e. hours, minutes, seconds as well as year, month and day. Some of the well-known features of the popular DS1307 RTC are mentioned below.

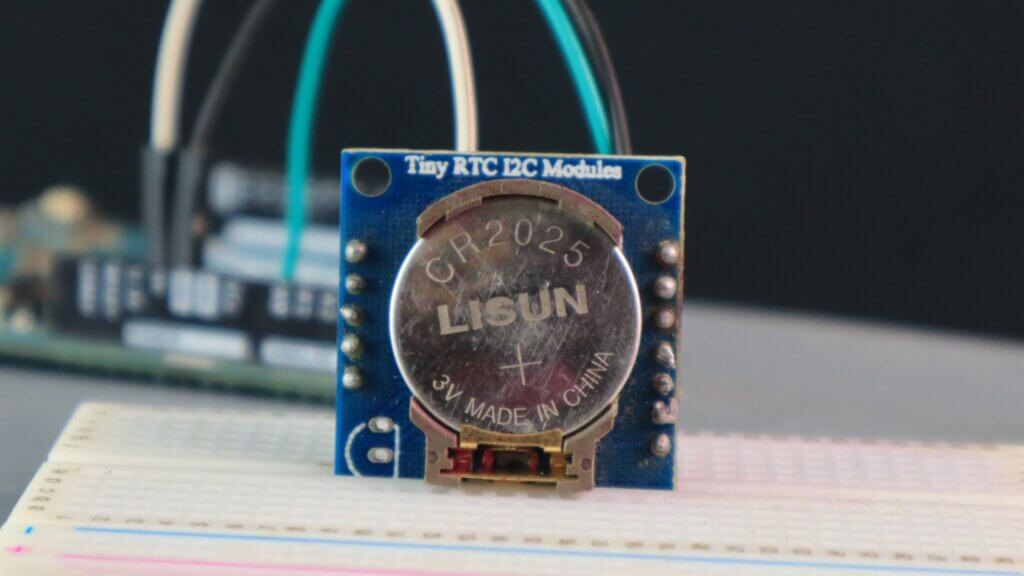

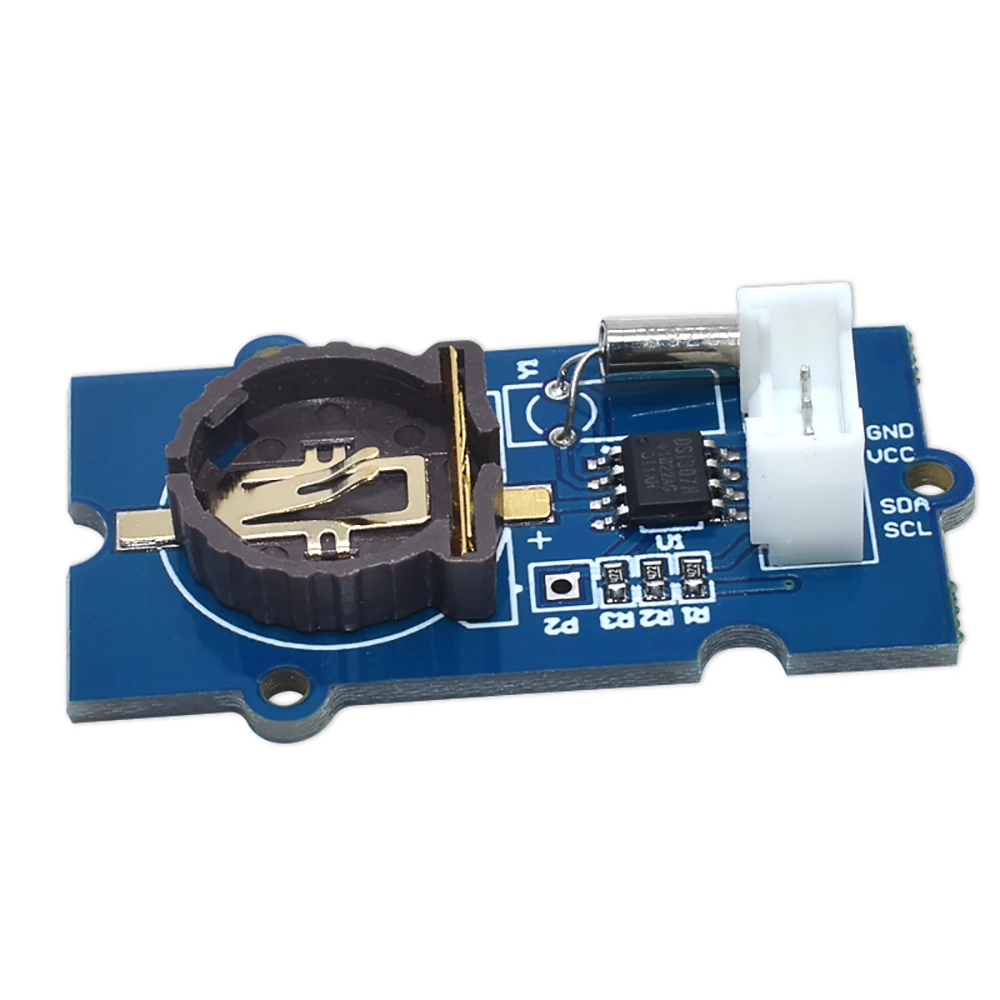

DS1307 RTC is available as modules, which consists of all the necessary components like Battery, connectors, pull-up resistors and crystal. One such module is used in this project and is shown below.

The following image shows the pin diagram of the DS1307 RTC IC. In order to reduce the power consumption, the number of pins on the IC has to be reduced. Hence, DS1307 RTC used I2C Communication.

X1 and X2: These are pins for connecting the crystal of frequency 32.768 KHz to enable the internal oscillator. If an external oscillator is connected to X1, then X2 can be left floating.

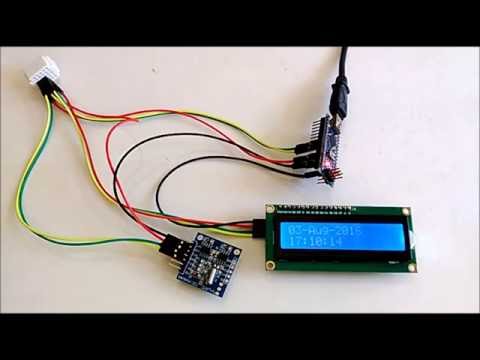

Now that we have seen a little bit about the Real Time Clock IC DS1307, we will proceed with the interface of Arduino and Real Time Clock. As mentioned earlier, the DS1307 RTC Module uses I2C Communication.

In the Arduino Real Time Clock I2C interface, the Arduino Microcontroller always acts as Master and the DS1307 acts as Slave. The Master in I2C Communication i.e. Arduino in this case, is responsible for clock signal, bus access, start and stop signals.

The following image shows the circuit diagram of the Arduino Real Time Clock DS1307 Interface. This circuit explains just the basic connections with respect to a DS1307 Module (a board that contains the DS1307 IC along with the crystal, Battery and pullup resistors).

In order to understand better about the DS1307 RTC Module, the following image will help you as it contains the circuit of a typical DS1307 Real Time Clock Module.

The design of the Arduino RTC Interface is quite straight forward. Connect the SDA and SCL pins of the DS1307 RTC to the SDA and SCL pins of Arduino i.e. pins A4 and A5.

A simple project where Arduino UNO is interfaced with DS1307 Real Time Clock is implemented here. In this project, we will be programming the DS1307 RTC with current date and time and see whether it actually keeps that data even if the power supply to Arduino is removed.

A special library called “RTClib” is used in the programming and it can be downloaded from this link. Make sure that it is downloaded first and added to the Arduino library database.

In order to upload the data and time into the DS1307 RTC IC, we have used a feature available in the RTClib library, where the Arduino will upload the date and time from the computer while uploading the code.

Recently we were exploring the Raspberry Pi PICO and thought of building a simple project. We thought of building a digital clock using a RTC. This is a simple DIY Digital clock with RTC DS1307 and Raspberry Pi PICO. You might have build a digital clock using Arduino, RTC and coded it with embedded C. In this project we will be using micro python and electronics. People who have the basic knowledge of python and electronics can build this project easily. It will help you to explore the possibilities of interfacing a RTC module with Pi PICO board. Lets start building this project.

DS1307 is a low cost real-time clock (RTC) module. The accuracy is good and works as a prefect time keeper. This RTC chip is built using Maxim – DS1307. It is also the heart of this module. It has a good feature of two-wire I2C interface. Using I2C protocol it is easy to interface it with different microcontrollers and development boards.

This module comes with an external 32kHz crystal for keeping accurate time. The only problem with these external crystals are, they are very temperature sensitive. The change in temperature affects their oscillation frequency. Although this change is negligible but in the long run it affects the time slightly.

The DS1307 RTC module is equipped with a coin battery source. This battery helps the chip to maintains accurate time even if there is a power interruption. This RTC module is also equipped with a 32 bytes 24C32 EEPROM chip manufactured by Atmel. It is use to save the configuration or time when setting it for first time.

The working of this project is simple. The RTC and LCD is connected with Raspberry Pi Pico using I2C protocol. The PICO acts as a brain of this project by running the micro python code in it. The RTC is responsible for storing the date and time. With the help of LCD display the date and time is displayed.

After placing all the components on a breadboard connect them as per the diagram shown below. Once the testing is done you can also mount these components on a plastic case.

You can download the code from below link. Unzip the file and open these files using Thonny IDE. Now we need to upload all these files in Raspberry Pi PICO. If you are not sure about uploading the python code files using Thonny IDE then you can follow the link below.

Once we have connected the components as per the connection diagram and uploaded the code, now its time to test the project. In the first run of the code we have to set the time as shown above. After setting the time it will display the date and time in LCD.

So we have connected a RTC DS13070 with Raspberry Pi PICO and LCD to display date and time. PICO ha equipped with RP2040 SOC chip. This will be a simple digital clock using micro python code. Its a beginner project for micro python learners. Do try this and also you can modify this project as per your need. Don’t forget to share this project with your friends.

This is the RTC Real Time Clock Module, this little breakout that uses the DS1307 to keep track of the current year, month, day as well as the current time. The module includes a rechargeable Lithium coin cell battery that will run the RTC without an external 5V power supply for around 1 year. This module also comes with 24C32 32K I2C EEPROM which brings a more stable way to read and write. The DS1307 RTC is accessed via the I2C protocol.

The ST7789 TFT module contains a display controller with the same name: ST7789. It’s a color display that uses SPI interface protocol and requires 3, 4 or 5 control pins, it’s low cost and easy to use. This display is an IPS display, it comes in different sizes (1.3″, 1.54″ …) but all of them should have the same resolution of 240×240 pixel, this means it has 57600 pixels. This module works with 3.3V only and it doesn’t support 5V (not 5V tolerant).

The ST7789 display module shown in project circuit diagram has 7 pins: (from right to left): GND (ground), VCC, SCL (serial clock), SDA (serial data), RES (reset), DC (or D/C: data/command) and BLK (back light).

As mentioned above, the ST7789 TFT display controller works with 3.3V only (power supply and control lines). The display module is supplied with 3.3V (between VCC and GND) which comes from the Arduino board.

To connect the Arduino to the display module, I used voltage divider for each line which means there are 4 voltage dividers. Each voltage divider consists of 2.2k and 3.3k resistors, this drops the 5V into 3V which is sufficient.

The first library is a driver for the ST7789 TFT display which can be installed from Arduino IDE library manager (Sketch —> Include Library —> Manage Libraries …, in the search box write “st7789” and install the one from Adafruit).

testdrawtext("Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur adipiscing ante sed nibh tincidunt feugiat. Maecenas enim massa, fringilla sed malesuada et, malesuada sit amet turpis. Sed porttitor neque ut ante pretium vitae malesuada nunc bibendum. Nullam aliquet ultrices massa eu hendrerit. Ut sed nisi lorem. In vestibulum purus a tortor imperdiet posuere. ", ST77XX_WHITE);

testdrawtext("Lorem ipsum dolor sit amet, consectetur adipiscing elit. Curabitur adipiscing ante sed nibh tincidunt feugiat. Maecenas enim massa, fringilla sed malesuada et, malesuada sit amet turpis. Sed porttitor neque ut ante pretium vitae malesuada nunc bibendum. Nullam aliquet ultrices massa eu hendrerit. Ut sed nisi lorem. In vestibulum purus a tortor imperdiet posuere. ",ST77XX_WHITE);

In many electronic projects it is necessary to run an operation according to the time or date And the calculation of the time and date shouldn’t stop when the system shuts down. For this purpose, Real Time Clock (RTC) modules are used. In this tutorial, you will learn how to use RTC DS1 with Arduino to make a reminder.

You can also keep tracking the exact time without using RTC systems, but RTCs have some important advantages. Here are some of these advantages:Low power consumption

Releasing system time from time calculation (this feature is critical because in many cases CPU is operating some delicate tasks like receiving sensors data. and if you don’t use RTC, CPU also has to keep track of the time and it can disrupt processors main tasks.)

RTCs often have an alternate source of power, so that they can continue to keep time while the primary source of power is off or unavailable. RTCs often use a 32.768 kHz crystal oscillator. But why 32,768? 32768 is equal to 215 and hence can generate 1 second easily. Also, the crystal must be small with proper width and low power consumption, which can be satisfied with using 32876 Hz. Higher frequencies are larger and fragile crystals, and the lower frequencies have more power consumption that 32,768KHz.

DS1307 module is one of the most affordable and common RTCs modules. It can accurately keep track of seconds, minutes, hours, days, months, and years.

The DS1307 module has the capability to install a 3-volt CR2023 backup battery. there is also an embedded EEPROM 24c32 memory on this module that can save 32kb of data. In addition, you can measure the environment temperature by installing a DS18B20 sensor on the built-in-place. And you can also read the backup battery voltage from BAT pin.

You need to set up date and time in your projects just once, and after that, you should delete the related line from your code. Otherwise, date and time will be set any time you turn the system on and it can cause some mistakes.

Uploading the code on your Arduino takes a few seconds and it can cause a few seconds delay in your time, compared to real time. So we suggest you to set your time a few seconds earlier before uploading the code.

A menu will be displayed on LCD after turning on the device. Choose your reminder mode ( you can move between options by Right key and select your desired mode by pressing Select key.) then set your alarm time (set the hour by UP and Down key, then go to minutes by pressing Right and set it up.) Now get to your daily works without any worry!

Been having a lot of fun with the LCD screen and a DS1307 Real Time Clock IC. After studying the schematics and DS1307 pinout, I made a breadboard sketch in Fritzing, tried it out and transferred the design to a small piece of stripboard. The usual pitfalls were encountered; a broken IC socket had to be de-soldered and replaced and I reversed the polarity of the coin cell holder. But I did end up with a functional "breakout board" I can use in other projects. And I reckon a small side-step like this can only help in developing the skills needed to tackle a big project.

I decided to make a new revised board, with proper pin headers and an activity indicator LED. The LED is toggled by the SQW (square wave) output on pin 7. This output is enabled by writing 0x10 to the DS1307 control register 0x07. The lower two bits control the frequency of the square wave and the default value of 0b00010000 equals 1 Hz, causing a slow blinking LED. Changing the register to 0b00010001 will set the frequency to 4096 Hz which produces a nice steady glow. Write 0b00010010 or 0b00010011 to select 8092 Hz or 32768 Hz and an even brighter LED..

Musically inclined readers will have noticed that 4096 Hz and 8096 Hz are solidly within the audible range for humans. And it is very easy to hook up a small speaker or Piëzo buzzer and make this little chip beep. Or you could disable the SQW output and switch it on when a certain condition, like reaching a certain date or time, has been met... add a few buttons to set and cancel the alarm and hey presto: the digital alarm clock!

The DS1307 has an added bonus of 56 bytes of storage space. It only takes 6 bytes to store a BCD DateTime. I will use one extra byte for alarm status (enabled/disabled) and another one for alarm type (once/daily/weekly etc). That leaves me with 56 / 8 bytes = 7 memory "slots" for alarms. Now all i have to do is write a clever piece of software that will allow me to set an alarm with two or three buttons.

PS: when i had finished building rev. 2 I just couldn"t get it working at all. I checked and double-checked all the obvious stuff (continuity, voltages) but the Arduino did not receive any data on the I2C bus. After a long time i more or less gave up and in a desperate last attempt, switched the SDA and SCL wires. Problem solved :)

Here you can find useful projects with description, schematics and PCB, electronics articles and other electronic engineering resources. Projects hosted on our website are contr...

A digital clock is a great invention in electronics science. Nowadays, digital clocks are used everywhere. The analog clocks are quite old-fashioned. So the digital clock takes its place day by day. The Arduino digital clock is looking very modern. It has many additional features also like temperature, alarm, timer, etc.

In this electronics project, we are going to build an Arduino digital clock with or without an RTC (Real Time Clock) module. The first circuit represents without RTC module and the second circuit represents with RTC module. The components we used in this project are quite basic and a little expensive. The circuit connection is very easy.

We build this digital clock with an Arduino, RTC module, and LCD display in this project. Here the clock we made is 24 hours clock. This means the time shows by the clock is 00.00 AM to 23.59. After 23.59 it resets to 0 again.

Arduino is one of the most popular electronics prototyping boards based on the ATmega328P microcontroller. ATmega328P is an AVR architecture based 8-bit microcontroller. Here I am using Arduino Nano for this project to give it a compact look.

A 16×2 LCD display is the most commonly used display unit for microcontroller-based applications. It supports 16 characters in a row with two such rows. It also supports special characters and even custom characters.

I2C Module has an inbuilt PCF8574 I2C chip that converts I2C serial data to parallel data for the 16 pins LCD display. It is currently available with a default I2C address of either 0x27 or 0x3F. With this I2C LCD module, we can able to show data via only 2 wires that are SDA and SCL pins.

The DS1307 real-time clock (RTC) is a low power, full binary-coded decimal (BCD) clock plus 56 bytes of NV SRAM. Address and data are transferred serially through an I2C bus. This clock provides seconds, minutes, hours, days, dates, months, and years.

A serial I2C bidirectional bus made a communication between the Arduino and the DS1307 RTC module. The I2C protocol is a technique for communicating a faster device (master mode) and a slower device (slave mode).

To make the circuit compact and give a professional look, I have designed the PCB after testing all the features of the Arduino Digital Clock Circuit PCB on the breadboard. I will explain in detail how we can design and order PCB for our project.

This project is sponsored by PCBWay.com. PCBWay is a Chinese-based PCB (printed circuit board) prototype, PCB assembly, SMD Stencil, and Flexible PCB manufacturer. They ship to more than 170 countries worldwide and process more than 2100 PCB orders a day. It feels like PCBWay gives an excellent price and customer service factor in one single serving. The quality of the PCB is awesome and its thickness is really great. What is also spectacular about PCBWay to me, as a maker and customer, is their service. From their friendly support staff to their intuitive, user-friendly website features, it all counts towards what makes PCBWay an ideal company and brand for any electronic hobbyists In this article, I will state that how can we order PCB from PCBWay with step by step guide.

They are not only producing FR-4 and Aluminum boards, but also advanced PCB like Rogers, HDI, Flexible and Rigid-Flex boards, at a very reasonable price.

SMT & THT assembly starts from only $30 with a free stencil and free worldwide shipping. The components can be sourced and provided by PCBWay, or by clients themselves.

With a real-time clock module, this circuit is working in automatic mode. Although we can manually set the time as our requirements through Arduino code. As we say that this is an automatic clock so the system can set time and date itself like a computer.

First of all, connect all two push buttons’ any one terminal to the ground. Then other terminals of the two buttons are connected to analog pins D8 and D9 of the Arduino respectively.

To make the circuit compact and give a professional look, I have designed the PCB after testing all the features of the Arduino Digital Clock on the breadboard. I will explain in detail how we can design and order PCB for our project.

The first button is for setting up the hour by sending a signal to the D8 pin. The second button is for setting up the minutes by sending a signal to the D9 pin of the Arduino.

The whole circuit is working as a continuous sequence. When the power goes out, the circuit will reset to its initial position. Then we need to again set the time via the push button. So this is a major drawback for this circuit.

For this project, it needs to set the real-time into Arduino code when uploading. But after that, we need not set the time every time when better die. Just remove the old battery and put the new one that’s it.

Yes, there is a few Arduino real-time clock (RTC) libraries in the library manager of the Arduino IDE software. These help to compile Arduino code and upload it into the Arduino board.

To make this clock is too easy. But the only drawback of this clock is when the power cut down, we need to set the time again from the beginning. To build this clock go to this blog and check out the second circuit.

The main purpose of using an RTC or a real-time clock is to provide a precise time and date which is very accurate. RTC is an electronic device in the form of an Integrated Chip (IC) available in various packaging options. It is powered by an internal lithium-ion battery.

An RTC maintains its clock by counting the cycles of an oscillator (32.768KHz Crystal Oscillator) circuit, an internal capacitor-based oscillator, or even an embedded quartz crystal. Some RTCs maintain the oscillator setting at the last known point before it went out of the lock with the power input.

This library enables you to use ISR-based PWM channels on AVR ATmega164, ATmega324, ATmega644, ATmega1284 with MCUdude MightyCore, to create and output PWM any GPIO pin

Minimal bit-bang send serial 115200 or 38400 baud for 1 MHz or 230400 baud for 8/16 MHz ATtiny clock.Perfect for debugging purposes.Code size is only 76 bytes@38400 baud or 196 bytes@115200 baud (including first call)

This library enables you to use Hardware-based PWM channels on Arduino AVR ATtiny-based boards (ATtiny3217, etc.), using megaTinyCore, to create and output PWM to pins.

This library enables you to use ISR-based PWM channels on Arduino AVR ATtiny-based boards (ATtiny3217, etc.), using megaTinyCore, to create and output PWM any GPIO pin.

Small low-level classes and functions for Arduino: incrementMod(), decToBcd(). strcmp_PP(), PrintStr, PrintStrN, printPad{N}To(), printIntAsFloat(), TimingStats, formUrlEncode(), FCString, KString, hashDjb2(), binarySearch(), linearSearch(), isSorted(), reverse(), and so on.

Cyclic Redundancy Check (CRC) algorithms (crc8, crc16ccitt, crc32) programmatically converted from C99 code generated by pycrc (https://pycrc.org) to Arduino C++ using namespaces and PROGMEM flash memory.

Write decimal numbers, hex numbers, temperature, clock digits, characters, and strings to the seven segment LED modules supported by the AceSegment library.

Various sorting algorithms for Arduino, including Bubble Sort, Insertion Sort, Selection Sort, Shell Sort (3 versions), Comb Sort (4 versions), Quick Sort (3 versions).

Date, time, timezone classes for Arduino supporting the full IANA TZ Database to convert epoch seconds to date and time components in different time zones.

Clock classes for Arduino that provides an auto-incrementing count of seconds since a known epoch which can be synchronized from external sources such as an NTP server, a DS3231 RTC chip, or an STM32 RTC chip.

Useful Arduino utilities which are too small as separate libraries, but complex enough to be shared among multiple projects, and often have external dependencies to other libraries.

Fast and compact software I2C implementations (SimpleWireInterface, SimpleWireFastInterface) on Arduino platforms. Also provides adapter classes to allow the use of third party I2C libraries using the same API.

This library allows to read a value from an analog input like an potentiometer, or from a digital input like an encoder. Moreover, allows to write it on digital output, exactly on PWM pin.

Enables Bluetooth® Low Energy connectivity on the Arduino MKR WiFi 1010, Arduino UNO WiFi Rev.2, Arduino Nano 33 IoT, Arduino Nano 33 BLE and Nicla Sense ME.

ESP32 + LwIP ENC28J60, including ESP32-S2, ESP32-S3 and ESP32-C3, Connection and Credentials Manager using AsyncWebServer, with enhanced GUI and fallback Web ConfigPortal.

ESP32 + LwIP W5500 / ENC28J60, including ESP32-S2, ESP32-S3 and ESP32-C3, Connection and Credentials Manager using AsyncWebServer, with enhanced GUI and fallback Web ConfigPortal.

ESP32 + LwIP W5500, including ESP32-S2, ESP32-S3 and ESP32-C3, Connection and Credentials Manager using AsyncWebServer, with enhanced GUI and fallback Web ConfigPortal.

(ESP8266 + LwIP W5500 / W5100(S) / ENC28J60) Connection and Credentials Manager using AsyncWebServer, with enhanced GUI and fallback Web ConfigPortal.

Simple Async HTTP Request library, supporting GET, POST, PUT, PATCH, DELETE and HEAD, on top of AsyncTCP library for ESP32/S2/S3/C3, WT32_ETH01 (ESP32 + LAN8720), ESP32 using LwIP ENC28J60, W5500, W6100 or LAN8720.

Simple Async HTTP Request library, supporting GET, POST, PUT, PATCH, DELETE and HEAD, on top of AsyncTCP libraries, such as AsyncTCP, ESPAsyncTCP, AsyncTCP_STM32, etc.. for ESP32 (including ESP32_S2, ESP32_S3 and ESP32_C3), WT32_ETH01 (ESP32 + LAN8720), ESP32 with LwIP ENC28J60, W5500 or W6100, ESP8266 (WiFi, W5x00 or ENC28J60) and currently STM32 wit

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey