tft display for stm32f4 manufacturer

A1: We have the integrated system for industrial parts quality control. We have IQC (incoming quality control), IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts prodution.

A4:Generally speaking, it will take us 15 working days for machining parts and 25 working days for stamping parts products. But we will shorten our lead time as soon as possible according to customers" demands.

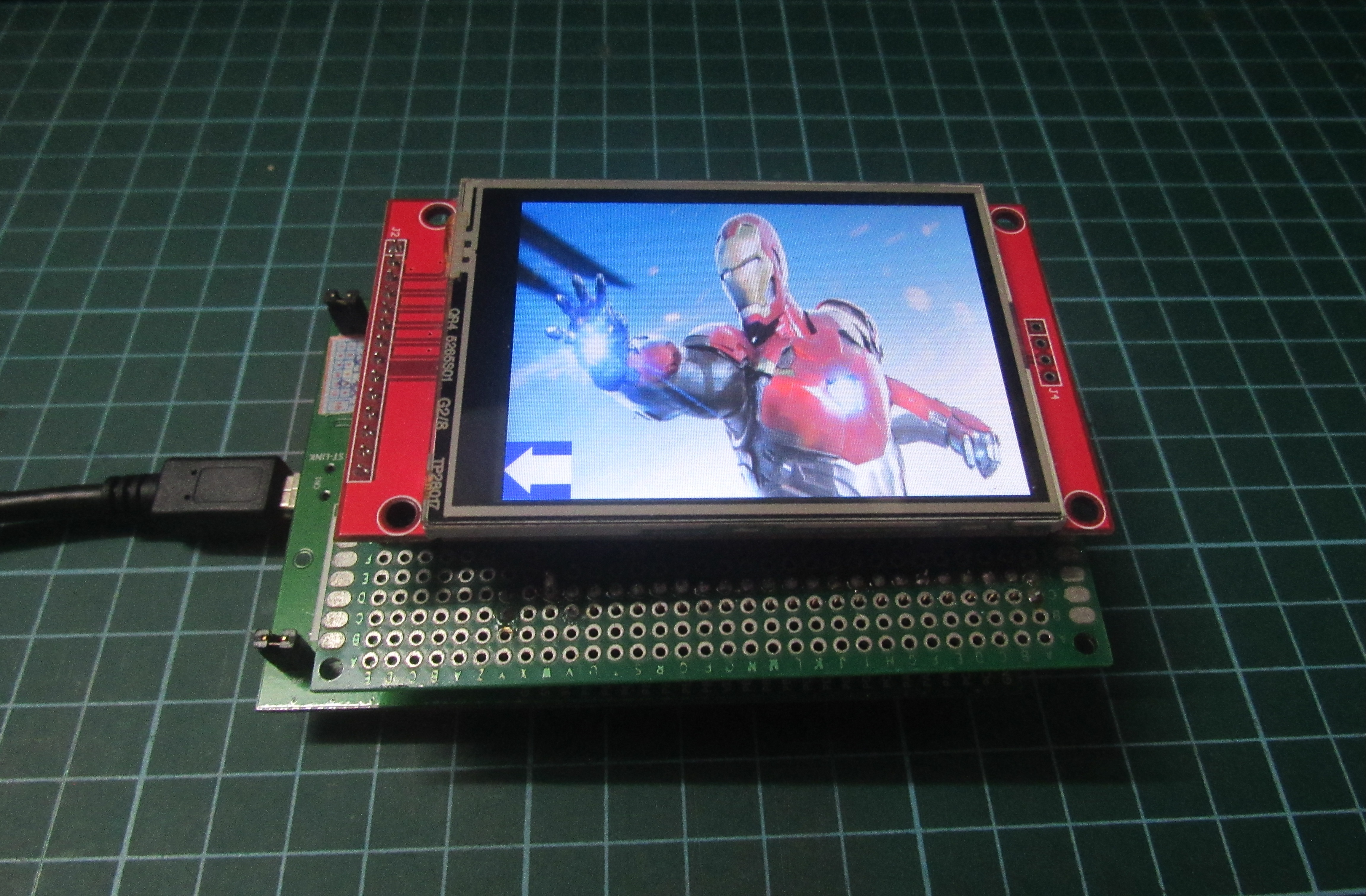

STM32F429 has also LTDC driver for LCD like that, but this driver we will use later. For now we will use SPI for driving in serial mode and some other pins for controlling.

Remember: This library can also be used, if you are not using STM32F429 Discovery. It can be used in previous STM32F4 Discovery board. All pins can be changed in defines.h file which is included in project.

Reduce the TFT GUI development time considerably with mikroC, mikroBasic or mikroPascal for ARM and mikromedia Plus for STM32 board. Buy this kit and save money.

7. To the extent that your personal data is processed on the grounds of your consent, you have the right to withdraw that consent. Withdrawal of consent has no bearing on the legitimacy of processing that was performed prior to the withdrawal.

The resulting output will depend on the previous state of the output data register. - For the LOW data pins, the corresponding GPIO port bits in BSRR[31:16] need to be set to 1 in order to update all the 8-bit data bus lines at once.

GPIO configuration is done similiar way as in example for SDRAM. But unfortuneatly TFT controller pins are shared in two alternate functions group (9 and 14), so there is third table with AF initialization values.

At this moment easiest way to display antything on LCD is use random content that SDRAM holds after power-up. Go to sdram.c file and comment following lines:

I"m using this library but the problem is that I get only two colors at my LCD screen. Black and Purple. That"s because this library is made for 8-bit databus.

I"m looking for a C library that can be used for 16-bit data bus. I have been looking at Github, but the only C libraries I found with 16-bit data bus is not suitable for STM32 or Arduino. Do you know one?

As a kind of semi-autonomous or fully self-help robot, service robots are able to perform useful service work for human beings, such as carrying, cleaning, and rescue. As service robots gradually enter the social life of people, they are now widely used in public places such as exhibition halls, restaurants, and hotels, which have a profound impact on improving the quality of human life and the service industry.

Usually, service robots are equipped with high-precision LIDAR, voice acquisition module, motion module, display screen, wireless connection module, and other major equipment. The robot uses LIDAR to build a high-precision indoor map, a voice module to receive voice commands, a motion module to move the robot to the target location, and a wireless module to receive remote commands from the controller to achieve remote intelligent control.

Here we take a single-story scenario of a high-end office building as an example. The robot needs to serve the office workers in the building at regular intervals, and the task requires the robot to sense the environment and its own motion state through intrinsic or extrinsic sensors and perform collision-free motion from the robot’s current location to the target location according to the principles of optimal time, shortest path, or lowest energy consumption.

To perform this task successfully, the floor environment is first scanned by using LIDAR to construct an indoor map and indicating the location of the task point with coordinates:

In order to enable the controller to remotely access the robot status and give control commands from the control center, I used the STM32F407 mainboard to interact with the robot through an external network card and the stone STVC043WT-01 display for UI design in the demo to improve the efficiency of the operator’s use, the schematic diagram of the design is as follows:

This article will focus on how to use the stone STVC043WT-01 to design a UI to display the status of the service robot in real-time. Before working on the stone display, we need to write a simple test demo to ensure that the remote control module receives the robot’s current status (robot ID, destination, x/y/z motor speed, coordinates of robot’s current position, etc.) over the wireless network in a timely manner.

Stone provides a set of display design tools that are easy to use, and we can complete the development of display demos in a very short time through the company’s STV series displays. Therefore, the Stone STVC043WT-01 display was chosen to monitor the status of the remote machine in real-time. The development of the display is divided into three main steps:

Right-click project file -> add to insert a picture drawn with other tools, note that the size of the picture must be consistent with the display, the size of the pictures used in this article are 480×272.

Insert the text variable in Robot ID and Destination, and insert the data variable in Motor speed and current location, as shown in the figure below. It should be noted that a Variable memory address represents the address where data or text is stored, and word Length represents the maximum length of displayable bytes.

After completing the above steps, check the screen configuration, make sure the baud rate is 115200 and the command handler is 0xA5 0x5A. After the check is completed, click the compile option and download the file to the display.

When the system starts, the display shows the Home Page, which contains six options. The system will establish a wireless connection between the remote console and the robot when we click on the connect option; conversely, the disconnect will disconnect the wireless connection. The show map option will display a map of the indoor environment which is created by the robot; the clear state option will initialize the system and send a command to interrupt the robot’s task execution to make it return to the starting point; the current state option displays and changes the robot’s state; and the return origin option will prompt the robot to return to the starting point.

Select the current state to check the current robot state. When the robot is at the starting point, the display shows the initial value of the robot state:

After setting the robot’s target, the robot starts its task, at which time the display will show the robot’s ID, destination, speed, and coordinates in real-time, as shown in the figure below, where the robot rotates at coordinates (174,269):

//Second, for the serial port number greater than 9 (for example, COM12), the serial port name in the CreateFile() function should be written "\. \COM12"。

We have many years of production and sales experience, we have accumulated rich strength in the 15.6 Inch VGA TFT Display, 15.6 Inch LCD Screen, 10.1 Inch LCD Display field. Since introduced the part overseas vanguard technology and the craft and formed the powerful technical support system, it has poured into the vigor for our development. We are strict with every part of our work.

This LCD panel has a built-in EK9716BB3+EK73002 controller, a 40pin 24-bit RGB Interface, can support All View full viewing angle with IPS technology. It is composed with 10 LEDs connected 2 in parallel and 1 in serial l, with backlight voltage 16.5V/current 20mA and 16:9 aspect ratio. Optional with 4 wire resistive touch panel (RTP) and projected capacitive touch screen (PCAP.). Sharing controller board same hardware with 5” TFT LCD 800x480 resolution and 7” 800x480 resolution.

LVDS displays can vary a lot. LVDS displays are not governed by a set of well defined rules like MIPI DSI displays are. Therefore, it is up to the LCD manufacturer and the LVDS display driver IC manufacturer to use LVDS interface as they please, as long as they follow the physical interface and logic levels.

Based on this data, we can pick an LVDS transmitter IC. SN75LVDS84 from Texas Instruments is great for use with LCD displays that can be driven by an STM32.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey