tft display driver manufacturer

LAPIS Technology"s display drivers realize uniform and fast pixel charging for 8K 120Hz, 75-inch, and larger panels with the unique technology of panel load charging.

Gaming monitors require a higher refresh rate *1 in order to display video smoothly.The higher the refresh rate, the shorter the time required to write the display data.

LAPIS Technology"s display drivers use high-speed point-to-point interface technology *2 (4Gbps), which enables large amounts of display data transfer in a short time.Our products have been used in many panels with high refresh rates such as 360Hz.

In automotive display, it is needed to ensure automotive quality, reduce the number of signal and power wires, and provide long-distance wiring.We will meet these needs with a unique point-to-point interface that reduces wiring number and enables long-distance transmission, as well as an anomaly detection function to ensure automotive quality.

LAPIS Technology"s display drivers realize uniform and fast pixel charging for 8K 120Hz, 75-inch, and larger panels with the unique technology of panel load charging.

Gaming monitors require a higher refresh rate *1 in order to display video smoothly.The higher the refresh rate, the shorter the time required to write the display data.

LAPIS Technology"s display drivers use high-speed point-to-point interface technology *2 (4Gbps), which enables large amounts of display data transfer in a short time.Our products have been used in many panels with high refresh rates such as 360Hz.

In automotive display, it is needed to ensure automotive quality, reduce the number of signal and power wires, and provide long-distance wiring.We will meet these needs with a unique point-to-point interface that reduces wiring number and enables long-distance transmission, as well as an anomaly detection function to ensure automotive quality.

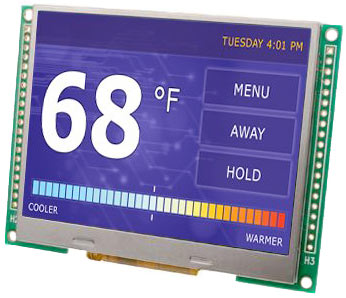

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

Raystar is a global leading LCD panel supplier and specialized in producing TFT LCD Panel, including Color TFT, Monochrome TFT Display and bar type TFT Display. Raystar Color TFT displays are available in various resolutions and offers a wide product range of small to medium-sized TFT-LCD modules from 0.96” to 12.3". The interface options are in MCU / RGB / SPI / UART / 8080 / LVDS. TFT Panel with control board or TFT LCD Panel with micro controller are also available.

INT043BTFT and INT043BTFT-TS are embedded display driver boards based on our 4.3 inch 480 x 272 RGB resolution TFT display module. Mounted on the embedded board is the Solomon Systech SSD1961 LCD controller that supports common RAM-less LCD drivers and offers the following features and benefits:

TFT LCDs have become the norm for small-to-medium size displays in a variety of products within industrial, medical, POS and consumer applications. Compared to passive-addressed monochrome LCDs, TFT displays offer higher contrast, wider viewing angles, faster response time and full color. And, TFT LCDs are now on cost parity with similar size passive LCD displays.

A typical TFT LCD module product consists of a TFT LCD panel, one or more COG (chip-on-glass) driver ICs, a backlight unit, and an interface FPC. Several TFT display interface technologies coexist today. Picking the right technology depends on specific end-product concerns. Most often the display panel input will dictate that choice since TFT panels are designed to be COG bonding pad compatible with a very limited number of driver ICs. This article discusses the interfaces between TFT LCD modules and the typical CPUs found in embedded applications.

Typical TFT interfaces are determined by the particular TFT panel size and resolution, as shown in the below table. HDMI and eDP require interface converting boards and generally are not used for small to medium-size TFT LCDs.TFT LCD SizesResolutionsTypical Interfaces UsedUp to 3.5″128×160 to 240×320SPI, parallel MPU or RGB

Only the three SPI signals, a CS, and a reset signal are needed. Drawbacks are the inability to read from the display, only write. Also, the frame rate is low and unsuitable for displaying video or high-resolution images.

The LCD controller signals are two types: data signals and control signals. The data signals are connected to the LCD data bus and depend on the LCD color depth (8-bit, 9-bit, 16-bit, 18-bit). The control signals are used to define the operation type (read or write), and whether the operation involves in addressing LCD registers or the display RAM.

An RGB interface is a special kind of parallel interface. This interface works for displays without a frame buffer. The MCU is responsible for updating the display, by providing both the RGB sub-pixel data (16-bit, 18-bit, 24-bit) and the timing signals (HSYNC, VSYNC, DE, CLK).

LVDS interfacing has several benefits for TFT displays. It is much less susceptible to EMI and crosstalk issues, allowing the transmitting device to be located farther from the display. Also, LVDS generally consumes less power, pin counts are lower and there are far fewer worries about signal integrity.

Modern TFT driver ICs are highly integrated chips combining the source driver, gate driver and timing controller (TCON) – as well as other functional circuits such as memory, power circuit, and image processors – into one single IC die. Some driver ICs support multiple interfaces that are selectable on the module FPC or through initialization code firmware.

As a designer and manufacturer of custom LCD modules, New Vision Display works with customers to select the most appropriate and cost-effective TFT display and electronic interface solution for their particular requirement. New Vision Display has nearly 30 years of industry experience as one of the world’s leading TFT LCD screen manufacturers.

INT028ATFT and INT028ATFT-TS are embedded display driver boards based on our 2.8 inch 240 x 320 RGB resolution TFT display module. Mounted on the embedded board is the RAIO RA8872 LCD controller that offers the following features and benefits:

A wide variety of tft lcd driver display options are available to you, You can also choose from original manufacturer, odm and agency tft lcd driver display,As well as from tft, ips, and standard.

This article will take you through a high level overview of all of the parts of a TFT LCD display. The vast majority of what I have read on the internet makes this whole issue massively complex. I’m quite sure that this complexity problem is a real reflection of the serious design and manufacturing complexity in these displays and drivers. That being said, to get a conceptual understanding is much simpler, and is the point of this article.

A significant amount of my learning about this subject came from a 195 page powerpoint presentation by Dr. Fang-Hsing Wang entitled “Flat Panel Display : Principle and Driving Circuit Design“. He has graciously allowed me to reproduce a few of his images. This dude knows way way more about these circuits than I do and I would encourage you to read his work.

The fundamental element in a TFT display is the liquid crystal. These elements have the property that the crystals will align from horizontal (which blocks the light) to vertical (which lets most of the light through) based on the electric field applied to them. Basically, you shine light through the liquid crystal, which blocks some or all of the light, the remainder of the white light then goes through a color filter to make red, green, or blue. It works like this:

This architecture means that every pixel in the display will require a red, green and blue element. And, you will need to control the voltage on all of the elements (which will be quite a lot on a screen of any size)

What does the schematic for one element in a pixel look like? And where is the T(transistor) in the TFT? The three letter acronym TFT stands for a thin film transistor that is physically on the top of the LCD matrix right next to each liquid crystal element. Here is a schematic model for one element in the array. C-LC represents the capacitance of the liquid crystal. CS is a storage capacitor that is used to hold the electric field across the liquid crystal when the transistor is OFF. To apply a voltage across the LC you just turn on the gate and apply the correct voltage to the column commonly known as the source.

You should notice that the “back” terminal of the two capacitors is called “VCOM” and is physically on the other side of the liquid crystal matrix from the TFT. All of the liquid crystal backsides in the display are connected to the same VCOM. A bit of painfulness in this system is that the CS capacitor leaks, which means that the LCD changes state which means that each pixel must be updated, properly called refreshed, on a regular basis.

If you have been thinking about this system you might have done a little bit of math and figured out that you are going to need an absolute boatload of source and gate driver signals. And you would be right! For example, a 4.3″ screen with 480×272 will require 480x272x3 elements which are probably organized into 480 rows by 816 columns. This would require a chip with at least 480+816=1296 pins, that is a lot. It turns out that for small screens <=3.5″ there are chips with enough pins to do the job. But, for larger screens, it requires multiple chips to do the job. The “…” in the picture above shows the driver chips being cascaded. The next thing to know is that “TFT Glass” usually has the driver chip(s) embedded into the screen at the edge (you can see that in the picture from Innolux above).

You must put a quite high voltage source >20v and drain <-10V across the liquid crystal at the right time to get it to do its thing. In order to pass that source voltage, the gate must be turned on at the right time to the right voltage, this is the purpose of the Gate Driver IC. The gate driver is conceptually simple and Dr. Wang drew a nice picture on page 7 of his presentation. You can see that it is basically a shift register, with one element per gate. You shift in a “1” and then clock it through the entire shift register which will have the effect of applying a 1 to each gate.

In its most basic form, the TFT source driver is responsible for taking an 8-bit digital input value representing the value of an individual LCD element and turning it into a voltage, the driving the voltage. Like this:

In reality there is some compromise of chip size, number of pins and time that is made by multiplexing pins, columns and rows. For example, many of the small screens appear to have 1 column driver for all of the reds, 1 driver for the blues and one for greens.

What appears to happen in real life on bigger screens is some combination of column and row multiplexing. In one display that I found there were 2x the number of rows which allows the columns to be multiplexed 2-1. The display is 1024×600. That requires 1024*3 RGBs in the column = 1536 pins. This means that you need to double the number of gate drivers, resulting in 1200 pins in the row direction. Here is a picture from their datasheet.

The last issue that I will address in TFT LCD drivers is called Gamma Correction or more simply Gamma. Gamma is an intensity adjustment factor. For any given digital intensity input, you will need a non-linear translation to a voltage output on the source. For example a doubling of digital input (so that a pixel appears twice as bright) you will not double but instead will have some non-linear translation of the output voltage.

The good news is that this gamma correction is built into the display drivers. From my reading, this is sometimes done with digital processing, and sometimes done with an analog circuit. But in general, it appears to be tuned and programmed into the driver by the panel vendor for these smaller display.

Winstar is a global leading Manufacturer of TFT LCD display based in Taiwan and China. Winstar offers a wide product range of small to medium sizes TFT display modules in sizes ranging such as 0.96",1.28", 1.77, 2", 2.4", 2.8", 3.2", 3.5", 4.3", 5" 5.6", 5.7", 7", 8", 9", 10.1", 10.2", 12.1" , 12.3" and 15" TFT (diagonal size of the active area) and so on . There are more than 250 TFT standard models listed on this website; furthermore, almost each item is acceptable to derivate from the standard items to meet the customers" requirement.

Winstar TFT displays are qualified under industrial standard including standard TFT-LCD modules, IPS TFT, High brightness TFT LCD (sunlight readable display), TFT panels with controller boards, Bar Type TFT, Wide Temperature TFT LCD, Winstar Clever System TFT and Touch screen display. These displays include landscape or portrait modes. Winstar has Mono TFT displays and full color TFTs in line, these displays are available in various resolutions as well as touch screen optional in resistive and projected capacitive (PCAP touch screen) technology. Many of our TFT display modules have more than one interface available including MCU, RGB, TTL, LVDS and MIPI DSI. Winstar TFT modules are perfect for a number of applications including industrial control, coffee machine, medical equipment, POS system, automation, GPS navigator, white goods, energy control, telecoms, medical equipment and etc.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey