how to fix an lcd display free sample

This article was co-authored by Linh Le and by wikiHow staff writer, Nicole Levine, MFA. Linh Le is a Certified Mobile Repair Specialist and the Owner of SC Mobile Repairs in San Clemente, California. With more than 12 years of experience, he specializes in smartphone, tablet, and smartwatch hardware repair. Linh has an iTech Mobile Device Repair Certification and an iOS Certification. He holds a Bachelor’s degree from The Franciscan University of Steubenville.

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

Image sticking (Ghosting)Sometimes, you will find the previous image still appearing at the background even if you change to another image. It is also called burn in. This kind of failure doesn’t need to repair by professionals. You can simply shut off the display overnight, this kind of problem will go away. Please do remember that displaying a static image for a long time should be avoided.

With the modern manufacturing process and design, this kind of failure rarely happens. Normally, it is caused by no power. Please check if the battery dead or adapter (power supply) failure or even check if you have plug in firmly or with the wrong power supply. 99% the display will be back on.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

Have you ever left your TV or monitor on for days, stuck on the same image? You return to your screen, only to find an image burned into the display. No matter what you do, it won"t go away. It is a permanent image burn.

Why do monitors and TVs get image burn? Why can"t manufacturers prevent LCDs and plasma screens from a burnt image imprint? Moreover, what can you do to fix an image burn?

In some cases, you can minimize the image burn effect. In others, you can remove the image burn completely, so long as it hasn"t been burning too long.

Before flat-screens and crystal displays, most TVs and monitors featured CRT (Cathode Ray Tube) technology. In CRTs, individual pixels comprise a red, blue, and green phosphor component. Depending on the intensity of each phosphor component, the pixel appears to the human eye as a unique color.

When a particular still image remains for too long, the intensity of each phosphor component diminishes at an uneven rate. The result is a ghost image on the screen, which is known as image burning.

Plasma displays use plasma, a gaseous substance containing free-flowing ions. When the plasma is not in use, the particles in the plasma are uncharged and display nothing. With the introduction of an electric current, the ions become charged and begin colliding, releasing photons of light.

This is a very simplified version of how a plasma screen works. However, the main thing to understand is that plasma screens use phosphor material (like CRTs) to turn those photons into images.

LCD and LED do not work in the same way as CRTs, either. LCD and LED screens use backlit liquid crystals to display colors. Although manufacturers market screens using LED and LCD, an LED screen is still a type of LCD. The white backlight filters through the liquid crystals, which extract particular colors per pixel.

LCD and LED displays don"t suffer from the same type of image burn as CRTs and plasma screens. They"re not completely clear, though. LCD and LED screens suffer from image persistence. Read on to find out more about image persistence.

Before you can fix screen burn-in, take a second to understand why these images burn in the first place. LCDs and LEDs don"t suffer from burn-in as seriously as plasma screens. But static images can leave an imprint on both display types if left alone for too long. So, why does image burn happen?

First, let"s tackle plasma screen burn-in. Remember why CRTs experience image burn? When a still image remains on the screen for too long, the phosphor components in each pixel wear out at different rates. The uneven burn rates leave behind a ghost image, forever etched into the screen.

Plasma screens also suffer from phosphor deterioration. Plasma burning occurs when pixels on the screen are damaged through long exposure. The phosphor loses its intensity and only shows the light it was fed repeatedly. In this case, the still image, which causes the burn.

LCD and LED screens can also experience image burn, though the image burn process can take longer to develop into a permanent issue. In addition, LCD and LED screens suffer from another issue, known as image retention (also known as image persistence or an LCD shadow).

Image retention is a temporary issue that you are more likely to notice before it becomes a permanent issue. However, proper image burn can still affect LCD, LED, and OLED screens.

Image retention is a different issue from image burn (although it is a precursor to image burn). For example, you"re using an image of a steam train as a reference point for a drawing. You have the steam train image on your screen for a few hours before you decide to play a video game instead.

When you load up the video game on the screen, you can still see the faint outline of the steam train on the screen. The steam train image will remain for a short while, but the movement and color changes of the video game (or film, TV show, or other media type) should erase the retained image.

The other thing to consider is that LED and OLED image burn-in, when it happens, is irreversible. That"s because of how LED and OLED screens work. Individual pixels within an LED display decay when they emit light.

Under normal use, an LED, OLED, or QLED screen won"t suffer image burn. However, if you leave your screen on a single channel for hours every day, then burn-in can become an issue, as it would with almost any screen.

Issues arise when a screen shows a single news channel 24 hours a day, every day, causing channel logos to burn-in, along with the outline of the scrolling news ticker and so on. News channels are a well-known source of television burn-in, no matter the screen type.

Image burn-in fixes exist for LCD and plasma screens. How effective an image burn-in fix is depends on the screen damage. Depending on the length and severity of the image burn, some displays may have permanent damage.

The best fix for screen burn is to prevent it in the first place. Okay, that isn"t super useful if your screen is already experiencing image burn. However, you should always try not to leave your screen on a still image for too long. The time it takes for an image to burn-in varies from screen to screen, between manufacturers, sizes, and panel type.

My personal rule of thumb is to turn off the display if I plan on being away for more than 15 minutes. That way, it is difficult to get caught out, plus you save yourself money on electricity costs and monitor or TV wear and tear.

Another prevention method is to reduce screen contrast as much as you can. Unfortunately, most screens aren"t calibrated correctly, often pushing the contrast and brightness settings too high.

Lower contrast means the lighting across your screen is more even. This means less strain on specific areas of the screen, which helps protect against image burning.

If your plasma or LCD screen already has image burn-in, you can try turning on white static for 12 to 24 hours. The constant moving of white-and-black across your screen in random patterns can help remove the ghost image from your screen.

Unfortunately, this won"t work for extreme cases. Some TVs will have a built-in pattern swiping option that basically accomplishes the same thing (filling your screen with random patterns).

Pixel-shift constantly slightly adjusts the image on your screen, which varies the pixel usage to counteract image burn. You might have to enable a pixel or screen shift option in your screen settings. Pixel-shift is a handy feature for LED and OLED screens that cannot recover from image burn and should help counteract an LCD shadow.

Other modern screens feature built-in screen refresh functions that the manufacturer will advise using to remove image retention and image burn issues.

The best tool for fixing ghost images is JScreenFix. The original program helps fix monitors with dead pixels, but the same company also released an "advanced" version of the tool, known as JScreenFix Deluxe.

While the Deluxe version uses advanced algorithms to repair burned screens and prolong plasma and LCD longevity, the official site is no longer up and running, and there is no way to download the full version officially.

You can find the free version of the Deluxe app online, but it is limited to 20 minutes running at a time. Furthermore, we"re not going to link out to the versions you can find online as we cannot verify the security of these installations. If you do use the Deluxe version, you do so at your own risk.

Another option is to set a completely white desktop background and leaving to run for a few hours. The solid color might reset the image burn. A solid color background is more likely to help with image persistence than image burn, but it is still worth trying.

If you have television burn-in, you can attach a laptop to your TV using an HDMI cable, extend your desktop to the television, and share the white screensaver. Hopefully, that will shift your television burn-in.

The team over at ScreenBurnFixer offers a few different ways you can attempt to fix screen burn on your TV or monitor. As with any other screen burn-in fixes, their chance of working depends on the scale of the issue.

You can head to the ScreenBurnFixer Video page and find a video that matches your screen type, then let the video play for as long as possible (we"re talking multiple hours, not a quick half an hour blast). Alternatively, head to the Chart page and find your device or a device that matches your specifications.

There are several ways you can attempt to fix screen burn-in. The results will vary between the screen type and the level of burn-in. A screen with extensive image burn may not clear entirely, although you might see an improvement.

Some screen degradation over time is understandable. However, if you follow the steps in this guide, you"ll protect your screen from image burn before it becomes a permanent issue.

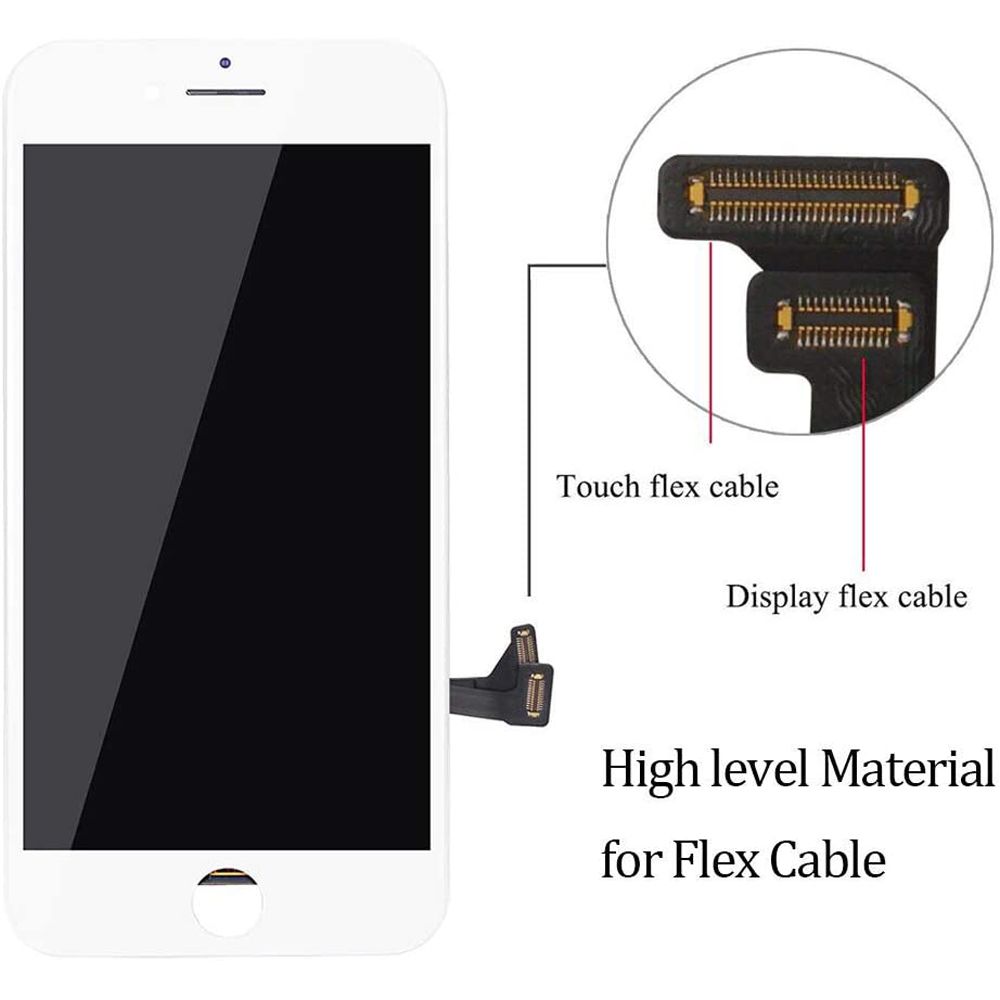

However, if the digitizer or LCD is also damaged during a fall, that screen no longer carries value because it cannot be refurbished. Repair shops cannot sell broken LCDs to refurbishing companies; therefore, they cannot offset the cost of an LCD repair. That is why repair stores often charge a little extra if there is damage to the LCD or digitizer, to make up for that loss. Repair stores that don’t have an additional charge for an LCD repair typically inflate their glass repair price to make up for the loss from damaged LCDs. If they have one price, that means everyone is paying more to cover the cost of customers who have damaged LCDs and customers who only have cracked glass. This is why TCR separates the price of glass and LCD repairs for you! If you only have cracked glass, you only have to worry about paying to replace the cracked glass.

If your phone or tablet’s glass is shattered there will be cracks or chips on the screen itself. If it is just the glass that is damaged, the device may still function and you may be able to use it normally. If this is the case, it is likely that only the glass needs to be replaced. To prevent further damage to your device it is best to get it repaired quickly. For example, if liquids seep through the cracks it could cause permanent damage to the LCD.

Many people may continue to use their touchscreen with shattered glass and delay fixing the glass on their devices; however, if the touchscreen isn’t responsive, it could be a sign of more significant damage to the device’s digitizer which is integrated with the LCD screen.

A pixelated screen can indicate LCD damage. This would look like a patch of multicolored dots, a line or lines of discoloration, or a screen with rainbow colors. For many people, these colors are an easy way to know that their LCD is broken and that they should get it repaired.

Dropping your phone isn’t the only reason you’ll end up with a pixelated screen. Over time, your screen’s LCD may break down through regular use. This happens to other devices aside from your smartphone or tablet. Pixelation can happen to TVs and computers, too. People typically decide to buy a new device when this happens. Fortunately, with an LCD repair, you can fix the device without needing to replace it.

A black screen or black spots on your smartphone or tablet is an indication of a damaged LCD. Often with a bad LCD, a phone may still turn on and make noises, but there is no clear picture. This does not necessarily mean any other part of the phone is damaged and a simple screen replacement will get it functioning again. Sometimes it can mean a battery or other internal component is damaged. It is best to have a highly qualified phone repair technician diagnose what is wrong so the appropriate repair can be made.

Fortunately, your mobile device is fixable whether you cracked the glass or damaged the LCD. Stop by or call TCR: Triangle Cellular Repair at (919) 263-2699 for a free diagnostic and quick, affordable cell phone repair in Chapel Hill and surrounding areas. We’re always happy to help!

TFT LCD image retention we also call it "Burn-in". In CRT displays, this caused the phosphorus to be worn and the patterns to be burnt in to the display. But the term "burn in" is a bit misleading in LCD screen. There is no actual burning or heat involved. When you meet TFT LCD burn in problem, how do you solve it?

Burn in is a noticeable discoloration of ghosting of a previous image on a display. It is caused by the continuons drive of certain pixels more than other pixels. Do you know how does burn in happen?

When driving the TFT LCD display pixels Continously, the slightly unbalanced AC will attract free ions to the pixels internal surface. Those ions act like an addition DC with the AC driving voltage.

Those burn-in fixers, screen fixer software may help. Once the Image Retention happened on a TFT, it may easy to appear again. So we need to take preventive actions to avoid burn in reappearing.

For normal white TFT LCD, white area presenting minimal drive, black area presenting maximum drive. Free ions inside the TFT may are attracted towards the black area (maximum drive area)

When the display content changed to full screen of 128(50%) gray color, all the area are driving at the same level. Those ions are free again after a short time;

Bought a new smartphone or want to check on the old smartphone matrix display? In this program you can test your LCD screen for the presence of dead / broken pixels and repair it. You can detect any stuck or dead pixel on your LCD screen.

If you detect any stuck or dead pixels you will be able to try to cure them. Provide easy way to fix the stuck pixel. The program will try to use different means for the treatment of stuck pixels. Also works for screen burn-in. Start and wait on the smartphone or tablet this app until the dead pixel or stuck pixel has been repaired or unstuck.

Dead pixel is stuck point or several points of the matrix screen, which does not properly reflect the color. Sometimes they are almost invisible, and you can be the owner of them without even noticing it. There are several treatments for dead pixels screen. Mechanical - physical impact directly on the affected area and a soft-that and it has me. We strongly recommend not to use the first method is for advanced users, as it is dangerous for the screen matrix.

The program can repair: Partial sub-pixel defects, Stuck sub-pixels, Dead or Broken (bad) pixels, Stuck versus dead pixels, Dark dot defects, Bright dot defects, phantoms (matrix burnup).

If within a few hours of program works the pixels is not revived, so they can not be brought back to life in this way - contact the service center. Fix your screen with this programm.

Many Apple products use liquid crystal displays (LCD). LCD technology uses rows and columns of addressable points (pixels) that render text and images on the screen. Each pixel has three separate subpixels—red, green and blue—that allow an image to render in full color. Each subpixel has a corresponding transistor responsible for turning that subpixel on and off.

Depending on the display size, there can be thousands or millions of subpixels on the LCD panel. For example, the LCD panel used in the iMac (Retina 5K, 27-inch, 2019) has a display resolution of 5120 x 2880, which means there are over 14.7 million pixels. Each pixel is made up of a red, a green, and a blue subpixel, resulting in over 44 million individual picture elements on the 27-inch display. Occasionally, a transistor may not work perfectly, which results in the affected subpixel remaining off (dark) or on (bright). With the millions of subpixels on a display, it is possible to have a low number of such transistors on an LCD. In some cases a small piece of dust or other foreign material may appear to be a pixel anomaly. Apple strives to use the highest quality LCD panels in its products, however pixel anomalies can occur in a small percentage of panels.

In many cases pixel anomalies are caused by a piece of foreign material that is trapped somewhere in the display or on the front surface of the glass panel. Foreign material is typically irregular in shape and is usually most noticeable when viewed against a white background. Foreign material that is on the front surface of the glass panel can be easily removed using a lint free cloth. Foreign material that is trapped within the screen must be removed by an Apple Authorized Service Provider or Apple Retail Store.

If you are concerned about pixel anomalies on your display, take your Apple product in for closer examination at an Apple Store, Apple Authorized Service Provider, or an Independent Repair Provider. There may be a charge for the evaluation. Genuine Apple parts are also available for out-of-warranty repairs through Self Service Repair.*

Apple has determined that a small percentage of iPhone 11 displays may stop responding to touch due to an issue with the display module. Affected devices were manufactured between November 2019 and May 2020.

If your iPhone 11 has been exhibiting this issue, please use the serial number checker below to see if your device is eligible for this program. If so, Apple or an Apple Authorized Service Provider will provide service, free of charge.

Choose one of the options below to have your iPhone 11 serviced. Your iPhone will be examined prior to any service to verify that it is eligible for this program.

If your iPhone 11 has any damage which impairs the ability to complete the repair, such as a cracked screen, that issue will need to be resolved prior to the service. In some cases, there may be a cost associated with the additional repair.

If you"re considering doing this, you have a 25+ year old Corvette. Vibrations, current flow, heat and time conspire to cause internal components to break down and solder joints to break. This manifests itself in the following ways:

Turn the key on. For the first few seconds, the lamp test should cause all segments on the cluster to be on. Make a note of any that are not on during the lamp test.

Set the DIC switch to Volts and make a note of the battery voltage. The testing procedures probably won"t be conclusive if the battery voltage is less than 11.5V.

25-40W Pencil Soldering Iron with pointed cone tip ($8.99 at Radio Shack - don"t use soldering guns or higher heat soldering irons! If tip of the iron isn"t clean, smooth and tinned, don"t use it - you"ll damage the circuit boards)

Sunlight causes the LCD polarizing filters to fade, which causes the information on the cluster to disappear. The LCD panels should appear black while the cluster is off. If you can see the colored info when the cluster is off, the polarizing film has faded and should be replaced. Click Here to buy.

Removing Solder: Use the solder wick to remove the solder which holds the old components in place. Place the wick over the solder to be removed and heat the top side of the wick. When it"s hot enough, the solder will flow from the connection to the wick. Use a fresh (copper-colored) piece of wick for each removal.

When soldering, heat the connector lead and the solder pad on the circuit board (simultaneously). Once these two locations are sufficiently heated, feed fresh solder into the joint.

Over time, heat, vibration and bad design cause the board connectors or their solder joints to fail. Not all look as bad as the one in Figure 1, but they almost always need to be replaced.

3) On the bottom circuit board (the one you took out last), remove the old connector using a soldering iron and desoldering braid or another desoldering method of your choice. When the solder has been removed and the connector is ready to be removed, you should be able to pull it away from the board by hand. Don"t use force to remove the connector, as the hole plating (which connects top traces to bottom traces) can be damaged! See Figure 2.

4) The connector will tend to warp when resoldered, which results in unevenly spaced pins. You can prevent this by temporarily installing the top board connector onto the pins of the bottom board connector.

6) Using a soldering iron and desoldering braid (or a desoldering method of your choice), remove the old white connector from the top board. When the solder has been removed and the connector is ready to be removed, you should be able to pull it away from the board by hand. Don"t use force to remove the connector, as the hole plating (which connects top traces to bottom traces) can be damaged!

12) Heat from the factory bulbs causes the riveted connection of the dimmer transistor to become loose over time. Scrape the sides of the heat sink tab (opposite end from the three leads) and then solder it to the large heat sink pad on the bottom board. See Figure 7.

13) Inspect the polarizing filters on the LCD panels. If you see a fade ring around the edges, consider replacing the polarizing filters on the LCD panels. Now is the time to do that repair. Click Here to purchase.

15) If the black paint on the back of the LCD panels has worn through, light will shine through the panel in areas other than the places it should. Use black enamel acrylic paint designed for glass and a small paint brush to repaint that area. Note that we supply the correct paint and a brush if you purchase our LCD Polarizing Film kit. Be careful to avoid areas near the factory graphics, and in the areas of the LCD segments!

If your cluster displays randomly flickering LCD segments along with intermittent backlighting, the onboard power supply (Fig 1) may need to be rebuilt. We sell a kit of parts to replace commonly needed components - Click Here

If your cluster is too dim during the day, or too bright in the evening or night, it may have a defective photocell. This is a low-cost part, and while the cluster is apart, it"s a great time to replace the photocell.

While the cluster is powered on, hold your hand over the photocell (top left corner). The cluster should dim noticeably. If not, the photocell may be defective. Consider replacing it with parts available here

You can also use a digital multimeter to check the photocell. Measure the resistance of the photocell (while it"s in-circuit is fine). It should measure <75k Ohms when exposed to room light, and > 1 Megaohm when dark. If it doesn"t, the dimmer functionality won"t work properly. Consider replacing it with parts available here

I"m looking for an enclosure for a project that will include one of the 2x8 character LCDs from seeedstudio and should have an IR panel and battery enclosure.

but accoring to the datasheet, the internal dimension is 60mm wide and according to seeedstudio, the LCD is 58mm wide. I"m worried I"ll have trouble fitting the LCD because it"s cutting too close, or in the best case the aesthetics will suffer because the display will be too far off center (it doesn"t look centered on its own PCB).

I"m working with a similar sized LCD but it"s going behind a panel rather than in a box. I am lucky that I can make my own cutout and fit the LCD into it. I"m not real sure how I"m going to protect the LCD though - it will be exposed to the elements.

Regardless of research or advice though I would suggest you get your hands on any remotely-possible container and trial fit your stuff. I never cease to be amazed at how different realitly is from my vague imaginings of what will fit.

oh, by the way, I have one of the Seeed modules in my hand and I would say the LCD face is pretty well centered on the board. It"s not EXACT but no more than a couple of mm further from the backlight end of the board than the connector end.

oh, also, I wasn"t able to get the Seeed module working myself. That doesn"t mean it won"t work for you but I moved on. If you do get it working I"d like to know.

Very good point about the difference between reality and a datasheet for an enclosure. For me to get the box I was linking too I"ll have to order it which means shipping fees and a nice long wait.

I have the seeedstudio LCD too. It was my original request that he stock them ;). I"m thinking a few mm off will look pretty crappy in the box though.

What trouble are you having getting it to work? It"s working for me, but I had to modify the time delays in the arduino liquidcystal library (the problem was with the library, not the display). I had a horribly frustrating time where it would work once in a while, but 95% of the time would never initialize.

I am having trouble with the 60mm red-green 8x8 matrix display though. I"ve only tested by directly connecting to the LEDs, through a resistor of course, and the brightness is very, very dim.

What trouble are you having getting it to work? It"s working for me, but I had to modify the time delays in the arduino liquidcystal library (the problem was with the library, not the display). I had a horribly frustrating time where it would work once in a while, but 95% of the time would never initialize.

I would get either blank or sometimes the black character boxes showing (I now know) that it was getting power. This was the first LCD module I bought and I had not yet learned about the liquidcrystal library so i was working just from the datasheet. The problem could have been my wiring or my code. I have it out now and I"ll try it again. What timing did you have to change?

In terms of centering, I just don"t believe I could detect the offset, maybe mine is not quite the same. How are you going to make the cutout for the LCD and attach it?

I have no idea how I"m going to cut the opening :). I was thinking of using a nibbler to make it a little on the small side and then adjusting with a file or a dremel with a grinding disc. Or just cutting it out with the dremel in the first place.

With respect to the cutout, dremeling or whatever is going to make a rough cut, at least in my hands. It would be really nice to be able to get an external bezel. The one already on there wouldn"t do for me though, I"d just have the rough edge outside it.

I decided to try mounting my prototype yesterday and found it doesn"t work anymore. There"s probably a short somewhere or a wire fell off. It semi-worked once of the 30-40 times I tested it. This hobby is frustrating at times. It was built on perf board with isolated holes, so it"s a big mess of spaghetti wiring so it"s probably easier to start again with a PCB now that I had the hardware working.

it looks better now since ive taped the sides but it was impossible to cut a perfect rectangle witha dremel, nor a box cutter, so i had to sand and sand, and, ofcourse, i over sanded and ended up with huge, awkward gaps between the sides of the lcd screen and the box...

it looks better now since ive taped the sides but it was impossible to cut a perfect rectangle witha dremel, nor a box cutter, so i had to sand and sand, and, ofcourse, i over sanded and ended up with huge, awkward gaps between the sides of the lcd screen and the box...

exactly what I"ve been worrying about. I foolishly expected there would be readily available plastic/chrome bezels that would fit neatly around stock-sized LCDs, no luck yet though.

One thing I"ve used is a shadow box. It"s like a picture frame but instead of holding a flat page it"s got an internal compartment to hold and display 3D objects. I paid around $10 at a crafts store for a 5x7 with about 2 inches inside. It came with a glass front and a felt-lined pressboard back. I made all the holes in the back board.

I got a couple of sample boxes like the one below from pactec. They have a wide variety on their web site. In this case the end is separate but probably too small for the LCD and the sides of the cases just leave you with the same issue of cutting your own hole and finishing it.

If you really want to get crafty, you can design your case out of acrylic sheets and get the parts laser-cut:SpikenzieLabs Mini Cut 5.5x5.5 - 1/8 Thick Acrylic [SPL-004001] - One 5.5 by 5.5 sheet of 1/8 thick acrylic, cut any way you like based on the drawing file that you upload. Upload your file and choose color from the list below.

Otherwise, a visit to Staples/Office/Business Depot is a good opportunity to pick some acrylic boxes, originally designed for different purposes (card holders, disk holders etc etc). And these are cheap.

Also, keep in mind that you can, relatively easy, bend your acrylic sheets. There are lots of articles on the internets on how to do this (basically heat up along the line you want to bend).

If waterproofing/dustproofing is not important, you can just sandwich your project (PCB, LCD etc) between 2 sheets of acrylic, with long screws and spacers.

That one looks good except for the lack of an IR panel. The data sheet for it though has no information on the size of the opening or the PCB dimensions. Also, my local supplier and digikey doesn"t stock it. Mouser seems to with a minimum order of 289 units. It also seems to be double the price of the hammond unit, though that"s not a problem (assuming it has all the hardware in the datasheet listed under different part numbers).

florinc: for now, custom making a box is beyond my ability. Knowing me, if I try I"ll never finish and it"ll just stop me from finishing any projects for a while. In grade 8 industrial arts, I got to play with a heat tool for bending it and it is fun to play with :).

I"m still surprised that there aren"t more readily available LCD mounting options. In my case I need something really weatherproof because I"m mounting on an exposed motorcycle surface but I haven"t see anything that would help finish off a project.

I think it is amazing that there isn"t already on the market a simpe palstic box with rectangular holes the size of the screens on LCD"s, which are all pretty standard.

As far as I can see there is a great market opportunity here for someone to manufacture these types of enclosures for the hobbyist electronics market.

Mike, I don"t think there is a single standard. I have three 16x2 LCD panels and all require different size cutouts. My 16x1 and 16x4 panels are different sizes again.

bill: There are some nice looking options there, though the ones with IR panels are a bit thinner which makes it harder to fit components. The main issue I seem to have is finding a source, I"m shocked that digi-key doesn"t seem to carry them. I have almost no local sources for electronics parts, but Hammond boxes seem to be one of the few things I can get locally.

For your weatherproof project, why not use florinc"s suggestion of a pelikan or otterbox? They"re expensive, but very weatherproof and available with clear tops for the display. For the interface if needed, you can rig up something IR so you don"t have to comprimise the weatherproofing.

Most of the manufacturers will do custom CNC routing or laser cutting for large orders, but that really doesn"t help the average hobbyist. You might be able to find a local machine shop to do the routing for you, or even get a router attachment for a Dremel tool, and build a small jig to get a clean hole.

Bill: You might be able to do something like the second example here http://www.sparkfun.com/commerce/static.php?name=custom_enclosure_design for yours. Maybe a short piece of 4" or 6" PVC pipe, and a couple of pieces of Lexan over the ends. Something larger than the hole in your gas tank cover.

I"ve seen the same need to provide enclosures for Arduino, and other DIY projects, and have started working on a couple of things. They are a few months off, so don"t really solve any problems now, but I"m trying to get a couple of manufacturers to work with me on a more modular enclosure design that would work better for the type of projects that Arduino, and other hobby projects seem to need.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

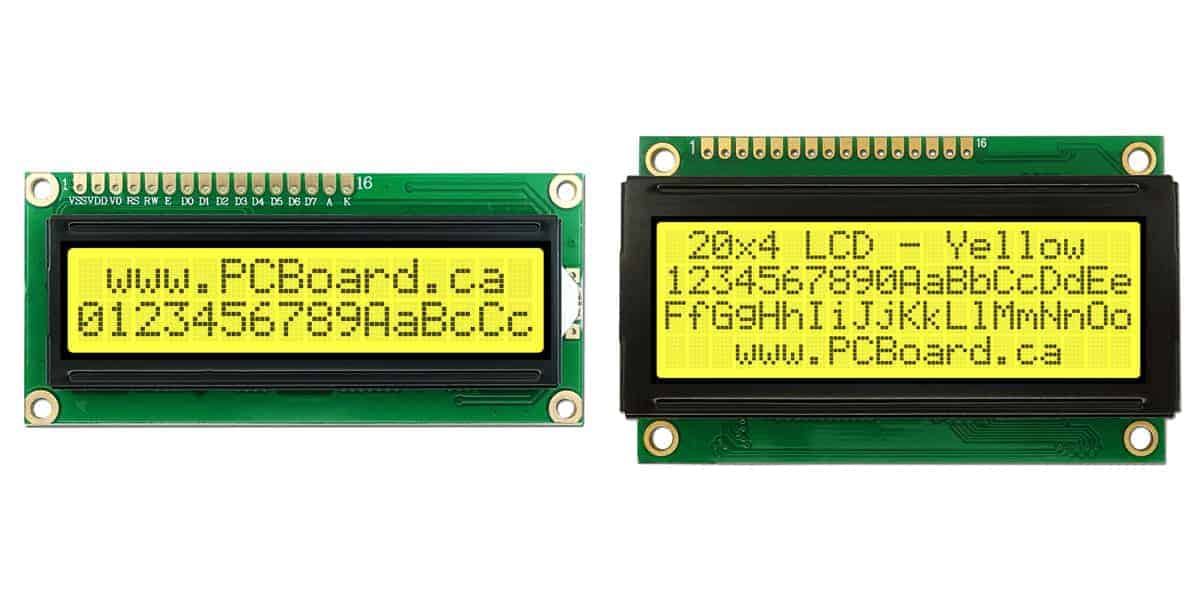

In this Arduino tutorial we will learn how to connect and use an LCD (Liquid Crystal Display)with Arduino. LCD displays like these are very popular and broadly used in many electronics projects because they are great for displaying simple information, like sensors data, while being very affordable.

You can watch the following video or read the written tutorial below. It includes everything you need to know about using an LCD character display with Arduino, such as, LCD pinout, wiring diagram and several example codes.

An LCD character display is a unique type of display that can only output individual ASCII characters with fixed size. Using these individual characters then we can form a text.

If we take a closer look at the display we can notice that there are small rectangular areas composed of 5×8 pixels grid. Each pixel can light up individually, and so we can generate characters within each grid.

The number of the rectangular areas define the size of the LCD. The most popular LCD is the 16×2 LCD, which has two rows with 16 rectangular areas or characters. Of course, there are other sizes like 16×1, 16×4, 20×4 and so on, but they all work on the same principle. Also, these LCDs can have different background and text color.

It has 16 pins and the first one from left to right is the Groundpin. The second pin is the VCCwhich we connect the 5 volts pin on the Arduino Board. Next is the Vo pin on which we can attach a potentiometer for controlling the contrast of the display.

Next, The RSpin or register select pin is used for selecting whether we will send commands or data to the LCD. For example if the RS pin is set on low state or zero volts, then we are sending commands to the LCD like: set the cursor to a specific location, clear the display, turn off the display and so on. And when RS pin is set on High state or 5 volts we are sending data or characters to the LCD.

Next comes the R/W pin which selects the mode whether we will read or write to the LCD. Here the write mode is obvious and it is used for writing or sending commands and data to the LCD. The read mode is used by the LCD itself when executing the program which we don’t have a need to discuss about it in this tutorial.

Next is the E pin which enables the writing to the registers, or the next 8 data pins from D0 to D7. So through this pins we are sending the 8 bits data when we are writing to the registers or for example if we want to see the latter uppercase A on the display we will send 0100 0001 to the registers according to the ASCII table. The last two pins A and K, or anode and cathode are for the LED back light.

After all we don’t have to worry much about how the LCD works, as the Liquid Crystal Library takes care for almost everything. From the Arduino’s official website you can find and see the functions of the library which enable easy use of the LCD. We can use the Library in 4 or 8 bit mode. In this tutorial we will use it in 4 bit mode, or we will just use 4 of the 8 data pins.

We will use just 6 digital input pins from the Arduino Board. The LCD’s registers from D4 to D7 will be connected to Arduino’s digital pins from 4 to 7. The Enable pin will be connected to pin number 2 and the RS pin will be connected to pin number 1. The R/W pin will be connected to Ground and theVo pin will be connected to the potentiometer middle pin.

We can adjust the contrast of the LCD by adjusting the voltage input at the Vo pin. We are using a potentiometer because in that way we can easily fine tune the contrast, by adjusting input voltage from 0 to 5V.

Yes, in case we don’t have a potentiometer, we can still adjust the LCD contrast by using a voltage divider made out of two resistors. Using the voltage divider we need to set the voltage value between 0 and 5V in order to get a good contrast on the display. I found that voltage of around 1V worked worked great for my LCD. I used 1K and 220 ohm resistor to get a good contrast.

There’s also another way of adjusting the LCD contrast, and that’s by supplying a PWM signal from the Arduino to the Vo pin of the LCD. We can connect the Vo pin to any Arduino PWM capable pin, and in the setup section, we can use the following line of code:

It will generate PWM signal at pin D11, with value of 100 out of 255, which translated into voltage from 0 to 5V, it will be around 2V input at the Vo LCD pin.

Here’s a simple code through which we can explain the working principle of the Liquid Crystal library. This is the code of the first example from the video:

First thing we need to do is it insert the Liquid Crystal Library. We can do that like this: Sketch > Include Library > Liquid Crystal. Then we have to create an LC object. The parameters of this object should be the numbers of the Digital Input pins of the Arduino Board respectively to the LCD’s pins as follow: (RS, Enable, D4, D5, D6, D7). In the setup we have to initialize the interface to the LCD and specify the dimensions of the display using the begin()function.

The cursor() function is used for displaying underscore cursor and the noCursor() function for turning off. Using the clear() function we can clear the LCD screen.

In case we have a text with length greater than 16 characters, we can scroll the text using the scrollDisplayLeft() orscrollDisplayRight() function from the LiquidCrystal library.

We can choose whether the text will scroll left or right, using the scrollDisplayLeft() orscrollDisplayRight() functions. With the delay() function we can set the scrolling speed.

The first parameter in this function is a number between 0 and 7, or we have to reserve one of the 8 supported custom characters. The second parameter is the name of the array of bytes.

So, we have covered pretty much everything we need to know about using an LCD with Arduino. These LCD Character displays are really handy for displaying information for many electronics project. In the examples above I used 16×2 LCD, but the same working principle applies for any other size of these character displays.

I hope you enjoyed this tutorial and learned something new. Feel free to ask any question in the comments section below and don’t forget to check out my full collection of 30+ Arduino Projects.

The Arduino family of devices is features rich and offers many capabilities. The ability to interface to external devices readily is very enticing, although the Arduino has a limited number of input/output options. Adding an external display would typically require several of the limited I/O pins. Using an I2C interface, only two connections for an LCD character display are possible with stunning professional results. We offer both a 4 x 20 LCD.

The character LCD is ideal for displaying text and numbers and special characters. LCDs incorporate a small add-on circuit (backpack) mounted on the back of the LCD module. The module features a controller chip handling I2C communications and an adjustable potentiometer for changing the intensity of the LED backlight. An I2C LCD advantage is that wiring is straightforward, requiring only two data pins to control the LCD.

A standard LCD requires over ten connections, which can be a problem if your Arduino does not have many GPIO pins available. If you happen to have an LCD without an I2C interface incorporated into the design, these can be easily

The LCD displays each character through a matrix grid of 5×8 pixels. These pixels can display standard text, numbers, or special characters and can also be programmed to display custom characters easily.

Connecting the Arduino UNO to the I2C interface of the LCD requires only four connections. The connections include two for power and two for data. The chart below shows the connections needed.

The I2C LCD interface is compatible across much of the Arduino family. The pin functions remain the same, but the labeling of those pins might be different.

Located on the back of the LCD screen is the I2C interface board, and on the interface is an adjustable potentiometer. This adjustment is made with a small screwdriver. You will adjust the potentiometer until a series of rectangles appear – this will allow you to see your programming results.

The Arduino module and editor do not know how to communicate with the I2C interface on the LCD. The parameter to enable the Arduino to send commands to the LCD are in separately downloaded LiquidCrystal_I2C library.

The LiquidCrystal_I2C is available from GitHub. When visiting the GitHub page, select the Code button and from the drop-down menu, choose Download ZIP option to save the file to a convenient location on your workstation.

Before installing LiquidCrystal_I2C, remove any other libraries that may reside in the Arduino IDE with the same LiquidCrystal_I2C name. Doing this will ensure that only the known good library is in use. LiquidCrystal_I2C works in combination with the preinstalled Wire.h library in the Arduino editor.

To install the LiquidCrystal_I2C library, use the SketchSketch > Include Library > Add .ZIP Library…from the Arduino IDE (see example). Point to the LiquidCrystal_I2C-master.zip which you previously downloaded and the Library will be installed and set up for use.

Several examples and code are included in the Library installation, which can provide some reference and programming examples. You can use these example sketches as a basis for developing your own code for the LCD display module.

There may be situations where you should uninstall the Arduino IDE. The reason for this could be due to Library conflicts or other configuration issues. There are a few simple steps to uninstalling the IDE.

The I2c address can be changed by shorting the address solder pads on the I2C module. You will need to know the actual address of the LCD before you can start using it.

Once you have the LCD connected and have determined the I2C address, you can proceed to write code to display on the screen. The code segment below is a complete sketch ready for downloading to your Arduino.

The code assumes the I2C address of the LCD screen is at 0x27 and can be adjusted on the LiquidCrystal_I2C lcd = LiquidCrystal_I2C(0x27,16,2); as required.

Similar to the cursor() function, this will create a block-style cursor. Displayed at the position of the next character to be printed and displays as a blinking rectangle.

This function turns off any characters displayed to the LCD. The text will not be cleared from the LCD memory; rather, it is turned off. The LCD will show the screen again when display() is executed.

After 40 spaces, the function will loop back to the first character. With this function in the loop part of your sketch, you can build a scrolling text function.

Scrolling text if you want to print more than 16 or 20 characters in one line then the scrolling text function is convenient. First, the substring with the maximum of characters per line is printed, moving the start column from right to left on the LCD screen. Then the first character is dropped, and the next character is displayed to the substring. This process repeats until the full string has been displayed on the screen.

The LCD driver backpack has an exciting additional feature allowing you to create custom characters (glyph) for use on the screen. Your custom characters work with both the 16×2 and 20×4 LCD units.

A custom character allows you to display any pattern of dots on a 5×8 matrix which makes up each character. You have full control of the design to be displayed.

To aid in creating your custom characters, there are a number of useful tools available on Internet. Here is a LCD Custom Character Generator which we have used.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey