tft lcd pcb connection fpc factory

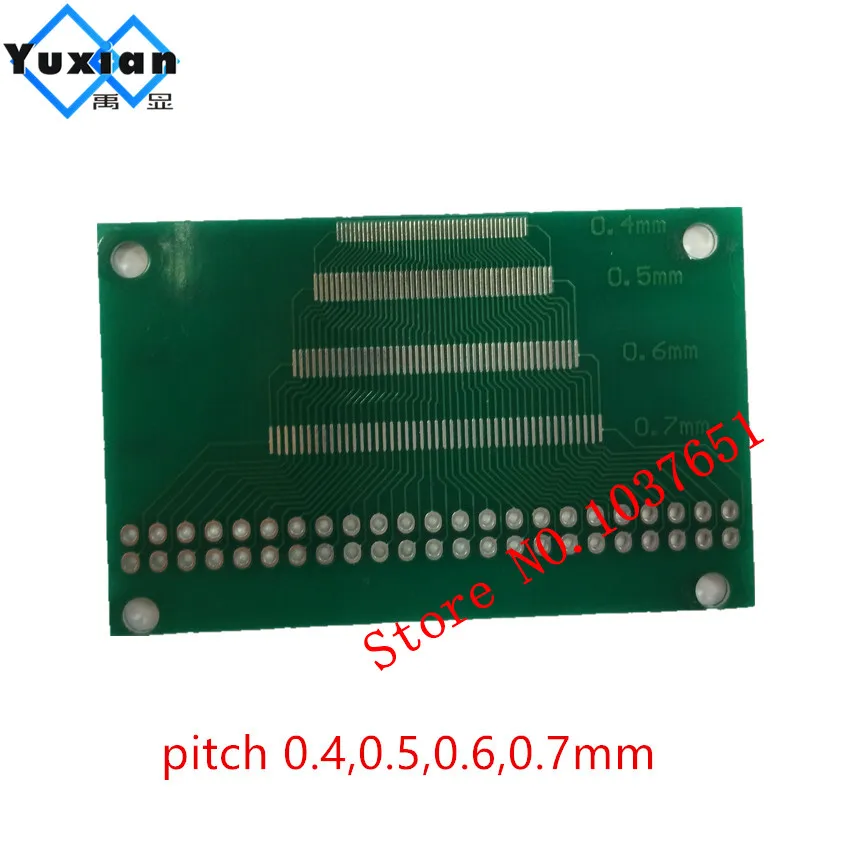

FPCs are typically used with a ZIF connector to connect to a PCB. When looking for a compatible ZIF connector for a given FPC, it is important to consider the pitch (spacing of the pins), the number of pins, whether the connector has contacts on the top, bottom, or both, and the material of the connectors on the FPC and the ZIF connector.

The modern technological lcd fpc units on Alibaba.com have high-density integration. These products have a high-quality output with robust yet flexible for easy folding. The diverse layering of circuits allows for more power and efficient working. The electronic gadgets have several contact pins for better connectivity. The large storage lcd fpc are suitable for multiple electronic items such as telecommunication and children"s toys.

Technologically advanced lcd fpc units have small-sized platforms, and that saves space for other items. Efficiency helps the users to save money on human resource hiring since the work can be done electronically. These products are durable and easy to handle with simple guidance from professionals. The high adaptability of terminal pins makes signals flow freely. With better connectivity, the users will enjoy the high-frequency performance from their electronics.

When looking for efficient lcd fpc units on Alibaba.com, users must check on what board size and thickness are compatible with the gadgets in question. The copper thickness should also be ideal. The layering type dictates where and how the connections will be. The integrated capacity is essential for any free flow of transmission frequencies. Soldering patterns and surface finishing show good work and better connectivity.

Better working capacities allow for better results. The connecting electronic gadgets have better construction designs for durability. The verified suppliers and comprehensive catalogs enhance trust and transparency in the market. Competitive lcd fpc make the purchasing journey enjoyable. Find the products on Alibaba.com for significant experiences.

The modern technological shenzhen lcd fpc units on Alibaba.com have high-density integration. These products have a high-quality output with robust yet flexible for easy folding. The diverse layering of circuits allows for more power and efficient working. The electronic gadgets have several contact pins for better connectivity. The large storage shenzhen lcd fpc are suitable for multiple electronic items such as telecommunication and children"s toys.

Technologically advanced shenzhen lcd fpc units have small-sized platforms, and that saves space for other items. Efficiency helps the users to save money on human resource hiring since the work can be done electronically. These products are durable and easy to handle with simple guidance from professionals. The high adaptability of terminal pins makes signals flow freely. With better connectivity, the users will enjoy the high-frequency performance from their electronics.

When looking for efficient shenzhen lcd fpc units on Alibaba.com, users must check on what board size and thickness are compatible with the gadgets in question. The copper thickness should also be ideal. The layering type dictates where and how the connections will be. The integrated capacity is essential for any free flow of transmission frequencies. Soldering patterns and surface finishing show good work and better connectivity.

Better working capacities allow for better results. The connecting electronic gadgets have better construction designs for durability. The verified suppliers and comprehensive catalogs enhance trust and transparency in the market. Competitive shenzhen lcd fpc make the purchasing journey enjoyable. Find the products on Alibaba.com for significant experiences.

TFT-LCD technology is based on semiconductor IC manufacturing processes, and is unique in that it uses glass substrates rather than traditional silicon wafers. For the TFT manufacturing process, thin film formation, such as CVD and PVD processes, is a very important part. The ODF process has been developed for the assembly of color filters and TFT substrates, and is used in large size LCDs.

First of all, the movement and arrangement of liquid crystal molecules need electrons to drive, so in the carrier of liquid crystal – TFT glass, there must be able to conduct the part to control the movement of liquid crystal, here will use ITO (Indium TIn Oxide, transparent conductive metal) to do this thing. ITO is transparent, also known as thin film conductive crystal so that it will not block the backlight.

The different arrangement of liquid crystal molecules and the rapid movement changes to ensure that each pixel accurately display the corresponding color, and the image changes precisely and quickly, which requires precision control of the liquid crystal molecules. ITO film requires special processing, as if printed circuitry on a PCB board, drawing conductive lines throughout the LCD board.

For array panels with back-channel etched TFT structure.The main process can be divided into 5 steps (5 lightings) according to the sequence of the layers to be made and the interrelationship between the layers.

The process includes: PECVD triple layer continuous film formation, island lithography, island dry lithography and other processes. After these processes, the final amorphous silicon island for TFT is formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

Specific processes include: S/D metal layer sputtering into a film, S/D lithography, S/D wet lithography, channel dry lithography and other processes. After these processes, the source, drain, channel and data lines of the TFT are finally formed on the glass substrate. At this point, the TFT has been produced. The graphics obtained after the process is completed are shown in the following figure.

The process includes PECVD, photolithography, and dry lithography of vias. After these processes, the final TFT channel protective insulation layer and guide through the hole are formed on the glass substrate. The graphics obtained after the process is completed are shown in the following figure.

Color filters can be produced by various methods; photolithography is a typical method. In photolithography, color filters are produced by exposing a glass substrate coated with a photographic color resist through a photomask. The resist is hardened to form the RGB pattern of the LCD.

When making LCD panels it is impossible to produce them one by one, which is too inefficient, so multiple pieces are processed at once and separated by cutting.

After that is bonding IC and FPC; assembling backlight module, the whole machine shell and other processes, relative to the front of the high-precision process to be simpler.

COG (Chip on Glass) and FPC (Flexible Printed Circuit) is a circuit connection method. Due to the many electrodes, one-to-one lining connection is very difficult. Nowadays, the common practice is to make an array of leads on the glass and a corresponding array of leads on the IC/FPC, and to connect the electrodes on the IC/FPC to the electrodes on the glass one-to-one through an anisotropic conductive film (ACF). The schematic diagram of the lead electrode array on the glass is as follows.

In addition to the above main process, there are some auxiliary processes in the module section, such as: laser cutting, electrical testing after cutting, electrical testing after bonding, electrical testing after assembly, microscopic inspection after cutting, microscopic inspection or automatic optical inspection after binding, shear force peel test after IC bonding, tensile peel test after FPC bonding, electrical aging after assembly, packaging and shipping, etc.

Let’s face it, full-colour TFT displays are cool and adding one to your project is going to instantly endow your project with coolness. The problem for the hobbyist is that they come with flexible flat connectors known as FPC or FFC connectors. These are designed to be soldered to a PCB using a ‘hot-bar’ device that is pressed across all the terminals at once, instantly soldering them to the board. Nice if you’ve got one.

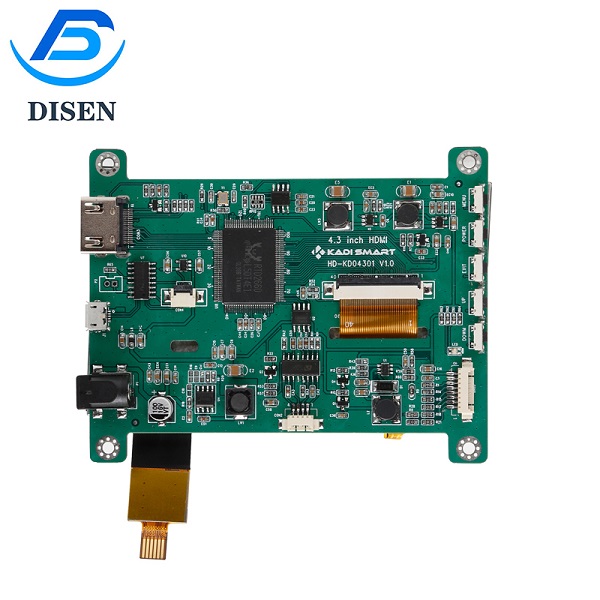

Help is at hand. There are many suppliers on ebay that will sell you a small TFT already mated to a PCB with the FPC connector broken out into a 2.54mm DIP header. If these satisfy your needs then buy them, you’ll be saving yourself a whole lot of work.

But what if the panel you want only comes ‘naked’, or perhaps you want to drive the signals directly as you’ll have to do if you want to stream video to it. If you fall into these categories then you are going to have to tackle the FPC connector yourself, and I’m going to show you how.

The breakout board is suitable for many different FPC pin pitches. By holding the FPC connector up against the board I can see that mine has a 0.8mm pitch and 37 terminals. As a bonus I can see that each terminal has a very small hole punched in it. This hole is designed to allow solder to flow up from underneath, making a better connection.

We are going to use a reflow technique to solder this connector. The idea is that we lay down solder on to the board pads and then reflow it to create the connection. I was surprised how easy this was.

Now is a great time to solder the DIP header into place because you’re not going to be able to get to it easily after the FPC connector has been soldered down.

Before starting on the FPC connector make sure you paste a thin layer of flux over the tinned board connectors. This will help the solder to reflow smoothly over the FPC terminals.

Working under the microscope or magnifier, carefully align the FPC connector with the tinned pads ensuring that it’s straight and that each terminal is completely overlapping the pad. Don’t overlap the pad more than the terminal length because there may be some traces further back on the connector that could cause a short circuit. Hold it down like that with one of your hands.

My advice is, for the prototype, work with another display. If it really comes to a commercial product, and the cost of the display becomes an issue, then start looking at solutions for integrating lower cost displays in discussion with the PCB manufacturer (who may also populate boards).

Adjust the length, position, and pinout of your cables or add additional connectors. Get a cable solution that’s precisely designed to make your connections streamlined and secure.

Choose from a wide selection of changes including shape, size, pinout, and component layout of your PCB to make it a perfect fit for your application.

This 5" LCD is a 800x480 high resolution IPS TFT display. The IPS technology delivers sunlight readable image quality with higher brightness, better color reproduction, image consistency and optical characteristics at any angle. This 24-bit true color Liquid Crystal Display with parallel RGB interface, includes better FPC design with EMI shielding on the cable. It also has a built-in ST7262 IC driver and offers the same mechanical footprint and pinout as the TN display. This TFT is RoHS compliant and does not come with a touchscreen.

Adjust the length, position, and pinout of your cables or add additional connectors. Get a cable solution that’s precisely designed to make your connections streamlined and secure.

eDP (embedded DisplayPort) cables are beginning to supersede LVDS as the cable assembly of choice for connecting driver boards to TFT displays. They use the same digital signal processing protocol as DisplayPort cables, but in a smaller physical connector.

Often manufactured from micro-coax cable, eDP cable assemblies require fewer connections than LVDS. They also offer all power, data and control signals through one single assembly. Where LVDS assemblies could require 18 signal wires, a comparative eDP cable would use only five.

Mechanical drawing of my EPD ePaper display GDE021A1 is shown below. Signals to the display are connected via a 24-pin flex flat cable. The pitch between pins is only 0.5mm. A suitable matching connector is MOLEX 52435-2471 FPC RCPT 24PIN 1ROW.

As the second attempt I designed a small prototyping PCB board to hold the 24-pin MOLEX FPC (0.5mm) connector for EPD display and a standard 24-pin header (2.54mm pitch). The PCB connects all MOLEX signals to the header. The board also includes all capacitors, a power transistor, a coil and diodes for switching/mode power supply to power the display. The circuit is copied from the display’s datasheet.

On Friday I sent the PCB to OSH Park for manufacture. As this is my first order in that company I am quite interested how it will turn out. I hope to get the board in about a week or two.

The present application claims priority to U.S. Provisional Application No. 62/613,717 filed Jan. 4, 2018, entitled “Chip in Glass for LCD Display (LCDCiG)” and U.S. Provisional Application No. 62/626,437 filed Feb. 5, 2018, entitled “Chip in Glass for LCD Display (LCDCiG) which are incorporated herein by reference in their entirety. FIELD OF THE INVENTION

Many different types of electronic devices include an electronic visual display that can provide visual information to a user. For example, a liquid-crystal display (LCD) is a widely used type of display that can be found is a wide range of electronic devices, including digital cameras, watches, calculators, and mobile telephones, including smartphones. An LCD is a flat-panel display that is often a desirable display option for several reasons, which may include that LCDs are relatively thin, light-weight, and efficient in terms of power consumption. In addition, the LCDs are known to have high resolution, high color display, and high definition.

The LCD in most electronic devices is part of an LCD module that has an LCD panel and a built-in driving circuit unit. The LCD panel typically includes a thin-film transistor (TFT) array substrate, a color filter substrate, a liquid crystal layer located between the TFT array substrate and the color filter substrate, and a backlight assembly disposed under the LCD panel to serve as a light source. The driving circuit unit typically includes an LCD Driver Integrated Circuit (driver IC) disposed at an outer ring of the LCD panel to drive the LCD panel. The LCD panel includes pixels in a matrix shape between two glass substrates (the TFT array substrate and the color filter substrate mentioned above) with a switching device for controlling signals respectively supplied to the pixels, like a thin-film transistor. An array of pixels is disposed between the two glass substrates in a matrix pattern on the TFT array substrate. A switching element, such as a TFT, is provided for each pixel for controlling drive signals to the respective pixel.

The driving circuit unit includes the above-mentioned driver IC, as well as a printed circuit board (PCB) on which driving circuits are provided for generating various signals for driving the LCD panel, such as control signals, clock signals, and data signals. The driver IC is connected to the LCD panel and the PCB to apply a signal to the TFTs, storage capacitors, pixel electrodes, and interconnect wiring of the LCD panel. The interconnect wiring includes gate bus-lines and data bus-lines arranged so that each pixel is individually addressable by the driving circuit unit. The driver IC includes a set of bonding pads with each bonding pad including a metal bump. The surface to which the driver IC is to be mounted is provided with a matching set of pads. The driver IC is mounted on the surface by bonding the set of bonding pads to the matching set of pads.

Chip On Glass (COG) and Chip On Film (COF) are two common methods for mounting a driver IC and connecting it to control an LCD panel. COG is a flip-chip bonding technology where the driver IC is mounted to a non-display region of the LCD panel"s array substrate using Anisotropic Conductive Film (ACF). COF is also a flip-chip bonding technology, but the driver IC is mounted to a flexible printed circuit board (FPC), which in turn is mounted to a non-display region of the LCD panel"s array substrate. This is undesirable because it results in LCD modules and LCD panels that have an overall footprint that is larger than that the actual display and dead edge regions that get covered for aesthetic reasons in the final product (e.g., smartphone or tablet computer).

FIGS. 1 and 2 illustrate an example of the non-display region caused by installation of a driver IC using a COG arrangement. FIG. 1 shows a perspective view of a display module 100, which illustrates an example of COG technology. The display module 100 includes an LCD panel 102, a driver region 104, and an FPC 106.

The LCD panel 102 is a multi-layer assembly that includes a stacked pair of transparent (with light transmissivity) glass substrates—an array substrate 108 and a filter substrate 110—that are separated by a liquid crystal layer (not shown). The liquid crystal layer contains liquid crystal molecules, which are substances that change optical characteristics when an electromagnetic field is applied. The manufacturing process includes injecting liquid crystal into a gap between the TFT array substrate 108 and the color filter substrate 110, thereby producing the LCD panel 102.

The array and filter substrates each include an aligned array of transparent electrodes that can apply electromagnetic fields to control the optical characteristics of a small respective area of liquid crystal material between the electrodes. Each electrode on the array substrate is associated with a respective transistor, for example a thin field transistor (TFT). The strength of the electromagnetic field between a pair of array substrate and filter substrate electrodes depends on the state of the respective TFT, which in turn depends on drive signals sent from the driver region 104. The filter substrate 110 is also a color filter substrate 110 in that it includes a respective color filter (not shown) for each pixel to add color to the displayed image.

The driver region 104 is a region of the LCD module 100 that provides a mounting location for a driver IC 112 (shown in FIG. 2). The driver IC 112 is an LSI chip including a driver circuit therein. The driver IC 112 is configured to operate based on signals (e.g., image data) from a remote signal source (not shown). The remote signal source can vary depending on the application. The driver IC 112 is configured to generate output drive signals from the input image signals, and to send the output drive signals to the display area of the liquid crystal panel 102. The driver 102 is directly mounted on the array substrate 108 of the liquid crystal panel 102 in a non-display area, that is, through a chip on glass (COG) mount method.

FIG. 2 shows a partial side view of the portion of the display module 100 near the driver IC 112. The driver IC 112 is a source driving integrated circuit package mounted on data lines. The driver IC 112 receives image signals via the image signal input bumps 114, converts the received image signals into corresponding drive signals (e.g., voltage or current signal), and transmits the drive signals to the LCD panel 102 via the driving signal output bumps 116.

The image signal input bumps 114 are connected to conductive patterns 118, which are in turn connected to the FPC 106 via an anisotropic conductive film (ACF) 120. The driving signal output bumps 116 are connected to data lines 122 via the anisotropic conductive film 120. The TFT array substrate 108 supports the conductive patterns 120 and data lines 122, as shown.

Thus, while the use of the display module 100 provides the convenience of an LCD panel 102 with an integrated driver IC 112, this technology still has several drawbacks that leave room for improvements. The technology involves several complicated and expensive types of connections and component mounting techniques, and the driver region of the array substrate creates dead space that prevents use of the entire display-module footprint as actual display area.

It would therefore be desirable to improve on prior LCD packaging technologies to reduce cost and dead space for the display. The present disclosure provides novel packaging technologies that include such desired improvements. BRIEF SUMMARY

According to some aspects of the present disclosure, a display module comprises a liquid crystal display (LCD) panel, which includes a thin-film transistor (TFT) array substrate having a liquid crystal layer side thereof opposite to a back-surface side thereof, wherein the TFT array substrate includes a plurality of pixels provided on the liquid crystal layer side thereof, wherein the TFT array substrate defines a driver cavity extending into the back-surface side thereof towards the liquid crystal layer side thereof to a cavity bottom, a color filter substrate facing the liquid crystal layer side of the TFT array substrate; and a liquid crystal layer disposed between the TFT array substrate and the color filter substrate; a driver integrated circuit (driver IC) for driving the LCD panel, wherein the driver IC is disposed in the driver cavity of the TFT array substrate, wherein the driver IC includes an interface side and a non-interface side opposite the interface side, wherein the interface side includes an image signal input pad and a driving signal output pad; and a redistribution layer (RDL) on the TFT array substrate, wherein the RDL extends over at least a portion of the driver IC, wherein the RDL provides at least one direct electrical connection between the driving signal output pad of the driver IC and at least one of the plurality of pixels.

In some embodiments, the display module further comprises a layer of adhesive for bonding the driver IC in the driver cavity of the TFT array substrate, wherein at least a portion of the layer of adhesive is disposed between the cavity bottom and the non-interface side of the driver IC.

In some embodiments, the display module further comprises a flexible printed circuit (FPC) mechanically coupled to the TFT array substrate, wherein the FPC is electrically coupled to the driver IC. In some such embodiments, the FPC includes a plurality of electrical traces, and at least one of the electrical traces is electrically connected to the image signal input pad of the driver IC.

According to some other aspects of the present disclosure, a method of manufacturing a display module comprises forming a plurality of thin film transistors on a liquid crystal layer side of an array substrate; forming a driver cavity in a back-surface side of the array substrate; wherein the back-surface side of the array substrate is opposite the liquid crystal layer side of the array substrate; forming a driver cavity in the back-surface side of the array substrate, wherein the driver cavity includes at least one sidewall extending into the TFT array substrate from the back-surface side thereof to a cavity bottom, adhering a driver integrated circuit (driver IC) in the driver cavity; forming a redistribution layer (RDL) on the back-surface side of the TFT array substrate, wherein the forming of the RDL includes forming at least a portion of an electrical connection between the driver IC and at least one of the plurality of pixels through at least one via; coupling a color filter substrate with the TFT array substrate such that the liquid crystal layer side of the TFT array substrate faces the color filter substrate; and forming a liquid crystal layer between the TFT array substrate and the color filter substrate.

In some embodiments, the method further comprises forming a die cavity in the back-surface side of the array substrate, wherein the die cavity includes at least one die-cavity sidewall extending into the TFT array substrate from the back-surface side thereof to a die-cavity bottom, and adhering an integrated circuit die (IC die) in the driver cavity.

In some embodiments, the forming of the RDL includes forming the RDL over at least a portion of the interface side of the driver IC; and the forming of the at least one electrical connection includes forming the at least one electrical connection between the driving signal output pad of the driver IC and at least one of the plurality of pixels.

According to further aspects of the present disclosure, a display module comprises a liquid crystal display (LCD) panel having a plurality of pixels and a thin-film transistor (TFT) array substrate, wherein the TFT array substrate defines a driver cavity that extends into a back-surface side of the TFT array substrate, the back-surface side being opposite to a liquid crystal layer side of the TFT array substrate, the driver cavity extending to a cavity bottom; a driver integrated circuit (driver IC) for driving the LCD panel, wherein the driver IC is disposed in the driver cavity, wherein the driver IC includes an interface side and a non-interface side opposite the interface side, wherein the interface side includes an image signal input pad and a driving signal output pad; and a flexible printed circuit (FPC) electrically coupled to the driver IC, wherein the image signal input pad is arranged to receive image signals from the FPC and the driving signal output pad is arranged to send driving signals to one or more of the plurality of pixels.

In some embodiments, the display module further comprises a layer of adhesive for bonding the driver IC in the driver cavity of the TFT array substrate, wherein at least a portion of the layer of adhesive is disposed between the cavity bottom and the non-interface side of the driver IC.

In some embodiments, the display module further comprises a redistribution layer (RDL) on the TFT array substrate, wherein the RDL provides at least one direct electrical connection between the driving signal output pad of the driver IC and at least one of the plurality of pixels.

In some embodiments, the FPC includes a plurality of electrical traces, and at least one of the electrical traces is electrically connected to the image signal input pad of the driver IC. BRIEF DESCRIPTION OF THE DRAWINGS

This disclosure relates to a liquid crystal module, and to methods for manufacturing a liquid crystal module having a driver integrated circuit (driver IC). Driver ICs are components of TFT-LCD panels that receive image data and deliver precise analog voltages or currents to an array of pixels on the TFT array substrate. When voltage is applied to the liquid crystal within each pixel, the liquid crystal is bent, thereby changing the intensity of light that passes through each individual pixel. Combined with the color filter on the front glass substrate, each pixel generates its own colors which, together with other pixels, make up the whole image on the panel.

Driver ICs for LCD panels include gate drivers and source drivers. Gate drivers turn on the transistor within each pixel cell on the horizontal row on the panel. When the transistors are turned on, source drivers will generate voltages that are applied to the liquid crystal within each pixel cell on that row for data input. The combination determines the colors generated by each pixel. Small-sized panel applications, such as mobile phones, will preferably include only a single source driver and a single gate driver, which are integrated into a single chip due to space and cost considerations.

The convenience of having a driver IC integrated into conventional LCD panels has helped to simplify the implementation of LCD technology into many different platforms, applications, and technology areas. However, the integrated driver IC has come at a cost because of the complexity and expense of manufacturing processes involved in the driver IC integration, in addition to the dead space (i.e., area of the LCD module footprint that cannot be used for displaying an image) resulting from mounting the driver IC and/or an FPC to the array substrate. The present disclosure includes improvements to LCD packaging technology that reduces the manufacturing cost of LCD modules and dead space associated with prior devices and manufacturing processes. For example, the present disclosure includes a driver cavity and driver IC arrangement, as well as other associated manufacturing processes, that eliminates the use of an anisotropic conductive film (ACF), reduces or eliminates surface traces on glass, reduces the number of Au bumps, and eliminates prior complex bonding between driver IC and FPC.

Many display and image-acquisition systems are, for various reasons, not capable of displaying or sensing the different color channels at the same site. Therefore, the pixel grid is divided into single-color regions that contribute to the displayed or sensed color when viewed at a distance. In some displays, these single-color regions are separately addressable elements and are sometimes referred to as subpixels. For example, LCDs typically divide each pixel vertically into three subpixels. However, for the sake of simplicity, this disclosure will simply refer to pixels with it being understood that references herein to pixels can apply equally to what are sometimes referred to as subpixels.

FIG. 3 shows a schematic, cross-sectional diagram of an exemplary embodiment of an LCD module 300 according to the present disclosure. The LCD module 300 includes an LCD panel 302, a driver integrated circuit (driver IC) 314, and a flexible printed circuit (FPC) 324. In general, the typical operation of the LCD module 300 would be as follows. The driver IC 314 would receive image data from some outside source via the FPC 324, such as other packaged ICs 340 mounted on a PCB 342 that is connected to a second end of the FPC 324. The driver IC 314 would evaluate the received image data, generate corresponding LCD drive signals, and transmit the drive signals to the LCD panel 302. The LCD panel 302 would receive the drive signals and operate the pixel array thereof to generate a visual representation of the image corresponding to the received image data.

The LCD panel 302 includes a thin-film transistor (TFT) array substrate 304 having a liquid crystal layer side (304a) thereof opposite to a back-surface side (304b) thereof. A color filter substrate 310 is coupled to the TFT array substrate 304, facing the liquid crystal layer side (304a) of the TFT array substrate 304. A liquid crystal layer 312 is disposed between the liquid crystal layer side 304aof the TFT array substrate 304 and the color filter substrate 310. The TFT array substrate 304 and the color filter substrate 310 can both be formed of glass. The LCD panel 302 also includes a plurality of TFT pixels 306 formed on the liquid crystal layer side (304a) of the TFT array substrate 304 between the TFT array substrate 304 and the color filter substrate 310. The TFT array substrate 304 also defines a driver cavity 308 extending into the back-surface side (304b) thereof towards the liquid crystal layer side thereof (304a) to a cavity bottom (308a). The TFT array substrate 304 also defines one or more die cavities 334 in the back-surface side 304bof the array substrate (304). The TFT array substrate 304 also defines one or more through-glass vias 328 that are formed in the back-surface side 304bof the array substrate (304) and extend through to the liquid crystal layer side 304ato provide for electrical connections between the driver IC 314 and the TFT pixels 306, as well as any other electrical connections that may be desired.

The driver IC 314 is configured for receiving image data that is sent to the display module 300, converting the received image data to LCD drive signals, and transmitting the LCD drive signals to the TFT pixels 306 so that the LCD panel 302 will display an image corresponding to the received image data.

The driver cavity 308 and die cavities 334 can be located inside the perimeter of the LCD panel 302 as shown in FIG. 3, which shows the driver cavity 308 and a die cavity 334 located behind the LCD panel 302 on the back-surface side 304bof the TFT array substrate 304. The LCD module 300 can be thought of as having a display area, which corresponds to the LCD panel 203 portion that generates an image, and a non-display area, which is everything else. From this perspective, the location of the driver cavity 308 and die cavities 334 in the illustrated embodiment can be designated as being in a display area because they are located inside the outer perimeter of the LCD panel 302. Thus, the illustrated embodiment increases the LCD display area ratio (ratio of display area to overall display module footprint) compared to prior art. The display area could be the same as the glass substrate, since no COF bonding is needed on the front side.

The driver cavity 308 and die cavities 334 extend into the TFT array substrate 304 from the back-surface side 304bof the TFT array substrate 304. The liquid crystal layer side thereof 304aof the TFT array substrate 304 constitutes an active side of the TFT array substrate 304 as being the same side of the TFT array substrate 304 on which the TFT pixels 306 are formed. Thus, the active side of the TFT array substrate 304 is also the side facing the color filter substrate 310.

In the illustrated embodiment, the driver cavity 308 and die cavities 334 extend into the TFT array substrate 304 to respective cavity bottoms. The driver IC 314 is disposed in the driver cavity 308, and additional integrated circuit dies (IC dies) 336 can be disposed in the driver die cavities 334. This allows additional ICs to be moved from off-module devices to the back-surface side of the display module to further reduce the footprint of a final configuration. In some embodiments, such as the illustrated embodiment, the driver IC 314 is adhered in the driver cavity 308 by an adhesive layer 322, and additional integrated circuit dies 336 can be adhered in the die cavities 334 by adhesive layers 322. The adhesive layers 322 can include any suitable adhesive, for example, using glue or a die attach film (DAF).

In some embodiments, such as the illustrated embodiment, the side walls of the driver cavity 308 and die cavities 334 are not in direct contact with the driver IC 314. Instead, a gap 330 is provided between side walls of the driver cavity 308 and the driver IC 314, and between side walls of the die cavities 334 and respective IC dies 336. As discussed below, after the driver IC 314 is placed in the driver cavity 308, a redistribution layer (RDL) 320 is formed over the driver IC 314 and on the back-surface side 304bof the TFT array substrate 304. The process of forming the RDL 320 begins with the forming of a dielectric layer over the TFT array substrate 304 and driver IC 314, during which the gaps 330 between side walls of the driver cavity 308 and the driver IC 314 are filled with a portion of the dielectric material of the RDL 320.

The driver IC 314 includes an image signal input pad 316 and a driving signal output pad 318. In preferred embodiments, the driver IC 314 and IC dies 336 are oriented in the respective driver cavity 308 and die cavities 334 to allow for ease of access to its input and output pads 316, 318 and any pads that may present on the IC dies 336. In some embodiments, the driver IC 314 has its input and output pads 316, 318 on one side, which serves as the interface side of the driver IC 314; also, the side opposite the interface side serves as the non-interface side of the driver IC 314. In such embodiments, it is preferred for the driver IC 314 to be oriented in the driver cavity 308 with the interface side facing up towards the cavity opening and with the non-interface side facing down towards the cavity bottom. This orientation will often allow for the easiest fabrication of electrical connections to and from the driver IC 314.

A redistribution layer (RDL) 320 is formed over the driver IC 314 and any IC dies 336 and on the back-surface side 304bof the TFT array substrate 304. In some embodiments, the lower surface of the RDL 320 is in direct contact with the TFT array substrate 304. In some embodiments, the formation of the RDL 320 can begin with organic coating or laminating dielectric material over TFT array substrate 304. During this process, the gaps 330 between side walls of the driver cavity 308 and the driver IC 314 are filled with a portion of the dielectric material. Next, a planarizing process can be performed if desired, for example a chemical mechanical planarizing (CMP) operation can be performed. At this point, the desired process can be completed to form the plurality of TFT pixels 306 and related circuitry on the TFT array substrate 304 for the LCD panel 302. This can include forming RDL connections between the driver IC 314 and the TFT pixels 306 through at least one through-glass via 328.

The RDL 320 is formed of dielectric material and includes one or more metallic interconnect structures 320aembedded in the dielectric material. The metallic interconnect structures include one or more metallic layers 320aand a plurality of via plug structures that provide for electrical connections as needed throughout the RDL 320. For example, the RDL 320 provides at least one direct electrical connection 320abetween the driving signal output pad 318 of the driver IC 314 and at least one of the plurality of TFT pixels 306. It should be noted that some metallic layers and via plug structures in the RDL 320 are omitted in the illustration presented in FIG. 3 for simplicity. The metallic interconnect structures can include one or more layers of Al, Cu, Sn, Ni, Au, Ag, or other suitable electrically conductive material.

A first end of an FPC 324 is mechanically connected to the back-surface side 304bof the TFT array substrate 304 via bumps formed of gold (Au) by known Au electroplating techniques.

The FPC 324 can include a base member made of synthetic resin (e.g., polyimide resin) having insulating properties and flexibility. A number of electrical traces (all represented by line 326 are formed on the base member, and at least one of the electrical traces is electrically connected to the image signal input pad 316 of the driver IC 314. The first end of the long dimension of the FPC 324 is connected to the driver IC 314 and to the TFT array substrate 304 as described earlier. A second end (distal end) can be connected to a variety of different devices or circuits depending on the application in which the display module 300 is ultimately used, for example such as other packaged ICs 340 mounted on a PCB 342 that is connected to a second end of the FPC 324.

FIG. 4 is a process flow diagram showing an exemplary method for fabricating a display module according to the present disclosure. In this embodiment, the method of manufacturing a display module includes a step 410 of forming a plurality of TFT pixels on the liquid crystal layer side of the TFT array substrate. Next, at step 420, through glass vias on are formed on the back surface side of the TFT array substrate to connect from the back surface side to the liquid crystal layer side. Next, step 430 involves forming one or more cavities, which can include a driver cavity and one or more die cavities, in the back surface side of the TFT array substrate. Next, step 440 involves adhering one or more semiconductor dice in the one or more cavities. Next, step 450, involves forming a dielectric layer over the back-surface side of the TFT array substrate. Finally, step 460 involves forming a redistribution layer (RDL) on the back-surface side of the TFT array substrate.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey