how to increase brightness of lcd display manufacturer

![]()

How does the song go?My future’s so bright I need to wear shadesI"ve got a job waiting for my graduationFifty thou a year, buys a lot of . . . coffee??????

This article is limited to monochrome since they perform better in direct sunlight and can still be read when the back light is off. Also, the tooling cost, if necessary, is much lower.

Swap out the transflective polarizer with a transmissive polarizer. This increases the brightness without increasing the amount of power necessary or decreasing the half-life of the LEDs. The one downside is the display will be a bit more difficult to read when the back light is off, but it is still readable.

Every monochrome display with a LED back light contains a current limiting resistor. The lower the resistor value, the higher the current draw. Hence the brighter the back light. The down side is the back light draws more power (not always good for battery powered products) and it reduces the half-life of the LED back light.

Once the design is done and your customers see the light, the good people at Masterelectronics.comcan hold your inventory so you have more time to ship shades to your customers.

![]()

For the video display developer LCD panels are available in many sizes and resolutions, they are also available with many choices of maximum brightness. The following considers the topic of LCD panel brightness, the choices, the methods for adjusting brightness and some brightness adjustment scenarios.

LCD panels are generally rated as to their maximum brightness level which is expressed in Nits, it is equal to Candela/sqm (cd/m2), and this will be at a particular color temperature as noted in the specification, usually 10,000 K. In terms of a practical understanding, the following is a rough guide:

Outdoor displays range from a low end of 700 nits to typically 1,000 or 1,500nits and up with 2,000~2,500nits and even up to 5,000nits seen with some models. This may include standard LCD panels, custom LCD panels as well as custom cut LCD panels.

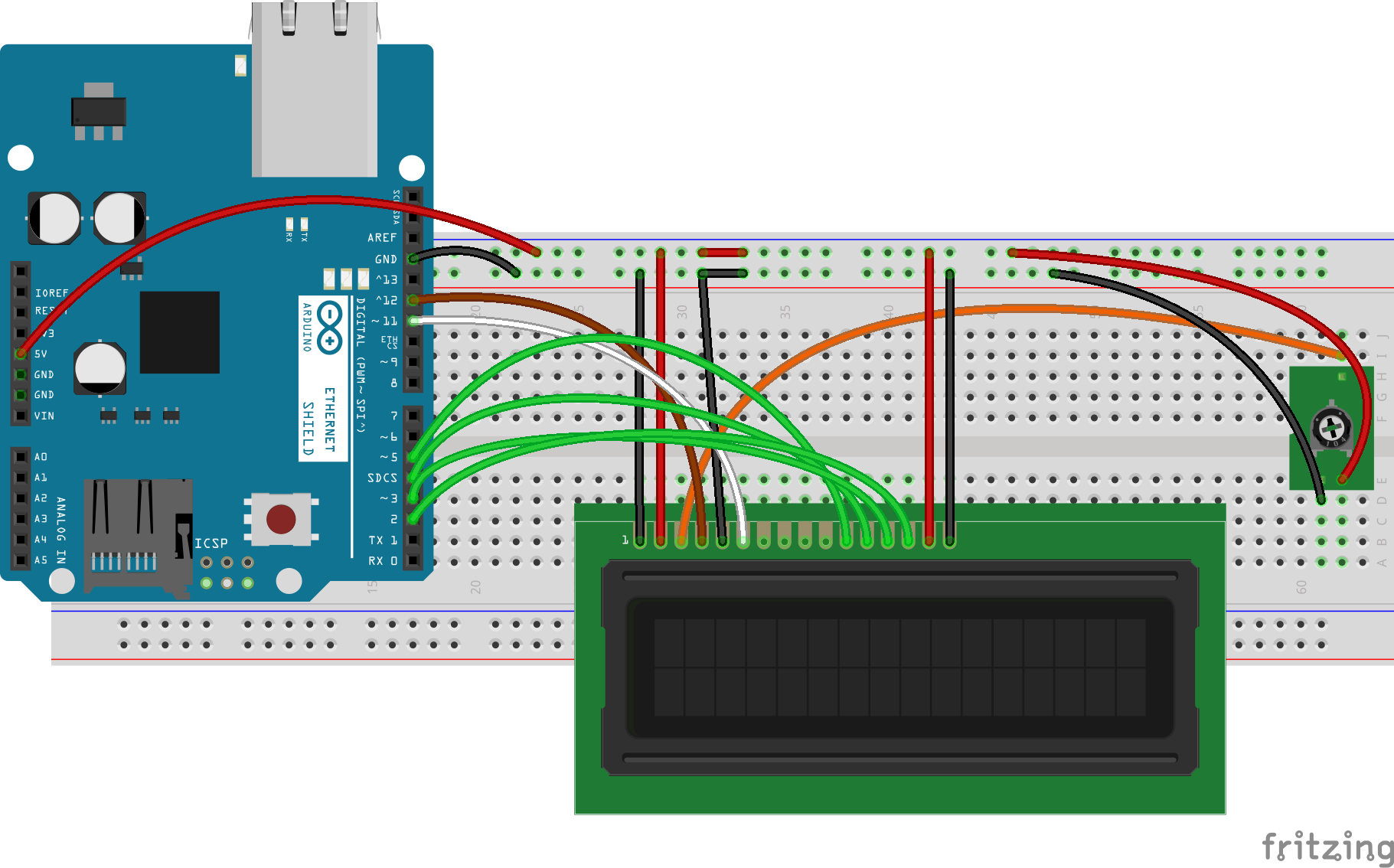

Virtually all LCD panels have a LED backlight these days, these are powered by an LED driver board. Brightness control via the driver board will be by one of two methods:

PWM (Pulse Width Modulation): This varies the duty cycle of the backlight “on time” – it is predominant in modern LCD panel LED backlight designs to enable support for digital brightness controls.

Analog: Uses a simple variable voltage to adjust brightness, for example this might be a dial or slider type potentiometer / variable resistor. To see how to enable analog backlight adjustment visit: https://www.digitalview.com/blog/brightness-adjustment/

One of the advantages of LED for the backlight is the range of adjustment that is possible, however it is important to note that the range varies significantly from model to model. Some industrial panels can be turned to very low light levels making them suitable for use in special environments such as at night. Lower cost panels limit the range of brightness to what might be required for typical usage, whereas panels with full range dimming from full off to full on require more complex backlight drivers.

Backlight lifetime: Many LCD panels have a backlight lifetime rating of 50,000 hours (typically measured to half brightness), this can be extended by running the LED backlight at a lower brightness level. Some panels may only offer 30,000 hours as a lower cost solution while other panels may offer up to 100,000 hours for high end applications.

An LCD panel backlight may be constructed so the LED’s are mounted directly behind a light guide diffuser, or they may be mounted along one or more edges of the light guide.

Active backlight: This is a function of some LCD panel backlights to automatically adjust the backlight brightness in response to the image. For more advanced systems there is an LED array making up the LED backlight, this adjusts the brightness in areas localized to the image being shown. This can greatly enhance the brightness across the display and is being used primarily with video, for example on consumer TV sets. It is not useful to all image types, for example a spreadsheet or content like maps or data is not likely to benefit.

Local dimming: Some LCD panels with direct LED may support local dimming so the LED’s are dimmed in response to the image close to them. This will not be at the same resolution as the LCD panel itself but will help greater contrast over the display by enhancing the brightness in bright areas of the image and darkening the image in dark parts of the image.

Both of the above techniques are likely to be more beneficial to certain types of content than others. For example a movie is likely to benefit more than a spreadsheet.

For the LCD monitor manufacturer it is important to consider that any covering over the LCD panel will reduce the brightness. For example the protective glass over a digital signage display, or a touch screen, or a semi-silvered mirror. So if a specific brightness is required the measurement should be taken with these in place.

There are various relatively low cost brightness meters available, typically in the couple of hundred dollars range. It is difficult to comment on the accuracy of these but we have found them to be within 5% of each other, though more importantly they do appear to be quite consistent in measurement so good for measurement comparisons. For more accurate measurement there are light meters from companies such as Minolta that can be calibrated, the cost may run into several thousand dollars.

Examples of light meters costing a few hundred dollars include SpyderX by Datacolor (needs a PC), a handheld meter is the SM208 by Sanpometer (search SM208 meter). Note: Many light meters, including smartphone apps, will be meters used for photography and not give readings in nits (or candelas). LCD panel specifications are typically measured using nits.

PWM and Analog: Most Digital View LCD controllers support PWM and Analog as a method for adjusting the backlight brightness level (this is noted in the column headed “Other” on the controller board summary table: https://www.digitalview.com/controllers/lcd-controllers-home.html. Also see https://www.digitalview.com/blog/brightness-adjustment/ for a guide to using a dial or slider type variable resistor to adjust the backlight.

DPMS (Display Power Management System): The backlight will be automatically turned off after a period if there is no valid video signal being received.

Ambient light sensor: The backlight is adjusted for brightness or powered off depending on ambient light conditions. This uses a light sensor attached to the LCD controller board, see https://www.digitalview.com/blog/light-sensor-app-note/ for more details.

The specifics of the backlight control are documented separately for each LCD controller model (product summary here) in the product manual available for download on the product page.

Note: There are two ways to adjust the perceived brightness of a LCD panel or LCD monitor, the backlight and the black-level. Very often, particularly in the past, the monitor brightness setting adjusted the black-level, this adjusts the LCD but not the backlight.

Color, color temperature etc: In addition to adjusting the brightness other settings may be adjusted as well. For example the color temperature or for example a switch to green monochrome for night vision.

Auto-dim if lights dimmed for a projector. This might be triggered by a command from a room sensor or automatically by an ambient light sensor (Autobrite+).

Night-safe lighting (update) : Dual-rail backlights can also be supported. These special backlight enable normal brightness and extreme low level brightness with custom night-safe lighting. Contact us for details.

Note: We have a blog on methods for implementing an ambient light sensor with Digital View LCD controller boards to automatically adjust the backlight or system power, see: Ambient Light Sensor

Update March 2019: Most of the above remains unchanged except for the increased availability of high bright LCD panels of around the 1,000 nit to 2,500 nit range. AUO for example has a number of large size LCD panels with 1,500 nit brightness for the digital signage market. Tianma has panels under 20″ with 1,000 nit to 1,500 nit brightness for various outdoor applications.

The other change is that high bright panels are now increasing edge-lit, this makes the panels thinner and these panels tend to use less power than the previous models. One of the benefits for monitor designers is easier heat management and reduced overall display system costs.

![]()

According to the working principle of LCD, the LCD module is a device that controls the light projection intensity when they are emitted from the backlight and passing through the polarizers and LCD panel for imaging.

In another word, the brightness of the LCD is determined by the amount of light that passing through the LCD panel (the transmittance rate of the LCD), the color filter (the transmittance rate of the CF), and the brightness of the backlight.

As the below figure and table show, when the light source (CCFL/LED) on side, assuming that the CCFL is 100%, it will lose 40% when passing through the light guide plate, lose 36% through the bottom polarizer, 18% through the LCD panel, and 1% on the surface reflection. Eventually, the utilization rate of CCFL is less than 5%.

From here we can know, how to improve the utilization rate of light is significant to enhance the brightness and color performance of LCD modules, even to the industry.

Backlight unit consists of the light source and layers of optical sheets which are used to guide the light direction as well as to enhance their utilization.

1. From the light source, we can increase the brightness, quantity, and power of the lamp, but the solution needs to consume more power and increase the size of BL.

2. From the light guide plate, it has high requirements for the material and design of the light guide plate. The solution is expensive but the increment of brightness is small.

Except for the light source, the above method third and fourth is more effective and common to adjust the brightness. Therefore, we will discuss them in the following article.

In addition to the high-reflective film at the lamp tube, the reflective film under the light guide plate is also essential. It requires a special particle structure to match the printed points of the light guide plate, which can reflect light, and make the reflected light more uniform.

With these particular reflective films, the brightness of the axis center of the LCD can be improved by nearly 30% without changing the design and mold.

As we know, LCD has a certain visual angle. When viewing the computer from the vertical direction, the brightness is relatively high; when viewing from a direction beyond the normal line, the brightness becomes low.

This meets the personal habit of laptop users. The function of prism film is to make the originally dispersed light concentrate to a certain angle around central observation so that the brightness at the axis center can be greatly increased.

By the principle of refraction and total reflection, the prism film makes the emitted light with more than 70 º reflect back and be reused, which can increase the brightness by 110% at the center of the axis.

As known, when the light passes through the bottom polarizer, there are 50% of the light is absorbed and wasted. If we use a series of BEF, we can reuse 50% of the polarized light that is originally absorbed.

As shown in the figure, the BEF allows P1 polarized light to pass through, and reflects P2 polarized light back for reuse to become P1 and P2, in the recycles, the brightness can be increased by 60%.

All in all, with the high-efficiency reflective film, prism film, and BEF together, the overall brightness can be increased by 230%. This method will need no change in design and tooling, but the cost increment of the backlight.

In different scenarios, terminals need particular brightness in order to provide a clear display to the end users. Hence, brightness is one of the common custom requirements in LCD projects.

![]()

The contrast ratio (CR) is a property of a display system, defined as the ratio of the luminance of the brightest color (white) to that of the darkest color (black) that the system is capable of producing.

If the LCD contrast is too low, it is hard to read. Different applications have different contrast requirement. For normal reading, the contrast needs to be >2; for medical, the contrast needs to be >10, for welding helmet, contrast should be >1,000.

The higher the efficiency, the better of the LCD contrast . It is especially important for negative display. Change from 98% to 99.9% polarizer, the contrast can increase from 45 to over 1000 for negative LCD, but for positive LCD, the contrast increases from 7 to 10 for positive LCD.

Positive LCD to Negative LCD (When the LCD is used indoor or dark environment, The contrast will increase a lot, but it will not display well with ambient light only, it is also more expensive)

For negative display, black mask can block the light bleeding, the contrast can be improved. Black mask can be done either outside cell (low cost) and inside cell (high cost).

![]()

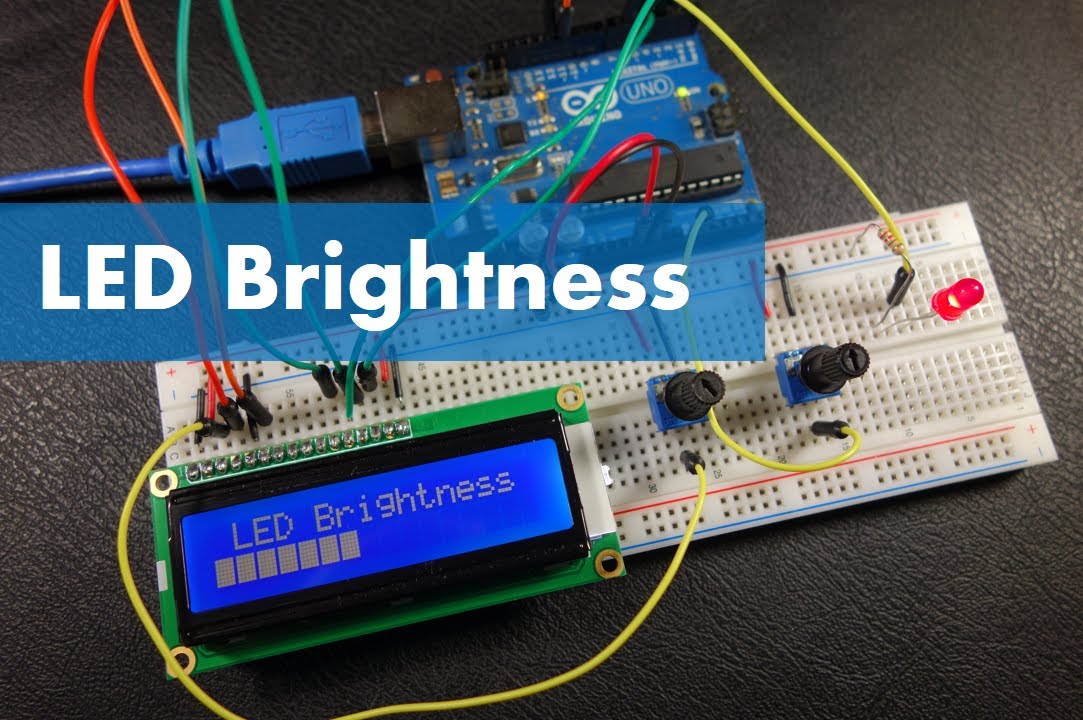

The brightness of an LCD backlight depends on a number of different variables. In order to get the best result, and optimize the lighting and display for the intended application , it’s important to understand more about each factor and how they make an impact. Let’s take a look at four of the most important keys to controlling backlight brightness with LCD lighting.

Perhaps the most obvious element is the actual amount of power supplied. This is the most straightforward and easiest way to either increase or decrease the brightness of an LCD backlight. Increasing the power to the LEDs, within the manufacturer’s allowable forward current range, increases the brightness of the lights, while decreasing power decreases brightness in the same fashion.

Even if a power source remains at a consistent strength, the efficiency of the LEDs and the system as a whole impact how bright the LCD lighting will be. By using superior components and technology, with superior efficiency, more brightness can be squeezed out of the same power source. Factors that may impact LED efficiency include the quality of the die, the chemical makeup of the LEDs, and even the color temperature of the LEDs.

Different types of LCDs offer different degrees of transmissivity, which refers to the degree that a medium allows something such as electromagnetic radiation, or in this case specifically visible light, to pass through it. LCDs may allow less than 1 percent of light to be transmitted from the backlight to the user, whereas others can result in almost no loss. Therefore, it’s essential to consider whether or not a backlight is required when selecting an LCD, and then to select an LCD with good transmissivity.

Not to be overlooked is the lightguide. The quality and efficiency of the lightguide will have a dramatic impact on the final brightness of the LCD backlight. The reason is simple enough, as it is the lightguide that directs the light from the LED to the LCD, and much can be lost along the way. Lightguides with high efficiency levels, including those with optical lens based light extraction patterns, can increase efficiency by 20 to 30 percent.

By considering these four key factors, any DIY LCD lighting project can become more successful. For more information on a full range of LED and LCD lighting products and technologies, contact us here. In addition to offering LCD backlight products, Global Lighting Technologies is a worldwide leader for developing a full range of efficient, innovative, and customized lighting solutions.

There are more and more TFT displays used in outdoor applications, such as automobile display, digital signage and kiosks. High ambient light in outdoor environment often causes wash-out image and renders the screen not readable. Readability & sustainability of TFT display under direct sunlight is becoming vital. Topway Display has been developing sunlight readable LCD display solution for years. The company understands the ins and outs of sunlight readable TFT LCD.

For an LCD to be readable in outdoor environment with very bright ambient light, the LCD screen’s brightness needs to exceed the intensity of light that is reflected from the display surface. To be comfortably viewed by human eyes, the LCD’s brightness needs to exceed its reflected light by a factor of 2.5 at minimum. Naturally, to make an LCD sunlight readable, we can work on two areas, increasing brightness or reducing reflectance.

On a clear day in direct sunlight, the ambient brightness is about 6000 cd/m2. And a typical TFT LCD with touch screen reflects about 14% of ambient light, which is around 840 cd/m2. These days, most LCD displays use LED backlight as light source. It is not too difficult to increase an LCD’s brightness to 800 ~ 1000 Nits, to overpower the bright reflected sunlight. Thus, you have a sunlight readable TFT LCD.

However, this method requires more backlight LEDs and/or higher driving current. The drawbacks are high power consumption, more heat dissipation, increased product size and shorter LED backlight lifespan. Apparently, increasing backlight to make TFT LCD sunlight-readable is not a very good solution.

Transflective TFT LCD is a TFT LCD with both transmissive and reflective characteristics. A partially reflective mirror layer is added between LCD and backlight. This change turns part of the reflected ambient light into LCD’s light source, increasing the TFT display’s brightness. However, transflective TFT LCD is more expensive than transmissive one. At the same time, the partially reflective mirror layer will block some of the backlight, making it not ideal in indoor or low ambient light environment.

What causes light reflection? When light traveling in one transparent medium encounters a boundary with another transparent medium, a portion of the light bounces off the border. Through the simplest version of Fresnel’s equation, we can calculate the amount of reflected light.

The total reflectance on a TFT LCD with touch panel is the sum of reflected light on any interface where two materials meet. As an example, between polarizer and display glass, the difference in index of refractions for the two materials is very small, around 0.1. So the reflected light on this interface is only 0.1%. As Fresnel’s equation points out, we should focus reflection reduction on air interfaces. For air, its index of refraction is 1; for glass, it is 1.5. And that results in a reflectance of 4.5%. Therefore, the three air interfaces contribute majority of TFT LCD’s reflectance, at about 13%.

The quick and easiest thing we can do to reduce air-glass interface reflectance is to use an Anti-Reflection and Anti-Glare film or apply AR coating. An external film with AR properties not only reduces reflected light, but also brings other benefits.

For food industry application, shattered glass is a serious problem. An LCD screen with external film solves this issue nicely. As for automotive applications, in an accident, broken LCD with top AR film won’t produce sharp edge glass that could harms auto occupant. Nevertheless, a top film always reduces TFT LCD’s surface hardness. And it is susceptible to scratches. On the other hand, AR coating retains LCD’s hardness and touch performance. But it comes with a bigger price tag.

Another quick and easy way to tackle reflectance is to affix a linear polarizer on the top of TFT screen. When ambient light gets to the top polarizer, only half of the light passes through. Which results in reflection light cutting to half. This is a very low cost way to increase TFT LCD’s contrast, such that making it more sunlight readable.

Laminating a circular polarizer in TFT LCD will get rid of a lot of reflectance. That is because when ambient light passes through circular polarizer it gets circularly polarized. And when it is reflected, the polarization direction flips by 180 degrees. So when reflected light comes back to the circular polarizer, nothing goes through to viewer’s eyes.

This method is very effective for an LCD display with resistive touch panel. We know resistive touch LCD has two air gaps: air gap between two ITO layers and air gap between touch panel and LCD display. Reflectance caused by the two air gaps is very high. Applying circular polarizer blocks off most of the reflected light, and makes the LCD display sunlight readable.

The disadvantage of such solution is its cost. Since we need not only a circular polarizer, but also a retarder film on the top of LCD display, making sure light originates from within LCD is not blocked by external circular polarizer.

Add AR films on both interfaces of internal air gap. The add-ons can reduce this area’s reflection from 8.5% to 2%. And since the AR films are not outside facing, they are much cheaper than the one used outside. Keeping the air gap also retains the ease of service, in case either touch panel or LCD display needs to be repaired.

The most effective way is to eliminate air gap totally, by using optical bonding. In plain language, we fill air gap with special optical adhesive, to smooth out the area’s refraction index differences. Such that reflectance caused by internal air gap drops from 8.5% to 0.5%. Optical bonding is expensive but effective way to improve TFT LCD sunlight readability. It enhances durability and resistance to impact. Moreover, no air gap means no moisture condensation and fogging.

There are many ways to make TFT LCDsunlight readable. They all have their own pros and cons. With 20+ years" LCD design and manufacturing experience, Topway knows how to create the best sunlight readable TFT LCD for challenging environments. Leave us a message and let"s start the conversation of creating suitable sunlight readable TFT LCD for your project.

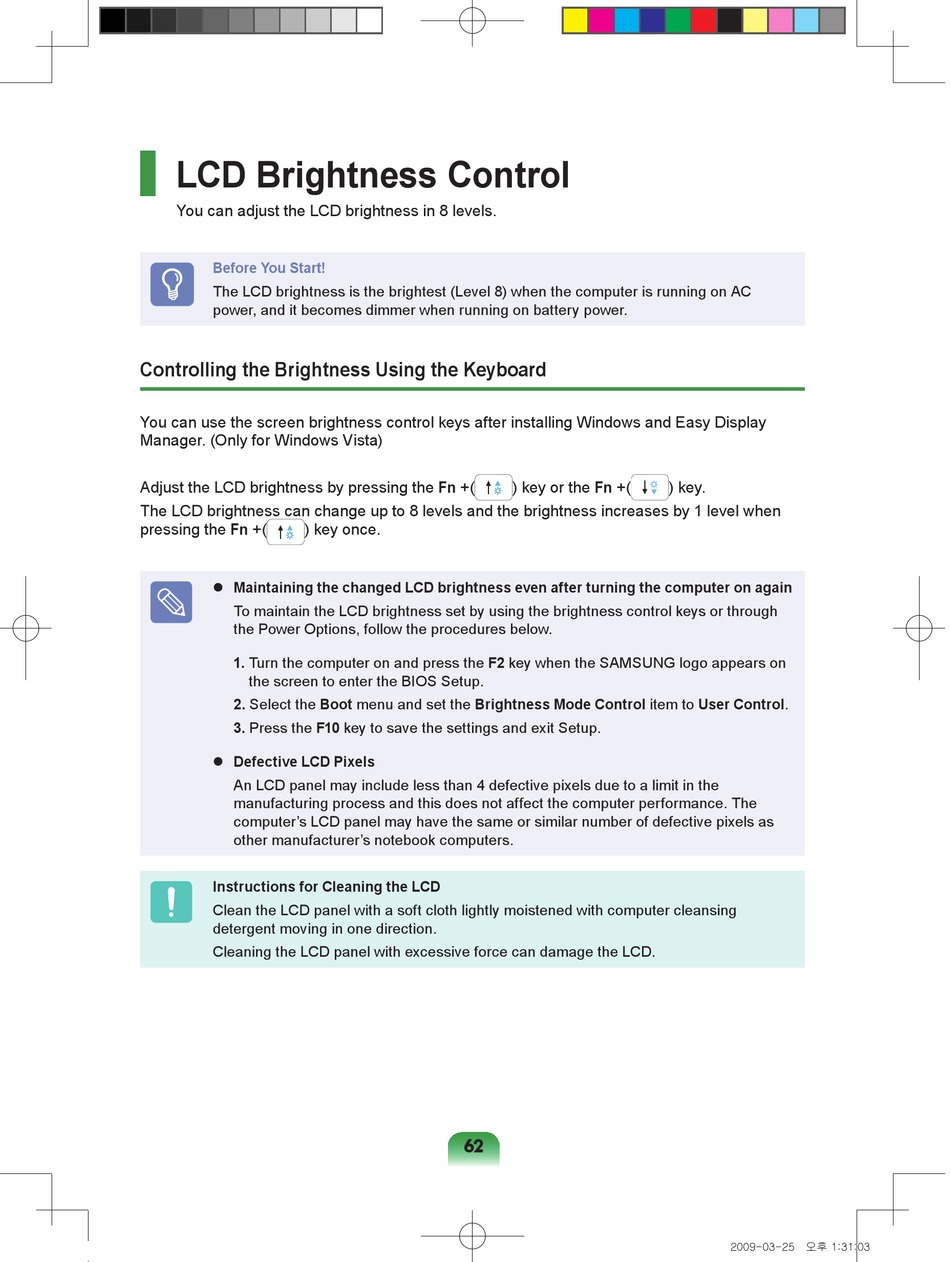

Note: Ensure to set your LCD panel to factory settings at this point. Otherwise, you will not get the best results. To reset your LCD panel to factory conditions, use the buttons that are located on the front, side, or back. However, if your LCD panel lets you set the gamma, you should set it to 2.2 or as close as possible.

Next, use the slider to adjust the gamma. To do this, move the slider until the dots in the middle of the image appear less visible. This changes both the brightness and color of your screen.

Note: Do not worry if you cannot make the circles in the center completely disappear. If you want a better way of testing, you can also use this gamma correction test image. Try to make as many numbers appear on the top and bottom bars as possible. With better LCD panel s, you can see 6 numbers in each bar, while lower-grade LCD panel s will only be able to show 4 numbers.

Note: If you cannot adjust the slider, you might have to change the gamma settings by using your LCD panel ’s controls. You should still keep the display settings window and gamma correction image test open while you do this.

Next, adjust the brightness. To do this, use the control buttons on your LCD panel until you can see the shirt and suit in the image, but not so much that the X stands out from the background. You should still be able to see the "X," but the wall behind it should not be washed out.

Note: Your screen looks different depending on what angle you are looking at it. For the best results, you should step back and look at your LCD panel from far away.

Next, adjust the contrast. To do this, use the buttons on your LCD panel. You want to set your contrast so you can just see the wrinkles and buttons on the shirt of the man in the figure. The background of the image should not be bright white.

Then adjust your colors. To do this, use the sliders at the bottom of the window until all the bars are a neutral gray. If you find this difficult, you can also download an image of color bars and use that image to see when your colors are off.

Next, click Previous calibration and Current calibration to see if you like the changes you made. Doing this will not change your calibration. You can go back and change any settings by clicking the arrow in the top-left corner of the window.

If you are satisfied with the new calibration, click Finish. If not, click Cancel, and you can start all over. To get the best results, you can do the steps over again. For best results, you might want to go through the steps again, but backward this time. This is because each step affects the next one, so changing the order helps you fine-tune your calibration even more.

Note: You can check the "Start ClearType Tuner…" box to adjust the clarity of text on your screen. You will then be asked to do a quick test to calibrate the text on your screen.

The human eye is capable of seeing a total brightness range of 1012 or more, but not simultaneously. For typical light levels the eye has an instantaneous dynamic range (IDR) of ~104 (10,000:1). The IDR may be viewed as a window of dynamic range that can slide up and down the total possible range as the eye adapts to different brightness levels. The center of the IDR is set by the average brightness within our field of view at a particular time.

As the actual brightness increases, though, the eye becomes less and less sensitive to changes in brightness. Said another way, it takes increasingly larger steps of actual brightness in order to realize equal steps of perceived brightness. Due to this compressive behavior the eye perceives just 360 nits as being half-way (50 percent of IDR) to the maximum of 2,000 nits.

So what gets in the way of displaying high contrast images? “The biggest enemy in outdoor or any high-ambient light applications is the reflection of ambient light from the front of a display,” Presley said. “These ambient reflections will effectively limit how black a display can go, akin to raising the noise floor of the display,” he said. “Also, reflected light will mix with the light being emitted by the display, so at the same time the color gamut will be compressed.”

Reflections are often categorized as being specular or diffuse. Specular reflection, also called glare, represents mirror-like reflection. Specular reflection can be an issue for both daytime and nighttime operation, as there can be many relatively strong sources of light at night as well. On the other hand, diffuse reflection represents scatter-like reflection, such as from a piece of rough paper. Diffuse reflection causes an incident ray of light to break into many smaller rays over a full hemisphere of reflected angles. Therefore, objects and light sources become “scattered” and unrecognizable upon reflection.

In reality, practically nothing exhibits purely specular or purely diffuse reflection. Since specular reflection is mirror-like then its effects are viewing angle dependent, whereas diffuse reflection has very low angular dependence. The low contrast image shown in Figure 1 is indicative of a display having a high diffuse reflection because the image is uniformly degraded and there are no obvious mirror-like reflections from any external objects or ambient light sources.

How much contrast ratio is enough? Many commercial displays claim to exceed 1,000,000:1, but this is always measured in a dark room with no ambient light. In truth, relatively modest contrast ratios can be sufficient for maintaining attractive content. Figure 4 below illustrates various contrast ratios via simple grey-scale blocks. Within every block the lighter colored square is the same shade; only the outer ring of each block is being varied. The difference between contrast ratios of 20:1 and 30:1 is scarcely evident, so 20:1 would appear to be a sufficient goal.

Sun Vision Display panels are100% reflective, meaning they have no backlight whatsoever. This makes them an excellent computer monitor solution for people looking to reduce blue light exposure or other common issues reported by people withcomputer-related vision syndromes. It also makes them an incredible solution for advertising in sunny places, where it can be difficult to view other display technologies - all without racking up hefty energy costs.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

2015, sold to giantplus and tce photomasks, gen 3 still operated by giantplus, gen 4 line sold to giantplus, equipment sold and line demolished, remainder operated by tce

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Colantonio, Andrea; Burdett, Richard; Rode, Philipp (2013-08-15). Transforming Urban Economies: Policy Lessons from European and Asian Cities. Routledge. ISBN 9781134622160. Archived from the original on 2019-01-01. Retrieved 2019-06-09.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

www.wisechip.com.tw. "WiseChip History – WiseChip Semiconductor Inc". www.wisechip.com.tw. Archived from the original on 2018-02-17. Retrieved 2018-02-17.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

Pooler, Michael (29 September 2015). "Subscribe to read". Financial Times. Archived from the original on 2019-10-25. Retrieved 2019-10-25. Cite uses generic title (help)

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey