how to increase brightness of lcd display brands

How does the song go?My future’s so bright I need to wear shadesI"ve got a job waiting for my graduationFifty thou a year, buys a lot of . . . coffee??????

This article is limited to monochrome since they perform better in direct sunlight and can still be read when the back light is off. Also, the tooling cost, if necessary, is much lower.

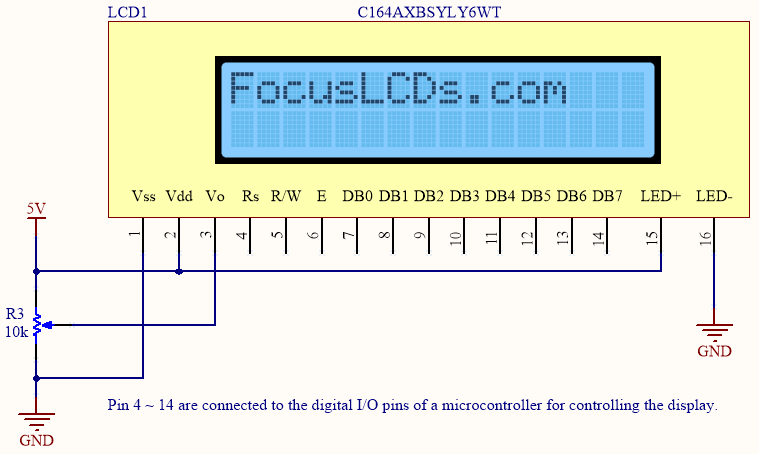

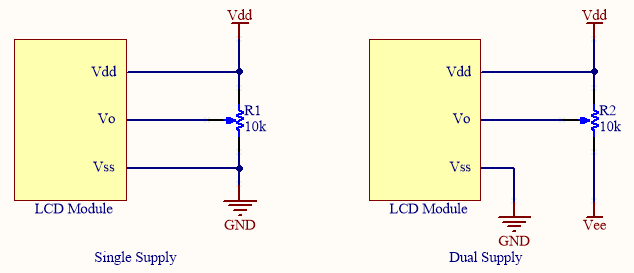

Swap out the transflective polarizer with a transmissive polarizer. This increases the brightness without increasing the amount of power necessary or decreasing the half-life of the LEDs. The one downside is the display will be a bit more difficult to read when the back light is off, but it is still readable.

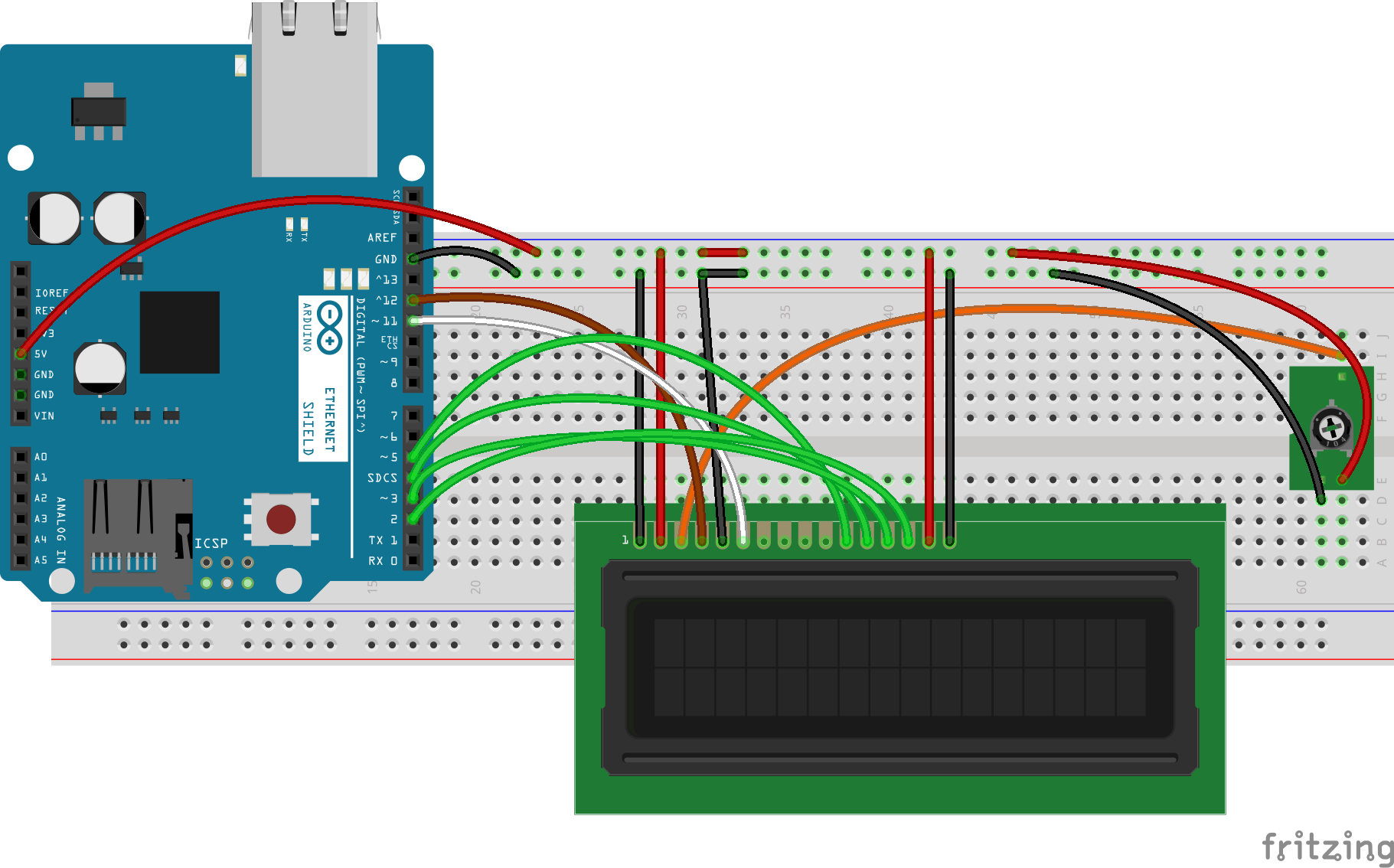

Every monochrome display with a LED back light contains a current limiting resistor. The lower the resistor value, the higher the current draw. Hence the brighter the back light. The down side is the back light draws more power (not always good for battery powered products) and it reduces the half-life of the LED back light.

Once the design is done and your customers see the light, the good people at Masterelectronics.comcan hold your inventory so you have more time to ship shades to your customers.

There are a few techniques that can be employed to make the LED backlight brighter, but if your goal is to compete with (or against) the direct sun light, there are better methods than to increase the brightness of the backlight.

“We need the brightest LED backlight possible for our new LCD design and we need to make sure that the LCD is sunlight readable.” This is a common request and the battle begins when engineers employ such techniques as PWM (pulse width modulation), reduction or elimination of current limiting resistors and overdriving the rated power limits with the final goal to make the backlight brighter.

Emissive & non-Emissive LCD modulesEmissive displays do not require a backlight since they produce their own light; an example of this is an OLED (Organic Light-Emitting Diode). OLED’s are readable in both dark and daylight environments.Non-Emissive displays require a backlight to illuminate the LCD when used in low or no ambient lighting conditions. Character, Graphic and Segment displays fall into this category and are the subject of this article.

What is a NIT? The brightness of a backlight is measured in "nits". As a general rule, one nit = the light produced by one candle. (It"s a bit more technical than that, but the idea works out the same.)

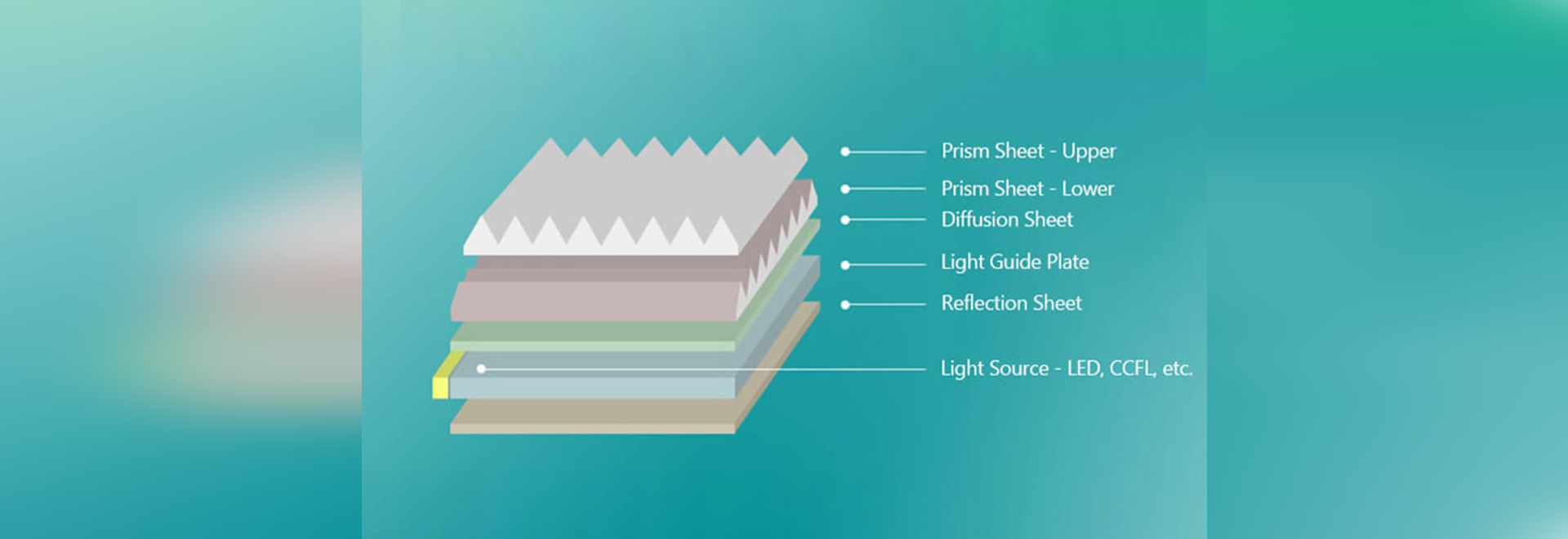

The majority of LCD display backlights are LED (Light Emitting Diode) and in most cases require the same power that is applied to the LCD logic (the power that drives the LCD only).

LED backlights require a current limiting resistor to reduce the driving current reaching the backlight. The lower the resistor value, the brighter the backlight.

Reducing the resistor value shortens the half-life of the LED backlight. The normal half-life of a LED backlight can range from 50K hours to 70K hours, but when overdriven the half-life can drop to 20K hours or less. This may not be an issue if the product has a short lifespan or if the backlight is rarely on, such as a cell phone.

The customer needs to decide on the tradeoff between making the LED backlight brighter and a dealing with a shorter half-life.Note: Half-life of the LED is the amount of time (in hours) for the LED to become half as bright as when it was first turned on. Half-Life is not when the backlight will burn out, but when it dims to half the brightness of when it was first turned on. MTBF (Mean Time Between Failures) is the amount of time before the backlight fails.

A second option to increasing the LED brightness is to replace the Transflective polarizer with a Transmissive polarizer.Note: Each LCD contains two polarizers, the front polarizer (facing the user) is always Transmissive; the rear polarizer is selected by the user.

One disadvantage of the Transmissive polarizer is that the display is difficult to read when the backlight is off. Transmissive is not recommended for battery powered product since the backlight must always be on.

For the video display developer LCD panels are available in many sizes and resolutions, they are also available with many choices of maximum brightness. The following considers the topic of LCD panel brightness, the choices, the methods for adjusting brightness and some brightness adjustment scenarios.

LCD panels are generally rated as to their maximum brightness level which is expressed in Nits, it is equal to Candela/sqm (cd/m2), and this will be at a particular color temperature as noted in the specification, usually 10,000 K. In terms of a practical understanding, the following is a rough guide:

Outdoor displays range from a low end of 700 nits to typically 1,000 or 1,500nits and up with 2,000~2,500nits and even up to 5,000nits seen with some models. This may include standard LCD panels, custom LCD panels as well as custom cut LCD panels.

Virtually all LCD panels have a LED backlight these days, these are powered by an LED driver board. Brightness control via the driver board will be by one of two methods:

PWM (Pulse Width Modulation): This varies the duty cycle of the backlight “on time” – it is predominant in modern LCD panel LED backlight designs to enable support for digital brightness controls.

Analog: Uses a simple variable voltage to adjust brightness, for example this might be a dial or slider type potentiometer / variable resistor. To see how to enable analog backlight adjustment visit: https://www.digitalview.com/blog/brightness-adjustment/

One of the advantages of LED for the backlight is the range of adjustment that is possible, however it is important to note that the range varies significantly from model to model. Some industrial panels can be turned to very low light levels making them suitable for use in special environments such as at night. Lower cost panels limit the range of brightness to what might be required for typical usage, whereas panels with full range dimming from full off to full on require more complex backlight drivers.

Backlight lifetime: Many LCD panels have a backlight lifetime rating of 50,000 hours (typically measured to half brightness), this can be extended by running the LED backlight at a lower brightness level. Some panels may only offer 30,000 hours as a lower cost solution while other panels may offer up to 100,000 hours for high end applications.

An LCD panel backlight may be constructed so the LED’s are mounted directly behind a light guide diffuser, or they may be mounted along one or more edges of the light guide.

Active backlight: This is a function of some LCD panel backlights to automatically adjust the backlight brightness in response to the image. For more advanced systems there is an LED array making up the LED backlight, this adjusts the brightness in areas localized to the image being shown. This can greatly enhance the brightness across the display and is being used primarily with video, for example on consumer TV sets. It is not useful to all image types, for example a spreadsheet or content like maps or data is not likely to benefit.

Local dimming: Some LCD panels with direct LED may support local dimming so the LED’s are dimmed in response to the image close to them. This will not be at the same resolution as the LCD panel itself but will help greater contrast over the display by enhancing the brightness in bright areas of the image and darkening the image in dark parts of the image.

Both of the above techniques are likely to be more beneficial to certain types of content than others. For example a movie is likely to benefit more than a spreadsheet.

For the LCD monitor manufacturer it is important to consider that any covering over the LCD panel will reduce the brightness. For example the protective glass over a digital signage display, or a touch screen, or a semi-silvered mirror. So if a specific brightness is required the measurement should be taken with these in place.

There are various relatively low cost brightness meters available, typically in the couple of hundred dollars range. It is difficult to comment on the accuracy of these but we have found them to be within 5% of each other, though more importantly they do appear to be quite consistent in measurement so good for measurement comparisons. For more accurate measurement there are light meters from companies such as Minolta that can be calibrated, the cost may run into several thousand dollars.

Examples of light meters costing a few hundred dollars include SpyderX by Datacolor (needs a PC), a handheld meter is the SM208 by Sanpometer (search SM208 meter). Note: Many light meters, including smartphone apps, will be meters used for photography and not give readings in nits (or candelas). LCD panel specifications are typically measured using nits.

PWM and Analog: Most Digital View LCD controllers support PWM and Analog as a method for adjusting the backlight brightness level (this is noted in the column headed “Other” on the controller board summary table: https://www.digitalview.com/controllers/lcd-controllers-home.html. Also see https://www.digitalview.com/blog/brightness-adjustment/ for a guide to using a dial or slider type variable resistor to adjust the backlight.

DPMS (Display Power Management System): The backlight will be automatically turned off after a period if there is no valid video signal being received.

Ambient light sensor: The backlight is adjusted for brightness or powered off depending on ambient light conditions. This uses a light sensor attached to the LCD controller board, see https://www.digitalview.com/blog/light-sensor-app-note/ for more details.

The specifics of the backlight control are documented separately for each LCD controller model (product summary here) in the product manual available for download on the product page.

Note: There are two ways to adjust the perceived brightness of a LCD panel or LCD monitor, the backlight and the black-level. Very often, particularly in the past, the monitor brightness setting adjusted the black-level, this adjusts the LCD but not the backlight.

Color, color temperature etc: In addition to adjusting the brightness other settings may be adjusted as well. For example the color temperature or for example a switch to green monochrome for night vision.

Auto-dim if lights dimmed for a projector. This might be triggered by a command from a room sensor or automatically by an ambient light sensor (Autobrite+).

Night-safe lighting (update) : Dual-rail backlights can also be supported. These special backlight enable normal brightness and extreme low level brightness with custom night-safe lighting. Contact us for details.

Note: We have a blog on methods for implementing an ambient light sensor with Digital View LCD controller boards to automatically adjust the backlight or system power, see: Ambient Light Sensor

Update March 2019: Most of the above remains unchanged except for the increased availability of high bright LCD panels of around the 1,000 nit to 2,500 nit range. AUO for example has a number of large size LCD panels with 1,500 nit brightness for the digital signage market. Tianma has panels under 20″ with 1,000 nit to 1,500 nit brightness for various outdoor applications.

The other change is that high bright panels are now increasing edge-lit, this makes the panels thinner and these panels tend to use less power than the previous models. One of the benefits for monitor designers is easier heat management and reduced overall display system costs.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

1. Download the latest utility program corresponding to your LCD Monitor model from ASUS Download Center, enter the model,and click on Driver & Tools.

2. Since the label printer does not have a backlight, the angle of the label printer and the lighting conditions can affect how well the display can be viewed. For optimum viewing, place the label printer on a flat surface and view the display at a 45 degree angle.

3. New out of the box label printers have a protective film on the display that needs to be removed. Removing the film slightly improves the display"s contrast and brightness.

3. If the contrastwas better but now it is harder to read, try printing a label to test if the batteries are low. The LCD can be difficult to read when the batteries are low.

For the ABL calculation to be significant, it should correspond to the way we perceive different luminosity levels. The eye is much more sensitive to small changes in luminosity in a dark environment than in a bright one. Although the measured change in luminosity may be the same, the brighter source is better because we don"t notice the change in brightness as much. Essentially, if a screen goes from 25cd/m² to 20 cd/m², it"s more noticeable than a screen going from 100 cd/m² to 95 cd/m². This linearization is done with the PQ EOTF, as you can see below.

Each step of 1/4096 along the PQ curve shows the nonlinear relationship between the target luminosity (vertical axis), and a similar, just noticeable difference in the stimulus (horizontal axis)

PQ is a function that relates luminosity with noticeable differences in brightness. When the PQ curve is divided into 4096 segments (12-bit), there are smaller steps that relate to the change in brightness; the horizontal dotted lines represent each step, and as you can see, the first step in each segment represents a higher change than the last segment. We use this to linearize all of our luminosity measurements for this test, ensuring the ABL best represents what"s seen.

You should set your TV’s backlighting/brightness to whatever level looks best in your room. Generally, you should keep it a bit dimmer when watching in a dark room and make it very bright in a room with lots of light. Adjusting the luminance of the TV doesn"t affect picture quality, so you can easily put it to whatever setting you like.

Backlight/Brightness/OLED Light:These settings are what increase the luminosity. The majority of LED TVs call it Backlight, but Samsung and Sony use Brightness. On OLEDs, it"s usually called OLED Light, but the Vizio OLED 2020 has a Luminance setting. Whatever they"re called, these settings are meant to adjust the luminance and are the best setting to use to get the brightest image possible.

Local Dimming: Some LED TVs include a feature that darkens the backlight to make blacks extra dark, and sometimes this feature even makes highlights even brighter. Local dimming isn"t always perfect, as it could cause blooming around bright objects. Learn more about local dimming

Contrast: The contrast setting increases the brightest white, which could help increase the overall luminosity. However, changing this setting also affects picture quality, so we don"t recommend changing it for the most part.

Brightness:Opposite of contrast, the brightness setting controls the black level, and on some TVs, the setting itself is called "Black Level". Decreasing it makes blacks darker, but that means you can easily lose details, so we don"t recommend changing it.

Gamma:Gamma affects the brightness of the overall scene, but it doesn"t have an impact on the luminosity. In our testing, we want TVs to follow a gamma target of 2.2; anything higher results in a darker overall image and lower means the image is brighter. Some TVs have gamma settings, so you should change it to your liking if you notice the overall image is too dark, even if you have the backlight at its max.

Eco Mode/Light sensor: Some TVs use a sensor to detect how much light is in the room and adjust the backlight accordingly. It can be helpful, but it can also change the brightness often while you"re watching, so it"s best to turn it off.

At the end of the day, you"re the one watching TV, so if you want to make the image brighter, do whatever it takes to make it look better for your viewing experience. These are just generalized recommendation settings, and it changes between TVs.

A TV"s brightness indicates how bright images can get on the screen. It matters most if you watch TV in a well-lit room, as you want your screen to get bright enough to combat glare; otherwise, it may be hard to see. We test for a TV"s brightness to know exactly how bright it can get, but also to see if it remains a consistent brightness level across different content. If you watch TV in dark rooms, then brightness shouldn"t be something to worry about.

With all the technological development that we have been following, visual communication is one of the ways of communication that has had the greatest impact on users.

The first steps in LCD technology began in 1897, when Karl Ferdinand Braun, a physicist and inventor, built the first cathode ray tube. This tiny tube would allow the first televisions to be built, creating an industry that has progressed quickly since its inception.

The second major advance in display technology came 10 years after Karl Ferdinand Braun, in 1907, with the discovery of electroluminescence by Henry Joseph Round.

With the advances in technology, besides the creation of displays with different shapes and availability, ultra high brightness LCDs displays have emerged, an ideal solution developed for outdoor, semi-outdoor and window/glass applications.

In order to cause impact and increase the visibility of a brand, company or business, the bet in digital signage solutions (displays, video walls and menu boards) has been an added value.

The display is an excellent tool for digital communication, which can be presented in shapes formats and its main objective is to attract the public’s attention.

With all the technological development that we have been following, visual communication is one of the forms of communication that has caused more impact on users.

The Video Wall consists of two or more displays placed close together to give the impression of being just one large display, showing part of the content in a synchronised manner.

Menu Boards are a digital menu capable of transforming the communication of restaurants, bars, cafes, shops, among other commercial spaces. The digital displays are a unique opportunity for owners, because they allow displaying products and services in different supports, in a more attractive and interactive way than the traditional one.

Ultra high brightness LCDs are suitable for bright outdoor environments, even under direct sunlight, and these can be used 24/7, providing high contrast and excellent colour reproduction with a clear and visible image. This display offers a good solution for applications in environments with high sunlight exposure, ensuring that not only can its contents be seen, but also noticed, thus being a great competitive advantage.

Despite their merely similar characteristics, ultra brightness LCDs and high brightness LCDs are different when it comes to the intensity of their brightness.

PARTTEAM & OEMKIOSKS has a unique experience in the field of interactive technologies and digital signage solutions, being concerned with the quality of the multimedia kiosks and digital billboards it manufactures and commercialises.

The lass with “micro-etching” or anti-reflective treatment almost completely eliminates reflections and is suitable for use in ultra high brightness LCDs.

This glass with anti-reflective treatment is suitable whenever image quality requirements are high, allowing the installation of digital kiosks and mupis in environments susceptible to high luminosity and high reflections.

The excellent transparency of this glass allows you to have a perfect view through the glass, capable of adapting to multiple uses, making the image clearer and more sparkling.

This type of glass offers an ultra-smooth experience, presenting a better touch experience. On sunny days, glare and reflections can be a huge problem obstructing vision.

The unique properties of anti-glare glass allow these annoying elements to be filtered out and reduced, enhancing the experience through a Ultra High Brightness LCD display.

The extra clear glass is usually used to obtain a real image quality. Compared to other glasses, extra clear glass is more transparent and offers a more optimized colour rendering.

It is important to invest in ultra high brightness LCDs, a solution for high ambient light incidence applications for outdoor, semi-outdoor and window-facing applications.

Ultra high brightness LCDs can be easily viewed in direct sunlight, such as window displays or outdoor cases, without the interference of glare from glass and surrounding reflections;

For digital mupis located outdoors, due to the great sun exposure to which they are subject daily, it is important to ensure the existence of conditions that allow easy visibility of the content.

In this sense, investing in ultra high brightness LCDs is an added value for the projection of content since it ensures that no visitor will remain indifferent to the content that is being transmitted, facilitating and improving communication. All this will allow a great competitive advantage for the companies/brands which choose this kind of displays.

Therefore, PARTTEAM & OEMKIOSKS recommends ultra high brightness LCDs in order to improve the communication between the brand/ establishment and the visitors.

There are endless technical arguments for determining which screens are the best, but if you set price aside, the deciding factor usually comes down to which screen produces the best visuals — the most accurate depiction of the world as we see it with our own eyes.

Leading screen manufacturers like Samsung have turned to nanotechnology that, ironically, can’t even be seen by the naked eye but produces jaw-droppingly rich, vibrant displays. An emerging technology called Quantum Dot enhances flat-panel LED displays, commercial TVs and curved widescreen monitors, revealing many more colors and adding the necessary brightness to take full advantage of technologies like High Dynamic Range (HDR).

Quantum Dots are essentially nanoparticles that manufacturers add to the layers of films, filters, glass and electronics — sometimes called the sandwich — that comprise a Liquid Crystal Display (LCD). When these Quantum Dots are illuminated, they re-emit light of a certain color. Developing the technology for the primary QLED colors (red, blue and green) has been a technological feat, and one Samsung has overcome with its R&D hub Samsung Advanced Institute of Technology (SAIT). The team successfully developed blue QLED technology in 2020.

Because of its investment in R&D, Samsung is, by far, the market leader in Quantum Dots development and display products, with a category it calls Quantum LED (QLED). Other display manufacturers using Quantum Dots technology often include “Q” or “Quantum” in product names to make the distinction from conventional LCDs.

Quantum Dots-enhanced displays compare favorably with super-premium Organic LED displays (OLEDs), but usually at less cost, and with none of the technical issues and limitations that OLED introduces (more on that later). Quantum Dots technology first found its way into the premium TV market, and is now increasingly being used by image-sensitive brands for commercial applications such as digital signage, where the depth and accuracy of color is critically important.

What is Quantum Dot technology? A Quantum Dot is a human-made nanoparticle that has semiconductor properties. They’re tiny, ranging in size from two to 10 nanometers, with the size of the particle dictating the wavelength of light it emits, and therefore the color. When Quantum Dots are hit with a light source, each dot emits a color of a specific bandwidth: Larger dots emit light that is skewed toward red, and progressively smaller dots emit light that is skewed more toward green.

Quantum Dots are usually applied to a sheet of film that sits as a layer in that “sandwich” in front of the LED backlight that’s used to illuminate an LCD. The light passes through the LCD display stack, with the Quantum Dot color filter layer enhancing and enabling the LCD to reveal a wider and more saturated range of colors than would otherwise be possible.

Many consumer and B2B brands place heavy importance on how their products look to the marketplace. Their brands’ colors are not just blue and red — they are very specific blues and reds. Brand owners often have rigorous guidelines that mandate how these colors are reproduced, and in the case of digital displays, Quantum Dots technology provides the level of accuracy they want. Samsung’s QLED displays, for example, enable more than a billion colors.

By one estimate, Quantum Dots increase the color gamut on LCD displays by up to 50 percent. That broad range of colors also enables more saturated colors — the vivid, intense color levels that “pop” on screens and draw viewer attention.

Using Quantum Dots means the range of colors and their accuracy is maintained even at peak brightness, while other display technologies like OLED might wash out colors when scenes require full brightness. The result with QLED is accurate, rich and detailed colors on displays, in any light.

Quantum Dots LCD displays are often compared to OLED flat panel displays, with both billed as premium visual experiences. To a casual observer, they can look very similar, but there are distinct differences.

In pure technical terms, they’re different in that LCDs are illuminated by integrated but distinct LED lighting arrays, whereas OLEDs are self-emissive — each pixel is its own light.

Both technologies offer a huge range of colors, delivering eye-popping visuals. But while Quantum Dots can reproduce that full range of colors even at peak brightness, when the image on an OLED display becomes too bright, its color capabilities are compromised, and diminishing the available spectrum. Samsung QLEDs have peak brightness levels as high as 4,000 nits, which is brighter than what’s needed for outdoor displays to overpower the glare of direct sunlight.

While a QLED will provide consistent color expression throughout its operating life, the organic material driving an OLED will fade (in technical terms, lose that color expression) as it ages. OLEDs — particularly running at high brightness — are also more susceptible to burn-in, or ghosts of images or text left when a screen element (such as a logo) stays up for too long.

When flat panel displays first came into the marketplace, much of the marketing story and buyer interest focused on their shape and scale. Then the focus turned to resolution, shifting from 720p to 1080p HD and then to 4K and even 8K.

Size and pixel counts are important, but in many respects the real determining factors for brands and business users is visual quality. The real benefits of Full HD, Ultra HD and beyond come when a display can deliver that volume of detail with an exceptional depth of color, no matter the visuals. Samsung’s QLED technology is supported by AI-powered machine learning, which can scale 4K UHD and Full HD content to 8K resolution without compromising quality.

Quantum Dots may seem like a term that could only excite nerds, but one look at a QLED display will generate admiration even from people who don’t want to know all the technical details.

Explore Samsung’s full lineup ofQLED displays, designed deliver realistic detail and vibrant color to showcase your business in the best light. Looking for more buying advice? You can find everything you need to know about choosing your LED displays for optimal viewing indoors and out in thisfree, comprehensive guide.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

2015, sold to giantplus and tce photomasks, gen 3 still operated by giantplus, gen 4 line sold to giantplus, equipment sold and line demolished, remainder operated by tce

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

Colantonio, Andrea; Burdett, Richard; Rode, Philipp (2013-08-15). Transforming Urban Economies: Policy Lessons from European and Asian Cities. Routledge. ISBN 9781134622160. Archived from the original on 2019-01-01. Retrieved 2019-06-09.

Shilov, Anton. "LG"s New 55+ inch OLED Plant in China Opens: Over 1m+ per Year". www.anandtech.com. Archived from the original on 2019-09-14. Retrieved 2019-12-18.

www.wisechip.com.tw. "WiseChip History – WiseChip Semiconductor Inc". www.wisechip.com.tw. Archived from the original on 2018-02-17. Retrieved 2018-02-17.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Shilov, Anton. "JOLED Starts Construction of New Printed OLED Facility". www.anandtech.com. Archived from the original on 2019-06-30. Retrieved 2019-06-30.

Pooler, Michael (29 September 2015). "Subscribe to read". Financial Times. Archived from the original on 2019-10-25. Retrieved 2019-10-25. Cite uses generic title (help)

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey