capacitive touchscreen vs tft lcd manufacturer

Touchscreens have changed the way people expect to interact with their devices. When it comes to smartphones and tablets, touch is the way to go. Even handheld game consoles, laptops, and car navigation systems are moving towards touch. Manufacturers of these devices need to give their respective consumers the responsiveness these consumers are looking for. Selecting the right TFT-LCD display to use for different devices is important.

For touch-sensitive displays, two types of technologies are used: resistive and capacitive. The main difference is in how they respond to touch. Mobile phone comparison site Omio indicates that resistive technology is more accurate but capacitive technology is more responsive.

To elaborate on that, resistive touchscreens allow input from fingers and non-finger objects, like a stylus. A stylus has a smaller point than a finger and makes interaction on a resistive screen more accurate. This makes the technology suitable for devices whose applications require high accuracy, like sketching and pinpoint games. Mobile devices that use a stylus typically have resistive touchscreens.

Capacitive touchscreens, on the other hand, offer more responsiveness with better optical clarity and multi-touch performance. They detect more complex finger gestures. These qualities are shown to be more important for general interaction so it’s more dominant in smartphones and tablets, as well as in other devices with small to medium screen sizes.

As you can see, capacitive screens get general usage while resistive screens cater to more specific applications. With this, TFT-LCD module manufacturers, like Microtips Technology, focus on continuously improving capacitive screen technology.

Electronic Design states that many technological advances can be used to integrate touch sensors directly into the display. In some, manufacturers stack-up the touch sensors and integrate the controller with the display driver ICs. These advances allowed thinner and smarter capacitive touchscreens – a trend that you see in many devices today. For example, Windows phones originally worked exclusively with resistive touchscreen technology but later on moved over to capacitive. If the continuous development of capacitive touchscreen technology becomes successful, these screens may soon have abilities they don’t possess at the moment, such as hover support, non-finger support, and many more.

Ais not a real display screen, but a component that is mounted above the LCD screen. The capacitive touch panel is a transparent tempered glass in appearance.

A capacitive touch panel is a touch panel that is transparent like glass and does not display anything or emit light.Thecapacitive touch panelfunction is to sense the user"s touch operation.

The TFT screen is the real display screen. TFT is the most widely used liquid crystal display material.The TFT LCD screen is a thin film transistor liquid crystal screen, which is a display screen, and has no function of sensing touch, and can only be used to display an image.

In the current display screen, two types of screens, a capacitive touch panel, and a, are usually used at the same time, and the two are vertically overlapped, and the TFT LCD panel is responsible for displaying images, and the capacitive touch screen is responsible for sensing user operations. It is the origin of "internal screen" and "outer screen".

Capacitance screen and resistance screen refer to the transparent and very thin touch film on the surface of mobile phone LCD screen. If that film belongs to capacitive touch layer, then such LCD screen is called capacitive screen; otherwise it is called resistance screen; the same LCD screen can be made into capacitive screen, also can be made into resistance screen. So what"s the difference between capacitive touch screen and TFT LCD screen?

Capacitive touch screen is not a real screen, but a component installed on the top of the LCD screen. The capacitive screen is a transparent toughened glass in appearance.

Capacitive touch screen is a kind of touch screen. It is transparent like glass, it does not display any content and does not emit light. Its function is to perceive user"s touch operation.

TFT screen is the real screen. TFT is one of the most widely used materials for LCD display, which is mainly used in low and middle-end display field, and is widely used in mobile phones. TFT LCD screen is a thin film transistor LCD screen. It is a kind of display screen. It has no touch sensing function and can only be used to display images.

Current mobile phones usually use both screens at the same time. They overlap up and down. TFT LCD screen is responsible for displaying images, while capacitive touch screen is responsible for perceiving user operation. This is the origin of "inner screen" and "outer screen".

What"s the difference between capacitive touch screen and TFT LCD screen? Do you understand? Sidico Technology Co., Ltd. is engaged in the research, production and sales of 8.8 inch strip LCD screen and industrial LCD screen. It provides TFT LCD screen, customized LCD screen and excellent strip LCD screen manufacturer for industrial LCD screen.

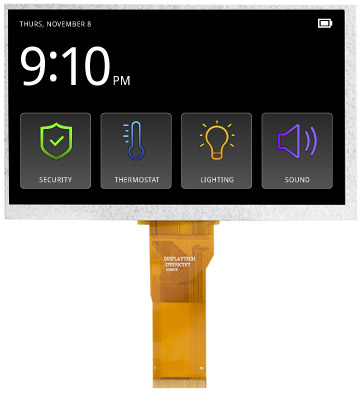

Take your product to the next level with a capacitive touch screen LCD by Displaytech. Our PCAP (projected capacitive) touch screen technology is a premium alternative to a resistive touchscreen. We offer capacitive touchscreens for our 2.8-inch, 3.5-inch, 4.3-inch, 5-inch and 7-inch TFT LCD displays.

Capacitive touch technology allows for an enhanced product user interface since it supports gestures and proximity sensing. Unlike resistive touch screens which rely on pressure, capacitive touch responds to an electric current and can handle multi-finger touch points. This means that capacitive touchscreens can be used with your bare finger and it supports gestures such as pinch-to-zoom or swipe.

The capacitive touch screen is stacked on the tft lcd display, there are two ways to make it, one is frame bonding, another one is optical bonding. the frame bonding means the capacitive touch screen attached on the tft screen by the double glue tapes via the lcd frame on the four sides. the optical bonding means the full lamination about the capacitive touch screen and tft lcd screen, that is the lamination is via OCA glue, and full lamination about the capacitive touch panel and tft lcd screen.

Projected capacitive touch (PCT) technology is a capacitive technology which allows more accurate and flexible operation, byetchingthe conductive layer. AnX-Y gridis formed either by etching one layer to form a grid pattern ofelectrodes, or by etching two separate, parallel layers of conductive material with perpendicular lines or tracks to form the grid; comparable to thepixelgrid found in manyliquid crystal displays(LCD).

There are many types of touch panel technologies available in the market, the popular types are we are going to discuss the two most widely used types, and compare resistive vs capacitive touch screen

Projected Capacitive Touch Panel (PCAP) was actually invented 10 years earlier than the first resistive touchscreen. But it was no popular until Apple first used it in iPhone in 2007. After that, PCAP dominates the touch market, such as mobile phones, IT, automotive, home appliances, industrial, IoT, military, aviation, ATMs, kiosks, Android cell phones etc.

Projected capacitive touchscreen contains X and Y electrodes with insulation layer between them. The transparent electrodes are normally made into diamond pattern with ITO and with metal bridge.

Human body is conductive because it contains water. Projected capacitive technology makes use of conductivity of human body. When a bare finger touches the sensor with the pattern of X and Y electrodes, a capacitance coupling happens between the human finger and the electrodes which makes change of the electrostatic capacitance between the X and Y electrodes. The touchscreen controller detects the electrostatic field change and the location.

Projected capacitive supports multiple touches (Multi-touch), so it supports a lot of gestures: Zoom in and out (pinch/spread), scroll, swipe, drag, slide, hold/press, rotate, tap etc.

With the new development, projected capacitive touch panels can support gloved hand touch with different glove materials and touch with water or even with salt water.

With the fast development of projected capacitive, resistive touchscreen devices market is shrinking rapidly but it is still widely used in some industrial applications because of the following advantages.

The following table shows the comparison of resistive and capacitive touch screens. It is up to your application to select the types of technology to use.

If you want to buy a new monitor, you might wonder what kind of display technologies I should choose. In today’s market, there are two main types of computer monitors: TFT LCD monitors & IPS monitors.

The word TFT means Thin Film Transistor. It is the technology that is used in LCD displays. We have additional resources if you would like to learn more about what is a TFT Display. This type of LCDs is also categorically referred to as an active-matrix LCD.

These LCDs can hold back some pixels while using other pixels so the LCD screen will be using a very minimum amount of energy to function (to modify the liquid crystal molecules between two electrodes). TFT LCDs have capacitors and transistors. These two elements play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy while still generating vibrant, consistent images.

Industry nomenclature: TFT LCD panels or TFT screens can also be referred to as TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology.

IPS (in-plane-switching) technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but has more enhanced features and more widespread usability.

These LCD screens offer vibrant color, high contrast, and clear images at wide viewing angles. At a premium price. This technology is often used in high definition screens such as in gaming or entertainment.

Both TFT display and IPS display are active-matrix displays, neither can’t emit light on their own like OLED displays and have to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light-emitting diodes) to generate their light hence utilizing less power and requiring less depth by design. Neither TFT display nor IPS display can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to produce the color consumers see. If you use a magnifier to inspect your monitor, you will see RGB color in each pixel. With an on/off switch and different level of brightness RGB, we can get many colors.

Winner. IPS TFT screens have around 0.3 milliseconds response time while TN TFT screens responds around 10 milliseconds which makes the latter unsuitable for gaming

Winner. the images that IPS displays create are much more pristine and original than that of the TFT screen. IPS displays do this by making the pixels function in a parallel way. Because of such placing, the pixels can reflect light in a better way, and because of that, you get a better image within the display.

Winner. While the TFT LCD has around 15% more power consumption vs IPS LCD, IPS has a lower transmittance which forces IPS displays to consume more power via backlights. TFT LCD helps battery life.

Normally, high-end products, such as Apple Mac computer monitors and Samsung mobile phones, generally use IPS panels. Some high-end TV and mobile phones even use AMOLED (Active Matrix Organic Light Emitting Diodes) displays. This cutting edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology.

What you need to choose is AMOLED for your TV and mobile phones instead of PMOLED. If you have budget leftover, you can also add touch screen functionality as most of the touch nowadays uses PCAP (Projective Capacitive) touch panel.

This kind of touch technology was first introduced by Steve Jobs in the first-generation iPhone. Of course, a TFT LCD display can always meet the basic needs at the most efficient price. An IPS display can make your monitor standing out.

Capacitive touch screen technologyUSES the human body’s current induction to work. The capacitive touch screen is a four-layer composite glass screen. The inner surface of the glass screen and the interlayer are coated with one layer of ITO respectively. The outermost layer is a thin layer of silica soil glass protective layer. When the finger touches the metal layer, the user and the touch screen surface form a coupling capacitor due to the electric field in the human body.

In order to realize multi-touch on a capacitive screen, it is necessary to add electrodes of mutual capacitance. In a simple words, it is to divide the screen into blocks and set a group of mutual capacitance modules in each area to work independently. Therefore, the capacitive screen can independently detect the touch situation of each area and simply realize multi-touch after processing.

Capacity Touch Panel USES the current induction of the human body to work. The capacitive screen is a four-layer composite glass screen. The inner surface of the glass screen and the interlayer are coated with ITO (indium sikgold oxide nano). The outermost layer is a protective layer of silica glass with a thickness of 0.0015mm.

Whena user capacitive touch screen, the electric field due to the human body, your fingers and face form a coupling capacitance, because the working plane to have a high-frequency signal, so the fingers on a very small current, respectively from the current screen in the four corners of the electrode, and theoretically through the four electrodes with the finger to the four corners of the current is proportional to the distance, the controller through the precise calculation of the four current ratio, it is concluded that location. It can achieve 99% accuracy, with a response speed of less than 3ms.

Projective capacitive touch screens etch different ITO conductive circuit modules on two layers of ITO conductive glass coatings. The etched patterns on the two modules are perpendicular to each other and can be thought of as sliders with continuous changes in X and Y directions. As the X and Y architectures are on different surfaces, their intersection forms a capacitor node. One slider can be used as the drive wire and the other as the detection wire. When a current passes through one of the wires in the drive wire, if there is a signal of a change in the capacitance outside, it will cause a change in the capacitance node on the other layer of wire. The change in capacitance can be detected by measuring the electrical circuit connected to it, and then converted to A digital signal by A/D controller, which can be processed by A computer to obtain the (X, Y) axis position, so as to achieve the positioning target.

Commonly used is the surface capacitive touch screen, which works in simple principle, low price, simple circuit design, but difficult to achieve multi-touch.

Projective capacitive touch screens are multi-finger touch. These two capacitive touch screens have the advantages of high light transmittance, fast response speed, and long life, etc. The disadvantages are: with the change of temperature and humidity, the capacitance value will change, resulting in poor work stability, often drift phenomenon, need to frequently proofread the screen, and can not wear ordinary gloves for touch positioning.

The projected capacitive touch screen can be divided into the capacitance and mutual capacitance screen two types, one of the more common mutual capacitance screen as an example, the internal electrode and receiving electrode by the driver, drive electrode signal low voltage high frequency projected onto the receiving electrode form stable current, when human exposure to the capacitance screen, earth due to the human body, fingers and capacitance screen to form an equivalent capacitance, and the high-frequency signal by the equivalent capacitance into the ground, in this way, the receiver receives charge is reduced, when fingers near the transmitter, electric charge, the more significant, according to the receiving end receives the current strength of to determine the touchpoint.

Arrays of transverse and longitudinal electrodes are made from ITO on the surface of the glass. These transverse and longitudinal electrodes form capacitors with the ground respectively. This capacitor is commonly referred to as self-capacitance, that is, the capacitance of the electrode to the ground. When the finger touches the capacitive screen, the capacitance of the finger will be superimposed on the capacitance of the screen, thus increasing the capacitance of the screen.

During touch detection, the horizontal and longitudinal electrode arrays are respectively detected from the capacitive screen. According to the changes of capacitance before and aftertouch, the horizontal coordinates and longitudinal coordinates are determined respectively, and then the touch coordinates of the plane are combined. The scanning method of self-capacitance is equivalent to projecting the touchpoints on the touch screen to the X-axis and Y-axis directions respectively, and then calculating the coordinates in the X-axis and Y-axis directions respectively, and finally combining them into the coordinates of the touchpoints.

If it is a single touch, the projection in the X and Y direction is unique, and the combined coordinates are unique. If there are two touches on the touch screen and the two touches are not in the same X direction or the same Y direction, then there are two projections in the X and Y direction respectively, and the combined coordinates are 4.Apparently, only two of the coordinates are real, and the other two are known as ghost points. Therefore, self – the capacitive screen can not achieve true multi-touch.

The mutual capacitor screen also USES ITO to make the transverse electrode and the longitudinal electrode on the glass surface. The difference between it and the self-capacitor screen is that the place where the two groups of electrodes cross will form a capacitor, that is, the two groups of electrodes form the electrodes of the capacitor respectively. When a finger touches a capacitive screen, the coupling between two electrodes near the touchpoint is affected, thus changing the capacitance between the two electrodes.

The advantage of the mutual capacitive screen is less wiring, and can simultaneously identify and distinguish the difference between multiple contacts since the capacitive screen can also sense multiple contacts, but because the signal itself is fuzzy, so can’t distinguish. In addition, the induction scheme of the mutual capacitive screen has the advantages of fast speed and low power consumption, because it can measure all the nodes in a driveline at the same time, thus reducing the number of acquisition cycles by 50%. The dual-electrode structure has the function of self-shielding external noise and can improve signal stability at a certain power level.

• Capacitive schemes last longer because the components in the capacitive touch screen do not need to move at all. In a resistive touch screen, the top layer of the ITO film needs to be thin enough to be elastic so that it bends down and touches the bottom layer of the ITO film.

• The choice of capacitor or resistor depends largely on the object touching the screen. If it is a finger touch, the capacitive touch screen is a better choice. If a stylus is needed, whether plastic or metal, a resistive touch screen will do. A capacitive touch screen can also use a stylus but requires a special stylus to work with it.

• Capacitive technology is wear-resistant, has a long service life, and has low maintenance costs when users use it, so the overall operating costs of manufacturers can be further reduced.

• Capacitive touch screens are designed to support multi-touch technology and are less responsive and less prone to wear and tear than resistive touch screens.

STONE provides a full range of 3.5 inches to 15.1 inches of small and medium-size standard quasi TFT LCD module, LCD display, TFT display module, display industry, industrial LCD screen, under the sunlight visually highlight TFT LCD display, industrial custom TFT screen, TFT LCD screen-wide temperature, industrial TFT LCD screen, touch screen industry. The TFT LCD module is very suitable for industrial control equipment, medical instruments, POS system, electronic consumer products, vehicles, and other products.

![]()

Capacitive touchscreen TFT LCDs are available in 2.8", 3.5", 4.3", 5.0", 7.0", and 10.1" diagonal sizes. Capacitive touch TFTs offer excellent contrast and clarity, have a built-in I2C interface, excellent dragging performance, and accept multi-point inputs, also known as multi-touch.

Capacitive touch panels are the more modern and advanced touchscreen option because of their advanced capabilities. They are commonly found in consumer products like smartphones, tablets, appliances, and monitors.

A capacitive touchscreen detects and responds to changes in capacitance caused by the screen"s electrostatic field when the screen"s surface is touched.

Capacitive touchscreen displays allow for touch gestures and respond to multi-touch inputs. You’ll typically be able to enter one to five touch inputs simultaneously, but some capacitive touchscreens can process even more.

Capacitive touchscreens deliver brighter, higher contrast images due to the makeup of their panels. Displays with capacitive touch screens are more durable than resistive touch screens because they are designed with cover glass on their top layer. In fact, all of our capacitive TFT displays have standard 0.7mm thick built-in cover glass and can be further

While the cost is currently higher than resistive touchscreens, capacitive touchscreens are quickly becoming the industry standard in touchscreen technology.

The enhanced responsiveness can be a downside depending on how and where the display is used. For example, a capacitive touchscreen would not easily respond to the user while wearing certain types of gloves. Although capacitive touchscreens don’t respond to inorganic inputs, they can still be accidentally activated by other conductive elements. One of the the most common elements that causes interruptions is water.

Rain, humidity, and condensation on the surface of capacitive touchscreens will often cause accidental inputs and reduced accuracy until the water is removed. This is one of the main reasons why a resistive touchscreen would be chosen over a capacitive touchscreen in certain situations.

Any device that utilizes touch gestures like swiping, pinching, or multi-touch will require a capacitive touchscreen. These features often help make capacitive touchscreen displays more intuitive and user-friendly than resistive touchscreens. Capacitive touchscreens are best suited for applications requiring improved touch responsiveness with better image brightness and contrast.

sense pressure on the display"s top layer and send a signal to the circuit layer to activate the touchscreen functionality. Because they use pressure to activate the touch inputs, resistive touchscreen displays can be used with a stylus, gloves, and other items. Resistive touchscreens are built without cover glass and made of plastic, making them more susceptible to dents and scratches.

Resistive touchscreens are often seen as the less advanced variety of touch panel compared to capacitive touch panels. However, being able to interact with non-organic inputs keeps these touchscreens relevant in specific industries.

Resistive touchscreen displays are less sensitive than capacitive touchscreen displays. This is considered an advantage in some cases and is why they’re chosen for specific applications. Resistive touchscreens will not respond to accidental inputs from the environment, so they won’t be interrupted by things like water spills or lightweight debris landing on the screen.

This type of touchscreen requires more intentional inputs from the user, making them more reliable in rugged and unstable environments. For example, a resistive touchscreen is the perfect solution on a construction site where water or debris might land on the screen. They’re also the best touchscreen display option for situations where the user is wearing gloves.

Resistive touchscreen panels are unfortunately more susceptible to dents and scratches. Their poor visibility in direct sunlight does not make them ideal for outdoor applications. Their inability to respond to multi-touch inputs can be a disadvantage in fast-paced applications requiring such. Because resistive touchscreens rely on the pressure applied to the top layer, they tend to be abused and mishandled, which makes them less durable over time than capacitive touchscreens.

Resistive touchscreen technology is ideal for low-cost applications involving rugged environments, indirect sunlight, and simple touch features. Fewer accidental touch inputs, better resistance to heat and moisture, and the ability to be operated with pretty much anything (stylus, pen, gloves, fingers, etc.) make this touchscreen technology a more reliable solution when user input is crucial.

While it’s clear that capacitive touchscreens are dominating the consumer electronics market, resistive touchscreens still have an advantage in some ways.

If you’re looking for a cost-effective touchscreen that can operate with simple tap inputs in rugged environments, resistive is the way to go. For more advanced and intuitive touchscreen technology with higher quality applications, choose capacitive touchscreens.

A projective capacitive touch screen is a clear overlay which uses measures nearby conductive disturbances. It consists of a piece of cover glass over a sensor grid layer made of transparent conductive material. The layer configuration used by this technology can accommodate multiple touch events, and reduces the transmittance, or brightness, of the display underneath by only 10% to 20%. Capacitive touch overlays can be heavier than their resistive counterparts, and are often more expensive. However, this technology is much harder than resistive touch, with a scratch hardness value of 6, and suffers limited degradation over its lifespan. Capacitive touch requires a direct finger input, or specialized glove or stylus. Nonetheless, this capacitive touch has become the input standard for advanced consumer applications.

_7.jpg)

If your applications require a wider viewing angle, Winstar O Film TFT technology will be what you need. There are many wider view angle technology for TFT displays in the market such as MVA (Multi-domain Vertical Alignment) and IPS (In-Plane Switching). Comparing to the MVA or IPS technology, O Film TFT has the advantage of pricing.

Most industrial application of TFT-LCD glasses that are available in the market are TN-LCD type. However, TN technology suffers from phenomenon called gray scale inversion. This means the display have one viewing side in which color of the image change suddenly after exceeding specified view angle. Therefore, the normal TFT models we offer which the viewing angle are limited. Currently, we offer a solution to enhance TN glass viewing angle and can overcome gray scale inversion. This is our TFT O-Film solution.

The modle of WF43VTZAEDNGA is a standard 4.3 inch O Film TFT LCD Capacitive Touchscreen Display which with a wide view angle solution. Winstar offers a wider view angle solution for our TFT product line. We add an O Film on top of the TFT TN-LCD glass to enhance the viewing angle. This will be a cost effectiveness solution in the industrial application for color TFT displays to enhance the view angle.

TFT Display modules with Capacitive Touch Screen are more user-friendly and have better performance compared with the ones with Resistive Touch Screen. There are many combinations of TFT display modules with projected capacitive touchscreen (PCAP) for you to choose from. We offer modules with various features including modules with control board, wide viewing angle, sunlight readable, wide temperature, and Monochrome. The available sizes are 0.96", 3.5", 3.9", 4.3", 5", 5.2" 5.7", 7" and 10.1"

Capacitive Touch Panel, WHITE LED backlight, All Viewing Angles, Wide temperature range, Transmissive polarizer, 450 NITS, CTP controller: FT6236, RoHS Compliant

The Capacitive touch panel is activated with anything containing an inductive load such as a finger or stylus. It allows for multi-touch options. When using the capacitive touch screen, the display needs a separate controller to interface with the touch panel. The display for capacitive touch is brighter since the touch panel is transparent.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

The Capacitive touch panel is activated with anything containing an inductive load such as a finger or stylus. It allows for multi-touch options. When using the capacitive touch screen, the display needs a separate controller to interface with the touch panel. The display for capacitive touch is brighter since the touch panel is transparent.

The Transmissive polarizer is best used for displays that run with the backlight on all the time. This polarizer provides the brightest backlight possible. If you have a need for a bright backlight with lower power drain, transmissive is a good choice for this TFT LCD display.

Focus LCDs can provide many accessories to go with your display. If you would like to source a connector, cable, test jig or other accessory preassembled to your LCD (or just included in the package), our team will make sure you get the items you need.Get in touch with a team member today to accessorize your display!

Focus Display Solutions (aka: Focus LCDs) offers the original purchaser who has purchased a product from the FocusLCDs.com a limited warranty that the product (including accessories in the product"s package) will be free from defects in material or workmanship.

A capacitive touchscreen consists of a display and a touch panel. A control is usually already integrated. Some call the capacitive touch panel display screen only the touch panel. In any case, however, it is about the possibility of making entries on a larger area in order to read outputs at the same time or to display keypads and input or output. hide. Vandal-proof glass panes are required for POI stations, in industry and medical technology it is necessary that the touch screen can also be operated with gloves (resistive touch panel).

Typical representatives of capacitive touch screens are the EA eDIPTFT display and the EA uniTFT capacitive touch display (linked here). You can buy these touchscreens in different sizes and designs.

The CFAF800480E0-050SC is a 5-inch color TFT LCD graphic display module with high-brightness, sunlight-readable backlight and a capacitive touch panel (CTP).

The touch panel can detect up to 5 separate touch points. This TFT display is suitable for industrial, media, embedded and other general-purpose display applications.

In chapter 7, we made use of the segmented LCD display on the Wonder Gecko Starter Kit through the use of a pre-built LCD library and driver when designing the user interface for the sprinkler timer. That made things easy for us, and we didn’t really need to dwell on how the driver worked. In this chapter, we will dig into some of those details so that we can connect the EFM32 to any kind of display we choose.

The display we will be using for this chapter is the Adafruit 2.8” 240x320 TFT LCD Capacitive Touch screen, shown below. We will interface with it over SPI for transferring image data and I2C for reading the touch interface. We will learn how to interface with it with our own drivers and build our own simple graphics libraries, as well.

Segmented Display: We have already worked with the segmented LCD display in chapter 7, also known as a character display. In such a display, there are a fixed matrix of LCD segments that are preconfigured in hardware to convey specific information. They are not flexible enough to display an image, but they don’t require many pins on the MCU and are easier to program. For example, the number “9” can be formed on such a display with as few as 6 signals.

Note that a new “Memory LCD” described in Silicon Labs application note AN0048 couples a memory device within each pixel so that constant refreshing is not necessary, reducing power consumption as well.

Graphical display screens have many different technologies, from passive-matrix Liquid Crystal Display (LCD) or active-matrix Thin Film Transistor (TFT) LCD, Light Emitting Diode (LED), or Organic LED (OLED). Display technology is not the focus of this chapter. No matter which technology you choose, you will still need to understand the topics of this chapter in order to display your images.

The LCD pixel matrix is the heart of the display. This part is responsible for displaying the image and, in the case of LCD displays, it will either allow or prevent light from a backlight to pass through. In the case of LED displays, the pixel matrix produces the light and forms the image in one step. No matter the process, the pixel matrix is comprised of an array of pixels in height and width of a certain color depth that make up the display. For the display used in this chapter, the color depth is 18 bits, consisting of 6 bits each for the red/blue/green components of a pixel. That means that the information required to paint the screen one time is 240 bits wide x 320 bits tall x 18 bits of color = 172,800 bytes. That’s a lot of data, and it is more data than we can hold in the RAM of the Wonder Gecko MCU. Therefore, it will require some intelligent code to drive the display or an external memory buffer to store the image data.

The backlight is necessary for TFT LCD displays to allow the display to be seen. Without a backlight, a color TFT LCD will show no image. A monochrome LCD is a little different, since the segments can be seen if they are in the “on” state. The brightness of an LCD screen is sometimes controlled by applying a Pulse Width Modulated (PWM) signal to a pin (or pins) that controls the LED backlight. This is exactly what we have already done in the last chapter to dim an LED.

A frame buffer is a block of RAM that holds all of the color information for every pixel (172 kB for this display) that is used to paint a single image (or “frame”) to the display. This buffer is required to exist somewhere in the system because it is used by the display driver chip to refresh the LCD image many times per second.

A capacitive touch screen requires no physical contact between the user and the sensor. Therefore, the sensor can be placed beneath hardened glass or plastic. A valid touch is formed by the change in capacitance measured on the sensor. A human finger can change the capacitance of this sensor, whereas a plastic stylus will not produce a change in capacitance. The capacitive touch screen used in this chapter uses a controller that communicates via the I2C interface.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey