controlling tft display factory

![]()

Display screen is everywhere nowadays. Do you still remember the TVs or computer monitors 20 years ago? They were quadrate, huge and heavy. Now let’s look at the flat, thin and light screen in front of you, have you ever wondered why is there such a big difference?

Actually, the monitors 20 year ago were CRT (Cathode Ray Tube) displays, which requires a large space to run the inner component. And now the screen here in your presence is the LCD (Liquid Crystal Display) screen.

As mentioned above, LCD is the abbreviation of Liquid Crystal Display. It’s a new display technology making use of the optical-electrical characteristic of liquid crystal.

Liquid crystal is a state of substance that has both the characteristics of liquid and solid crystal. It don’t emit light itself, but it can let the light pass perfectly in specific direction. Meanwhile, liquid crystal molecule will rotate under the influence of a electric field, and then the light goes through it will rotate too. That said, liquid crystal can be a switch of light, which is the key in display technology.

STN LCD: STN is for Super-twisted Nematic. The liquid crystal in STN LCD rotate more angles than that in TN LCD, and have a different electrical feature, allowing STN LCD to display more information. There are many improved version of STN LCD like DSTN LCD (double layer) and CSTN LCD (color). This LCD is used in many early phones, computers and outdoor devices.

TFT LCD: TFT is for Thin Film Transistor. It’s the latest generation of LCD technology and has been applied in all the displaying scenario including electronic devices, motor cars, industrial machines, etc. When you see the word ‘transistor’, you may realize there’s integrated circuits in TFT LCD. That’s correct and the secret that TFT LCD has the advantage of high resolution and full color display.

In a simple way, we can divide TFT LCD into three parts, from bottom to top they are: light system, circuit system and light and color control system.In manufacturing process, we’ll start from inner light and color control system and then stretch out to whole module.

It’s accustomed to divide TFT LCD manufacturing process into three main part: array, cell and module. The former two steps are about the production of light and color control system, which contains TFT, CF (color filter) and LC (liquid crystal), named a cell. And the last step is the assembly of cell, circuit and light system.

Now let’s turn to the production of TFT and CF. Here is a common method called PR (photoresist) method. The whole process of PR method will be demonstrated in TFT production.

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

TFT (Thin Film Transistor) LCD (Liquid Crystal Display) dominates the world flat panel display market now. Thanks for its low cost, sharp colors, acceptable view angles, low power consumption, manufacturing friendly design, slim physical structure etc., it has driven CRT(Cathode-Ray Tube) VFD ( Vacuum Fluorescent Display) out of market, squeezed LED (Light Emitting Diode) displays only to large size display area. TFT LCD displays find wide applications in TV, computer monitors, medical, appliance, automotive, kiosk, POS terminals, low end mobile phones, marine, aerospace, industrial meters, smart homes, handheld devices, video game systems, projectors, consumer electronic products, advertisement etc. For more information about TFT displays, please visit our knowledge base.

There a lot of considerations for how to choose a most suitable TFT LCD display module for your application. Please find the check list below to see if you can find a right fit.

It is the start point for every project. There aretwo dimensions to consider: outside dimension (width, height, thickness) and AA (active area or pixel area). Orient Display’s standard product line ranges from 1.0” to 32”. Our OLED size can go down to 0.66” which fit for wearable devices.

Resolution will decide the clearance. Nobody likes to see a display showing pixel clearly. That is the reason for better resolution, going from QVGA, VGA to HD, FHD, 4K, 8K. But higher resolution means higher cost, power consumption, memory size, data transfer speed etc. Orient Display offers low resolution of 128×128 to HD, FHD, we are working on providing 4K for our customers. For full list of resolution available, please see Introduction: LCD Resolution

TFT screen brightness selection is very important. You don’t want to be frustrated by LCD image washout under bright light or you drain the battery too fast by selecting a super brightness LCD but will be used indoor only. There are general guidance listed in the table below.

Orient Display offers standard brightness, medium brightness , high brightness, and high end sunlight readable IPS TFT LCD display products for our customers to choose from.

If the budget is tight, TN type TFT LCD can be chosen but there is viewing angle selection of either 6 o’clock or 12 o’clock. Gray scale inversion needs to be taken of carefully. If a high-end product is designed, you can pay premium to select IPS TFT LCD which doesn’t have the viewing angle issue.

It is similar to viewing angle selection, TN type TFT LCD has lower contrast but lower cost, while IPS TFT LCD has much high contrast but normally with higher cost. Orient Display provides both selections.

Normal TFT LCD displays provide wide enoughtemperature range for most of the applications. -20 to 70oC. But there are some (always) outdoor applications like -30 to 80oC or even wider, special liquid crystal fluid has to be used. Heater is needed for operating temperature requirement of -40oC. Normally, storage temperature is not an issue, many of Orient Display standard TFT display can handle -40 to 85oC, if you have any questions, feel free to contact our engineers for details.

Power consideration can be critical in some hand-held devices. For a TFT LCD display module, backlight normally consumes more power than other part of the display. Dimming or totally shutdown backlight technology has to be used when not in use. For some extreme power sensitive application, sleep mode or even using memory on controller consideration has to be in design. Feel free to contact our engineers for details.

Genetic Interfaces: Those are the interfaces which display or touch controller manufacturers provide, including parallel, MCU, SPI(,Serial Peripheral Interface), I2C, RGB (Red Green Blue), MIPI (Mobile Industry Processor Interface), LVDS (Low-Voltage Differential Signaling), eDP ( Embedded DisplayPort) etc. Orient Display has technologies to make the above interface exchangeable.

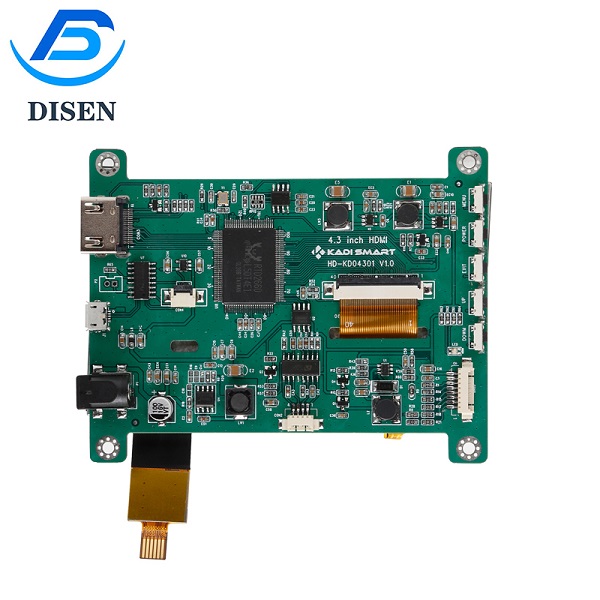

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

If you can’t find a very suitable TFT LCD Display in our product line, don’t be discouraged. The products listed on our website is only small part of standard products. We have thousands of standard products in our database, feel free to contact our engineers for details.

If you like to have a special display, Orient Display is always flexible to do partial custom solution. For example, to modify the FPC to different length or shape, or use as fewer pinouts as possible, or design an ultra-bright LCD display, or a cover lens with your company logo on it, or design an extreme low power or low cost TFT display etc. our engineers will help you to achieve the goals. The NER cost can start from hundreds of dollars to Thousands. In rare case, it can be tens of thousands of dollars.

A fully custom TFT LCD panel can have very high NRE cost. Depending on the size of the display, quantity and which generation production line to be used. The tooling cost can start from $100,000 to over $1M.

Orient Display sunlight readable TFT displays can be categorized into high brightness TFT displays, high contrast IPS displays, transflective TFT displays, Blanview TFT displays etc.

The brightness of our standard high brightness TFT displays can be from 700 to 1000 nits. With proper adding brightness enhancement film (BEF) and double brightness enhancement film (DBEF) and adjustment of the LED chips, Orient Display high brightness TFT products can achieve 1,500 to 2,000 nits or even higher luminance. Orient Display have special thermal management design to reduce the heat release and largely extend LED life time and reduce energy consumption.

Our high contrast and wide viewing angle IPS displays can achieve contrast ratio higher than 1000:1 which can make readability under strong sunlight with lower backlight luminance. High brightness IPS displays have been widely accepted by our customers with its superb display quality and it has become one of the best sellers in all our display category.Transflective display is an old monochrome display technology but it has been utilized in our color TFT line for sunlight readable application. Orient Display has 2.4” and 3.5” to choose from.

Blanview TFT displays are the new technology developed by Ortustech in Japan. It can provide around 40% of energy consumption for TFT panels which can use smaller rechargeable or disposable batteries and generate less heat. The price is also lower than traditional transflective TFT displays. Orient Display is partnering with the technology inventor to provide 4.3” and 5.0”.

Orient Display can also provide full customized or part customized solutions for our customers to enhance the viewing experience. Orient Display can provide all the different kinds of surface treatments, such as AR (Anti-reflection); AG (Anti-glare), AF (Anti-finger print or Anti-smudge); AS (Anti-smashing); AM (Anti-microbial) etc. Orient Display can also provide both dry bonding (OCA, Optical Clear Adhesive), or wet bonding (OCR, Optical Clear Resin and OCG, Optical Clear Glue) to get rid of light reflective in air bonding products to make the products much more readable under sunlight and be more robust.

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch.

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

Engineers are always looking for lower cost, faster, more convenient interfaces to transmit signals and to accept data and commands. The numbers of available interfaces available in the market can be dazzling. Orient Display follows market trends to produce various kind of interfaces for our customers to choose.

Genetic Interfaces: Those are the interfaces which display or touch controller manufacturers provide, including parallel, MCU, SPI(,Serial Peripheral Interface), I2C, RGB (Red Green Blue), MIPI (Mobile Industry Processor Interface), LVDS (Low-Voltage Differential Signaling), eDP ( Embedded DisplayPort) etc. Orient Display has technologies to make the above interface exchangeable.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

Raystar is a global leading LCD panel supplier and specialized in producing TFT LCD Panel, including Color TFT, Monochrome TFT Display and bar type TFT Display. Raystar Color TFT displays are available in various resolutions and offers a wide product range of small to medium-sized TFT-LCD modules from 0.96” to 12.3". The interface options are in MCU / RGB / SPI / UART / 8080 / LVDS. TFT Panel with control board or TFT LCD Panel with micro controller are also available.

INT028ATFT and INT028ATFT-TS are embedded display driver boards based on our 2.8 inch 240 x 320 RGB resolution TFT display module. Mounted on the embedded board is the RAIO RA8872 LCD controller that offers the following features and benefits:

Winstar is a global leading Manufacturer of TFT LCD display based in Taiwan and China. Winstar offers a wide product range of small to medium sizes TFT display modules in sizes ranging such as 2.4″ TFT LCD, 2.8″ TFT LCD, 3.2″ TFT LCD, 3.5″ TFT Display, 4.3 inch TFT LCD, 5 TFT LCD, 5.6 TFT LCD, 5.7 inch Display, 7 ” TFT LCD, 8″ TFT, 9″ TFT, 10.1″ TFT LCD, 10.2″ TFT LCD, 12.1″ TFT LCD , 12.3″ TFT LCD (diagonal size of the active area) and so on . There are more than 200 TFT standard models listed on this website; furthermore, almost each item is acceptable to derivate from the standard items to meet the customers’ requirement.Winstar TFT displays are qualified under industrial standard including standard TFT-LCD modules, IPS TFT, High brightness TFT LCD (sunlight readable display), TFT panels with controller boards, Bar Type TFT, Wide Temperature TFT LCD, Winstar Clever System TFT and Touch screen display. These displays include landscape or portrait modes. Winstar has Mono TFT displays and full color TFTs in line, these displays are available in various resolutions as well as touch screen optional in resistive and projected capacitive (PCAP touch screen) technology. Many of our TFT display modules have more than one interface available including MCU, RGB, TTL, LVDS and MIPI DSI. Winstar TFT modules are perfect for a number of applications including industrial control, coffee machine, medical equipment, POS system, automation, GPS navigator, white goods, energy control, telecoms, medical equipment and etc.

RFF800P-1IW-DBN is one of the models in our P series---8-inch TFT-LCD display module with controller board. The resolution of this module is 800x480 pixels. The P series mainly uses RA8875 Controller IC. The TFT modules of this series are all characterized by the 36pin MCU 8080 8/16-bits Pin define, and 8/16-bits 6800 Pin define Interface can be selected through Jump. In addition, you can request external expansion of Chinese fonts (Optional) and flash memory. Through the built-in PWM Command of RA8875 IC, it can control its backlight and DMA (Direct Memory Access) to accelerate graphics.

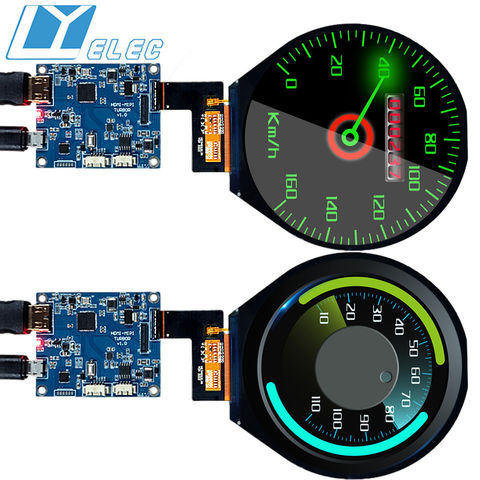

6.Special share LCD can be customized,such as bar,square and round LCD display can be customized or any other special shaped display is available to custom.

Winstar is a global leading Manufacturer of TFT LCD display based in Taiwan and China. Winstar offers a wide product range of small to medium sizes TFT display modules in sizes ranging such as 0.96",1.28", 1.77, 2", 2.4", 2.8", 3.2", 3.5", 4.3", 5" 5.6", 5.7", 7", 8", 9", 10.1", 10.2", 12.1" , 12.3" and 15" TFT (diagonal size of the active area) and so on . There are more than 250 TFT standard models listed on this website; furthermore, almost each item is acceptable to derivate from the standard items to meet the customers" requirement.

Winstar TFT displays are qualified under industrial standard including standard TFT-LCD modules, IPS TFT, High brightness TFT LCD (sunlight readable display), TFT panels with controller boards, Bar Type TFT, Wide Temperature TFT LCD, Winstar Clever System TFT and Touch screen display. These displays include landscape or portrait modes. Winstar has Mono TFT displays and full color TFTs in line, these displays are available in various resolutions as well as touch screen optional in resistive and projected capacitive (PCAP touch screen) technology. Many of our TFT display modules have more than one interface available including MCU, RGB, TTL, LVDS and MIPI DSI. Winstar TFT modules are perfect for a number of applications including industrial control, coffee machine, medical equipment, POS system, automation, GPS navigator, white goods, energy control, telecoms, medical equipment and etc.

STONE provides customers with an Intelligent HMI solution. The intelligent TFT LCD module with a Cortex-M4 32-bit CPU can be controlled by any MCU via simple Hex Instruction through the UART port. STONE TFT LCD module consists of a CPU, TFT drives, flash memory, UART port, power supply, etc. STONE also provides a basic control program and powerful design software (STONE TOOL Box). https://www.stoneitech.com/product/by-size/4-3-tft-lcd-display

A wide variety of tft display board touch controller options are available to you, You can also choose from original manufacturer, odm and agency tft display board touch controller,As well as from tft, ips, and standard.

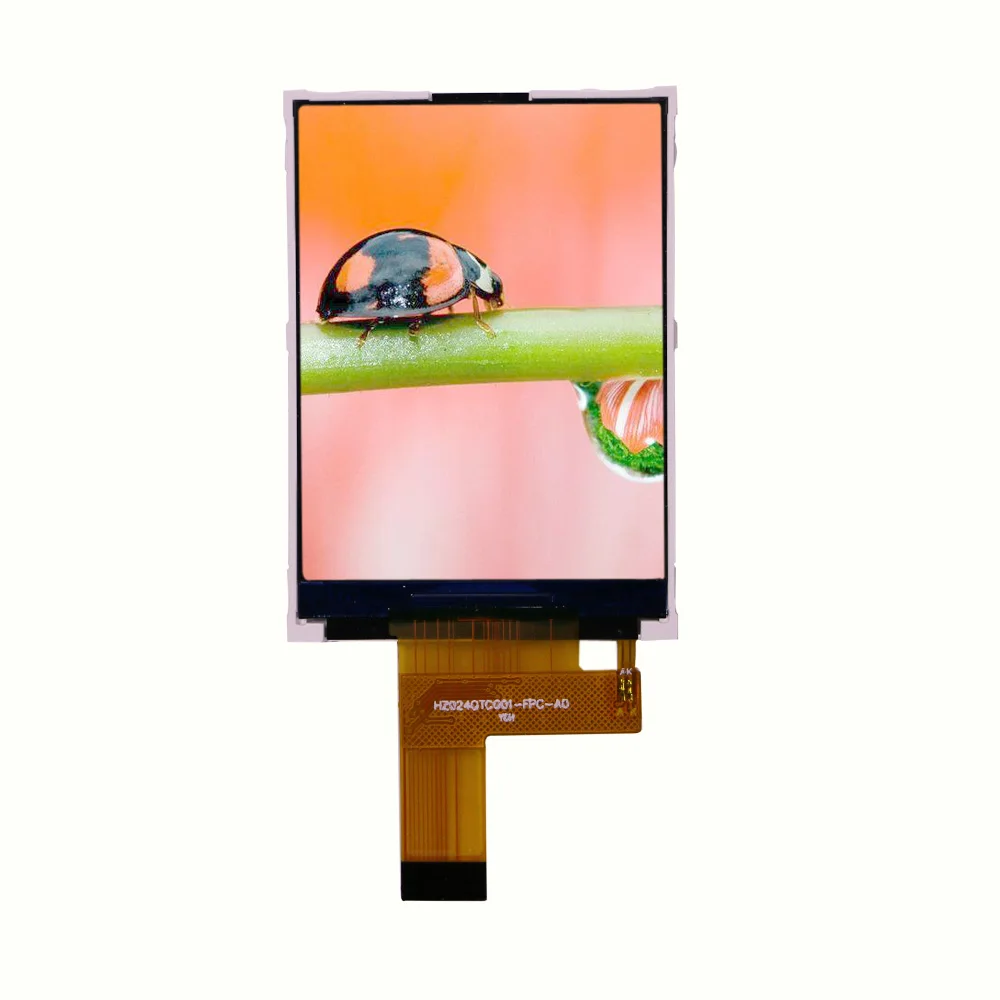

This graphic display module is a 2.4" diagonal, full color TFT. Suitable for embedded applications, it is low-power, uses a white LED backlight, and has an integrated touch panel which has its connection brought out to the main TAB connector for the display.

It has an on-board controller and 3v single voltage for supply and logic (backlight not included), so you can easily use any modern microcontroller to interface with this display. It uses an 8 or 16 bit parallel interface, specified via connections to the display.

The connector on the CFAF240320K-024T-TS is a flex tail mated with a "COG" (chip on glass) display construction. This style of connector is designed to be soldered directly to corresponding pads on your PCB by using a hot-bar soldering machine. High volume contract manufacturers will be familiar with this type of construction and its assembly methods. There are hot-bar soldering machines made that are designed for prototype, rework or repair work of TAB connections.

For many years, TFT displays have been the dominating technology in visualization. TFT LCDs are all around in our daily lives — in consumer and automotive applications, in our business environments, in healthcare, and within communication devices, home appliances, and factory automation products. While there are many LCD products available today, they’re not all suitable for every application. This is especially the case for industrial LCD monitors. To determine the best LCD display for your application, it’s important to understand your target market and its unique design issues.

The vast majority of LCD displays are designed for consumer devices such as smartphones, cameras, tablet computers, and gaming devices. But they have very different requirements than those for industrial applications. Due to very competitive pricing and quick production cycles, consumer display modules don’t always incorporate the durability, reliability, and advanced features required to survive in an industrial environment. Product life cycles are also typically much shorter in consumer applications. Screens manufactured for these applications are generally only available for one, in best case two years.

In contrast, display modules for industrial applications require Long product life cycles— often up to ten years or more. Plus, when an industrial module is discontinued by the manufacturer, a successor product should be backward-compatible so as to fit into the existing enclosure without requiring a redesign of the entire system.

The ability to withstand temperature variations as well as shock and vibration is also a key consideration when selecting displays for today’s industrial applications. They must be resilient enough to withstand frequent bumps or jiggles by machine operators and surrounding equipment, and also must be able to handle various operating temperatures.

Industrial displays are typically housed in an enclosure as part of a larger piece of equipment. In these situations, the heat generated by the surrounding equipment gets trapped within the enclosure, which can be detrimental to many displays. Therefore, it’s important to keep the real storage and operating temperature requirements in mind when choosing a display. While measures can be taken to dissipate the generated heat — such as using fans within the enclosure — the most efficient way to ensure compliance with the storage and operating temperature requirements is to select a display that is optimized for these types of environments. Fortunately, improvements in liquid-crystal materials have made it possible to extend the operating temperature ranges of LCDs from –30 to 80°C presently.

It’s important that displays used in industrial applications support clear and precise viewing from multiple angles under a variety of ambient light conditions. The brighter the environment, the more difficult it can be to read a standard transmissive LCD display with a typical brightness of 250 to 300 cd/m2. NVD has developed displays that can perform in the 800-cd/m2-and-higher range by implementing high-efficiency LEDs for the backlight unit– if necessary, in combination with special brightness enhancement films.

Increasing the display’s contrast ratio is another effective way that display manufacturers can improve display readability in bright environments. Typical contrast ratios for non-industrial displays are in the range of 200:1 to 300:1, which may not be sufficient when a machine operator is viewing the display from a distance. Displays with contrast ratios around 500:1 or greater are better suited for industrial environments. Another benefit of this method is that it doesn’t increase power consumption.

Multi-angle readability is another key selection factor. In a typical industrial environment, a machine operator is more likely to be positioned at an off-angle rather than right in front of the screen. Implementing a display designed for consumer applications typically doesn’t work well in this situation, as there is image distortion and color shifting when viewed at an angle. But, a number of technologies have been employed to improve off-angle viewing in displays, making them suitable for industrial applications. Some film-based technologies yield viewing angles of 160º horizontally and 140º vertically, but in some cases, this is still not sufficient. In-plane switching technology (IPS), multi-domain vertical alignment (MVA), and fringe field switching (FFS)offer alternatives. These proprietary technologies are able to achieve viewing angles of almost 90-degrees into all four directions without any color shift.

Size and resolution also play a role in overall readability. Displays between 2 and 15-inch diagonal sizes are used most often in industrial applications. These sizes provide sufficient area to view figures, waveforms, and other graphical data without taking up too much real estate on a piece of equipment.

From an aspect ratio 4:3 initially, industrial displays are now shifting to wide formats with WVGA to WXGA resolutions. The wide-aspect format enables users to view longer waveforms and more data on a single display. These display modules can also be designed to incorporate touch-key functions, allowing equipment manufacturers to skip physical switches and buttons and design HMIs based more on software than hardware.

New Vision Display’s experts are prepared to assist in defining appropriate solutions for all applications and in helping find the right balance between manufacturing cost and performance.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey