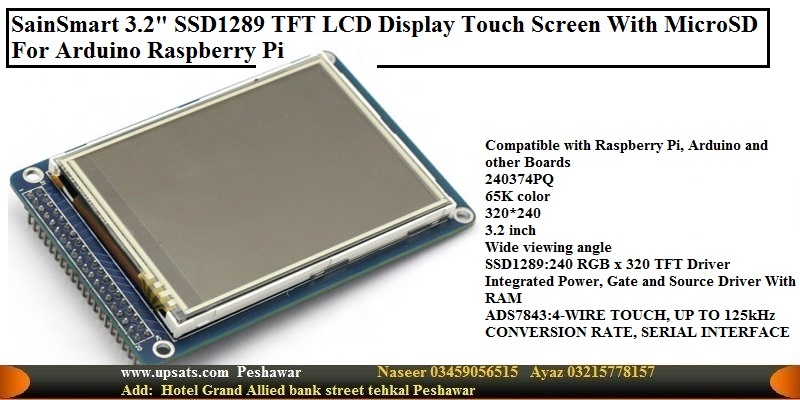

sainsmart 3.2 ssd1289 tft lcd datasheet in stock

SainSmart 3.2" TFT LCD Displayis a LCD touch screen module. It has 40pins interface and SD card and Flash reader design. It is a powerful and mutilfunctional module for your project.The Screen include a controller SSD1289, it"s a support 8/16bit data interface , easy to drive by many MCU like STM32 ,AVR and 8051. It is designed with a touch controller in it . The touch IC is ADS7843 , and touch interface is included in the 40 pins breakout. It is the version of product only with touch screen and touch controller.

SainSmart 3.2" TFT LCD Display is a LCD touch screen module. It has 40pins interface and SD card and Flash reader design. It is a powerful and mutilfunctional module for your project.The Screen include a controller SSD1289, it"s a support 8/16bit data interface , easy to drive by many MCU like STM32 ,AVR and 8051. It is designed with a touch controller in it . The touch IC is ADS7843 , and touch interface is included in the 40 pins breakout. It is the version of product only with touch screen and touch controller.

3.2"" TFT LCD module with 40 IO, it is more than a LCD module and colleagues also includes an SD card slot, whether with touch function. (Here we are with touch screen function module)

sainsmart 3.2 tft lcd display is a lcd touch screen module. it has 40pins interface and sd card and flash reader design. it is a powerful and mutilfunctional module for your project.the screen include a controller ssd1289, it s a support 8 16bit data interface , easy to drive by many mcu like stm32 ,avr and 8051. it is designed with a touch controller in it . the touch ic is ads7843 , and touch interface is included in the 40 pins breakout. it is the version of product only with touch screen and touch controller. specification:

I puzzled some hours with exactly the same hardware setup and made a quick & dirty, but successfully test script, combining LCD, Touch and SD Card Features.

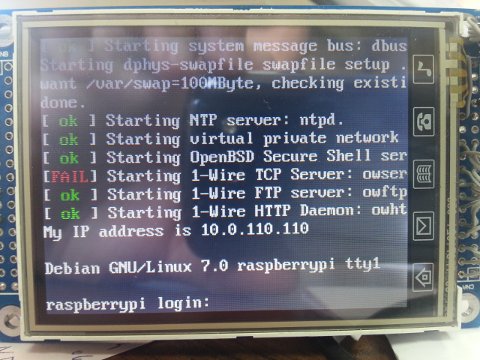

The LCD panel also supports parallel mode, which is what you would need to use for the highest speed updates, but the Raspberry Pi doesn"t have enough pins for that, so you can probably forget about playing video on there.

The rest is just a matter of writing the software. The Arduino code is probably a good starting place, but you will most likely have to spend some time studying the datasheets too.

EDIT: It appears that although the SSD1289 chip supports 3 and 4 pin serial modes, they are not brought out to the connector. It should be possible to connect it as shown in

Reason: The hooks on the backight of ER-TFT032-3.1 is always complained by most customers for inconvenient assembly. So we cancel the hooks in the new version of ER-TFT032-3.2.That"s the only difference for these two versions.

ER-TFT032-3.2 is 240x320 dots 3.2" color tft lcd module display with ILI9341 controller and optional 4-wire resistive touch panel and 3.2 inch capactive touch panel with controller FT6236,superior display quality,super wide viewing angle and easily controlled by MCU such as 8051, PIC, AVR, ARDUINO ARM and Raspberry PI.It can be used in any embedded systems,industrial device,security and hand-held equipment which requires display in high quality and colorful image.It supports 8080 8/16-bit parallel,3/4-wire serial interface. FPC with zif connector is easily to assemble or remove.Lanscape mode is also available.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!".Here is the link for 3.2"TFT Touch Shield with Libraries, Examples.Schematic Diagram for Arduino Due,Mega 2560 and Uno . For 8051 microcontroller user,we prepared the detailed tutorial such as interfacing, demo code and development kit at the bottom of this page.

I have the same LCD as you do. i was wondering if you could help me with the pinout of the LCD... valdodov has a different lcd and his schematic doesn"t transfer well to the one you have i think. is there a schematic that you could post or tell me where BL_CNT is connected from the 4094s to the LCD?

Where did you find the pin out for the sainsmart touch screen? We were looking at the following data sheet and it has different pin assignments. Please help us clear up this confusion. Thank you!!the display in your datasheet uses ILI9325 driver chip for the display.

We were following the instructions on github/notro/fbtft/wiki but I think I just realized that that"s a different method. So in order to install the kernel/modules should we use the compiled files on Voldadov"s site? If so, how do I copy those drivers? I extracted them to the desktop then did:

I am working for several months with the Raspberry and I also know a few experminete performed. Well me too interested this project. I myself already so bought a 3.2 "touchscreen, but I dunno exactly how to wire the. Could you maybe make a wiring diagram. That would be very nice.For example, with http://fritzing.org/

-What driver?I am using the same chips and TFT as you are using. The driver i am using is Raspbian. I am using a breadboard but i have checked the circuit multiple times using a multimeter to confirm the connections so i am not sure if that is an issue.

Thanks for the Kernel but on my Pi is nothing to go the Display is not working. I have the Sainsmart 3,2 TFT with the Modul that is in the Video (selfmade) but i find no error in my circuit board it is with 3 74HC4094 and 1 74HC4040 . ? Is there a Kernel that Support this Version with no updates.?

I am sure that many people are trying to make their Raspis to display video to a nonHDMI/nonCOmposite LCD screen using its SPI port, so I hope this thread will help all of us seeking expertise with the SSD1289 controller.

LCD Screens with SSD1289 controller sold in eBay for less than 10$. They include a touch screen film and an SD card reader. For the video, the screen needs 16pins for 16bits of data + 4-5 controll pins.

The problem with pi, is that its SPI does not offer that many GPIOs to "talk" to the screen using parallel mode. Although SSD1289 controller supports serial mode/interface, the LCD screen does not offer this capability. But this guy here: http://spritesmods.com/?art=spitft&page=1 made a nice schematic using a counter and 3 shift registers to get a parallel interface out of a serial. He also gives a kernel patch to enable the ssd1289 driver to use his hardware implementation but unfortunately he made it for Carambola linux platform. His patches include an ssd1289 driver he made from scratch, KConfig patch for adding his shift-registers hardware support to kernel and modifications to the SPI module of carambola.

The difficult part here is to enable the ssd1289 driver from the SPI module (arch/arm/mach-bcm2708/bcm2708.c). I have made some attempts to make SPI "see" the ssd1289 without success.

I used kernel compilation on the Raspi (built once on a usb stick and execute make after each time to only build the changed file) Crosscompiling made the ssd1289 driver to throw a compilation error (I can"t remember the error message).

However, I connected 3 LEDs to MOSI, SCKL, CS0 of raspi set default framebuffer to dev/fb01 and tried to write something to it and the LEDs were blinking. I assume that commands are writen to SPI through the ssd1289 driver correctly.

when you connect the raspi to the power SPI /CS goes HIGH this causes reset of 4020 and its Q5 goes LOW. It is not correct situation for the LCD. You can"t keep it"s /CS LOW forever.

I am afraid that the person that sent me the screen from china (ebay) sent screen with other chip than SSD1289. The only thing that I managed to display on screen was a full pale blue colour.

My intention is to attempt to write a script to send some dummy data, at a 1 second clock speed. It should prove if the circuit is working correctly, and assuming there is no minimum clock speed on the SSD1289, it should load data to it as intended. If you"re right with the cs polarity being wrong, I"d have though it easy enough to prove by manually sending it the other way. Am I missing something?

3. In static int ssd1289_spi_write(struct ssd1289 *item, unsigned short value, unsigned int isdata) you should send 4 bytes not3 like in the SpriteMods"s patch.

4. In static void ssd1289_copy(struct ssd1289 *item, unsigned int index) you should use byte by byte sending not block sending. Tomorrow i"ll investigate why it is not working with block sending.

It is a bit different than the one valdodov uses (it has 40 pins, incudes an SD card slot, etc). Also my screen does not have the pinout printed on the back. I tried to contact the guy from ebay so he may could send me / hep me with the pinout but without success. I assumed that the pinout would be the same as SSD1289 datasheet or the 40pins schematics I ve found on the internet.

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

I know this one Clive. I"ve actually got the TFT connected to the Arduino mega2560 via an adapterboard from seeedstudios. The ITDBGraph16 and Touch libraries work well albeit a little slow on the 8 bit 2560. Very easy libraries to use though. The TFT in question has an SSD1289 driver. I have ordered some female to female jumper wires to connect the board as in the diagram here:

I had acquired 2 Novametrix 515C pulse oximeter units that were slightly different versions but both contained a graphic LCD module which has the identification "DMF-50427N" on them and is made by Optrex. The DMF-50427N displays 128 x 64 pixels with each pixel being black and the interface is a parallel type ideal to be connected to a simple CPU or microcontroller although the LCD module only understands a few commands. You can read more about the oximeter at:

The LCD module uses 2 hd61202 column (segment) drivers designed for dot matrix displays and for interfacing with a microcontroller or something similar. For the datasheet please click here:

I used an Arduino Uno to test the LCD and the sketch I wrote you can find for download at the bottom of this page as "Novametrix_515C_LCD_Test.ino". Download it, write the sketch to your Uno and then with the power off connect it to the LCD as follows (LCD pins numbers are included):

I have not used the LED backlight but to use it you will need to connect LED+ (19) to 5V via suitable limiting resistor (datasheet specifies maximum LED current of 60mA and forward voltage of 4.1V @ 30mA) and LED- (20) to GND. What you must do is supply the LCD contrast voltage to LCD VLC pin 3 which can be from approx. -7V to -9V, the voltage of which will adjust the LCD contrast. To generate the negative voltage you can use my power supply circuit from:

When you power the Arduino you should see on the LCD 4 rectangles of different sizes, if not, double check your connections and try adjusting the contrast voltage.

Now looking at the Arduino sketch if you go to the setup function you will see that the I/O is set up for communicating with the LCD; because the LCD is always in write mode (R/W is connected to GND) we never have to change the direction of the data pins (D0 to D7) but it is useful to be able to read information from the LCD such as whether it is busy executing an instruction (because of the use of digitalWrite() and its slowness it is not necessary to check if the LCD is still executing an instruction). After we have set up the I/O and set the default state we call LCD_rst() which simply takes RST low for 1ms and then returns it high, waiting another 1ms before exiting (which isn"t really necessary).

Back to setup() and we call LCD_send_command() twice to turn on both displays as after reset the LCD is in the off state. LCD_send_command() takes as inputs the instruction value to write to the LCD and the Arduino pin number of the LCD chip select I/O pin and then calls LCD_send_data() passing the input values and "false" so that LCD_send_data() knows that an instruction is being sent rather than display data. Function LCD_send_data() first sets LCD D/I to instruction mode (low) then sets D2 to D9 to the instruction value by writing to the Arduino ports directly so that we don"t need to use individual digitalWrite() to set each bit. Lastly, E (enable) goes low, the relevant driver chip is enabled by taking the input low and then both E and the chip select inputs go back high.

Returning to setup() again the next function we call is LCD_clr_disp() which clears the display by writing zeros to the entire display memory but the routine simply calls function LCD_write_all_disp() and passes zero as its input. Function LCD_write_all_disp() sets up a loop from 0 to 7 (LCD_max_X = 8) and at the start of the loop we set the X address for both driver chips. Horizontally we can access each pixel across by setting the Y address (which should really be called "X") and with each write to display memory Y will increase by 1 but vertically the X address (would be better called "Y") must be set which selects from 1 of 8 pages (using values 0 to 7). Each page is 64 x 8 pixels and writing a byte will set 8 pixels vertically. I"ll show it visually as the first page only:

In LCD_write_all_disp() we set the Y address to 0 before setting up another loop which goes from 0 to 63 so we can write to all 64 pixels horizontally for both driver chips (which will cover the 128 pixels across in total) by calling LCD_send_disp_data() which calls LCD_send_data() but tells it we want to write to display data by passing "true" for the second parameter.

Also in setup(), after LCD_clr_disp(), is the commented out call to function LCD_fill_disp() (un-comment to enable) which like LCD_clr_disp() calls LCD_write_all_disp() but gives it the value 0xFF so all pixels are written to. Toward the end of setup() there are 4 calls to LCD_draw_rect() to draw rectangles of different sizes and in turn LCD_draw_rect() calls LCD_draw_horiz_line() and LCD_draw_vert_line() to draw the 4 sides of the rectangle. Not that I"ve included the horizontal length (horiz_len) and vertical length (vert_len) with the starting pixel (top-left point) rather than the length being added on resulting in an extra pixel as I"ve seen with saw drawing routines. In LCD_draw_horiz_line() we first do some basic checks to make sure the X, Y and len values are valid and then we calculate LCD_disp_value so we can effectively move the line vertically into 1 of the 8 "slots". To get the X address it is just a matter of dividing the Y value by 8 and then we can set that for both driver chips regardless of which one will actually be used. Next, we test to see if the line starts on the left side of the display (chip 1) or the right side (chip 2) by comparing the X start value (X) and then remembering the result by updating variable update_LCD_left. With that out of the way we create a loop to count from 0 to length (len) - 1 so that we can write each pixel of the line horizontally. However, before we update the display we must check if we have moved from the left side of the display to the write by checking if the current coordinate X position (X_pos) if 64 or higher and if so then update_LCD_left is updated. Then we can call LCD_send_disp_data() for the appropriate driver chip with the previously calculated display value in LCD_disp_value.

On to function LCD_draw_vert_line() in which we check X, Y and len are valid and then determine whether we need to update the left or right side of the display and set variable update_LCD_left accordingly. We do a simple calculation to set x_count_limit to the number of line segments, that is, the number of X pages to update. Next we go into a loop to update each X page and at the beginning of the loop we calculate the current Y coordinate value (the pixel at the top of the X page) and then set the X page address value to the coordinate Y position/8 for whichever driver chip we are updating. To actually draw the line we set LCD_disp_value to 0xFF which is then shifted left or right to form the start or end of the line or if it"s a middle segment then 0xFF is outputted untouched as the line segment will be a completed 8 bits. The last thing to do is set the Y address as each display write will increase Y by 1 yet we are drawing a vertical line whose X coordinate value will not change, and we also send the display data by calling LCD_send_disp_data().

A big issue with the line and rectangle drawing routines is that they will overwrite any other display data close by and if a rectangle is drawn with horizontal or vertical length of 8 or less then likely it won"t display correctly as one of the lines drawn will be in the same X page. A workaround to fix the problem would either be to modify the circuit so that the LCD"s display memory can be read or to maintain a display buffer on the Arduino, so that new writes to the display can be combined with whatever is already in display memory. The sketch is only test code and it could do we more boundary checking but at least it shows off a little of what the display can do.

desertcart is the best online shopping platform where you can buy SainSmart 3.2" TFT LCD Display+Touch Panel+PCB adapter SD Slot for Arduino 2560 from renowned brand(s). desertcart delivers the most unique and largest selection of products from across the world especially from the US, UK and India at best prices and the fastest delivery time.

desertcart ships the SainSmart 3.2" TFT LCD Display+Touch Panel+PCB adapter SD Slot for Arduino 2560 to and more cities in Maldives. Get unlimited free shipping in 164+ countries with desertcart Plus membership. We can deliver the SainSmart 3.2" TFT LCD Display+Touch Panel+PCB adapter SD Slot for Arduino 2560 speedily without the hassle of shipping, customs or duties.

desertcart buys SainSmart 3.2" TFT LCD Display+Touch Panel+PCB adapter SD Slot for Arduino 2560 directly from the authorized agents and verifies the authenticity of all the products. We have a dedicated team who specialize in quality control and efficient delivery. We also provide a free 14 days return policy along with 24/7 customer support experience.

Yes, it is absolutely safe to buy SainSmart 3.2" TFT LCD Display+Touch Panel+PCB adapter SD Slot for Arduino 2560 from desertcart, which is a 100% legitimate site operating in 164 countries. Since 2014, desertcart has been delivering a wide range of products to customers and fulfilling their desires. You will find several positive reviews by desertcart customers on portals like Trustpilot, etc. The website uses an HTTPS system to safeguard all customers and protect financial details and transactions done online. The company uses the latest upgraded technologies and software systems to ensure a fair and safe shopping experience for all customers. Your details are highly secure and guarded by the company using encryption and other latest softwares and technologies.

HY-TFT320 is a 3.2 inch TFT LCD Screen module, 320*240 (resolution), 65K color, 34pins interface , not just a LCD breakout, but include the Touch screen, SD card. So it’s a powerful extension module for your project.

This Screen includes a controller SSD1289, it’s 16bit data interface, easy to drive by many MCU like STM32 ,AVR and 8051.HY-TFT320 is designed with a touch controller in it . The touch IC is XPT2046 , and touch interface is included in the 34 pins breakout. Another useful extension in this module is the SD Card socket . It use the SPI mode to operate the SD card, the SPI interface include in the 40pins breakout.

The UTFT library is required to be installed to get this screen model display. This library is especially designed for 3.2” TFT LCD screen using 16 bit mode. The library require the following connections.

Note: The TFT controller model needs to be declared in the initializing statement. ITDB02 myGLCD(38,39,40,41) needs to be modified as myGLCD(38,39,40,41,ITDB32S) when using Arduino Mega2560.ITDB02 myGLCD(19,18,17,16,ITDB32S) needs to be commented when using Aduino UNO. Otherwise it just show a blank screen. In practice, RS, WR, CS, RSET can be connected to any free pin. But the pin number must be in accord with myGLCD(RS,WR,CS,RST).

The LCD has a 3.2" 4-wire resistive touch screen lying over it. The Touch libraryneeds to be installed to get it works. This library is designed for 2.4’’ TFT, 3.2” TFT LCD screen module.

The default setting is accurate for 2.4” TFT module, but you need to calibrate when using 3.2” TFT module. A program to calibrate the touch screen is included in the example. If you touch screen is inaccurate, you need to run touch_calibration. Follow the on-screen instruction to calibrate the touch screen. Better not use your finger to calibrate it, use your accessory touch pen to pressure the frontsight with stength. Then record the calibration parameters and apply them in ITDB02_Touch.cpp in your touch screen library.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey